Professional Documents

Culture Documents

WPS-91 Rev-00

WPS-91 Rev-00

Uploaded by

EILA545 QAQC0 ratings0% found this document useful (0 votes)

38 views18 pagesOriginal Title

WPS-91 REV-00

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

38 views18 pagesWPS-91 Rev-00

WPS-91 Rev-00

Uploaded by

EILA545 QAQCCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 18

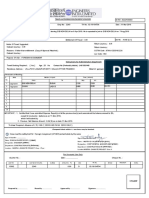

Format No: QD ~ 1.1,

Mi Ad ONSHORE CONSTRUCTION LLC

‘ABU DHABI Shoot No: 1 of 2

QW- 482 FOR WELDING PROCEDURE SPECIFICATIONS (WPS)

(Bee Ai.204 1, Section IX, ASME Boller and Proccuro Vocoo! Codo)

Company Name: ONSHORE CONSTRUCTION LLC 7 ‘By: K.BANGAR RAJU

WO Ne QHOUORE PIpINeMawen.et aw: 2 Laiw ‘Howo10n No: U1

‘Supporting POR No: ONSHORE/PIPING/DSIPOR-91 Date: 15-11-19 Revision No: 00

Welding Processes: GTAW ‘Type: Manual

(Automatic, Manual, Machine, of Semi-Auto)

JOINTS (GW-A07 JOINT SKETCH

Design: Refer Sketch (Attachment

Backing: No

Backing Material (Type): NA

(Refer to both backing and retainers)

STA BO

Hi Metal Non fusing Metal

© Nonmetaite Us Uther

1.6mm £05 mm

x6.35mm the

‘Sketches, Production Drawings, Weld Symbols or Written Description should show the general arrangement ofthe parts to be

welded. When applicable, the root spacing and the details of weld groove may be specified.

(At the option of the Mig, sketches may be attached to illustrate joint design, weld layers and bead sequence, e.g, for notch toughness

procedures, for multiple process procedures etc.)

* BASE METALS (QW-403)

P.No: 08 Group No: 01 To P.No: 45 Group No: NA

‘Specification Type and Grade» ASTM A312. TP304 OR EQUIVALENT

To

‘Specification Type and Grade ‘8407 UNS NO8811 OR EQUIVALENT

Chem, Analysis and Mech. Prop.

TO

(Chem, Analysis and Mech, Prop.

Thickness Range:

Base Meta:

Pipe Dia Range:

Other: NA

“FILLER METALS (QW-404) GTAW (Root) ‘SMAW (Others)

‘AWS No (Class) ERNICES, NA,

‘Spec No (SFA) 5.14 NA,

F. No. 43 NA

‘A. No. =

(‘Size of Filer Metal 16/24mm NA.

Deposited Weld Metal

“Thickness Range

‘Groove 2.7mm (Max) NA

Fillet All NA

Electrode-Flux (Class) > NA,

Flux Trade Name = NA,

‘Consumable Insert NA NA,

‘Other: ‘Approved Manufacturer: SAB, D&H Secheron ADOR & Bohler Welding

iz

NA

B

io

ig

&

1.50 12.70 mm Fillet All

All Fillet: All

:

7 ‘ONSHORE CONSTRUCTION LLC rome

Ny or ‘ABU DHABI se

i WELDING PROCEDURE SPECIFICATION (WPS) ‘Sheet No: 2 of 2

WPS NO: ONSHORE/PIPING/DS/WPS-91 Rev No: 4

- Date: 24711-2019

POSITION (QW-06 POSTWELD HEAT TREATMENT (QW.407)

Posiion ofGroove: 86 (ALL) Rate ofHeaing —: NA

Welding Progression: Uphill Soaking Temp MA

Position of Fillet: All ‘Soaking Time NA

Cooling Rate NA

| PREHEAT (ow-408) GAS (QW-408) ~

reheat Temp Min: | NA Gas | BCompMinture | Flow Rate

Tnferpass Temp Max: | 150°C Shieling “Argon 90057% | Bto 2LPM

Preheat Maintenance: | No Traling WA NA NA

(Conn o sped heatng where applicable shouldbe resoeea) | Backing ‘igor 3.987% | TO TaLPM

ELECTRICAL CHARACTERISTICS (QW-409

GunentACorDC: DC Potary GTAW- Straight

‘Amps (Range 60.955 Amp Volts (Range) 9.10 125 Vols

(Amps and volts range should be recorded for each electrode size, Position and Thickness etc. This information may be listed in a

‘Tabular form similar to that shown below)

‘Tungsten Electrode Size and Type: 2.4 mm dia, 2% Thoriated

(Pure Tungsten, 2% Thoriated)

Mode of Metal Transfer for GMAW: NA

(Spray are, shot circuiting arc etc.)

Electrode Wire Feed Speed Range: NA

TECHNIQUE (QW-470 - ~

‘String or Weave Bead Both (Weaving not to exceed 25 times core dia. of filer

Orifice or Gas Cup Size 6 to 10mm

Init 188 Cleaning Brushing & Grinding

Method of Back Gauging NA

Oscilation| NA

Contact Tube to Work Distance NA

Multiple or Single Pass (er side) Multiple

‘Multiple or Single Electrodes Single

‘Travel Speed (Range) Refer Below Table

Peening NA

Other NA

Filer Metal Current vot | TVTSPET | Heat input

Woldterem | Preeee | cae | OS | Ene Ane, | ranoorn | ae, aime, | Remarks

Rootpass | GTAW | ERNICr-3 | 16/20 | DCEN | 60-62 | 9-10 | 301-328 | 1.09t01.19

Hotpass | GTAW | ERNICr-3 | 1.6/2.0 | DCEN | 70-80 | 9-11 38-55.8 | 0.8t0 1.15

Filler passes | GTAW | ERNICr-3 | 1.6/2.0 | DCEN | 75-95 | 10-12 | 43.01-636 | 1.3to1.14

Filler passes | GTAW | ERNiCr-3 | 1.6/2.0 | DCEN | 75-95 | 11-125 | 309-647 | 1.1t015

Remaining | GTAW | ERNiCr-3 | 1.6/20 | DCEN | 91-96 | 11-125 | 43,7-57.05 | 1.18 t01.5

Pass

ee ni oni

a

tule

(QW-185 SUGGESTED FORMAT FOR PROCEDURE Tfomana-ansvs

(oy AA ‘QUALIFICATION RECORD (PQR)

i" Ss (See QW-200.2, Section IX, ASME Boiler and Pressure Vessel Code) |e... opp

Record Actual Conditions Used to Weld Test Coupon

usione consraucron uc

im ONSHORE PNG /OSPOR-SL Ta Date IE

SN NSHORE/PPING/OS WPS tecoT Bat: wee

[cain roses era “Type -Maaual

tomate, Manual or SenT AST

rors rawa02y

mM Re

Pe 1496.5

Groove Design of rest Coupon

(For combination the deposited weld metal thieknes sal ie recorded foreach ler metal or proces used)

POST WELD HEAT TREATMENT (QW-A07)

base metaLs(aW-403) Heating Rate NA

ateratspec. ASTM 8407 UNS Host ASTI A212 T 204 Holding Temperature Na

pe orGrade oiing Tine NA

pe. oer cooing ate NA

rou no

meknes fet coupon

ameter tres coupon

enn ROS FR

foter Jans (aw-a08)

Percent Compasiion

[ALLER erATs (awa) ca (cases) (inure) (ow nate

Joes not sta sriting AHL 359970 12M

fs tas) TENET —Hrating Nik

tere No z sean ARSON aoe DEaw

Jb tres ett i ELECTRICAL CHARACTERISTICS (QW-a09)

vets etl escness 335

etch ae no. SES7ETSSS eure as

irae Mamet No x

otras hots Tansy

osmon aw-405) Pty ce

pston of Grove 6 unten lero se ati

loner

oter Trecwwae(aw-a20)

[evel speed 2o02toszoswman

seo Weave ead sort

PREHEAT TaW=20 fosrtston i

reset tena rg ts snes eric) rss —

Imerys Tem, Ta Siw or utp tote Ste

omer omer

jedlayes | _ Process ie ea Scent oa Teese Testing im

els aye 08 pa ipewray | mrprange] Fre | mango imm/mny |_Metinet in

Fao caw |aewers [a6 [ban 3 30-328 To

[ects ‘craw | “ears [16 [ba Si a5 as-is

pes ‘sta “ewer | “46 [been E50 wo Boss 1-48

oss craw | ener “16 [been ars | —misia3 | ssa acts

[nas raw —erwers [18 been 135 ans S705 Tisza

Poe ‘craw | ~enwers | “6 | ban 3155 10 7525 ais

Checked by

Prepared by Porn SAPEM or

TIS

sien

ame

(OM

(QW-483 SUGGESTED FORMAT FOR PROCEDURE,

QUALIFICATION RECORD (POR)

(See QW-200.2, Section IX, ASME Boiler and Pressure Vessel Code)

Record Actual Conditions Used to Weld Test Coupon

omer

Tes TEs (QW80)

— oI em mare a9 | SRO Tor mmr cr

Tame T

ot cae mao mao cut | eae

or 335 7a23 7057 paint

08 = = Tp304Base Metal

oo seo Test (w-160)

THEATERS ST THERE ST

je TOUGHNESS TEST (QW-470)

me meron [eam 8] ae a

= : a

WA wt

TTT,

fram RETR r i

lene

joss tects:

bcm arm

ener ee

Cremona Sicamanae

ween Mae : rTAHASAIYA REDON HOS

[rest conbucreo ey MIOWAL ENGINEERING, 5B Eleganza mallikota Leki

CCERTMIOATE NO.MWI9111 beaet2019

hacer mar me stare WTS COR Ane CORE ND TS WEIS WER PREPARED

abe ad ESTED W ACONDANE WT ne RONEN CX cH HO ASME CE

are means MANUFACTURED: ONSHORE CONSTRUCTON LC ABLONL

Prepared by onsnone ] Checked by sareM rt

ORE Mirabils Carmetol) |

Syst

oxen sion 7 "Bere cn

ame ame : vain Kou Asse

pare lowe TAAL lowe

;

MDwatl

ENGINEERING

Midwal Engineering Services Limited

5B Eleganza Mall, Ikota, Lekki 101245, Lagos

08104000061-4 info@midwaleng.com

ACCREDITED”

Testing

Laboratery

Test Certificate Cover Page

Client: Onshore Construction FZE, Abu Dhabi

Lekki Free Trade zone,

Lagos State, Nigeria

Project: Dangote Refinery Project

Attention:

Test(s) Conducted — Tensile, Bend and

Macrograph Tests.

Report No: MW191111_ Issue: 1

Client Order No:

Midwal Requisition No: OCL-158-1119

TestDate: 22 November 2019

Report Date: 22 November 2019

*Coupon Description Information*

TEST CONDUCTED Procedure Qualification Test

PQR NUMBER _ONSHORE/PIPING/DISIPOR: 91

WELDER STAMP e THULASAYYA REDDY-\ wos |

DESCRIPTION Welded Pipe |

Material A lees B -

: Grade | ASTM B407 (UNS NO8611) |

Dimension | __1.25"Diax6.35mm thick _|

| Heat Number |

Origin | 7 |

| cuienT SPECIFICATION

"APPLICABLE CODE

WPS NUMBER

ASME IX, ASME B31.3

__ ONSHORE? PIPING/DISWPS- 91 (MANUAL)

| WELDING PROCESS. GTAW |

ILLER WIRE /ELECTRODE a __ERNICRS _

[WELDING POSITION occas - |

JOINT TYPE - ie _ Single V-Butt _ |

Midwal Engineering

Test Certificate No: MW191111

Page 1 of 4

MiDWwaL

ENGINEERING

Midwal Engineering Services Limited

5B Eleganza Mall, kota, Lekki 101245, Lagos

info@midwaleng.com

08104000061-4

ACCREDITED”

Testing

Laboratory

Test Certificate

Onshore Construction FZE, Abu Dhabi

| Tensile Test - ASME IX

Cert No: MW191111 Issue: 1

Acceptance Criteria: Tensile Stress = 450N/mm* Minimum

I Dimensions | Area Toure [outs 7 Gt TT Cosnmont

il Imm] [mm] | [kN] | [Nimm’} | fmm | comments

001: Transverse 6.33x13.27 | 84.00 | 52.49 | 624.84 | NA | NIA | Passed

002: Transverse 5.99 x 13.06 78.23 49.57 633.63 NIA NIA Passed

001: Failure in A312 TP304 Side

002: Failure in A312 TP304 Side

[Bend Test- ASME IX | Acceptance Criteria: QW-163 :

= ier — Di

Item Position | Dimension | Bend Angle | Former Dia =

- [mm] rl _ {mm :

003: Side Bend 45° 6 180 24 Passed

004; Side Bend 135° 6 180 24 Passed

| 005: Side Bend 225° 6 180 2 |

006: Side Bend 318° 6 180 24 Passed

“Comments: 006 — Open Discontinuity

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- EIL Procedure For Technical Audit - 5-1940-8020 Rev. 5Document26 pagesEIL Procedure For Technical Audit - 5-1940-8020 Rev. 5EILA545 QAQCNo ratings yet

- Sor 8108Document39 pagesSor 8108EILA545 QAQCNo ratings yet

- Piping Spec. For A23LDocument11 pagesPiping Spec. For A23LEILA545 QAQCNo ratings yet

- ALKYLATION LINE SCHEDULE - A545-142-02-LSC-001 - Rev-9Document68 pagesALKYLATION LINE SCHEDULE - A545-142-02-LSC-001 - Rev-9EILA545 QAQCNo ratings yet

- 0.5 La 614 1129 A23kDocument1 page0.5 La 614 1129 A23kEILA545 QAQCNo ratings yet

- Dokumen - Tips Nace-Tm0177Document36 pagesDokumen - Tips Nace-Tm0177EILA545 QAQCNo ratings yet

- Deviation Permit Feb 25, 2022Document2 pagesDeviation Permit Feb 25, 2022EILA545 QAQCNo ratings yet

- Astm A 403 Gr. WP304L-S Astm A 403 Gr. WP304L-WX Astm A 182 GR.F304LDocument2 pagesAstm A 403 Gr. WP304L-S Astm A 403 Gr. WP304L-WX Astm A 182 GR.F304LEILA545 QAQCNo ratings yet

- Haji Ali Time Sheet Oct-2021Document4 pagesHaji Ali Time Sheet Oct-2021EILA545 QAQCNo ratings yet

- Part List & Materials of ConstructionDocument2 pagesPart List & Materials of ConstructionEILA545 QAQCNo ratings yet

- GQ NiaziDocument2 pagesGQ NiaziEILA545 QAQCNo ratings yet

- Tank 100% PWHT ProcedureDocument32 pagesTank 100% PWHT ProcedureEILA545 QAQC100% (1)

- Procedure For Ferrite TestDocument5 pagesProcedure For Ferrite TestEILA545 QAQCNo ratings yet

- One-Line Diagram - OLV1 (Load Flow Analysis) : Scheme-1Document1 pageOne-Line Diagram - OLV1 (Load Flow Analysis) : Scheme-1EILA545 QAQCNo ratings yet

- Sinoma Minutes of MeetingDocument1 pageSinoma Minutes of MeetingEILA545 QAQCNo ratings yet

- FWD: Design Clarification For SS Piping Support-RegDocument2 pagesFWD: Design Clarification For SS Piping Support-RegEILA545 QAQCNo ratings yet

- 101&111-CT-PR-7641 &7642-5125 &5126 (Vol 01 of 61)Document250 pages101&111-CT-PR-7641 &7642-5125 &5126 (Vol 01 of 61)EILA545 QAQCNo ratings yet

- GA of Fabric Expansion BellowDocument17 pagesGA of Fabric Expansion BellowEILA545 QAQCNo ratings yet

- Project Approvals: A545-00-161-RFM-HTR-LS-0598/R1Document7 pagesProject Approvals: A545-00-161-RFM-HTR-LS-0598/R1EILA545 QAQCNo ratings yet

- Weld Joint Fouling With Support Pad - Branch ConnectionDocument2 pagesWeld Joint Fouling With Support Pad - Branch ConnectionEILA545 QAQCNo ratings yet

- Site Welders Register As On 08.08.20Document12 pagesSite Welders Register As On 08.08.20EILA545 QAQCNo ratings yet

- Document No: A545-Page 1 of 2Document2 pagesDocument No: A545-Page 1 of 2EILA545 QAQCNo ratings yet

- Document No: A545-Page 1 of 9Document9 pagesDocument No: A545-Page 1 of 9EILA545 QAQCNo ratings yet

- Tank Calibration Procedure by EORDR MethodDocument9 pagesTank Calibration Procedure by EORDR MethodEILA545 QAQCNo ratings yet

- Document No: A545-Page 1 of 4Document4 pagesDocument No: A545-Page 1 of 4EILA545 QAQCNo ratings yet

- Document Number: P1066-Ctd-Qac-Itp-003 Document Title: Inspection & Test Plan For Fabrication, Erection & Testing of Piping WorkDocument16 pagesDocument Number: P1066-Ctd-Qac-Itp-003 Document Title: Inspection & Test Plan For Fabrication, Erection & Testing of Piping WorkEILA545 QAQCNo ratings yet

- Tankguard Storage (EIL) - PQTDocument4 pagesTankguard Storage (EIL) - PQTEILA545 QAQCNo ratings yet

- P1066-CTD-QAC-ITP-004-Rev-A-Inspection & Test Plan For Surface Preparation, Painting & Coating Works-Approved Code-BDocument16 pagesP1066-CTD-QAC-ITP-004-Rev-A-Inspection & Test Plan For Surface Preparation, Painting & Coating Works-Approved Code-BEILA545 QAQCNo ratings yet

- RT AccepDocument1 pageRT AccepEILA545 QAQCNo ratings yet

- P1066-CTD-QAC-ITP-001-Rev-C-ITP For Fabrication, Erection & Testing of Tank WorkDocument9 pagesP1066-CTD-QAC-ITP-001-Rev-C-ITP For Fabrication, Erection & Testing of Tank WorkEILA545 QAQCNo ratings yet