Professional Documents

Culture Documents

Schedule of Accreditation United Kingdom Accreditation Service

Schedule of Accreditation United Kingdom Accreditation Service

Uploaded by

termmmCopyright:

Available Formats

You might also like

- 4 Performance Test Report For Dental X Ray EquipmentDocument4 pages4 Performance Test Report For Dental X Ray Equipmentnavin betalluNo ratings yet

- Crochet Tunisian PrimerDocument7 pagesCrochet Tunisian PrimerVerónica Bertero100% (4)

- NAAC011-AC14-Close-UKCA-DOP-01-Jan-2022Document3 pagesNAAC011-AC14-Close-UKCA-DOP-01-Jan-2022AMGConsultadoriaNo ratings yet

- Automotive Research Association of IndiDocument31 pagesAutomotive Research Association of IndiVAIBHAV INSTRUMENTATIONNo ratings yet

- EMF Test Report: Ericsson Street Macro 6701 B261 (FCC) : Rapport Utfärdad Av Ackrediterat ProvningslaboratoriumDocument13 pagesEMF Test Report: Ericsson Street Macro 6701 B261 (FCC) : Rapport Utfärdad Av Ackrediterat Provningslaboratoriumiogdfgkldf iodflgdfNo ratings yet

- En 301 489-1-17 Wlan - Trblu24-00100 - 2017Document31 pagesEn 301 489-1-17 Wlan - Trblu24-00100 - 2017Manohar T MNo ratings yet

- Schedule of Accreditation United Kingdom Accreditation ServiceDocument2 pagesSchedule of Accreditation United Kingdom Accreditation ServiceebbasinghNo ratings yet

- Tbcdne m2 ManualDocument8 pagesTbcdne m2 Manualtranvietdung1998qnNo ratings yet

- Denison Mayes Group ScheduleDocument10 pagesDenison Mayes Group Schedulethorster12345No ratings yet

- Analyzer SiteHawk SK4500TC SK6000TCDocument2 pagesAnalyzer SiteHawk SK4500TC SK6000TCstephaneNo ratings yet

- 2018-12-01 Sound Calibrator NC-74Document3 pages2018-12-01 Sound Calibrator NC-74chunyao0602No ratings yet

- L19-456-2 Com FinalDocument7 pagesL19-456-2 Com FinalVERONICANo ratings yet

- Vibration SeverityDocument11 pagesVibration SeverityDr. R. SharmaNo ratings yet

- Example: Calibration Certificate Calibration CertificateDocument2 pagesExample: Calibration Certificate Calibration CertificateAhmad Atsari SujudNo ratings yet

- Mod 7 Optical Measurements & Testing TOMEAST110Document36 pagesMod 7 Optical Measurements & Testing TOMEAST110Mao BourichaNo ratings yet

- 16,76mm (88.2) LamiGlass Sound ReductionDocument1 page16,76mm (88.2) LamiGlass Sound ReductionUmberto TavaresNo ratings yet

- Dokumen Pengujian Tera HertzDocument57 pagesDokumen Pengujian Tera HertzAhmad HariyantoNo ratings yet

- 8015-0151-00-Al-Cd 1133-19-Gf-Ogf4-J-Vd-9507-00001 - 00 - Ut ProcedureDocument7 pages8015-0151-00-Al-Cd 1133-19-Gf-Ogf4-J-Vd-9507-00001 - 00 - Ut ProcedureRami KsidaNo ratings yet

- EA Ultrasonic Level Transmitter - B0Document6 pagesEA Ultrasonic Level Transmitter - B0Rubens MarquesNo ratings yet

- Mactex W2Document1 pageMactex W2Kyaw ThihaNo ratings yet

- Basic Total Harmonic Distortion (THD) Measurement: PurposeDocument7 pagesBasic Total Harmonic Distortion (THD) Measurement: PurposeS shek DhavudNo ratings yet

- R Rec SM.1138 3 201910 I!!pdf eDocument10 pagesR Rec SM.1138 3 201910 I!!pdf eshivasraiNo ratings yet

- Models For Physical Communication Channels: HapterDocument12 pagesModels For Physical Communication Channels: HapterAbdullah Al Noman MarufNo ratings yet

- Analyzer SiteHawk SK4500TC SK6000TC SK9000TCDocument2 pagesAnalyzer SiteHawk SK4500TC SK6000TC SK9000TClauguicoNo ratings yet

- MKS 05 Terra With Bluetooth Channel Operating ManualDocument151 pagesMKS 05 Terra With Bluetooth Channel Operating ManualSergiu BadalutaNo ratings yet

- DE-LiDAR TFmini Datasheet-V1.7-EN PDFDocument10 pagesDE-LiDAR TFmini Datasheet-V1.7-EN PDFDarell Timothy TariganNo ratings yet

- Quality Product Certification ReinforcementDocument3 pagesQuality Product Certification ReinforcementsamiNo ratings yet

- Balluf BTL0324 PDFDocument2 pagesBalluf BTL0324 PDFEwin ApriansyahNo ratings yet

- En 301 489-1-17 - Msd30ag - 2017-03Document24 pagesEn 301 489-1-17 - Msd30ag - 2017-03Manohar T MNo ratings yet

- Schedule of Accreditation United Kingdom Accreditation ServiceDocument14 pagesSchedule of Accreditation United Kingdom Accreditation ServiceTahir NizamNo ratings yet

- SSRN Id3531621 PDFDocument7 pagesSSRN Id3531621 PDFahmedNo ratings yet

- Current Rating CalculationDocument3 pagesCurrent Rating CalculationArifin TriyantoNo ratings yet

- IPC-TM-650 Test Methods Manual: 3000 Lakeside Drive, Suite 309S Bannockburn, IL 60015-1249Document24 pagesIPC-TM-650 Test Methods Manual: 3000 Lakeside Drive, Suite 309S Bannockburn, IL 60015-1249Alberto SaldivarNo ratings yet

- Multiple Feedback CircuitDocument7 pagesMultiple Feedback CircuitbelmontNo ratings yet

- Lab 2Document4 pagesLab 2Israr AhmadNo ratings yet

- Temperature Measuring Transducer - MINI MCR-SL-PT100-LP-NC - 2810308Document6 pagesTemperature Measuring Transducer - MINI MCR-SL-PT100-LP-NC - 2810308ChamaraNo ratings yet

- MODULE-2 RAdar EquationDocument21 pagesMODULE-2 RAdar Equationsavitha A PNo ratings yet

- Phase Noise App Note Part3 0Document12 pagesPhase Noise App Note Part3 0Anonymous CYdagINo ratings yet

- Comparative For SpectroDocument4 pagesComparative For SpectrolordniklausNo ratings yet

- Vishay Telefunken: D D D D D D D D DDocument7 pagesVishay Telefunken: D D D D D D D D DFauzan Akbar SahriNo ratings yet

- RWTH Advanced Lab Course Bachelor - Johnson NoiseDocument14 pagesRWTH Advanced Lab Course Bachelor - Johnson NoiseEnzo SanfratelloNo ratings yet

- Size Distribution Report by Intensity: Sample DetailsDocument1 pageSize Distribution Report by Intensity: Sample DetailsMarcel HidajatNo ratings yet

- Certificate Mid Certificate tc7050 Rev 6 F Series Micro Motion en 65310 PDFDocument5 pagesCertificate Mid Certificate tc7050 Rev 6 F Series Micro Motion en 65310 PDFGuru DevaNo ratings yet

- R Rec SM.1138 0 199510 S!!PDF eDocument8 pagesR Rec SM.1138 0 199510 S!!PDF eshivasraiNo ratings yet

- Laboratory Report On Amplitude Modulation Circuit: (Communication Engineering Lab)Document10 pagesLaboratory Report On Amplitude Modulation Circuit: (Communication Engineering Lab)Sneh Sagar RajputNo ratings yet

- EYE Diagram SRS-Testing - WP - TNT - AeDocument8 pagesEYE Diagram SRS-Testing - WP - TNT - AeYaseen NaasNo ratings yet

- Datasheet KM303 - Central Monoxido PDFDocument2 pagesDatasheet KM303 - Central Monoxido PDFruiNo ratings yet

- Acoustic AssistantDocument1 pageAcoustic AssistantPedro FreitasNo ratings yet

- Gzem240100009101 DDocument47 pagesGzem240100009101 Dtugcebender90No ratings yet

- MPE Report 6211898Document9 pagesMPE Report 6211898nat-tamail.ruNo ratings yet

- Siemens-Vdo cdr500 Philips 22dc403-75Document16 pagesSiemens-Vdo cdr500 Philips 22dc403-75Артем РудьNo ratings yet

- Magnetic SensorsDocument35 pagesMagnetic SensorsBijoy KunduNo ratings yet

- Medidas Criticas em RFDocument16 pagesMedidas Criticas em RFWalton William Ferraz RochaNo ratings yet

- Expt 8 BJT Single Stage AmplifierDocument5 pagesExpt 8 BJT Single Stage Amplifiersamarth0% (1)

- ProReact en Digital Hazardous Areas Guide 2Document5 pagesProReact en Digital Hazardous Areas Guide 2saoborjaNo ratings yet

- 33 KV CT A - RRP Agro (Edited)Document4 pages33 KV CT A - RRP Agro (Edited)JRC TestingNo ratings yet

- 24 BOQDocument4 pages24 BOQmanleviNo ratings yet

- Japan Test Report: Report No.: JR1D0705AC Page No.: 1 of 16 Report Version: Rev. 01Document68 pagesJapan Test Report: Report No.: JR1D0705AC Page No.: 1 of 16 Report Version: Rev. 01polish001No ratings yet

- Expt3 Am DemodulationDocument9 pagesExpt3 Am DemodulationRichel Noronio RoblesNo ratings yet

- 7381 Ugeng0004Document2 pages7381 Ugeng0004termmmNo ratings yet

- Bedienungsanleitung Galvotest ENDocument2 pagesBedienungsanleitung Galvotest ENtermmmNo ratings yet

- Fluke 6331 7321 7341 7381 Katalogseite enDocument2 pagesFluke 6331 7321 7341 7381 Katalogseite entermmmNo ratings yet

- PVPM1500x DatasheetDocument2 pagesPVPM1500x DatasheettermmmNo ratings yet

- Manual Durometro Pce 900 v1Document17 pagesManual Durometro Pce 900 v1termmmNo ratings yet

- EX310 UM-enDocument13 pagesEX310 UM-entermmmNo ratings yet

- Reading Analog Gauges Using Open CV For Hazardous Area ApplicationsDocument4 pagesReading Analog Gauges Using Open CV For Hazardous Area ApplicationstermmmNo ratings yet

- Programmable DC Power Supply (Solar Array Simulation) Model 62000H-S SeriesDocument8 pagesProgrammable DC Power Supply (Solar Array Simulation) Model 62000H-S SeriestermmmNo ratings yet

- Euromet Em-S11Document64 pagesEuromet Em-S11termmmNo ratings yet

- Euromet - em k2Document152 pagesEuromet - em k2termmmNo ratings yet

- How To Write Scripts For Test Script Processing (TSP) : Application NoteDocument19 pagesHow To Write Scripts For Test Script Processing (TSP) : Application NotetermmmNo ratings yet

- Euramet Em-S38Document36 pagesEuramet Em-S38termmmNo ratings yet

- FLUKE187&189: Series Maintenance ManualDocument28 pagesFLUKE187&189: Series Maintenance ManualtermmmNo ratings yet

- Humidity/Temperature Sensor: User ManualDocument38 pagesHumidity/Temperature Sensor: User ManualtermmmNo ratings yet

- nf9fx 105g6841 R134a 220v 50hz 04-2019 Desd408o322Document2 pagesnf9fx 105g6841 R134a 220v 50hz 04-2019 Desd408o322termmmNo ratings yet

- 2790 Sourcemeter Switch System SpecificationsDocument6 pages2790 Sourcemeter Switch System SpecificationstermmmNo ratings yet

- And You: AC DC Shunts Can Believe Their Specs?Document6 pagesAnd You: AC DC Shunts Can Believe Their Specs?termmmNo ratings yet

- SPEC-2700K June2014Document4 pagesSPEC-2700K June2014termmmNo ratings yet

- F12 Calibration of Rogowski CoilsDocument1 pageF12 Calibration of Rogowski CoilstermmmNo ratings yet

- 1KW-61433-0 Increasing ProductivityNetworking Instruments AppsBrief 070518Document14 pages1KW-61433-0 Increasing ProductivityNetworking Instruments AppsBrief 070518termmmNo ratings yet

- CA Tinycal 10 enDocument2 pagesCA Tinycal 10 entermmmNo ratings yet

- Agilent 34970A: Data Acquisition / Switch UnitDocument273 pagesAgilent 34970A: Data Acquisition / Switch UnittermmmNo ratings yet

- JFW Spec Sheet 50B-054Document1 pageJFW Spec Sheet 50B-054termmmNo ratings yet

- 5069 INSCAL Insulation Tester Calibration SystemDocument1 page5069 INSCAL Insulation Tester Calibration SystemtermmmNo ratings yet

- Spy RF Modem Ethernet: User ManualDocument14 pagesSpy RF Modem Ethernet: User ManualtermmmNo ratings yet

- Digital Power Meter Model 66200 SeriesDocument4 pagesDigital Power Meter Model 66200 SeriestermmmNo ratings yet

- Views, Synonyms, and SequencesDocument46 pagesViews, Synonyms, and Sequencesprad15No ratings yet

- CityTouch Connect ApplicationDocument13 pagesCityTouch Connect ApplicationYerko Navarro FloresNo ratings yet

- Gs Survey & Engineers: Tax InvoiceDocument2 pagesGs Survey & Engineers: Tax InvoiceShivendra KumarNo ratings yet

- Karens A-MDocument21 pagesKarens A-Mapi-291270075No ratings yet

- Confronting The Storm: Regenerating Leadership and Hope in The Age of UncertaintyDocument38 pagesConfronting The Storm: Regenerating Leadership and Hope in The Age of UncertaintyCharlene Kronstedt100% (1)

- Dvp-Es2 Ss2 Sa2 Sx2-Program o en 20110302Document609 pagesDvp-Es2 Ss2 Sa2 Sx2-Program o en 20110302puskyboyNo ratings yet

- Varistor Catalog PDFDocument254 pagesVaristor Catalog PDFsantosh_babar_26100% (1)

- Peter Welz - ADocument4 pagesPeter Welz - AkrishfabicoipadNo ratings yet

- Kullie StrainGageManualDigitalDocument67 pagesKullie StrainGageManualDigitalDizzixxNo ratings yet

- Revised 04/01/2021Document33 pagesRevised 04/01/2021Kim PowellNo ratings yet

- An Innovative Method To Increase The Resolution of Optical EncodersDocument6 pagesAn Innovative Method To Increase The Resolution of Optical EncodersFuadMuzaki09No ratings yet

- Exercises No 1: Exercise 1Document6 pagesExercises No 1: Exercise 1M ILHAM HATTANo ratings yet

- Cesabb 300 B 400Document8 pagesCesabb 300 B 400BeyzaNo ratings yet

- Stressed Syllable, While Free Vowels Are Those That May Stand in A Stressed Open Syllable With No Following ConsonantDocument2 pagesStressed Syllable, While Free Vowels Are Those That May Stand in A Stressed Open Syllable With No Following ConsonantResiNo ratings yet

- Summer Holiday Homework IdeasDocument5 pagesSummer Holiday Homework Ideasafeungtae100% (1)

- Standard CVDocument3 pagesStandard CVSurzo Chandra DasNo ratings yet

- A G Gardiner EssaysDocument50 pagesA G Gardiner Essaysngisjqaeg100% (2)

- Egyptian PPP Law 67 For 2010 EnglishDocument17 pagesEgyptian PPP Law 67 For 2010 EnglishReham El AbnoudyNo ratings yet

- Lesson Plan PatrickDocument4 pagesLesson Plan PatrickPatrick Jerome SilvanoNo ratings yet

- Discussion Questions Activity NoDocument2 pagesDiscussion Questions Activity NoAngilene Lacson CabinianNo ratings yet

- Classification of Common Musical InstrumentsDocument3 pagesClassification of Common Musical InstrumentsFabian FebianoNo ratings yet

- VarahamihiraDocument6 pagesVarahamihiraSTAR GROUPS100% (1)

- Disinfection Cabinet and Insect KillersDocument4 pagesDisinfection Cabinet and Insect Killerssathya moorthy KamakottiNo ratings yet

- Database Systems, Eleventh Edition by Coronel Morris, Course Technology 2014Document5 pagesDatabase Systems, Eleventh Edition by Coronel Morris, Course Technology 2014LaluMohan KcNo ratings yet

- Symptoms of HypoglycemiaDocument20 pagesSymptoms of Hypoglycemiakenny StefNo ratings yet

- Rev29jan2019oftemplate OSHprogram Asof 290119Document12 pagesRev29jan2019oftemplate OSHprogram Asof 290119GelinaNo ratings yet

- Hellermann Tyton PDFDocument152 pagesHellermann Tyton PDFanon_34390801No ratings yet

- Impromptu SpeechDocument25 pagesImpromptu SpeechJerome Bulaun100% (1)

- Geothermal Well Operation and Maintenance: Sverrir ThorhallssonDocument23 pagesGeothermal Well Operation and Maintenance: Sverrir ThorhallssonLaras PutiNo ratings yet

Schedule of Accreditation United Kingdom Accreditation Service

Schedule of Accreditation United Kingdom Accreditation Service

Uploaded by

termmmOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Schedule of Accreditation United Kingdom Accreditation Service

Schedule of Accreditation United Kingdom Accreditation Service

Uploaded by

termmmCopyright:

Available Formats

Schedule of Accreditation

issued by

United Kingdom Accreditation Service

2 Pine Trees, Chertsey Lane, Staines-upon-Thames, TW18 3HR, UK

RSL NDT Ltd

Issue No: 005 Issue date: 13 April 2021

Unit 9 Contact: Mr Eric Duguid

Murcar Commercial Park Tel: +44 (0)1224 822600

Denmore Road E-Mail: eric.duguid@rslndt.com

9882 Bridge of Don Website: www.rslndt.com

Accredited to Aberdeen

ISO/IEC 17025:2017 AB23 8JW

Calibration performed at the above address only

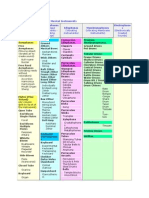

DETAIL OF ACCREDITATION

Calibration and

Measurement Capability

Measured Quantity

Range (CMC) Expressed as an Remarks

Instrument or Gauge

Expanded Uncertainty

(k = 2)

ELECTRICAL VERIFICATION of

ULTRASONIC FLAW

DETECTION EQUIPMENT

As BS EN ISO 22232-1:2020

Group 2 tests and including the

following calibrations and

quantities:

Pulser Voltage 5.0 %

Pulser Risetime 3.8 ns

Pulse duration 1.5 ns For instruments designed to

comply with BS EN 12668-

1:2010, the pulse width is

determined at 10 % of the pulse

height, otherwise the 50 %

points are used.

Frequency response

0.01 MHz to 50 MHz 5.9 % at -3 dB point For instruments designed to

comply with BS EN 12668-

1:2010, the centre frequency f0

is calculated using f0 = √(fu x fl),

otherwise the expression

f0 = (fu + fl)/2 is used.

Equivalent input noise 1.1 x 10-9 V/√Hz Using Method B as described in

Section 9.4.3.3 of

BS EN ISO 22232-1:2020.

Calibrated attenuator 0.70 dB

Gain linearity 0.70 dB

Vertical Linearity 1.8 % of screen height

Assessment Manager: MJLP Page 1 of 3

S c h e dul e of Ac c re d it a ti o n

issued by

United King dom Accreditation Service

2 Pine Tree s, Chert sey Lane, Staines-u pon-Thames, TW18 3 HR, UK

RSL NDT Ltd

9882 Issue No: 005 Issue date: 13 April 2021

Accredited to

ISO/IEC 17025:2017

Calibration performed at main address only

Calibration and

Measurement Capability

Measured Quantity

Range (CMC) Expressed as an Remarks

Instrument or Gauge

Expanded Uncertainty

(k = 2)

CALIBRATION OF EDDY

CURRENT TEST SETS

Frequency Generator 100 Hz to 10 MHz 20 ppm In accordance with

BS EN ISO 15548-1:2013, 6.2.1

Oscillator Drive 1 V to 14 V

100 Hz to 2 MHz 1.9 % to 2.9 % In accordance with

BS EN ISO 15548-1:2013, 6.2.4

Harmonic Distortion 0 % to 1000 % 5.4 % of value or 5.0 % In accordance with

distortion, whichever is greater. BS EN ISO 15548-1:2013, 6.2.2

System Gain 10 dB to 50 dB Using step attenuator.

10 kHz 0.29 dB

Horizontal and Vertical Linearity 15 % to 80 % of FSH Using step attenuator and

10 kHz 2.0 % of FSH oscilloscope.

Alarm Functional test only

System Noise Functional test with results

presented graphically.

ASME Tube Functional test with results

presented graphically.

Absolute probe test Functional test with results

presented graphically.

END

Assessment Manager: MJLP Page 2 of 3

S c h e dul e of Ac c re d it a ti o n

issued by

United King dom Accreditation Service

2 Pine Tree s, Chert sey Lane, Staines-u pon-Thames, TW18 3 HR, UK

RSL NDT Ltd

9882 Issue No: 005 Issue date: 13 April 2021

Accredited to

ISO/IEC 17025:2017

Calibration performed at main address only

Appendix - Calibration and Measurement Capabilities

Introduction

The definitive statement of the accreditation status of a calibration laboratory is the Accreditation Certificate and the associated Schedule of

Accreditation. This Schedule of Accreditation is a critical document, as it defines the measurement capabilities, ranges and boundaries of the

calibration activities for which the organisation holds accreditation.

Calibration and Measurement Capabilities (CMCs)

The capabilities provided by accredited calibration laboratories are described by the Calibration and Measurement Capability (CMC), which

expresses the lowest uncertainty of measurement that can be achieved during a calibration. If a particular device under calibration itself

contributes significantly to the uncertainty (for example, if it has limited resolution or exhibits significant non-repeatability) then the uncertainty

quoted on a calibration certificate will be increased to account for such factors. The CIPM-ILAC definition of the CMC is as follows:

A CMC is a calibration and measurement capability available to customers under normal conditions:

(a) as published in the BIPM key comparison database (KCDB) of the CIPM MRA; or

(b) as described in the laboratory’s scope of accreditation granted by a signatory to the ILAC Arrangement.

The CMC is normally used to describe the uncertainty that appears in an accredited calibration laboratory's schedule of accreditation and is the

uncertainty for which the laboratory has been accredited using the procedure that was the subject of assessment. The CMC is calculated

according to the procedures given in M3003 and is normally stated as an expanded uncertainty at a coverage probability of 95 %, which

usually requires the use of a coverage factor of k = 2. An accredited laboratory is not permitted to quote an uncertainty that is smaller than the

published CMC in certificates issued under its accreditation.

The CMC may be described using various methods in the Schedule of Accreditation:

As a single value that is valid throughout the range.

As an explicit function of the measurand or of a parameter (see below).

As a range of values. The range is stated such that the customer can make a reasonable estimate of the likely uncertainty at any point within

the range.

As a matrix or table where the CMCs depend on the values of the measurand and a further quantity.

In graphical form, providing there is sufficient resolution on each axis to obtain at least two significant figures for the CMC.

Expression of CMCs - symbols and units

In general, only units of the SI and those units recognised for use with the SI are used to express the values of quantities and of the associated

CMCs. Nevertheless, other commonly used units may be used where considered appropriate for the intended audience. For example, the term

“ppm” (part per million) is frequently used by manufacturers of test and measurement equipment to specify the performance of their products.

Terms like this may be used in Schedules of Accreditation where they are in common use and understood by the users of such equipment,

providing their use does not introduce any ambiguity in the capability that is being described.

When the CMC is expressed as an explicit function of the measurand or of a parameter, this often comprises a relative term (e.g., percentage)

and an absolute term, i.e. one expressed in the same units as those of the measurand. This form of expression is used to describe the

capability that can be achieved over a range of values. Some examples are shown below. It should be noted that these expressions are not

mathematical formulae but are instead written in a commonly used shorthand for expressing uncertainties - therefore, for the purposes of

clarity, and indication of how they are to be interpreted is also provided below.

DC voltage, 100 mV to 1 V: 0.0025 % + 5.0 μV:

Over the range 100 mV to 1 V, the CMC is 0.0025 %∙V + 5.0 μV, where V is the measured voltage.

Hydraulic pressure, 0.5 MPa to 140 MPa: 0.0036 % + 0.12 ppm/MPa + 4.0 Pa

Over the range 0.5 MPa to 140 MPa, the CMC is 0.0036 %∙p + (0.12∙10-6∙p∙10-6) + 4.0 Pa, where p is the measured pressure in Pa.

It should be noted that the percentage symbol (%) simply represents the number 0.01. In cases where the CMC is stated only as a percentage,

this is to be interpreted as meaning percentage of the measured value or indication.

Thus, for example, a CMC of 1.5 % means 1.5 ∙ 0.01 ∙ i, where i is the instrument indication.

Assessment Manager: MJLP Page 3 of 3

You might also like

- 4 Performance Test Report For Dental X Ray EquipmentDocument4 pages4 Performance Test Report For Dental X Ray Equipmentnavin betalluNo ratings yet

- Crochet Tunisian PrimerDocument7 pagesCrochet Tunisian PrimerVerónica Bertero100% (4)

- NAAC011-AC14-Close-UKCA-DOP-01-Jan-2022Document3 pagesNAAC011-AC14-Close-UKCA-DOP-01-Jan-2022AMGConsultadoriaNo ratings yet

- Automotive Research Association of IndiDocument31 pagesAutomotive Research Association of IndiVAIBHAV INSTRUMENTATIONNo ratings yet

- EMF Test Report: Ericsson Street Macro 6701 B261 (FCC) : Rapport Utfärdad Av Ackrediterat ProvningslaboratoriumDocument13 pagesEMF Test Report: Ericsson Street Macro 6701 B261 (FCC) : Rapport Utfärdad Av Ackrediterat Provningslaboratoriumiogdfgkldf iodflgdfNo ratings yet

- En 301 489-1-17 Wlan - Trblu24-00100 - 2017Document31 pagesEn 301 489-1-17 Wlan - Trblu24-00100 - 2017Manohar T MNo ratings yet

- Schedule of Accreditation United Kingdom Accreditation ServiceDocument2 pagesSchedule of Accreditation United Kingdom Accreditation ServiceebbasinghNo ratings yet

- Tbcdne m2 ManualDocument8 pagesTbcdne m2 Manualtranvietdung1998qnNo ratings yet

- Denison Mayes Group ScheduleDocument10 pagesDenison Mayes Group Schedulethorster12345No ratings yet

- Analyzer SiteHawk SK4500TC SK6000TCDocument2 pagesAnalyzer SiteHawk SK4500TC SK6000TCstephaneNo ratings yet

- 2018-12-01 Sound Calibrator NC-74Document3 pages2018-12-01 Sound Calibrator NC-74chunyao0602No ratings yet

- L19-456-2 Com FinalDocument7 pagesL19-456-2 Com FinalVERONICANo ratings yet

- Vibration SeverityDocument11 pagesVibration SeverityDr. R. SharmaNo ratings yet

- Example: Calibration Certificate Calibration CertificateDocument2 pagesExample: Calibration Certificate Calibration CertificateAhmad Atsari SujudNo ratings yet

- Mod 7 Optical Measurements & Testing TOMEAST110Document36 pagesMod 7 Optical Measurements & Testing TOMEAST110Mao BourichaNo ratings yet

- 16,76mm (88.2) LamiGlass Sound ReductionDocument1 page16,76mm (88.2) LamiGlass Sound ReductionUmberto TavaresNo ratings yet

- Dokumen Pengujian Tera HertzDocument57 pagesDokumen Pengujian Tera HertzAhmad HariyantoNo ratings yet

- 8015-0151-00-Al-Cd 1133-19-Gf-Ogf4-J-Vd-9507-00001 - 00 - Ut ProcedureDocument7 pages8015-0151-00-Al-Cd 1133-19-Gf-Ogf4-J-Vd-9507-00001 - 00 - Ut ProcedureRami KsidaNo ratings yet

- EA Ultrasonic Level Transmitter - B0Document6 pagesEA Ultrasonic Level Transmitter - B0Rubens MarquesNo ratings yet

- Mactex W2Document1 pageMactex W2Kyaw ThihaNo ratings yet

- Basic Total Harmonic Distortion (THD) Measurement: PurposeDocument7 pagesBasic Total Harmonic Distortion (THD) Measurement: PurposeS shek DhavudNo ratings yet

- R Rec SM.1138 3 201910 I!!pdf eDocument10 pagesR Rec SM.1138 3 201910 I!!pdf eshivasraiNo ratings yet

- Models For Physical Communication Channels: HapterDocument12 pagesModels For Physical Communication Channels: HapterAbdullah Al Noman MarufNo ratings yet

- Analyzer SiteHawk SK4500TC SK6000TC SK9000TCDocument2 pagesAnalyzer SiteHawk SK4500TC SK6000TC SK9000TClauguicoNo ratings yet

- MKS 05 Terra With Bluetooth Channel Operating ManualDocument151 pagesMKS 05 Terra With Bluetooth Channel Operating ManualSergiu BadalutaNo ratings yet

- DE-LiDAR TFmini Datasheet-V1.7-EN PDFDocument10 pagesDE-LiDAR TFmini Datasheet-V1.7-EN PDFDarell Timothy TariganNo ratings yet

- Quality Product Certification ReinforcementDocument3 pagesQuality Product Certification ReinforcementsamiNo ratings yet

- Balluf BTL0324 PDFDocument2 pagesBalluf BTL0324 PDFEwin ApriansyahNo ratings yet

- En 301 489-1-17 - Msd30ag - 2017-03Document24 pagesEn 301 489-1-17 - Msd30ag - 2017-03Manohar T MNo ratings yet

- Schedule of Accreditation United Kingdom Accreditation ServiceDocument14 pagesSchedule of Accreditation United Kingdom Accreditation ServiceTahir NizamNo ratings yet

- SSRN Id3531621 PDFDocument7 pagesSSRN Id3531621 PDFahmedNo ratings yet

- Current Rating CalculationDocument3 pagesCurrent Rating CalculationArifin TriyantoNo ratings yet

- IPC-TM-650 Test Methods Manual: 3000 Lakeside Drive, Suite 309S Bannockburn, IL 60015-1249Document24 pagesIPC-TM-650 Test Methods Manual: 3000 Lakeside Drive, Suite 309S Bannockburn, IL 60015-1249Alberto SaldivarNo ratings yet

- Multiple Feedback CircuitDocument7 pagesMultiple Feedback CircuitbelmontNo ratings yet

- Lab 2Document4 pagesLab 2Israr AhmadNo ratings yet

- Temperature Measuring Transducer - MINI MCR-SL-PT100-LP-NC - 2810308Document6 pagesTemperature Measuring Transducer - MINI MCR-SL-PT100-LP-NC - 2810308ChamaraNo ratings yet

- MODULE-2 RAdar EquationDocument21 pagesMODULE-2 RAdar Equationsavitha A PNo ratings yet

- Phase Noise App Note Part3 0Document12 pagesPhase Noise App Note Part3 0Anonymous CYdagINo ratings yet

- Comparative For SpectroDocument4 pagesComparative For SpectrolordniklausNo ratings yet

- Vishay Telefunken: D D D D D D D D DDocument7 pagesVishay Telefunken: D D D D D D D D DFauzan Akbar SahriNo ratings yet

- RWTH Advanced Lab Course Bachelor - Johnson NoiseDocument14 pagesRWTH Advanced Lab Course Bachelor - Johnson NoiseEnzo SanfratelloNo ratings yet

- Size Distribution Report by Intensity: Sample DetailsDocument1 pageSize Distribution Report by Intensity: Sample DetailsMarcel HidajatNo ratings yet

- Certificate Mid Certificate tc7050 Rev 6 F Series Micro Motion en 65310 PDFDocument5 pagesCertificate Mid Certificate tc7050 Rev 6 F Series Micro Motion en 65310 PDFGuru DevaNo ratings yet

- R Rec SM.1138 0 199510 S!!PDF eDocument8 pagesR Rec SM.1138 0 199510 S!!PDF eshivasraiNo ratings yet

- Laboratory Report On Amplitude Modulation Circuit: (Communication Engineering Lab)Document10 pagesLaboratory Report On Amplitude Modulation Circuit: (Communication Engineering Lab)Sneh Sagar RajputNo ratings yet

- EYE Diagram SRS-Testing - WP - TNT - AeDocument8 pagesEYE Diagram SRS-Testing - WP - TNT - AeYaseen NaasNo ratings yet

- Datasheet KM303 - Central Monoxido PDFDocument2 pagesDatasheet KM303 - Central Monoxido PDFruiNo ratings yet

- Acoustic AssistantDocument1 pageAcoustic AssistantPedro FreitasNo ratings yet

- Gzem240100009101 DDocument47 pagesGzem240100009101 Dtugcebender90No ratings yet

- MPE Report 6211898Document9 pagesMPE Report 6211898nat-tamail.ruNo ratings yet

- Siemens-Vdo cdr500 Philips 22dc403-75Document16 pagesSiemens-Vdo cdr500 Philips 22dc403-75Артем РудьNo ratings yet

- Magnetic SensorsDocument35 pagesMagnetic SensorsBijoy KunduNo ratings yet

- Medidas Criticas em RFDocument16 pagesMedidas Criticas em RFWalton William Ferraz RochaNo ratings yet

- Expt 8 BJT Single Stage AmplifierDocument5 pagesExpt 8 BJT Single Stage Amplifiersamarth0% (1)

- ProReact en Digital Hazardous Areas Guide 2Document5 pagesProReact en Digital Hazardous Areas Guide 2saoborjaNo ratings yet

- 33 KV CT A - RRP Agro (Edited)Document4 pages33 KV CT A - RRP Agro (Edited)JRC TestingNo ratings yet

- 24 BOQDocument4 pages24 BOQmanleviNo ratings yet

- Japan Test Report: Report No.: JR1D0705AC Page No.: 1 of 16 Report Version: Rev. 01Document68 pagesJapan Test Report: Report No.: JR1D0705AC Page No.: 1 of 16 Report Version: Rev. 01polish001No ratings yet

- Expt3 Am DemodulationDocument9 pagesExpt3 Am DemodulationRichel Noronio RoblesNo ratings yet

- 7381 Ugeng0004Document2 pages7381 Ugeng0004termmmNo ratings yet

- Bedienungsanleitung Galvotest ENDocument2 pagesBedienungsanleitung Galvotest ENtermmmNo ratings yet

- Fluke 6331 7321 7341 7381 Katalogseite enDocument2 pagesFluke 6331 7321 7341 7381 Katalogseite entermmmNo ratings yet

- PVPM1500x DatasheetDocument2 pagesPVPM1500x DatasheettermmmNo ratings yet

- Manual Durometro Pce 900 v1Document17 pagesManual Durometro Pce 900 v1termmmNo ratings yet

- EX310 UM-enDocument13 pagesEX310 UM-entermmmNo ratings yet

- Reading Analog Gauges Using Open CV For Hazardous Area ApplicationsDocument4 pagesReading Analog Gauges Using Open CV For Hazardous Area ApplicationstermmmNo ratings yet

- Programmable DC Power Supply (Solar Array Simulation) Model 62000H-S SeriesDocument8 pagesProgrammable DC Power Supply (Solar Array Simulation) Model 62000H-S SeriestermmmNo ratings yet

- Euromet Em-S11Document64 pagesEuromet Em-S11termmmNo ratings yet

- Euromet - em k2Document152 pagesEuromet - em k2termmmNo ratings yet

- How To Write Scripts For Test Script Processing (TSP) : Application NoteDocument19 pagesHow To Write Scripts For Test Script Processing (TSP) : Application NotetermmmNo ratings yet

- Euramet Em-S38Document36 pagesEuramet Em-S38termmmNo ratings yet

- FLUKE187&189: Series Maintenance ManualDocument28 pagesFLUKE187&189: Series Maintenance ManualtermmmNo ratings yet

- Humidity/Temperature Sensor: User ManualDocument38 pagesHumidity/Temperature Sensor: User ManualtermmmNo ratings yet

- nf9fx 105g6841 R134a 220v 50hz 04-2019 Desd408o322Document2 pagesnf9fx 105g6841 R134a 220v 50hz 04-2019 Desd408o322termmmNo ratings yet

- 2790 Sourcemeter Switch System SpecificationsDocument6 pages2790 Sourcemeter Switch System SpecificationstermmmNo ratings yet

- And You: AC DC Shunts Can Believe Their Specs?Document6 pagesAnd You: AC DC Shunts Can Believe Their Specs?termmmNo ratings yet

- SPEC-2700K June2014Document4 pagesSPEC-2700K June2014termmmNo ratings yet

- F12 Calibration of Rogowski CoilsDocument1 pageF12 Calibration of Rogowski CoilstermmmNo ratings yet

- 1KW-61433-0 Increasing ProductivityNetworking Instruments AppsBrief 070518Document14 pages1KW-61433-0 Increasing ProductivityNetworking Instruments AppsBrief 070518termmmNo ratings yet

- CA Tinycal 10 enDocument2 pagesCA Tinycal 10 entermmmNo ratings yet

- Agilent 34970A: Data Acquisition / Switch UnitDocument273 pagesAgilent 34970A: Data Acquisition / Switch UnittermmmNo ratings yet

- JFW Spec Sheet 50B-054Document1 pageJFW Spec Sheet 50B-054termmmNo ratings yet

- 5069 INSCAL Insulation Tester Calibration SystemDocument1 page5069 INSCAL Insulation Tester Calibration SystemtermmmNo ratings yet

- Spy RF Modem Ethernet: User ManualDocument14 pagesSpy RF Modem Ethernet: User ManualtermmmNo ratings yet

- Digital Power Meter Model 66200 SeriesDocument4 pagesDigital Power Meter Model 66200 SeriestermmmNo ratings yet

- Views, Synonyms, and SequencesDocument46 pagesViews, Synonyms, and Sequencesprad15No ratings yet

- CityTouch Connect ApplicationDocument13 pagesCityTouch Connect ApplicationYerko Navarro FloresNo ratings yet

- Gs Survey & Engineers: Tax InvoiceDocument2 pagesGs Survey & Engineers: Tax InvoiceShivendra KumarNo ratings yet

- Karens A-MDocument21 pagesKarens A-Mapi-291270075No ratings yet

- Confronting The Storm: Regenerating Leadership and Hope in The Age of UncertaintyDocument38 pagesConfronting The Storm: Regenerating Leadership and Hope in The Age of UncertaintyCharlene Kronstedt100% (1)

- Dvp-Es2 Ss2 Sa2 Sx2-Program o en 20110302Document609 pagesDvp-Es2 Ss2 Sa2 Sx2-Program o en 20110302puskyboyNo ratings yet

- Varistor Catalog PDFDocument254 pagesVaristor Catalog PDFsantosh_babar_26100% (1)

- Peter Welz - ADocument4 pagesPeter Welz - AkrishfabicoipadNo ratings yet

- Kullie StrainGageManualDigitalDocument67 pagesKullie StrainGageManualDigitalDizzixxNo ratings yet

- Revised 04/01/2021Document33 pagesRevised 04/01/2021Kim PowellNo ratings yet

- An Innovative Method To Increase The Resolution of Optical EncodersDocument6 pagesAn Innovative Method To Increase The Resolution of Optical EncodersFuadMuzaki09No ratings yet

- Exercises No 1: Exercise 1Document6 pagesExercises No 1: Exercise 1M ILHAM HATTANo ratings yet

- Cesabb 300 B 400Document8 pagesCesabb 300 B 400BeyzaNo ratings yet

- Stressed Syllable, While Free Vowels Are Those That May Stand in A Stressed Open Syllable With No Following ConsonantDocument2 pagesStressed Syllable, While Free Vowels Are Those That May Stand in A Stressed Open Syllable With No Following ConsonantResiNo ratings yet

- Summer Holiday Homework IdeasDocument5 pagesSummer Holiday Homework Ideasafeungtae100% (1)

- Standard CVDocument3 pagesStandard CVSurzo Chandra DasNo ratings yet

- A G Gardiner EssaysDocument50 pagesA G Gardiner Essaysngisjqaeg100% (2)

- Egyptian PPP Law 67 For 2010 EnglishDocument17 pagesEgyptian PPP Law 67 For 2010 EnglishReham El AbnoudyNo ratings yet

- Lesson Plan PatrickDocument4 pagesLesson Plan PatrickPatrick Jerome SilvanoNo ratings yet

- Discussion Questions Activity NoDocument2 pagesDiscussion Questions Activity NoAngilene Lacson CabinianNo ratings yet

- Classification of Common Musical InstrumentsDocument3 pagesClassification of Common Musical InstrumentsFabian FebianoNo ratings yet

- VarahamihiraDocument6 pagesVarahamihiraSTAR GROUPS100% (1)

- Disinfection Cabinet and Insect KillersDocument4 pagesDisinfection Cabinet and Insect Killerssathya moorthy KamakottiNo ratings yet

- Database Systems, Eleventh Edition by Coronel Morris, Course Technology 2014Document5 pagesDatabase Systems, Eleventh Edition by Coronel Morris, Course Technology 2014LaluMohan KcNo ratings yet

- Symptoms of HypoglycemiaDocument20 pagesSymptoms of Hypoglycemiakenny StefNo ratings yet

- Rev29jan2019oftemplate OSHprogram Asof 290119Document12 pagesRev29jan2019oftemplate OSHprogram Asof 290119GelinaNo ratings yet

- Hellermann Tyton PDFDocument152 pagesHellermann Tyton PDFanon_34390801No ratings yet

- Impromptu SpeechDocument25 pagesImpromptu SpeechJerome Bulaun100% (1)

- Geothermal Well Operation and Maintenance: Sverrir ThorhallssonDocument23 pagesGeothermal Well Operation and Maintenance: Sverrir ThorhallssonLaras PutiNo ratings yet