Professional Documents

Culture Documents

Raw Material Requirement

Raw Material Requirement

Uploaded by

Sanjula Edirisinghe0 ratings0% found this document useful (0 votes)

6 views3 pagesThe document discusses the raw material requirements for a sugar and co-generation plant as well as a distillery unit. It provides tables listing the various raw materials needed, including sugarcane, lime, bagasse, molasses, grains, and chemicals. It specifies the sources and transportation methods of the raw materials. The bagasse generated from sugar production is sufficient to power the existing co-generation plant but additional bagasse will be required after expansion. Fuel needs for the distillery incineration boiler will be met from concentrated spent wash and bagasse.

Original Description:

Original Title

cost 1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses the raw material requirements for a sugar and co-generation plant as well as a distillery unit. It provides tables listing the various raw materials needed, including sugarcane, lime, bagasse, molasses, grains, and chemicals. It specifies the sources and transportation methods of the raw materials. The bagasse generated from sugar production is sufficient to power the existing co-generation plant but additional bagasse will be required after expansion. Fuel needs for the distillery incineration boiler will be met from concentrated spent wash and bagasse.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

6 views3 pagesRaw Material Requirement

Raw Material Requirement

Uploaded by

Sanjula EdirisingheThe document discusses the raw material requirements for a sugar and co-generation plant as well as a distillery unit. It provides tables listing the various raw materials needed, including sugarcane, lime, bagasse, molasses, grains, and chemicals. It specifies the sources and transportation methods of the raw materials. The bagasse generated from sugar production is sufficient to power the existing co-generation plant but additional bagasse will be required after expansion. Fuel needs for the distillery incineration boiler will be met from concentrated spent wash and bagasse.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

Raw Material Requirement

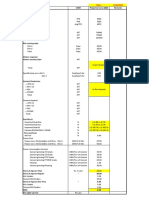

Raw materials required for Sugar and Co-Gen Plant

Sugarcane is the main raw material. Sugar cane is obtained from the farmers within 40 km

radius. The raw materials required are given in Table 1.

Table 1: Details of raw materials for Sugar plant

After

Sl Existing: Source Mode of

Raw Materials expansion:

No 5,000 TCD transport

10,000 TCD

1 Sugar Cane, TPM 1,50,000 3,00,000 Villages in 40 km radius

2 Lime, TPM 180-200 300-350

3 Flocculent, TPM 200-210 400-410

4 Washing Soda , TPM 5-10 15-20

5 Caustic Soda, TPM 5-10 15-20

6 Color Precipitant, TPM 5-10 15-20

7 Refinery Flocculent, TPM 5-10 15-20

By trucks

8 Phosphoric Acid, TPM 5-10 15-20

through

9 Defoaming Agent, TPM 5-10 15-20 Local

Road

10 Antiscalent, TPM 5-10 15-20

11 Mill Sanitation (Bacteriocide), TPM 5-10 15-20

12 Sulfamic Acid, TPM 5-10 15-20

13 Rodine, TPM 5-10 15-20

14 Formic Acid, l/month 5-10 15-20

13 Lubricants (Wheel bearing grease, 2-3 4-5

Lubricating oils etc.,), KL/month

The details of raw materials for existing and proposed expansion co-gen plant are given in

Table 2 and Table 3 below.

Table 1: Bagasse requirement for Steam generation at Co-Gen Plant

Existing: After Expansion:

PARTICULARS

5000 TCD 10,000 TCD

Steam generated per Ton of Bagasse 2 Ton 2 Ton

Total Boiler capacity (in TPH) 165 255

Total Bagasse required to generate steam

1980 1980

based on total boiler Capacity (in Ton/Day)

Table 2: Bagasse Generated at Sugar Plant and its requirement for Co-Gen Plant

Existing: After Expansion:

PARTICULARS

5,000 TCD 10,000 TCD

At Sugar Plant:

Bagasse @ 32% (in Ton/Day) 1,600 3,200

No. of days of Sugar crushing at Sugar Plant 240 240

Total Bagasse Available (in Tons per Annum) 3,84,000 7,68,000

Bagasse requirement for Co-Generation Plant: 35 MW Capacity 35 MW Capacity

No. of days of Operation of Co-Generation Plant 330 330

Bagasse required for Boiler of 165 TPH (in Tons/Day) 1,980* 1,980**

Total Bagasse required for Boiler (in Tons per Annum) 6,53,400* 6,53,400**

* Currently, the steam requirement for Sugar plant process is less than 165 TPH. Thus, Boiler

is operated at lower capacity to generate steam. Therefore, the bagasse generated 1,600

Ton/Day is adequate.

** After expansion of sugar crushing capacity, the steam requirement will be more and

theBoiler will be run at full capacity to generate power and steam. There will be excess

bagasse of 1,14,600 TPA and will be used in the distillery incineration boiler of 52 TPH.

Raw materials required for Distillery Plant

Details of the raw materials required for process, their source of procurement and mode of

transportation is given in Table 4.Fuel requirement by distillery unit &its mode of transportation

is provided in Table 5.

Table 3: Raw material requirement for Distillery unit

Estimated

Sl. Existing Mode of

Raw Materials Quantity after Source

No. quantities transport

expansion

From own

Molasses C Heavy (in KLD) 250 1743 Pipe line /Tanker

sugar plant

From own

Molasses B Heavy (in KLD) 218 1569 Pipe line /Tanker

sugar plant

1 From own

Cane juice syrup (in KLD) Nil 1452 Pipeline

sugar plant

Grains includes wheat /

broken rice / maize / barley / Nil 1100 Local Lorries /Trucks

sorghum (in TPD)

2 Sulphuric Acid, l/d 30-35 190-200 Local HDPE Containers

3 Urea, kg/d 35-40 250-300 Local Plastic containers

4 Antifoam agent, kg/d 30-35 190-200 Local HDPE containers

5 DAP, kg/d 10-15 45-55 Local Plastic containers

6 Dry Yeast, kg/d 10-20 75-85 Local Plastic containers

7 Caustic Flakes kg/d 35-40 250-300 Local Plastic containers

8 Magnesium Sulphate kg/d 10-15 45-55 Local Plastic containers

9 Nitric Acid l/d 15-20 95-110 Local Plastic containers

Table 4: Fuel requirement of distillery unit & mode of transportation

Sl. Existing After Expansion

Fuel Source Transportation

No. MT/day MT/day

For Incineration Boiler – 52 TPH

Direct feeding to boiler

Conc. Spent From distillery

1 450-480 450-480 through pipeline and

Wash process

nozzles.

Bagasse

Feeding through belt

(supplementary- From own

2 170-190 170-190 conveyer from sugar unit

alternative fuel sugar plant

/truck

to coal)

You might also like

- Sample Scoping ReportDocument92 pagesSample Scoping ReportEm Mar0% (1)

- P10 Introduction To Coking ProcessDocument75 pagesP10 Introduction To Coking ProcessJosé Guadarrama100% (3)

- Paradip Refinery Project Write UpDocument25 pagesParadip Refinery Project Write UpHarsha Jayaram100% (3)

- Jharkhand Sor 2016 (2) R.A PDFDocument419 pagesJharkhand Sor 2016 (2) R.A PDFDebasish Misra100% (12)

- Sugar Mill Feasibility Report PDFDocument23 pagesSugar Mill Feasibility Report PDFBaba YagaNo ratings yet

- Coke Oven PlantDocument45 pagesCoke Oven PlantSameer Shekhar100% (1)

- Project Pre-Feasibility Report (PFR) : Expansion For Chlorinated Paraffin Wax & Sulpho Chlorinated Paraffin WAXDocument46 pagesProject Pre-Feasibility Report (PFR) : Expansion For Chlorinated Paraffin Wax & Sulpho Chlorinated Paraffin WAXAyush Singh ChauhanNo ratings yet

- MITCON Consultancy Executive Summary Renuka Sugar Parbhani PlantDocument17 pagesMITCON Consultancy Executive Summary Renuka Sugar Parbhani PlantsenioranantNo ratings yet

- Maharashtra Pollution Control Board: SR No Product Maximum Quantity UOMDocument15 pagesMaharashtra Pollution Control Board: SR No Product Maximum Quantity UOMsalesNo ratings yet

- Maharashtra Pollution Control Board: SR No Product Existing Quantity Proposed Quantity Total UOMDocument11 pagesMaharashtra Pollution Control Board: SR No Product Existing Quantity Proposed Quantity Total UOMsalesNo ratings yet

- 01 Mar 2022 18215388016397500PFRDocument11 pages01 Mar 2022 18215388016397500PFREE 52 virendra KulkarniNo ratings yet

- Andhra Pradesh Pollution Control Board Zonal Office: KurnoolDocument3 pagesAndhra Pradesh Pollution Control Board Zonal Office: KurnoolVijay SethupathiNo ratings yet

- MP - Ethanol - 05 - Mar - 2018 - 1206345039U47U7WOPFRfinalDocument52 pagesMP - Ethanol - 05 - Mar - 2018 - 1206345039U47U7WOPFRfinalParitosh BNo ratings yet

- Executive Summary (English) 1Document24 pagesExecutive Summary (English) 1vinit rajanNo ratings yet

- Weekly Planning June W3-22Document2 pagesWeekly Planning June W3-22anurag soniNo ratings yet

- 0 0 01 Oct 2015 1127076201AdditionalInformationsugarmillLtdDocument33 pages0 0 01 Oct 2015 1127076201AdditionalInformationsugarmillLtdNitin KurupNo ratings yet

- Amrut Enterprises: Subject: Techno Commercial Offer For Required Modifications in Existing WTP Plant (200 KLD)Document1 pageAmrut Enterprises: Subject: Techno Commercial Offer For Required Modifications in Existing WTP Plant (200 KLD)Perma NCRNo ratings yet

- Apar Silvassa LubesDocument8 pagesApar Silvassa LubesROOPDIP MUKHOPADHYAYNo ratings yet

- Maharashtra Pollution Control Board: SR No Product Existing Quantity Proposed Quantity Total UOMDocument12 pagesMaharashtra Pollution Control Board: SR No Product Existing Quantity Proposed Quantity Total UOMsalesNo ratings yet

- Techno Com Proposal - COMBINED PROJECT-2Document137 pagesTechno Com Proposal - COMBINED PROJECT-2Sadiq TurkiNo ratings yet

- Berth Details: ContinuedDocument2 pagesBerth Details: ContinuedVahid SarfarazNo ratings yet

- Avid CteDocument8 pagesAvid CteSubroto KarmokarNo ratings yet

- Broad Tentative Estimates EikflowMay2024Document1 pageBroad Tentative Estimates EikflowMay2024sachinmittal.nitkNo ratings yet

- CTO COKE Oven II 31122027Document18 pagesCTO COKE Oven II 31122027Mohit Kumar DasNo ratings yet

- CTO CompressedDocument19 pagesCTO CompressedSuryakanta PradhanNo ratings yet

- EIA Andhra SugarsDocument3 pagesEIA Andhra SugarsRavi PanaraNo ratings yet

- Zonal 2 2018.23 WCPMDocument32 pagesZonal 2 2018.23 WCPMyv singlaNo ratings yet

- 10 Nov 2017 144732027APLUEJTGPFRRev03Document42 pages10 Nov 2017 144732027APLUEJTGPFRRev03scp1965No ratings yet

- 4 Project Description: 4.1 Baiji RefineryDocument123 pages4 Project Description: 4.1 Baiji Refineryduraid ahmadNo ratings yet

- TNPL PDFDocument16 pagesTNPL PDFDeepanNo ratings yet

- Nalco ProjectDocument36 pagesNalco ProjectPrasant Kumar100% (1)

- Sugar Industry Effluent Treatment Plant. Evaluation and Recommendations - Wealthy WasteDocument11 pagesSugar Industry Effluent Treatment Plant. Evaluation and Recommendations - Wealthy WasteMahmudul HasanNo ratings yet

- Ex - Sum RCFDocument11 pagesEx - Sum RCFMohammadAlAmeenNo ratings yet

- 16 Sep 2019 171500577N8HBJ50QExSumDocument3 pages16 Sep 2019 171500577N8HBJ50QExSumOm PatelNo ratings yet

- Techno-Commercial Offer 120KLD TM Based On SBR Technology, VrindavanDocument9 pagesTechno-Commercial Offer 120KLD TM Based On SBR Technology, VrindavanTech MongerNo ratings yet

- Naini Paper Mill ExpansionDocument38 pagesNaini Paper Mill Expansionabhishek kumar singhNo ratings yet

- 4 004 Potassium Carbonate Carryover PDFDocument25 pages4 004 Potassium Carbonate Carryover PDFZen AlkaffNo ratings yet

- Revised 2 KLD ETP Quotation - Mahesh Deshmukh Dated 17-06-2024Document8 pagesRevised 2 KLD ETP Quotation - Mahesh Deshmukh Dated 17-06-2024Kwwality PorkNo ratings yet

- Bio Gas Plant From Kitchen WasteDocument4 pagesBio Gas Plant From Kitchen WasteBasanth NadellaNo ratings yet

- Standard Data Book (Road & Bridge)Document10 pagesStandard Data Book (Road & Bridge)Anonymous aNyCxZWNo ratings yet

- Welspun Ec PCB PDFDocument40 pagesWelspun Ec PCB PDFraghuarjunNo ratings yet

- Dhampur Sugar Mill Rajpura-Pre-Feasibility Report for Sugar-Cogen-Distillery-June 2024Document52 pagesDhampur Sugar Mill Rajpura-Pre-Feasibility Report for Sugar-Cogen-Distillery-June 2024SRINIVASAN TNo ratings yet

- Rate Analysis Programme MorthDocument362 pagesRate Analysis Programme MorthAman SrivastavaNo ratings yet

- Cost Calculation of Jamtara-Dumka ProjectDocument24 pagesCost Calculation of Jamtara-Dumka ProjectnsureshbabuNo ratings yet

- 03 Road Map Presentation ItalyDocument26 pages03 Road Map Presentation ItalyKURAF MUHENDISLIK AŞ.No ratings yet

- D P ChocolatesDocument3 pagesD P ChocolatesAbhishek PattanshetterNo ratings yet

- Kanoria Chemicals and Industries LimitedDocument6 pagesKanoria Chemicals and Industries LimitedAPIIC EENo ratings yet

- ION ExchangeDocument10 pagesION ExchangesalesNo ratings yet

- SP PresentationDocument15 pagesSP PresentationARGHYA MANDALNo ratings yet

- 0 0 26 Nov 2014 1823468631prefeasibility Report PDFDocument68 pages0 0 26 Nov 2014 1823468631prefeasibility Report PDFPawan PatilNo ratings yet

- Stefanus Johan Biogas Future and Opportunities-R2Document15 pagesStefanus Johan Biogas Future and Opportunities-R2Bimo Nuswantoro SugardoNo ratings yet

- Case Study: Round - 1Document9 pagesCase Study: Round - 1Rajat RanjanNo ratings yet

- The Refining Industry in IraqDocument29 pagesThe Refining Industry in Iraqanwar alamNo ratings yet

- Prudent 190 KLD STPDocument7 pagesPrudent 190 KLD STPabhi_monNo ratings yet

- Coal Preparation I PolandDocument33 pagesCoal Preparation I Polandruzmir100% (1)

- Technical Proposal: Gypsum Powder Production Line With Capacity 60000 Tons Per YearDocument25 pagesTechnical Proposal: Gypsum Powder Production Line With Capacity 60000 Tons Per YearJohn TesfamariamNo ratings yet

- India Cements Production ReportDocument7 pagesIndia Cements Production ReportJCSNo ratings yet

- P FD FileDocument13 pagesP FD FileNavanita Saikia MechNo ratings yet

- Technical Report of Formic Acid PlantDocument6 pagesTechnical Report of Formic Acid PlantMuzzamilNo ratings yet

- RMP 1Document10 pagesRMP 1Anonymous l5X3VhTNo ratings yet

- Multiphase Reactor Engineering for Clean and Low-Carbon Energy ApplicationsFrom EverandMultiphase Reactor Engineering for Clean and Low-Carbon Energy ApplicationsYi ChengNo ratings yet

- Layug V IACDocument1 pageLayug V IACYasser MambuayNo ratings yet

- Essay EnvironmentDocument4 pagesEssay Environmenttuevptvhd100% (2)

- Assignment For InterviewDocument34 pagesAssignment For InterviewBurugolla RaviNo ratings yet

- Practical File AI - Class 10Document3 pagesPractical File AI - Class 10pawankvs2008No ratings yet

- S17.s1 - Final Project - Inglés 3 - MANUEL LAURA MAMANIDocument3 pagesS17.s1 - Final Project - Inglés 3 - MANUEL LAURA MAMANIManuel Sebastian Laura MamaniNo ratings yet

- ION-Evolution - ERA PANOS-RSDocument29 pagesION-Evolution - ERA PANOS-RSSokratesNo ratings yet

- Kiosk Design & Construction CriteriaDocument33 pagesKiosk Design & Construction CriteriaAdson AlcantaraNo ratings yet

- A Master Forms Residential IndexDocument70 pagesA Master Forms Residential IndexAlberta Real EstateNo ratings yet

- The Secret SharerDocument3 pagesThe Secret ShareranbarasiNo ratings yet

- Debug Tacacs CiscoDocument5 pagesDebug Tacacs CiscodeztrocxeNo ratings yet

- Course Registration SystemDocument11 pagesCourse Registration Systemananthprasad91100% (3)

- Sisymposiumharrisburgpaworkshoptraceyvincent PDFDocument76 pagesSisymposiumharrisburgpaworkshoptraceyvincent PDFNancyNo ratings yet

- Plants and Animals Live Together Lesson PlanDocument3 pagesPlants and Animals Live Together Lesson Planapi-374921894No ratings yet

- Terms and Conditions On The Issuance and Use of RCBC Credit CardsDocument15 pagesTerms and Conditions On The Issuance and Use of RCBC Credit CardsGillian Alexis ColegadoNo ratings yet

- Merritt Morning Market 3714 - July 20Document2 pagesMerritt Morning Market 3714 - July 20Kim LeclairNo ratings yet

- Role Based Training - Managing Work (Projects) in PlanviewDocument89 pagesRole Based Training - Managing Work (Projects) in PlanviewMark StrolenbergNo ratings yet

- Case CX TrainingDocument20 pagesCase CX Traininghoward100% (27)

- Bulletin Low Res 2Document19 pagesBulletin Low Res 2Аксана ГатауллинаNo ratings yet

- Braille PresentationDocument10 pagesBraille PresentationHakeem And Hadrian XDSNo ratings yet

- Bpacr FinalDocument7 pagesBpacr FinalNivedita CharanNo ratings yet

- 3 R Eceptive Skills: Reading: How Can You Help Your Students Improve Their Reading?Document5 pages3 R Eceptive Skills: Reading: How Can You Help Your Students Improve Their Reading?Anita MadunovicNo ratings yet

- 2018 Trial 1 Biology Questions and Marking SchemeDocument11 pages2018 Trial 1 Biology Questions and Marking SchemeKodhekNo ratings yet

- 80 3689 01 Threaded ConnectionsDocument12 pages80 3689 01 Threaded ConnectionsMiguel Alfonso Ruiz MendezNo ratings yet

- NLC English 7 Enhancement LP v.1Document85 pagesNLC English 7 Enhancement LP v.1patric maturan100% (1)

- Kci Fi001261149Document9 pagesKci Fi001261149minjokcsy99No ratings yet

- Polymers in Our Daily Life PDFDocument2 pagesPolymers in Our Daily Life PDFAnjali Reddy ANo ratings yet

- George The SlugDocument4 pagesGeorge The SlugAndrewBayangNo ratings yet

- Bus TicketDocument3 pagesBus Ticketk57hzsrnckNo ratings yet

- Kavity StadiumDocument21 pagesKavity StadiumD.V.Srinivasa RaoNo ratings yet