Professional Documents

Culture Documents

A. Design Case: Analysis For Design-1 B. Member Information

A. Design Case: Analysis For Design-1 B. Member Information

Uploaded by

Sopanat BoonkhanCopyright:

Available Formats

You might also like

- Back To Back AngleDocument6 pagesBack To Back AngleAnonymous vGKYNSP0% (1)

- Homework 6 Solutions 2Document61 pagesHomework 6 Solutions 2Abhinash KumarNo ratings yet

- Module 1.2 Dynamics of Rigid BodiesDocument9 pagesModule 1.2 Dynamics of Rigid BodiesJOSE FERNANDO GEMPERLE100% (1)

- Flowmaster v7.0 Easy GuideDocument109 pagesFlowmaster v7.0 Easy Guidepinenamu100% (1)

- AISC Design Guide 29 - Vertical Bracing Connections - Analysis and Design 2 de 2 PDFDocument196 pagesAISC Design Guide 29 - Vertical Bracing Connections - Analysis and Design 2 de 2 PDFMartin Cristobal CupitayNo ratings yet

- Example Problem 3.1 Given: Results SummaryDocument25 pagesExample Problem 3.1 Given: Results SummarygertjaniNo ratings yet

- Albaytar, Mark Joseph ADocument26 pagesAlbaytar, Mark Joseph AMark JosephNo ratings yet

- Trelawney Modern Design Beam CalculationDocument48 pagesTrelawney Modern Design Beam CalculationLandel SmithNo ratings yet

- A. Design Case: Analysis For Design-1 B. Member InformationDocument5 pagesA. Design Case: Analysis For Design-1 B. Member InformationSopanat BoonkhanNo ratings yet

- W18X46 W3-7 1/2" NW 30 10 106: The Beam Design Is AdequateDocument7 pagesW18X46 W3-7 1/2" NW 30 10 106: The Beam Design Is Adequateஅம்ரு சாந்திவேலுNo ratings yet

- Structural Analylsis and Design ComputationsDocument8 pagesStructural Analylsis and Design ComputationsDorothy Leonardo ObriqueNo ratings yet

- Results For LegsDocument9 pagesResults For LegsOscar MarinNo ratings yet

- Lorenzana Assignment 2 Machine Design 1Document7 pagesLorenzana Assignment 2 Machine Design 1Lister NambatacNo ratings yet

- Single Angle FlexureDocument7 pagesSingle Angle FlexureJose Ernesto Martinez MendozaNo ratings yet

- Alternate Beam DesignDocument14 pagesAlternate Beam DesignLandel SmithNo ratings yet

- Case StudiesDocument10 pagesCase StudiesUmair RafiqNo ratings yet

- Squarefooting CalculatorDocument2 pagesSquarefooting CalculatorNazar BazaraaNo ratings yet

- Bridge PortionDocument16 pagesBridge PortionNagara SelvarajNo ratings yet

- Bearing Design Method BDocument1 pageBearing Design Method BwaheedNo ratings yet

- Footing Proportioning and Reinforcement: Isolated Footing Design FaDocument6 pagesFooting Proportioning and Reinforcement: Isolated Footing Design FaTefera TemesgenNo ratings yet

- PurlinDocument12 pagesPurlinKhandaker Khairul Alam0% (1)

- Precast Driven Pile Section Analysis: Input DataDocument1 pagePrecast Driven Pile Section Analysis: Input DatacivixxNo ratings yet

- Precast Prestressed Concrete Girder Bridge - Design ExampleDocument37 pagesPrecast Prestressed Concrete Girder Bridge - Design Examplerammiris100% (1)

- Ma - TUL WING WALL ABT RENGATDocument9 pagesMa - TUL WING WALL ABT RENGATandreNo ratings yet

- Structural Analysis JoemarieDocument4 pagesStructural Analysis JoemarieRey Christi Lopez CasuyonNo ratings yet

- Calculation Sheet: NPCC N/A Member Design - Aisc (Compact) VBDocument12 pagesCalculation Sheet: NPCC N/A Member Design - Aisc (Compact) VBinnovativekarthi0% (1)

- Diseño DiafragmaDocument3 pagesDiseño DiafragmaJulia Quispe BejarNo ratings yet

- Reinforced Concrete Column Capacity: MaterialsDocument8 pagesReinforced Concrete Column Capacity: Materialsqazalbash1109588No ratings yet

- SMRF AciDocument19 pagesSMRF AciShivaun SeecharanNo ratings yet

- PileCaps Important Calculation (SI Units)Document8 pagesPileCaps Important Calculation (SI Units)Kaushal RautNo ratings yet

- Flexure IWF ExaminationDocument6 pagesFlexure IWF ExaminationriandiNo ratings yet

- 1001 Aisc C1a Moment Frame DesignDocument4 pages1001 Aisc C1a Moment Frame DesignAaron EasleyNo ratings yet

- AISC ExamplesIIA1-31Document118 pagesAISC ExamplesIIA1-31Royal OtisNo ratings yet

- Midas Structural Design Calabanga Municipal Slaughterhouse: Engr. Christian R. Encila, M. ASCEDocument10 pagesMidas Structural Design Calabanga Municipal Slaughterhouse: Engr. Christian R. Encila, M. ASCEChristian EncilaNo ratings yet

- Col30x30 CONCRETE COLUMN DESIGNDocument2 pagesCol30x30 CONCRETE COLUMN DESIGNOmar RubioNo ratings yet

- Check Point#3Document1 pageCheck Point#3EakJhuanNo ratings yet

- Isolated Footing - 09mar2021Document12 pagesIsolated Footing - 09mar2021Troy ValeriaNo ratings yet

- 4F Design-2Document12 pages4F Design-2Jake CortezNo ratings yet

- Slab Design 6x6 PanelDocument3 pagesSlab Design 6x6 Panelpiyush singhNo ratings yet

- Nozzle Qualify WRC-107Document8 pagesNozzle Qualify WRC-107Sodsai LamtharnNo ratings yet

- Seismic Design For Special MomentDocument2 pagesSeismic Design For Special MomentreynoldNo ratings yet

- ETABSDocument1 pageETABSJasser BerriosNo ratings yet

- Base Shear ComputationDocument5 pagesBase Shear ComputationAmante MorenoNo ratings yet

- Coursera Quiz 3Document4 pagesCoursera Quiz 3Miriam OntiverosNo ratings yet

- Doubly Reinforced BeamDocument19 pagesDoubly Reinforced BeamLavender HoneyNo ratings yet

- Carbon Fiber Spreadsheet - MathcadDocument5 pagesCarbon Fiber Spreadsheet - MathcadMai CNo ratings yet

- Ps AppendixE A11yDocument11 pagesPs AppendixE A11yJesus HilarioNo ratings yet

- Spreader 150T - PL100 A36Document8 pagesSpreader 150T - PL100 A36rustamriyadiNo ratings yet

- Design of Two-Way Slab: Structural Calculation Residential BuildingDocument1 pageDesign of Two-Way Slab: Structural Calculation Residential Buildingfrancis sebastian lagamayoNo ratings yet

- NC 9303 1733 005 0 Perhitungan Balok Konsol GBK: As Max ofDocument3 pagesNC 9303 1733 005 0 Perhitungan Balok Konsol GBK: As Max ofRafli Hasuna HakimNo ratings yet

- Shear Analysis - Beams: V F' B A F V V V V + V +Document4 pagesShear Analysis - Beams: V F' B A F V V V V + V +S. M. Habibul AhsanNo ratings yet

- 2 ND Order Analysis ExampleDocument76 pages2 ND Order Analysis ExampleChristian Pinto100% (1)

- Axially Loaded Member: Axial Load and Normal Stress Under Equilibrium Load, Elastic DeformationDocument16 pagesAxially Loaded Member: Axial Load and Normal Stress Under Equilibrium Load, Elastic DeformationHoda HosnyNo ratings yet

- Metal Z-Purlins Design Based On AISI S100/SI-10: Input Data & Design Summary @: 12 (QDocument4 pagesMetal Z-Purlins Design Based On AISI S100/SI-10: Input Data & Design Summary @: 12 (QMahesh MNo ratings yet

- 1-Span Frame R-Beam Design By:: DL LLDocument2 pages1-Span Frame R-Beam Design By:: DL LLChanNo ratings yet

- Column Analysis and Design v1Document8 pagesColumn Analysis and Design v1jn.adstudioNo ratings yet

- Purlins 2aDocument1 pagePurlins 2aKrishnaNo ratings yet

- FoundationDocument102 pagesFoundationTeav PoliNo ratings yet

- Ch5 Compression SteelDocument12 pagesCh5 Compression Steelمحمد ابراهيم ابراهيمNo ratings yet

- Design of Rectangular Combined Footing Supporting Two Axially Loaded ColumnsDocument3 pagesDesign of Rectangular Combined Footing Supporting Two Axially Loaded ColumnsThirdie LerajeNo ratings yet

- Exercises in Electronics: Operational Amplifier CircuitsFrom EverandExercises in Electronics: Operational Amplifier CircuitsRating: 3 out of 5 stars3/5 (1)

- Machine Design 4th Edn Norton PDFDocument1,269 pagesMachine Design 4th Edn Norton PDFhaiter paredes100% (1)

- Ee Rev03 - Quiz 1Document5 pagesEe Rev03 - Quiz 1JAMEL C IBRAHIMNo ratings yet

- Projectile MotionDocument22 pagesProjectile MotionChris PuelasNo ratings yet

- Physics 2204 Worksheet 8 Conservation of Mechanical Energy 2018Document11 pagesPhysics 2204 Worksheet 8 Conservation of Mechanical Energy 2018Flora Mae Factor ViñasNo ratings yet

- Glossary of Conveyor Belt TermsDocument6 pagesGlossary of Conveyor Belt TermsWaris La Joi WakatobiNo ratings yet

- Narayana 30-05-2022 Outgoing SR Jee Main Model GTM 4 QP Final SolDocument12 pagesNarayana 30-05-2022 Outgoing SR Jee Main Model GTM 4 QP Final SolYuva AkhilNo ratings yet

- Class XI Physics DPP Set (12) - NLMDocument20 pagesClass XI Physics DPP Set (12) - NLMSaurabh KumarNo ratings yet

- MSTE 2 - Part 1Document2 pagesMSTE 2 - Part 1aisen agustinNo ratings yet

- Pamantasan NG Lungsod NG MaynilaDocument15 pagesPamantasan NG Lungsod NG MaynilaChristianAngeloTOnaroNo ratings yet

- Mce-211-Lecture Note 4-The Heat EngineDocument29 pagesMce-211-Lecture Note 4-The Heat EngineNithin NDNo ratings yet

- Minor Project PresentationDocument22 pagesMinor Project Presentationmaheshwar299No ratings yet

- Developing A Proposed Satellite Reaction Wheel Model With Current Mode ControlDocument5 pagesDeveloping A Proposed Satellite Reaction Wheel Model With Current Mode ControlJahnavi VurityNo ratings yet

- 02 Tooth Gear Coupling BoWexDocument20 pages02 Tooth Gear Coupling BoWexTeddy NsNo ratings yet

- Static Analysis of Timoshenko Beams Using Isogeometric ApproachDocument9 pagesStatic Analysis of Timoshenko Beams Using Isogeometric ApproachcapicaNo ratings yet

- Corosion Assignment FullDocument104 pagesCorosion Assignment FullVelavan KNo ratings yet

- Tutorial - 1: Dr. N.Gobinath SMEC, VIT ChennaiDocument11 pagesTutorial - 1: Dr. N.Gobinath SMEC, VIT Chennaishoovam123No ratings yet

- Class of Compliant MechDocument3 pagesClass of Compliant MechRogelioB.AlobIINo ratings yet

- Krahn, J. (2007) - Limit Equilibrium, Strength Summation and Strength Reduction Methods For Assessing Slope Stability.Document8 pagesKrahn, J. (2007) - Limit Equilibrium, Strength Summation and Strength Reduction Methods For Assessing Slope Stability.HUGINo ratings yet

- Formulas For Computing The Tidal Accelerations: Due To The Moon and The SunDocument5 pagesFormulas For Computing The Tidal Accelerations: Due To The Moon and The Sunratna fitriNo ratings yet

- Structural and Aeroelastic Flutter Analysis of Wing Store Systems and Structural Modification Approach in AeroelasticityDocument157 pagesStructural and Aeroelastic Flutter Analysis of Wing Store Systems and Structural Modification Approach in AeroelasticityIsmailNo ratings yet

- Lab Report Experiment 2 Phy 433 1 1 PDFDocument18 pagesLab Report Experiment 2 Phy 433 1 1 PDFHANY NUR AQILAH YUSOFNo ratings yet

- Balancing & Alignment PDFDocument144 pagesBalancing & Alignment PDFamirthraj74100% (3)

- Ejercicios PDFDocument4 pagesEjercicios PDFserepoesia10No ratings yet

- Static MixersDocument5 pagesStatic Mixershwang2No ratings yet

- MHT CET IMP FormulaDocument282 pagesMHT CET IMP FormulaklmbrthrsNo ratings yet

- Reinforced Concrete Beam Design Procedure - : StateDocument4 pagesReinforced Concrete Beam Design Procedure - : Statensureshbabu100% (1)

A. Design Case: Analysis For Design-1 B. Member Information

A. Design Case: Analysis For Design-1 B. Member Information

Uploaded by

Sopanat BoonkhanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A. Design Case: Analysis For Design-1 B. Member Information

A. Design Case: Analysis For Design-1 B. Member Information

Uploaded by

Sopanat BoonkhanCopyright:

Available Formats

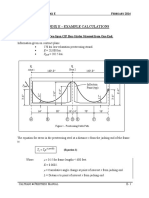

Steel Member Design Detail Report AISC-ASD89 [User's Unit : kgf, cm]

A. Design Case: Analysis for Design-1

B. Member Information

a. Member Name

- Brace-163 [257]

b. Material

- SS400 (KS) [1] A 4.524e-01 in2

- Fy = 2400.00 kgf/cm2 Asy 2.262e-01 in2

c. Section Asz 2.262e-01 in2

- PG 42.7x2.3 [3] Iy 1.434e-01 in4

- Typical rolled section Iz 1.434e-01 in4

d. Member Length 1.681 Sy 1.709e-01 in3

- L = 129.575 cm Sz 1.709e-01 in3

1.5

z

- Ly = 129.575 cm, Lz = 129.575 cm Zy 2.293e-01 in3

- Lb = 129.575 cm (at 0.00L, 0.00 y

Zz 2.293e-01 in3

cm)

e. Effective Length Factor ry 5.630e-01 in

- Ky = 1.000, Kz = 1.000 rz 5.630e-01 in

f. Member Parameters

- Cb = 1.000

- Cv = 1.000

C. Position Result

a. Design Result by Check Position

Axial Bending-y Bending-z Shear-z Shear-y Combined

Pu(kgf/ fby(kgf/ fbz(kgf/ fvz(kgf/ fvy(kgf/

LC cm2) LC cm2) LC cm2) LC cm2) LC cm2) LC

Position Ratio

B B B B B B

Ratio Ratio Ratio Ratio Ratio

LC -611.86 LC 0.00 LC 0.00 LC 0.00 LC 0.00 LC

0.00L 0.63

B1 0.63 B1 0.00 B1 0.00 B1 0.00 B1 0.00 B1

LC -611.86 LC 0.00 LC 0.00 LC 0.00 LC 0.00 LC

1.00L 0.63

B1 0.63 B1 0.00 B1 0.00 B1 0.00 B1 0.00 B1

b. Description of Load Combinations

- LCB1 : 1.00D+1.00L

D. Check Slenderness Ratio

KyL/ry = 90.612 < 200.000 KzL/rz = 90.612 < 200.000

Major(Y) axis Minor(Z) axis

Ky = 1.000 Program Determined Kz = 1.000 Program Determined

1.000 x 129.575 / 1.430 = 90.612 1.000 x 129.575 / 1.430 = 90.612

E. Check Combined Ratio (at 0.00L, 0.00 cm)

Combination LCB1 (1.00D+1.00L)

Axial -611.862 kgf/cm2 / -970.973 kgf/cm2 = 0.630 <

OK

1.000

Check Axial Stress

( f ¿¿ a)¿ 1) Calculate compressive stress E

f a=P/ A g = -611.862 kgf/cm 2

(Q¿¿ s)¿ 2) Calculate reduction factor of slender unstiffened elements App.B5.2

Qs = 1.000

(Q¿¿ a) ¿ 3) Calculate reduction factor of slender stiffened elements App.B5.2

Qa = 1.000

( F ¿¿ a)¿ 4) Calculate allowable compressive stress E2

Q=Q s Q a = 1.000

Kl /r

C c=

√

2 π 2 E

Fy

= 90.612 < = 131.422 - Inelastic Buckling

( Kl / r)

2

Q[1− ]F y

2 C c2

F a= = 970.973 kgf/cm

3

2

5 3(Kl / r) (Kl / r )

+ − 3

3 8 Cc 8C c

f b y / Fby M 0.000 kgf/cm2 / 1,584.003 kgf/cm2 = 0.000 < 1.000 Need Check

oment 0.000 kgf/cm2 / 1,440.002 kgf/cm2 = 0.000 < 1.000 Need Check

Check flexural stress about major axis (Y)

1) Section Parameters

I comp = 5.970 cm4

I tens = 5.970 cm4

C comp = 2.135 cm

C tens = 2.135 cm

2) Calculate flexural stress F

f bcy =M y C comp

/ =I comp

0.000 kgf/cm2

f bty=M y Ctens

/ I=tens

0.000 kgf/cm2

3) Calculate allowable flexural stress F2

F bcy =F bty =0.6

=F1,584.003

y kgf/cm 2

Check flexural stress about minor axis (Z)

1) Section Parameters

I comp = 5.970 cm4

I tens = 5.970 cm4

C comp = 2.135 cm

C tens = 2.135 cm

2) Calculate flexural stress

f bcz=M z C comp

/ I=comp

0.000 kgf/cm2

f btz =M z Ctens

/ I tens

= 0.000 kgf/cm2

3) Calculate allowable flexural stress F2

F bcz=F btz =0.6 F1,440.002

= y kgf/cm 2

Combination LCB1 (1.00D+1.00L)

Combined

0.630 < 1.000 OK

Check Combined Stress Ratio

1) Calculate interaction ratio of combined stress H

Rmax =¿ f a / F

a ∨¿

= 0.630

F. Check Shear Capacity Major Axis (at 0.00L, 0.00 cm)

Combination LCB1 (1.00D+1.00L)

Shear

0.000 kgf/cm2 / 960.002 kgf/cm2 = 0.000 < 1.000 Need Check

Check shear stress about major axis(Z)

1) Calculate shear stress F

A vz = 2.919 cm 2

f vz =V z / A vz = 0.000 kgf/cm2

2) Calculate allowable shear stress F4

F vz =0.4 F y = 960.002 kgf/cm2

G. Check Shear Capacity Minor Axis (at 0.00L, 0.00 cm)

Combination LCB1 (1.00D+1.00L)

Shear

0.000 kgf/cm2 / 960.002 kgf/cm2 = 0.000 < 1.000 Need Check

Check shear stress about minor axis(Y)

1) Calculate shear stress F

A vy = 2.919 cm 2

f vy =V y / A vy = 0.000 kgf/cm2

2) Calculate allowable shear stress F4

F vy =0.4 F y = 960.002 kgf/cm 2

H. Check Deflection (at 0.00L, 0.00 cm)

Combination NONE

Deflection

0.000 cm / 0.000 cm = 0.000 < 1.000 Not Check

You might also like

- Back To Back AngleDocument6 pagesBack To Back AngleAnonymous vGKYNSP0% (1)

- Homework 6 Solutions 2Document61 pagesHomework 6 Solutions 2Abhinash KumarNo ratings yet

- Module 1.2 Dynamics of Rigid BodiesDocument9 pagesModule 1.2 Dynamics of Rigid BodiesJOSE FERNANDO GEMPERLE100% (1)

- Flowmaster v7.0 Easy GuideDocument109 pagesFlowmaster v7.0 Easy Guidepinenamu100% (1)

- AISC Design Guide 29 - Vertical Bracing Connections - Analysis and Design 2 de 2 PDFDocument196 pagesAISC Design Guide 29 - Vertical Bracing Connections - Analysis and Design 2 de 2 PDFMartin Cristobal CupitayNo ratings yet

- Example Problem 3.1 Given: Results SummaryDocument25 pagesExample Problem 3.1 Given: Results SummarygertjaniNo ratings yet

- Albaytar, Mark Joseph ADocument26 pagesAlbaytar, Mark Joseph AMark JosephNo ratings yet

- Trelawney Modern Design Beam CalculationDocument48 pagesTrelawney Modern Design Beam CalculationLandel SmithNo ratings yet

- A. Design Case: Analysis For Design-1 B. Member InformationDocument5 pagesA. Design Case: Analysis For Design-1 B. Member InformationSopanat BoonkhanNo ratings yet

- W18X46 W3-7 1/2" NW 30 10 106: The Beam Design Is AdequateDocument7 pagesW18X46 W3-7 1/2" NW 30 10 106: The Beam Design Is Adequateஅம்ரு சாந்திவேலுNo ratings yet

- Structural Analylsis and Design ComputationsDocument8 pagesStructural Analylsis and Design ComputationsDorothy Leonardo ObriqueNo ratings yet

- Results For LegsDocument9 pagesResults For LegsOscar MarinNo ratings yet

- Lorenzana Assignment 2 Machine Design 1Document7 pagesLorenzana Assignment 2 Machine Design 1Lister NambatacNo ratings yet

- Single Angle FlexureDocument7 pagesSingle Angle FlexureJose Ernesto Martinez MendozaNo ratings yet

- Alternate Beam DesignDocument14 pagesAlternate Beam DesignLandel SmithNo ratings yet

- Case StudiesDocument10 pagesCase StudiesUmair RafiqNo ratings yet

- Squarefooting CalculatorDocument2 pagesSquarefooting CalculatorNazar BazaraaNo ratings yet

- Bridge PortionDocument16 pagesBridge PortionNagara SelvarajNo ratings yet

- Bearing Design Method BDocument1 pageBearing Design Method BwaheedNo ratings yet

- Footing Proportioning and Reinforcement: Isolated Footing Design FaDocument6 pagesFooting Proportioning and Reinforcement: Isolated Footing Design FaTefera TemesgenNo ratings yet

- PurlinDocument12 pagesPurlinKhandaker Khairul Alam0% (1)

- Precast Driven Pile Section Analysis: Input DataDocument1 pagePrecast Driven Pile Section Analysis: Input DatacivixxNo ratings yet

- Precast Prestressed Concrete Girder Bridge - Design ExampleDocument37 pagesPrecast Prestressed Concrete Girder Bridge - Design Examplerammiris100% (1)

- Ma - TUL WING WALL ABT RENGATDocument9 pagesMa - TUL WING WALL ABT RENGATandreNo ratings yet

- Structural Analysis JoemarieDocument4 pagesStructural Analysis JoemarieRey Christi Lopez CasuyonNo ratings yet

- Calculation Sheet: NPCC N/A Member Design - Aisc (Compact) VBDocument12 pagesCalculation Sheet: NPCC N/A Member Design - Aisc (Compact) VBinnovativekarthi0% (1)

- Diseño DiafragmaDocument3 pagesDiseño DiafragmaJulia Quispe BejarNo ratings yet

- Reinforced Concrete Column Capacity: MaterialsDocument8 pagesReinforced Concrete Column Capacity: Materialsqazalbash1109588No ratings yet

- SMRF AciDocument19 pagesSMRF AciShivaun SeecharanNo ratings yet

- PileCaps Important Calculation (SI Units)Document8 pagesPileCaps Important Calculation (SI Units)Kaushal RautNo ratings yet

- Flexure IWF ExaminationDocument6 pagesFlexure IWF ExaminationriandiNo ratings yet

- 1001 Aisc C1a Moment Frame DesignDocument4 pages1001 Aisc C1a Moment Frame DesignAaron EasleyNo ratings yet

- AISC ExamplesIIA1-31Document118 pagesAISC ExamplesIIA1-31Royal OtisNo ratings yet

- Midas Structural Design Calabanga Municipal Slaughterhouse: Engr. Christian R. Encila, M. ASCEDocument10 pagesMidas Structural Design Calabanga Municipal Slaughterhouse: Engr. Christian R. Encila, M. ASCEChristian EncilaNo ratings yet

- Col30x30 CONCRETE COLUMN DESIGNDocument2 pagesCol30x30 CONCRETE COLUMN DESIGNOmar RubioNo ratings yet

- Check Point#3Document1 pageCheck Point#3EakJhuanNo ratings yet

- Isolated Footing - 09mar2021Document12 pagesIsolated Footing - 09mar2021Troy ValeriaNo ratings yet

- 4F Design-2Document12 pages4F Design-2Jake CortezNo ratings yet

- Slab Design 6x6 PanelDocument3 pagesSlab Design 6x6 Panelpiyush singhNo ratings yet

- Nozzle Qualify WRC-107Document8 pagesNozzle Qualify WRC-107Sodsai LamtharnNo ratings yet

- Seismic Design For Special MomentDocument2 pagesSeismic Design For Special MomentreynoldNo ratings yet

- ETABSDocument1 pageETABSJasser BerriosNo ratings yet

- Base Shear ComputationDocument5 pagesBase Shear ComputationAmante MorenoNo ratings yet

- Coursera Quiz 3Document4 pagesCoursera Quiz 3Miriam OntiverosNo ratings yet

- Doubly Reinforced BeamDocument19 pagesDoubly Reinforced BeamLavender HoneyNo ratings yet

- Carbon Fiber Spreadsheet - MathcadDocument5 pagesCarbon Fiber Spreadsheet - MathcadMai CNo ratings yet

- Ps AppendixE A11yDocument11 pagesPs AppendixE A11yJesus HilarioNo ratings yet

- Spreader 150T - PL100 A36Document8 pagesSpreader 150T - PL100 A36rustamriyadiNo ratings yet

- Design of Two-Way Slab: Structural Calculation Residential BuildingDocument1 pageDesign of Two-Way Slab: Structural Calculation Residential Buildingfrancis sebastian lagamayoNo ratings yet

- NC 9303 1733 005 0 Perhitungan Balok Konsol GBK: As Max ofDocument3 pagesNC 9303 1733 005 0 Perhitungan Balok Konsol GBK: As Max ofRafli Hasuna HakimNo ratings yet

- Shear Analysis - Beams: V F' B A F V V V V + V +Document4 pagesShear Analysis - Beams: V F' B A F V V V V + V +S. M. Habibul AhsanNo ratings yet

- 2 ND Order Analysis ExampleDocument76 pages2 ND Order Analysis ExampleChristian Pinto100% (1)

- Axially Loaded Member: Axial Load and Normal Stress Under Equilibrium Load, Elastic DeformationDocument16 pagesAxially Loaded Member: Axial Load and Normal Stress Under Equilibrium Load, Elastic DeformationHoda HosnyNo ratings yet

- Metal Z-Purlins Design Based On AISI S100/SI-10: Input Data & Design Summary @: 12 (QDocument4 pagesMetal Z-Purlins Design Based On AISI S100/SI-10: Input Data & Design Summary @: 12 (QMahesh MNo ratings yet

- 1-Span Frame R-Beam Design By:: DL LLDocument2 pages1-Span Frame R-Beam Design By:: DL LLChanNo ratings yet

- Column Analysis and Design v1Document8 pagesColumn Analysis and Design v1jn.adstudioNo ratings yet

- Purlins 2aDocument1 pagePurlins 2aKrishnaNo ratings yet

- FoundationDocument102 pagesFoundationTeav PoliNo ratings yet

- Ch5 Compression SteelDocument12 pagesCh5 Compression Steelمحمد ابراهيم ابراهيمNo ratings yet

- Design of Rectangular Combined Footing Supporting Two Axially Loaded ColumnsDocument3 pagesDesign of Rectangular Combined Footing Supporting Two Axially Loaded ColumnsThirdie LerajeNo ratings yet

- Exercises in Electronics: Operational Amplifier CircuitsFrom EverandExercises in Electronics: Operational Amplifier CircuitsRating: 3 out of 5 stars3/5 (1)

- Machine Design 4th Edn Norton PDFDocument1,269 pagesMachine Design 4th Edn Norton PDFhaiter paredes100% (1)

- Ee Rev03 - Quiz 1Document5 pagesEe Rev03 - Quiz 1JAMEL C IBRAHIMNo ratings yet

- Projectile MotionDocument22 pagesProjectile MotionChris PuelasNo ratings yet

- Physics 2204 Worksheet 8 Conservation of Mechanical Energy 2018Document11 pagesPhysics 2204 Worksheet 8 Conservation of Mechanical Energy 2018Flora Mae Factor ViñasNo ratings yet

- Glossary of Conveyor Belt TermsDocument6 pagesGlossary of Conveyor Belt TermsWaris La Joi WakatobiNo ratings yet

- Narayana 30-05-2022 Outgoing SR Jee Main Model GTM 4 QP Final SolDocument12 pagesNarayana 30-05-2022 Outgoing SR Jee Main Model GTM 4 QP Final SolYuva AkhilNo ratings yet

- Class XI Physics DPP Set (12) - NLMDocument20 pagesClass XI Physics DPP Set (12) - NLMSaurabh KumarNo ratings yet

- MSTE 2 - Part 1Document2 pagesMSTE 2 - Part 1aisen agustinNo ratings yet

- Pamantasan NG Lungsod NG MaynilaDocument15 pagesPamantasan NG Lungsod NG MaynilaChristianAngeloTOnaroNo ratings yet

- Mce-211-Lecture Note 4-The Heat EngineDocument29 pagesMce-211-Lecture Note 4-The Heat EngineNithin NDNo ratings yet

- Minor Project PresentationDocument22 pagesMinor Project Presentationmaheshwar299No ratings yet

- Developing A Proposed Satellite Reaction Wheel Model With Current Mode ControlDocument5 pagesDeveloping A Proposed Satellite Reaction Wheel Model With Current Mode ControlJahnavi VurityNo ratings yet

- 02 Tooth Gear Coupling BoWexDocument20 pages02 Tooth Gear Coupling BoWexTeddy NsNo ratings yet

- Static Analysis of Timoshenko Beams Using Isogeometric ApproachDocument9 pagesStatic Analysis of Timoshenko Beams Using Isogeometric ApproachcapicaNo ratings yet

- Corosion Assignment FullDocument104 pagesCorosion Assignment FullVelavan KNo ratings yet

- Tutorial - 1: Dr. N.Gobinath SMEC, VIT ChennaiDocument11 pagesTutorial - 1: Dr. N.Gobinath SMEC, VIT Chennaishoovam123No ratings yet

- Class of Compliant MechDocument3 pagesClass of Compliant MechRogelioB.AlobIINo ratings yet

- Krahn, J. (2007) - Limit Equilibrium, Strength Summation and Strength Reduction Methods For Assessing Slope Stability.Document8 pagesKrahn, J. (2007) - Limit Equilibrium, Strength Summation and Strength Reduction Methods For Assessing Slope Stability.HUGINo ratings yet

- Formulas For Computing The Tidal Accelerations: Due To The Moon and The SunDocument5 pagesFormulas For Computing The Tidal Accelerations: Due To The Moon and The Sunratna fitriNo ratings yet

- Structural and Aeroelastic Flutter Analysis of Wing Store Systems and Structural Modification Approach in AeroelasticityDocument157 pagesStructural and Aeroelastic Flutter Analysis of Wing Store Systems and Structural Modification Approach in AeroelasticityIsmailNo ratings yet

- Lab Report Experiment 2 Phy 433 1 1 PDFDocument18 pagesLab Report Experiment 2 Phy 433 1 1 PDFHANY NUR AQILAH YUSOFNo ratings yet

- Balancing & Alignment PDFDocument144 pagesBalancing & Alignment PDFamirthraj74100% (3)

- Ejercicios PDFDocument4 pagesEjercicios PDFserepoesia10No ratings yet

- Static MixersDocument5 pagesStatic Mixershwang2No ratings yet

- MHT CET IMP FormulaDocument282 pagesMHT CET IMP FormulaklmbrthrsNo ratings yet

- Reinforced Concrete Beam Design Procedure - : StateDocument4 pagesReinforced Concrete Beam Design Procedure - : Statensureshbabu100% (1)