Professional Documents

Culture Documents

(SOP-CM-PI-027) AirWater Pressure Test (Normal)

(SOP-CM-PI-027) AirWater Pressure Test (Normal)

Uploaded by

HMN YDVCopyright:

Available Formats

You might also like

- Prescription - 217923 - 27 07 2020 - Dr. Prof. Sanjay Sinha - Apollo 247Document3 pagesPrescription - 217923 - 27 07 2020 - Dr. Prof. Sanjay Sinha - Apollo 247badenaga75% (4)

- Itp GeneratorDocument4 pagesItp Generatormuhammad afrizalNo ratings yet

- Instruction Manual: Fuel Valve Test Device MODEL: HDFD-1100Document16 pagesInstruction Manual: Fuel Valve Test Device MODEL: HDFD-1100Vlad KorzhovNo ratings yet

- Heat of Reaction Lab ReportDocument11 pagesHeat of Reaction Lab ReportKrishna Preeya0% (1)

- PSV Calculation and PhilosophyDocument33 pagesPSV Calculation and PhilosophysbmmlaNo ratings yet

- Intellectual Developmental DisabilitiesDocument16 pagesIntellectual Developmental DisabilitiesChege DennisNo ratings yet

- ITP PLUMBING WORKS SampleDocument1 pageITP PLUMBING WORKS SampleJay Chris L. Beron75% (4)

- Transformer Oil Test ReportDocument2 pagesTransformer Oil Test Reportibubu2380% (5)

- IB Biology Revision Notes FULLDocument3 pagesIB Biology Revision Notes FULLAtulya BharadwajNo ratings yet

- Step Plan TL OperationDocument6 pagesStep Plan TL OperationHMN YDVNo ratings yet

- Confined Space (SOP-CM-PI-034) 밀폐공간 배관작업-영어Document5 pagesConfined Space (SOP-CM-PI-034) 밀폐공간 배관작업-영어HMN YDVNo ratings yet

- ITP Boiler PDFDocument13 pagesITP Boiler PDFMúhámmád ÁbrorNo ratings yet

- Piping Forklift Operation: - ContentsDocument6 pagesPiping Forklift Operation: - ContentsHMN YDVNo ratings yet

- HMMI Inspection and Test Plan Rev - 0Document35 pagesHMMI Inspection and Test Plan Rev - 0Nimas AfinaNo ratings yet

- Boiler 3.1Document112 pagesBoiler 3.1Aldy Bagus PratamaNo ratings yet

- Hampdon Wind Tunnel H 6910 12 CDLDocument41 pagesHampdon Wind Tunnel H 6910 12 CDLardiantio887No ratings yet

- Quality/Critical Checks: Safety ChecksDocument5 pagesQuality/Critical Checks: Safety ChecksCynthy Ivonne Torres PerezNo ratings yet

- Ceiling TAX InstallationDocument4 pagesCeiling TAX InstallationHMN YDVNo ratings yet

- Inspection Request Form Plant PipingDocument1 pageInspection Request Form Plant Pipingck19654840No ratings yet

- Checklist of EquipmentsDocument113 pagesChecklist of EquipmentsM.zuhair asifNo ratings yet

- ECC-MECH-GAS-24-018Document2 pagesECC-MECH-GAS-24-018Jeyaseelan JohNo ratings yet

- Step Plan - Duct InstallationDocument5 pagesStep Plan - Duct InstallationHMN YDVNo ratings yet

- Shield - ItpDocument3 pagesShield - Itpmechsasi1988No ratings yet

- Task Sheet - Replace and Pressure Test Pipework - Kensington OlympiaDocument4 pagesTask Sheet - Replace and Pressure Test Pipework - Kensington OlympiaLeeJB09No ratings yet

- Inspection PlanDocument1 pageInspection PlanMohit SharmaNo ratings yet

- Theory and Practice of The Closed-Chamber Drillstelll Test MethodDocument6 pagesTheory and Practice of The Closed-Chamber Drillstelll Test MethodvastaguenNo ratings yet

- Hazrad IdentificationDocument36 pagesHazrad IdentificationKhaledAhmedNo ratings yet

- Inspection Test Plan (Itp) at Site: Natural Gas Transportation Development Project - Siak RiauDocument6 pagesInspection Test Plan (Itp) at Site: Natural Gas Transportation Development Project - Siak Riauanang_pri100% (1)

- Itp SwitchgearDocument3 pagesItp Switchgearmuhammad afrizalNo ratings yet

- 4pipefitting Pressure Test 170129022549 PDFDocument13 pages4pipefitting Pressure Test 170129022549 PDFKamarul NizamNo ratings yet

- (SOP-CM-PI-018) Sprinkler Head InstallationDocument6 pages(SOP-CM-PI-018) Sprinkler Head InstallationHMN YDVNo ratings yet

- Air Blowing Package (Sample)Document3 pagesAir Blowing Package (Sample)YusufNo ratings yet

- 06 Well Testing 201102Document27 pages06 Well Testing 201102Hosni Ben Mansour100% (2)

- Piping & Support Installation Work: - Flow Step PlanDocument6 pagesPiping & Support Installation Work: - Flow Step PlanHMN YDVNo ratings yet

- C0M-14 Hydrostatic Test of Pressure VesselDocument3 pagesC0M-14 Hydrostatic Test of Pressure VesselHong Trung DuongNo ratings yet

- Normal Procedures Checklist RTS Seneca V 2016 13062016 PDFDocument14 pagesNormal Procedures Checklist RTS Seneca V 2016 13062016 PDFboero115No ratings yet

- Check List for BWTSDocument3 pagesCheck List for BWTSAngelo TubongbanuaNo ratings yet

- Itp Motor Control Center (MCC)Document3 pagesItp Motor Control Center (MCC)muhammad afrizal0% (1)

- 11drillstem Testing Operations and AnalysisDocument67 pages11drillstem Testing Operations and AnalysistauseefaroseNo ratings yet

- Safety Valve Test 2.0: The Innov AtionDocument8 pagesSafety Valve Test 2.0: The Innov AtionKauffman LOKONo ratings yet

- Wellhead PlatformDocument7 pagesWellhead PlatformMd KhanNo ratings yet

- 2.0 Pressure TestingDocument11 pages2.0 Pressure TestingHATEMNo ratings yet

- 1ra HydrotestingDocument4 pages1ra HydrotestingMohammed Amer PashaNo ratings yet

- 2nd Week - Force&moment - 2015 PDFDocument22 pages2nd Week - Force&moment - 2015 PDFAnusha RaviNo ratings yet

- CH0302 Process InstrumentationDocument45 pagesCH0302 Process InstrumentationGirish GuptaNo ratings yet

- Tra Hyl QCP em Gen 00999 00 Pressure Test ReportDocument2 pagesTra Hyl QCP em Gen 00999 00 Pressure Test ReportMurtada OmerNo ratings yet

- Load-Sensing Valve (LSV) 475 72.: Test and Setup InstructionsDocument4 pagesLoad-Sensing Valve (LSV) 475 72.: Test and Setup InstructionsRafael LecuNo ratings yet

- Petroleum Production EngineeringDocument59 pagesPetroleum Production EngineeringanmolNo ratings yet

- Function Test Cert. DHSV v-14 April 05,2023Document1 pageFunction Test Cert. DHSV v-14 April 05,2023muhamad.iqbaaal11No ratings yet

- 757-005-4 Pump Performance Test - Rev.ADocument2 pages757-005-4 Pump Performance Test - Rev.Afsbv7fx9No ratings yet

- RKP23002 - INSPECTION SCHEDULE (2024.may.15,16)Document2 pagesRKP23002 - INSPECTION SCHEDULE (2024.may.15,16)Mỹ Phạm AnhNo ratings yet

- Gate Valves For Wellhead: Inspection Data Sheet (I D S)Document5 pagesGate Valves For Wellhead: Inspection Data Sheet (I D S)kais rguiguiNo ratings yet

- 47.HDEC-HSE-F0047 Pressure Test PermitDocument1 page47.HDEC-HSE-F0047 Pressure Test PermitRonn CaiNo ratings yet

- Duplex SumpDocument1 pageDuplex Sumpahmedbhit04No ratings yet

- Ra HydrotestingDocument4 pagesRa HydrotestingAmmar RazaNo ratings yet

- Qap Ball ValveDocument1 pageQap Ball ValveOmextitech EnterpriseNo ratings yet

- Test Procedure 8.4 Condenser Performance TestDocument19 pagesTest Procedure 8.4 Condenser Performance TestLakshmi Narayan100% (2)

- VP N2 Me Pro 001 001Document3 pagesVP N2 Me Pro 001 001phuoc leNo ratings yet

- Ata 21Document3 pagesAta 21Rohan SinghNo ratings yet

- 112 - Check List For Ac SystemDocument1 page112 - Check List For Ac SystemR MathirajNo ratings yet

- Pendulum Impact Testers - Impact Testing Machine - Aimil - Com - PDFDocument12 pagesPendulum Impact Testers - Impact Testing Machine - Aimil - Com - PDFAimil Ltd.100% (1)

- POM 2 IngDocument20 pagesPOM 2 IngAlex Trujillo GutiérrezNo ratings yet

- RLC-AH-QP-91-3001 Inspection Test Plan For Plumbing Works-1Document6 pagesRLC-AH-QP-91-3001 Inspection Test Plan For Plumbing Works-1nighttrasherNo ratings yet

- Construction Equipment Work Plan Lifting EquipmentDocument2 pagesConstruction Equipment Work Plan Lifting EquipmentHMN YDVNo ratings yet

- HSENMR003 - Near Miss Incident ReportDocument4 pagesHSENMR003 - Near Miss Incident ReportHMN YDVNo ratings yet

- Support Instalation WorkDocument1 pageSupport Instalation WorkHMN YDVNo ratings yet

- Ceiling TAX InstallationDocument4 pagesCeiling TAX InstallationHMN YDVNo ratings yet

- Piping Forklift Operation: - ContentsDocument6 pagesPiping Forklift Operation: - ContentsHMN YDVNo ratings yet

- (SOP-CM-PI-018) Sprinkler Head InstallationDocument6 pages(SOP-CM-PI-018) Sprinkler Head InstallationHMN YDVNo ratings yet

- Confined Space (SOP-CM-PI-034) 밀폐공간 배관작업-영어Document5 pagesConfined Space (SOP-CM-PI-034) 밀폐공간 배관작업-영어HMN YDVNo ratings yet

- Step Plan TL OperationDocument6 pagesStep Plan TL OperationHMN YDVNo ratings yet

- Piping & Support Installation Work: - Flow Step PlanDocument6 pagesPiping & Support Installation Work: - Flow Step PlanHMN YDVNo ratings yet

- Step Plan - Duct InstallationDocument5 pagesStep Plan - Duct InstallationHMN YDVNo ratings yet

- Initial (Annual) Risk Assessment 최초 (정기) 위험성평가 R0Document14 pagesInitial (Annual) Risk Assessment 최초 (정기) 위험성평가 R0HMN YDVNo ratings yet

- Thesis DidanaliDocument36 pagesThesis DidanaliHemenMoNo ratings yet

- Heating, Air ConditioningDocument64 pagesHeating, Air ConditioningCésar Arturo Pajuelo EspinozaNo ratings yet

- Kolmeks Pump Catalogue Low PDFDocument260 pagesKolmeks Pump Catalogue Low PDFMykola Titov50% (2)

- Early Elementary Education Cert - P-5 With Concentration in Early Childhood Education - Cert Birth To Age 5-BSRDocument3 pagesEarly Elementary Education Cert - P-5 With Concentration in Early Childhood Education - Cert Birth To Age 5-BSRUniversity of LouisvilleNo ratings yet

- The Right To Sexual Orientation, CG ProjectDocument9 pagesThe Right To Sexual Orientation, CG ProjecttanayaNo ratings yet

- HydrationDocument1 pageHydrationfidaauddinNo ratings yet

- Idiomatic ExpressionDocument27 pagesIdiomatic ExpressionJess Jess100% (1)

- LDocument8 pagesLTamara Monsalve100% (1)

- Chrissa Mae T. Catindoy BS Medical Technology 3A: Group Classification Pathologic SignificanceDocument5 pagesChrissa Mae T. Catindoy BS Medical Technology 3A: Group Classification Pathologic SignificanceChrissa Mae Tumaliuan CatindoyNo ratings yet

- SPK Manual 2007-2009Document26 pagesSPK Manual 2007-2009jlhood65No ratings yet

- Hydrotest ProcedureDocument3 pagesHydrotest Procedureaman131100% (2)

- Exp't 51: Nitration of NitrobenzeneDocument4 pagesExp't 51: Nitration of NitrobenzenelovehopeNo ratings yet

- Life Safety Solutions Specification Sheet 6557Document323 pagesLife Safety Solutions Specification Sheet 6557Ernesto CamposNo ratings yet

- Osram OutdoorDocument95 pagesOsram OutdoorDiana Rose TapelNo ratings yet

- Jurnal Tentang Jamur ObatDocument12 pagesJurnal Tentang Jamur ObatCut Kandy SafieraNo ratings yet

- Reading Comprehension B2 ESL Elephant Tea GardenDocument4 pagesReading Comprehension B2 ESL Elephant Tea GardenAnna MayerNo ratings yet

- Antenna EffectDocument5 pagesAntenna Effectstudius1No ratings yet

- Mobrey Squitch-2: Ultrasonic Liquid Level SwitchDocument2 pagesMobrey Squitch-2: Ultrasonic Liquid Level SwitchPhan CườngNo ratings yet

- Validation and Qualification of Heating, Ventilation, Air ConDocument18 pagesValidation and Qualification of Heating, Ventilation, Air ConJai MurugeshNo ratings yet

- 17-03-10 Inductive Conductivity Transmitter CIT-8920Document30 pages17-03-10 Inductive Conductivity Transmitter CIT-8920Juan CarvajalNo ratings yet

- Xenon 21-22 Sheet Without Answer (EUDIOMETRY)Document3 pagesXenon 21-22 Sheet Without Answer (EUDIOMETRY)Krishna GoyalNo ratings yet

- About Epistaxis or Nosebleeds: If You Have Any Problems or Questions, Please ContactDocument2 pagesAbout Epistaxis or Nosebleeds: If You Have Any Problems or Questions, Please ContactGHAPRC RUDRAPURNo ratings yet

- Danika Sanders Student Teacher ResumeDocument2 pagesDanika Sanders Student Teacher Resumeapi-496485131No ratings yet

- Ijims 2017 105Document7 pagesIjims 2017 105Marcos HoilNo ratings yet

- Root Resorption Due To Dental Trauma: General PrinciplesDocument22 pagesRoot Resorption Due To Dental Trauma: General PrinciplesBogdan PopescuNo ratings yet

(SOP-CM-PI-027) AirWater Pressure Test (Normal)

(SOP-CM-PI-027) AirWater Pressure Test (Normal)

Uploaded by

HMN YDVOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(SOP-CM-PI-027) AirWater Pressure Test (Normal)

(SOP-CM-PI-027) AirWater Pressure Test (Normal)

Uploaded by

HMN YDVCopyright:

Available Formats

- CONTENTS -

Air/Water pressure Test (Normal)

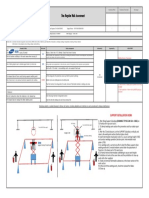

□ WORK FLOW

□ STEP PLAN

□ PRE, ING, AFTER CHECK LIST

□ EMERGENCY CONTACT INFO.

Reason for Revision Department

NO. DATE Supervision Drafter

MECH

0 19.09.01 First Enactment

□ Air/Water pressure Test (Normal) FLOW

C&T C&T

Processes Supervision

Mech Safety

SUBCON

START

Document number : SOP-CM-PI-027

Date of enactment : 2019. 09. 01

Air/Water Pressure Test Plan

R H - H

Safety Plan

- W R H

DRI Review

- R R H

SOP training N - W W H

O

Y

E a field notice N - W - H

S O

Y TBM

E - W W H

S

Air/Water Pressure Pressurization

W W W H

Check if the first air pressure leaks or

not N

O H H - H

Y Wait for the specified test time

E W W - H

S

Check if the last air pressure leaks or

N

not O H H - H

Y

E FLUSHING

S W W W H

TURN - ON

- - - H

Finish

H: HOLD POINT – The test point subject directly measures the test / test (after-process cannot be started)

W: WITNESS POINT – Measurement of a test / test in the presence of a target

□ Air/water pressure Test(normal) STEP-PLAN

R: RECORD REVIEW-Review by the inspection / test report

Safety

Sequence of work Process description Potential risk

Management

-Increase of pressure value -Wait until the ambient

1) TBM after checking air/water pressure section.

by thermal expansion temperature is reached.

1. Air/Water Pressure -Risk of damage to valve and -Setting up test interval

2) set pressure value

test equipment by other parcels and placing monitors

Pressurization 3) Air/Water pressure Test Plan Report workers in test section

3) Submit and approve safety management plan

Document number : SOP-CM-PI-027

Date of enactment : 2019. 09. 01

4) Personnel for all areas of air/water pressure

-Take the radio with you

-React immediately in case of Leak

5) Pressurization

1) To install the pressure gauge, install one of the top

-After completing the air

2. Check if the first air

pressure test, check the valve

end and one of the bottom to check if there is a

open/close status and

pressure leaks or not immediately respond to

leak or not. -Risk of accidents by Leak

initial pressure by placing

-Risk of blindness during eye

personnel in the piping

2) Primary inspection through soap bubble contact by air leak

installation section.

-Check if safety glasses are

inspection and visual inspection worn in the pressurized

section

3) Check the pressure gauge grid lines

-After completing the air

3. Wait for the specified

pressure test, check the valve

1) Place monitoring personnel around piping

open/close status and

test time -Risk of accidents by Leak immediately respond to

2) Check the pressure gauge scale at 1HR intervals

-Risk of blindness during eye initial pressure by placing

contact by air leak personnel in the piping

-Attach eye care sticker to initial pressure gauge and

installation section.

-Check if safety glasses are

record pressure value

worn in the pressurized

section

-After completing the air

4. Check if the last air

pressure test, check the valve

open/close status and

pressure leaks or not immediately respond to

-Risk of accidents by Leak

initial pressure by placing

1) Check the pressure gauge scale -Risk of blindness during eye

personnel in the piping

contact by air leak

installation section.

-Check if safety glasses are

worn in the pressurized

section

1)After completion of the air/water test

5. FLUSHING, Turn on

-Drain the air/water pressure inside the pipe (caution

of open and close the valve).)

- Risk of blindness due to -Check if safety glasses are

pressure when flushing worn in the Flushing section

2)Turn on

-enough air to refill water

3)Install the valve (LOTO).

1) cleanup the site

6. Cleanup

Document number : SOP-CM-PI-027

Date of enactment : 2019. 09. 01

Document number : SOP-CM-PI-027

Date of enactment : 2019. 09. 01

EMERGENCY CONTACT

Contact Target Name Contact No.

Medical

SAMSUNG

Medical center 74288-11679

SAMSUNG

C&T Control Room 85270-39774

SAMSUNG Main S.B. KIM 74285-48101

C&T

Sub D.K. JEONG 88262-10063

Main I.G. KIM 98182-09299

SAFETY

Sub PRADIP 95997-30919

Main Kim Kyung Bum 98184-34517

SUB-CON

Sub B.Ramamoorthy 96263-22255

Document number : SOP-CM-PI-027

Date of enactment : 2019. 09. 01

You might also like

- Prescription - 217923 - 27 07 2020 - Dr. Prof. Sanjay Sinha - Apollo 247Document3 pagesPrescription - 217923 - 27 07 2020 - Dr. Prof. Sanjay Sinha - Apollo 247badenaga75% (4)

- Itp GeneratorDocument4 pagesItp Generatormuhammad afrizalNo ratings yet

- Instruction Manual: Fuel Valve Test Device MODEL: HDFD-1100Document16 pagesInstruction Manual: Fuel Valve Test Device MODEL: HDFD-1100Vlad KorzhovNo ratings yet

- Heat of Reaction Lab ReportDocument11 pagesHeat of Reaction Lab ReportKrishna Preeya0% (1)

- PSV Calculation and PhilosophyDocument33 pagesPSV Calculation and PhilosophysbmmlaNo ratings yet

- Intellectual Developmental DisabilitiesDocument16 pagesIntellectual Developmental DisabilitiesChege DennisNo ratings yet

- ITP PLUMBING WORKS SampleDocument1 pageITP PLUMBING WORKS SampleJay Chris L. Beron75% (4)

- Transformer Oil Test ReportDocument2 pagesTransformer Oil Test Reportibubu2380% (5)

- IB Biology Revision Notes FULLDocument3 pagesIB Biology Revision Notes FULLAtulya BharadwajNo ratings yet

- Step Plan TL OperationDocument6 pagesStep Plan TL OperationHMN YDVNo ratings yet

- Confined Space (SOP-CM-PI-034) 밀폐공간 배관작업-영어Document5 pagesConfined Space (SOP-CM-PI-034) 밀폐공간 배관작업-영어HMN YDVNo ratings yet

- ITP Boiler PDFDocument13 pagesITP Boiler PDFMúhámmád ÁbrorNo ratings yet

- Piping Forklift Operation: - ContentsDocument6 pagesPiping Forklift Operation: - ContentsHMN YDVNo ratings yet

- HMMI Inspection and Test Plan Rev - 0Document35 pagesHMMI Inspection and Test Plan Rev - 0Nimas AfinaNo ratings yet

- Boiler 3.1Document112 pagesBoiler 3.1Aldy Bagus PratamaNo ratings yet

- Hampdon Wind Tunnel H 6910 12 CDLDocument41 pagesHampdon Wind Tunnel H 6910 12 CDLardiantio887No ratings yet

- Quality/Critical Checks: Safety ChecksDocument5 pagesQuality/Critical Checks: Safety ChecksCynthy Ivonne Torres PerezNo ratings yet

- Ceiling TAX InstallationDocument4 pagesCeiling TAX InstallationHMN YDVNo ratings yet

- Inspection Request Form Plant PipingDocument1 pageInspection Request Form Plant Pipingck19654840No ratings yet

- Checklist of EquipmentsDocument113 pagesChecklist of EquipmentsM.zuhair asifNo ratings yet

- ECC-MECH-GAS-24-018Document2 pagesECC-MECH-GAS-24-018Jeyaseelan JohNo ratings yet

- Step Plan - Duct InstallationDocument5 pagesStep Plan - Duct InstallationHMN YDVNo ratings yet

- Shield - ItpDocument3 pagesShield - Itpmechsasi1988No ratings yet

- Task Sheet - Replace and Pressure Test Pipework - Kensington OlympiaDocument4 pagesTask Sheet - Replace and Pressure Test Pipework - Kensington OlympiaLeeJB09No ratings yet

- Inspection PlanDocument1 pageInspection PlanMohit SharmaNo ratings yet

- Theory and Practice of The Closed-Chamber Drillstelll Test MethodDocument6 pagesTheory and Practice of The Closed-Chamber Drillstelll Test MethodvastaguenNo ratings yet

- Hazrad IdentificationDocument36 pagesHazrad IdentificationKhaledAhmedNo ratings yet

- Inspection Test Plan (Itp) at Site: Natural Gas Transportation Development Project - Siak RiauDocument6 pagesInspection Test Plan (Itp) at Site: Natural Gas Transportation Development Project - Siak Riauanang_pri100% (1)

- Itp SwitchgearDocument3 pagesItp Switchgearmuhammad afrizalNo ratings yet

- 4pipefitting Pressure Test 170129022549 PDFDocument13 pages4pipefitting Pressure Test 170129022549 PDFKamarul NizamNo ratings yet

- (SOP-CM-PI-018) Sprinkler Head InstallationDocument6 pages(SOP-CM-PI-018) Sprinkler Head InstallationHMN YDVNo ratings yet

- Air Blowing Package (Sample)Document3 pagesAir Blowing Package (Sample)YusufNo ratings yet

- 06 Well Testing 201102Document27 pages06 Well Testing 201102Hosni Ben Mansour100% (2)

- Piping & Support Installation Work: - Flow Step PlanDocument6 pagesPiping & Support Installation Work: - Flow Step PlanHMN YDVNo ratings yet

- C0M-14 Hydrostatic Test of Pressure VesselDocument3 pagesC0M-14 Hydrostatic Test of Pressure VesselHong Trung DuongNo ratings yet

- Normal Procedures Checklist RTS Seneca V 2016 13062016 PDFDocument14 pagesNormal Procedures Checklist RTS Seneca V 2016 13062016 PDFboero115No ratings yet

- Check List for BWTSDocument3 pagesCheck List for BWTSAngelo TubongbanuaNo ratings yet

- Itp Motor Control Center (MCC)Document3 pagesItp Motor Control Center (MCC)muhammad afrizal0% (1)

- 11drillstem Testing Operations and AnalysisDocument67 pages11drillstem Testing Operations and AnalysistauseefaroseNo ratings yet

- Safety Valve Test 2.0: The Innov AtionDocument8 pagesSafety Valve Test 2.0: The Innov AtionKauffman LOKONo ratings yet

- Wellhead PlatformDocument7 pagesWellhead PlatformMd KhanNo ratings yet

- 2.0 Pressure TestingDocument11 pages2.0 Pressure TestingHATEMNo ratings yet

- 1ra HydrotestingDocument4 pages1ra HydrotestingMohammed Amer PashaNo ratings yet

- 2nd Week - Force&moment - 2015 PDFDocument22 pages2nd Week - Force&moment - 2015 PDFAnusha RaviNo ratings yet

- CH0302 Process InstrumentationDocument45 pagesCH0302 Process InstrumentationGirish GuptaNo ratings yet

- Tra Hyl QCP em Gen 00999 00 Pressure Test ReportDocument2 pagesTra Hyl QCP em Gen 00999 00 Pressure Test ReportMurtada OmerNo ratings yet

- Load-Sensing Valve (LSV) 475 72.: Test and Setup InstructionsDocument4 pagesLoad-Sensing Valve (LSV) 475 72.: Test and Setup InstructionsRafael LecuNo ratings yet

- Petroleum Production EngineeringDocument59 pagesPetroleum Production EngineeringanmolNo ratings yet

- Function Test Cert. DHSV v-14 April 05,2023Document1 pageFunction Test Cert. DHSV v-14 April 05,2023muhamad.iqbaaal11No ratings yet

- 757-005-4 Pump Performance Test - Rev.ADocument2 pages757-005-4 Pump Performance Test - Rev.Afsbv7fx9No ratings yet

- RKP23002 - INSPECTION SCHEDULE (2024.may.15,16)Document2 pagesRKP23002 - INSPECTION SCHEDULE (2024.may.15,16)Mỹ Phạm AnhNo ratings yet

- Gate Valves For Wellhead: Inspection Data Sheet (I D S)Document5 pagesGate Valves For Wellhead: Inspection Data Sheet (I D S)kais rguiguiNo ratings yet

- 47.HDEC-HSE-F0047 Pressure Test PermitDocument1 page47.HDEC-HSE-F0047 Pressure Test PermitRonn CaiNo ratings yet

- Duplex SumpDocument1 pageDuplex Sumpahmedbhit04No ratings yet

- Ra HydrotestingDocument4 pagesRa HydrotestingAmmar RazaNo ratings yet

- Qap Ball ValveDocument1 pageQap Ball ValveOmextitech EnterpriseNo ratings yet

- Test Procedure 8.4 Condenser Performance TestDocument19 pagesTest Procedure 8.4 Condenser Performance TestLakshmi Narayan100% (2)

- VP N2 Me Pro 001 001Document3 pagesVP N2 Me Pro 001 001phuoc leNo ratings yet

- Ata 21Document3 pagesAta 21Rohan SinghNo ratings yet

- 112 - Check List For Ac SystemDocument1 page112 - Check List For Ac SystemR MathirajNo ratings yet

- Pendulum Impact Testers - Impact Testing Machine - Aimil - Com - PDFDocument12 pagesPendulum Impact Testers - Impact Testing Machine - Aimil - Com - PDFAimil Ltd.100% (1)

- POM 2 IngDocument20 pagesPOM 2 IngAlex Trujillo GutiérrezNo ratings yet

- RLC-AH-QP-91-3001 Inspection Test Plan For Plumbing Works-1Document6 pagesRLC-AH-QP-91-3001 Inspection Test Plan For Plumbing Works-1nighttrasherNo ratings yet

- Construction Equipment Work Plan Lifting EquipmentDocument2 pagesConstruction Equipment Work Plan Lifting EquipmentHMN YDVNo ratings yet

- HSENMR003 - Near Miss Incident ReportDocument4 pagesHSENMR003 - Near Miss Incident ReportHMN YDVNo ratings yet

- Support Instalation WorkDocument1 pageSupport Instalation WorkHMN YDVNo ratings yet

- Ceiling TAX InstallationDocument4 pagesCeiling TAX InstallationHMN YDVNo ratings yet

- Piping Forklift Operation: - ContentsDocument6 pagesPiping Forklift Operation: - ContentsHMN YDVNo ratings yet

- (SOP-CM-PI-018) Sprinkler Head InstallationDocument6 pages(SOP-CM-PI-018) Sprinkler Head InstallationHMN YDVNo ratings yet

- Confined Space (SOP-CM-PI-034) 밀폐공간 배관작업-영어Document5 pagesConfined Space (SOP-CM-PI-034) 밀폐공간 배관작업-영어HMN YDVNo ratings yet

- Step Plan TL OperationDocument6 pagesStep Plan TL OperationHMN YDVNo ratings yet

- Piping & Support Installation Work: - Flow Step PlanDocument6 pagesPiping & Support Installation Work: - Flow Step PlanHMN YDVNo ratings yet

- Step Plan - Duct InstallationDocument5 pagesStep Plan - Duct InstallationHMN YDVNo ratings yet

- Initial (Annual) Risk Assessment 최초 (정기) 위험성평가 R0Document14 pagesInitial (Annual) Risk Assessment 최초 (정기) 위험성평가 R0HMN YDVNo ratings yet

- Thesis DidanaliDocument36 pagesThesis DidanaliHemenMoNo ratings yet

- Heating, Air ConditioningDocument64 pagesHeating, Air ConditioningCésar Arturo Pajuelo EspinozaNo ratings yet

- Kolmeks Pump Catalogue Low PDFDocument260 pagesKolmeks Pump Catalogue Low PDFMykola Titov50% (2)

- Early Elementary Education Cert - P-5 With Concentration in Early Childhood Education - Cert Birth To Age 5-BSRDocument3 pagesEarly Elementary Education Cert - P-5 With Concentration in Early Childhood Education - Cert Birth To Age 5-BSRUniversity of LouisvilleNo ratings yet

- The Right To Sexual Orientation, CG ProjectDocument9 pagesThe Right To Sexual Orientation, CG ProjecttanayaNo ratings yet

- HydrationDocument1 pageHydrationfidaauddinNo ratings yet

- Idiomatic ExpressionDocument27 pagesIdiomatic ExpressionJess Jess100% (1)

- LDocument8 pagesLTamara Monsalve100% (1)

- Chrissa Mae T. Catindoy BS Medical Technology 3A: Group Classification Pathologic SignificanceDocument5 pagesChrissa Mae T. Catindoy BS Medical Technology 3A: Group Classification Pathologic SignificanceChrissa Mae Tumaliuan CatindoyNo ratings yet

- SPK Manual 2007-2009Document26 pagesSPK Manual 2007-2009jlhood65No ratings yet

- Hydrotest ProcedureDocument3 pagesHydrotest Procedureaman131100% (2)

- Exp't 51: Nitration of NitrobenzeneDocument4 pagesExp't 51: Nitration of NitrobenzenelovehopeNo ratings yet

- Life Safety Solutions Specification Sheet 6557Document323 pagesLife Safety Solutions Specification Sheet 6557Ernesto CamposNo ratings yet

- Osram OutdoorDocument95 pagesOsram OutdoorDiana Rose TapelNo ratings yet

- Jurnal Tentang Jamur ObatDocument12 pagesJurnal Tentang Jamur ObatCut Kandy SafieraNo ratings yet

- Reading Comprehension B2 ESL Elephant Tea GardenDocument4 pagesReading Comprehension B2 ESL Elephant Tea GardenAnna MayerNo ratings yet

- Antenna EffectDocument5 pagesAntenna Effectstudius1No ratings yet

- Mobrey Squitch-2: Ultrasonic Liquid Level SwitchDocument2 pagesMobrey Squitch-2: Ultrasonic Liquid Level SwitchPhan CườngNo ratings yet

- Validation and Qualification of Heating, Ventilation, Air ConDocument18 pagesValidation and Qualification of Heating, Ventilation, Air ConJai MurugeshNo ratings yet

- 17-03-10 Inductive Conductivity Transmitter CIT-8920Document30 pages17-03-10 Inductive Conductivity Transmitter CIT-8920Juan CarvajalNo ratings yet

- Xenon 21-22 Sheet Without Answer (EUDIOMETRY)Document3 pagesXenon 21-22 Sheet Without Answer (EUDIOMETRY)Krishna GoyalNo ratings yet

- About Epistaxis or Nosebleeds: If You Have Any Problems or Questions, Please ContactDocument2 pagesAbout Epistaxis or Nosebleeds: If You Have Any Problems or Questions, Please ContactGHAPRC RUDRAPURNo ratings yet

- Danika Sanders Student Teacher ResumeDocument2 pagesDanika Sanders Student Teacher Resumeapi-496485131No ratings yet

- Ijims 2017 105Document7 pagesIjims 2017 105Marcos HoilNo ratings yet

- Root Resorption Due To Dental Trauma: General PrinciplesDocument22 pagesRoot Resorption Due To Dental Trauma: General PrinciplesBogdan PopescuNo ratings yet