Professional Documents

Culture Documents

Pilfer Proof Caps - Project Report

Pilfer Proof Caps - Project Report

Uploaded by

baddy2inOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pilfer Proof Caps - Project Report

Pilfer Proof Caps - Project Report

Uploaded by

baddy2inCopyright:

Available Formats

PILFER PROOF CAPS

A. INTRODUCTION

Pilfer Proof caps are being used in Pharmaceuticals, Chemicals, Food industries

and Distilleries as Glass bottle closures. The main consumption is from

distilleries. The consumption is increasing with the increase in standard of

living of the people.

B. PRODUCT USES AND SPECIFICATIONS

Pilfer Proof caps are meant to provide to the contents in a container protection

against substitution, adulteration or pilfering. Once the PP cap is fixed on the

package it is ordinarily not possible to tamper with the contents of the package

without destroying the special device in the closure which is intended to

provide such protection. The roll seal aluminium closure is most extensively

used cap fitted on the glass bottles containing the products such as liquor,

pharmaceuticals, chemicals, syrups and squashes.

Bureau of Indian Standards have not prescribed any standards .The PP caps

manufactured should conform to the requirement of the customer with

reference to the sizes, designs, standards/specifications

C. MARKET POTENTIAL

The market demand for PP caps is increasing with the overall development of

the industries and general standard of living of the people. PP caps are used as

a cover for mainly glass containers. The glass bottles are used in milk

packaging, pharmaceuticals, breweries, oils and cosmetics and soft drinks

industry. The main use pattern of glass bottles in various areas is as follows

Milk schemes 15%

Pharmaceuticals 25%

Breweries 30%

Oils & cosmetics, Food 16%

Soft drinks industry 14%

The consumption of PP caps is increasing as the consumption of theses usage

sector is increasing year after year.

D. TECHNICAL ASPECTS

1. Installed Capacity

The proposed machine would work for single shift a day for 300 days. The total

installed capacity of the unit is 100 000 PP caps per day. On this basis the

installed capacity will be 300 lakhs PP caps per annum.

2. Plant and Machinery

The following machineries are required for production.

Machine name Quantity Value

(Nos) (Rs. lakhs)

32 Tonne capacity un-geared fixed stroke, fixed 1 4.50

inclined, power press, fitted with pneumatic friction

clutch and brake, one shot lubrication device and

suitable electrical

Multi spindle knurling, beading machine complete 1 3.00

with electricals and cap feeder device

Three cavity die set suitable for 28 mm PP caps die 1 1.05

comprising diagonal pillar set with feeder plate and

other standard accessories

Roll feed attachment for automatic strip feeding up to 1 0.40

0.3mm thickness and width 175 mm with standard

accessories

Rotary wads assembling machine complete with 1 3.50

suitable electricals and digital counter. Machine

synchronized with knurling machine

Shearing machine pedal operated with strip collection 1 0.40

tray

Ring separator sorting drum for scrap rings with 1 0.40

electricals

Inspection conveyor 1 0.55

Big step conveyor and silo 1 0.80

Small step conveyor 1 0.70

Cap sealing machine pedal operated for testing caps 1 0.40

Electrical control Panel with sensor 1 1.60

1 HP blower with electricals & pipe synchronization 1 0.20

Testing Instruments &Misc. Tools 0.30

Total 18.00

3. Manufacturing Process

The manufacturing involves the following process

Printing the desired design on aluminium sheets

I

Blanking and drawing cap on the punching machine by fitting the multiple die

for a particular size

I

Finishing the cap by giving final shape which gives knurling, grooving

perforation of the beading

I

Fitting circular washers in the cap manually wherever required

I

Packing and Despatching

4. Raw Material

The raw materials required for manufacturing aluminium PP caps is 33 or 34

Gauge of hard Aluminium sheets. This material can be procured from any

reputed dealers of Aluminium sheets. The other consumables required are PVC

coated Wads which are available in all cities. Printing can be done on job work

basis.

5. Land & Building

A rented place with 2000 sqft. area is required. The monthly rent is estimated

at Rs.20,000 and also an advance of Rs.200 000.

6. Utilities

Power:

The total power requirement of the unit will be 20 HP

Water:

Water is required only for human consumption.

Man power:

Category Nos. Monthly Total monthly

Salary Salary

Super 1 8000 8000

Skilled 3 6000 18000

Unskilled 2 4000 8000

Assist 1 5000 5000

Security 2 4000 8000

47000

Add : Benefits 20% 9400

Total wages per month 56400

Total wages per annum [Rs.lakhs] Rs.6.77 lakhs

7. Implementation Schedule

If financing arrangement is made available the project can be implemented

within three months period.

8. ASSUMPTIONS

73.45

Installed capacity per annum Pilfer Proof Caps 180 Lakhs Nos

Capacity utilization-Year -1 60%

Year-2 70%

Year-3 80%

Selling price per unit Pilfer Proof Caps Re.0.40 per piece

Material cost at 100% Qty. (inclg. Rate/MT (Rs.) Value

wastage) (Rs.lakhs)

Half Hard Aluminium Sheets 57.6 Mt 111545/MT 64.25

Printing 1.80

PVC Coated Wads 5.00

Packing cost 2.40

Total 73.45

Consumables per annum-at 100% (Rs.lakhs) Included in

materials

Power and Fuel-100% (Rs.lakhs) Rs.1.87 lakhs

Wages & salaries -100% Rs.6.77 lakhs

Repairs & Maintenance p.m. Rs10000/-

Depreciation Written Down Value

Method

General & administration Expenses per Rs.50000/-

month

Selling expenses 3% on Sales

Interest on term loan and Working capital finance 13% p.a.

Income tax provision 34% on profit

LIST OF MACHINERY SUPPLIERS

1. Narendra Press-tech pvt ltd

P.P.26,27 & 9/97(V) Lane no.10

Behind Police Station

Anand Prabhat Industrial Estate

New delhi-110 005.

2. Advance Packaging

10/65 Industrial Area

Kirti nagar

New Delhi-110 015

LIST OF RAW MATERIAL SUPPLIERS

1. Premier Metal engineering Corporation

JVL Towers

117, Nelson Manikem Road

Chennai-600 029.

2. Southern Aluminium Company

New No.22, Mooker Nallamuthu Street

Chennai-600 001.

3. Zenith Traders

New No.62, Nynuyappa naicken street

Chennai-600 003.

4. Tamilnadu Aluminium Company

44, basin Bridge Road

Mint

Chennai-600 025

FINANCIAL ASPECTS

1. COST OF PROJECT

[Rs.lakhs]

Land & Building (Advance) 2.00

Plant & Machinery 18.00

Other Misc. assets 1.00

Pre-Operative expenses 2.00

Margin for WC 1.78

24.78

2. MEANS OF FINANCE

Capital 11.28

Term Loan 13.50

24.78

3. COST OF PRODUCTION & PROFITABILITY STATEMENTS

Years 1 2 3

Installed Capacity (lakhs) 300 300 300

Utilisation 60% 70% 80%

Production/Sales p.a. (lakhs) 180 210 240

Selling Price/ lakh caps (Rs.lakhs) 0.40 lakh

Sales Value (Rs.lakhs) 72.00 84.00 96.00

Raw Materials (Including consumables) 44.07 51.42 58.76

Power 1.12 1.31 1.50

Wages & Salaries 6.77 7.11 7.47

Repairs & Maintenance 1.20 1.26 1.32

Depreciation 3.15 2.68 1.83

Cost of Production 56.31 63.78 70.88

Admin, & General expenses 6.00 6.30 6.62

Selling expenses 2.16 2.52 2.88

Interest on Term Loan 1.76 1.54 1.10

Interest on Working Capital 0.73 0.73 0.73

Total 66.96 74.87 82.21

Profit Before Tax 5.04 9.13 13.79

Provision for tax 1.71 3.10 4.69

Profit After Tax 3.33 6.03 9.10

Add: Depreciation 3.15 2.68 1.83

Cash Accruals 6.48 8.71 10.93

4. WORKING CAPITAL:

Months Values % Margin Bank

Consumption Amount Finance

Raw Materials 0.75 2.75 25% 0.69 2.06

Consumables 1.00 0.00 25% 0.00 0.00

Finished goods 0.25 1.17 25% 0.29 0.88

Debtors 0.50 3.00 10% 0.30 2.70

Expenses 1.00 0.50 100% 0.50 0.00

7.42 1.78 5.64

5. PROFITABILITY RATIOS BASED ON 80% UTILISATION

Profit after Tax 9.10

9%

Sales 96.00

Profit before Interest and Tax 15.62

51%

Total Investment 30.42

Profit after Tax 9.10

81%

Promoters' Capital 11.28

6. BREAK EVEN LEVEL

[Rs.lakhs]

Fixed Cost (FC):

Wages & Salaries 7.47

Repairs & Maintenance 1.32

Depreciation 1.83

Admin. & General expenses 6.62

Interest on TL 1.10

18.34

Profit Before Tax (P) 13.79

FC x

BEL = 100 18.34 x 80 x 100

FC +P 32.13 100

46% of installed capacity

You might also like

- Chapter 01 - Introduction To Federal Taxation in CanadaDocument40 pagesChapter 01 - Introduction To Federal Taxation in CanadaDonna So100% (2)

- Paper ConesDocument8 pagesPaper ConesEng.Abdalla Qassem50% (2)

- Smart Axis Automatic Chasing Machine ManualDocument38 pagesSmart Axis Automatic Chasing Machine Manualvser19No ratings yet

- Computer Training InstituteDocument10 pagesComputer Training InstituteaefewNo ratings yet

- Onion Dehydration: Project ProfileDocument4 pagesOnion Dehydration: Project ProfileMallikarjunReddyObbineniNo ratings yet

- Note For ExamDocument58 pagesNote For ExamMichael Al100% (1)

- Pre-Admission Testing: Practice Math Questions: Button Located Within The Window of This DocumentDocument9 pagesPre-Admission Testing: Practice Math Questions: Button Located Within The Window of This DocumentFloydSpiritzNo ratings yet

- Disposable Plastic Cup: Profile No.: 61 NIC Code: 17092Document6 pagesDisposable Plastic Cup: Profile No.: 61 NIC Code: 17092navyaNo ratings yet

- Offer For Twin Scrubbers Systems Plant-Rev-1Document3 pagesOffer For Twin Scrubbers Systems Plant-Rev-1Vinay TungeNo ratings yet

- DPR For Konark Coir ClusterDocument252 pagesDPR For Konark Coir ClusterAvijitSinharoyNo ratings yet

- Bread Manufacturing UnitDocument5 pagesBread Manufacturing UnitKaran VaghelaNo ratings yet

- Two Wheeler Repair and Service UnitDocument8 pagesTwo Wheeler Repair and Service UnitSurendra SharmaNo ratings yet

- Project of Rexin BagDocument11 pagesProject of Rexin BagShayan Pitruja100% (1)

- Maintnenance IndigoDocument40 pagesMaintnenance IndigoJavier Martinez CañalNo ratings yet

- Survey of Cattle Feed Channel and An Including Dealer District Network and Dairies and ToDocument39 pagesSurvey of Cattle Feed Channel and An Including Dealer District Network and Dairies and ToKing Deepak SnehiNo ratings yet

- Neer Project ReportDocument2 pagesNeer Project ReportanimeshbariarNo ratings yet

- Proposal For 30TPD Wheat Flour PlantDocument34 pagesProposal For 30TPD Wheat Flour Plantसंदीप योगेन्द्र शर्माNo ratings yet

- Setiing Up A Computer Business CenterDocument11 pagesSetiing Up A Computer Business CenterRaushan SolankiNo ratings yet

- Pre-Feasibility Study Prime Minister's Small Business Loan SchemeDocument20 pagesPre-Feasibility Study Prime Minister's Small Business Loan SchemeMian Adi Chaudhry100% (1)

- Project Profile On Manufacturing of Palm PlateDocument9 pagesProject Profile On Manufacturing of Palm PlateGangaraboina Praveen MudirajNo ratings yet

- Hand Gloves Project Report 2010Document9 pagesHand Gloves Project Report 2010karthik rNo ratings yet

- Plastic BucketDocument5 pagesPlastic Bucketallahoudine9876No ratings yet

- Maa Pitambra - BANK Project ReportDocument76 pagesMaa Pitambra - BANK Project ReportSanu KS100% (1)

- Hitachi Iclean Split Ac ManualDocument4 pagesHitachi Iclean Split Ac ManualBiplab BeheraNo ratings yet

- DPR - पोल्ट्री फीड युनिटDocument43 pagesDPR - पोल्ट्री फीड युनिटNirikshan BhandareNo ratings yet

- Academia-Cat en HRDocument616 pagesAcademia-Cat en HRetsimo100% (1)

- Dehydrated VegetablesDocument6 pagesDehydrated VegetablesTrans TradesNo ratings yet

- Alu CapsDocument10 pagesAlu CapsindusexposiumNo ratings yet

- Cleanroom-Rfp Iitg 250116 PDFDocument168 pagesCleanroom-Rfp Iitg 250116 PDFKim Jongin100% (1)

- Mini Dal MillDocument4 pagesMini Dal MillLitesh MahakalkarNo ratings yet

- Jadibuti DocumentDocument278 pagesJadibuti Documentpokhralikanchha100% (1)

- Accounts List (Detail) : Account # Account Type DR/CR Header/Detail Level ChequeDocument4 pagesAccounts List (Detail) : Account # Account Type DR/CR Header/Detail Level ChequeEka RatihNo ratings yet

- 2.2.49. Falling Ball Viscometer MethodDocument2 pages2.2.49. Falling Ball Viscometer MethodDheeraj Shukla100% (1)

- Polygranite India Catalog - MinDocument18 pagesPolygranite India Catalog - MinChinmaya PradhanNo ratings yet

- HartDocument10 pagesHartSandhya RaghunathNo ratings yet

- Surgical Bandage-Ok-35-R PDFDocument2 pagesSurgical Bandage-Ok-35-R PDFSuresh KaushikNo ratings yet

- How To Make Multigrain Atta at HomeDocument12 pagesHow To Make Multigrain Atta at HomeAravind SastryNo ratings yet

- 05.15 Quotation of Automatic Sachet Filling and Sealing MachineDocument6 pages05.15 Quotation of Automatic Sachet Filling and Sealing MachineJean Pool C SNo ratings yet

- Wheel Balancing & Alignment UnitDocument9 pagesWheel Balancing & Alignment UnitKARTIKEYA TIWARI100% (1)

- Bio-Degratable Plastic BagDocument13 pagesBio-Degratable Plastic BagVickesh MalkaniNo ratings yet

- 123Document191 pages123RINKKI GUPTANo ratings yet

- Central Luzon State University: Plant Watering PumpDocument14 pagesCentral Luzon State University: Plant Watering PumpJohn Henry TenorioNo ratings yet

- Price ListDocument17 pagesPrice ListAvijitSinharoyNo ratings yet

- Spice Grinding Unit Chilli, Turmeric, CuminDocument12 pagesSpice Grinding Unit Chilli, Turmeric, Cuminveer marathaNo ratings yet

- Recipe - Hyderabadi Mutton Biryani - The Times of India PDFDocument5 pagesRecipe - Hyderabadi Mutton Biryani - The Times of India PDFSuresh Babu BonthuNo ratings yet

- Merck Price List 2018 To 2019 Vijay ChemicalsDocument404 pagesMerck Price List 2018 To 2019 Vijay Chemicalsnikhilesh2011No ratings yet

- Model DPR Fish FeedDocument30 pagesModel DPR Fish FeedPrabhakara Rao ThanikondaNo ratings yet

- PH CONTROL IN A BIOREACTOR PDFDocument45 pagesPH CONTROL IN A BIOREACTOR PDFrijilpoothadiNo ratings yet

- SMEDA Compartmentalized Cold StorageDocument19 pagesSMEDA Compartmentalized Cold StoragemkhalilanwarNo ratings yet

- Bought Leaf Factories DibrugarhDocument13 pagesBought Leaf Factories Dibrugarhgat2bmoahNo ratings yet

- Plastic Carry BagsDocument8 pagesPlastic Carry BagsRavi PrakashNo ratings yet

- Starch From Maize: Detailed Feasibility ReportDocument44 pagesStarch From Maize: Detailed Feasibility ReportMehak DhimanNo ratings yet

- Linea de Produccion SemiautomaticaDocument9 pagesLinea de Produccion SemiautomaticaIvanhoe UrrNo ratings yet

- Rice & Dal Mill Machinery PDFDocument9 pagesRice & Dal Mill Machinery PDFSHASHI SHEKARNo ratings yet

- Product Costing Detailed Designv5Document59 pagesProduct Costing Detailed Designv5adit1435No ratings yet

- Offer-NJP1200 Capsule Filling Machine-Aligned TechDocument8 pagesOffer-NJP1200 Capsule Filling Machine-Aligned TechNanang's FriendNo ratings yet

- 1st Fortnight ReportDocument3 pages1st Fortnight Reportvaibhav_stupifyNo ratings yet

- Project Report On Automated Coconut Processing PlantDocument10 pagesProject Report On Automated Coconut Processing PlantEIRI Board of Consultants and PublishersNo ratings yet

- Japan Export GuideDocument43 pagesJapan Export GuideRosy SeafoodNo ratings yet

- Vegetables Based Project-Self-Employment Oppertunities-Mynampati Sreenivasa RaoDocument7 pagesVegetables Based Project-Self-Employment Oppertunities-Mynampati Sreenivasa Raomcs_msr3023100% (1)

- Dal MillDocument14 pagesDal MillAMBESHNo ratings yet

- Plastic CratesDocument9 pagesPlastic CratesfawwazNo ratings yet

- Sustainable Value Creation in the Fine and Speciality Chemicals IndustryFrom EverandSustainable Value Creation in the Fine and Speciality Chemicals IndustryNo ratings yet

- SS Tax PlanDocument12 pagesSS Tax PlanChristianNo ratings yet

- Speech From The Throne 2020Document34 pagesSpeech From The Throne 2020NunatsiaqNewsNo ratings yet

- 01 Republic Vs CA, 258 SCRA 712Document6 pages01 Republic Vs CA, 258 SCRA 712Louiegie Thomas San JuanNo ratings yet

- Commercial Dispatch Eedition 3-16-21Document12 pagesCommercial Dispatch Eedition 3-16-21The DispatchNo ratings yet

- CIR vs. Pilipinas ShellDocument2 pagesCIR vs. Pilipinas ShellMCNo ratings yet

- National Income Sunil Panda SirDocument30 pagesNational Income Sunil Panda SirAnanya GuptaNo ratings yet

- Exercises 4 Financial Planning BudgetingDocument2 pagesExercises 4 Financial Planning BudgetingKyle PereiraNo ratings yet

- Thesis Political EconomyDocument6 pagesThesis Political Economyaflowlupyfcyye100% (2)

- Summer Internship Report NitinDocument44 pagesSummer Internship Report Nitinbhardwajbhardwaj05No ratings yet

- May 16 2013 Mount Ayr Record-NewsDocument14 pagesMay 16 2013 Mount Ayr Record-NewsMountAyrRecordNewsNo ratings yet

- Vuca World Implicated Into SCM - FinalDocument12 pagesVuca World Implicated Into SCM - Finalthanhvan34No ratings yet

- The Local Government Code of The PhilippinesDocument57 pagesThe Local Government Code of The PhilippinesfloraralphNo ratings yet

- Commissioner Vs Magsaysay LinesDocument2 pagesCommissioner Vs Magsaysay LinesVerlynMayThereseCaroNo ratings yet

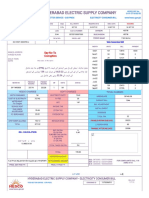

- Hesco Online BillDocument1 pageHesco Online BillGuru bhaiNo ratings yet

- Strategic Analysis of InfosysDocument35 pagesStrategic Analysis of InfosysAbhishek SrivastavaNo ratings yet

- Macroeconomic Aims and Policies and Trade 5 June 2012 (Students)Document21 pagesMacroeconomic Aims and Policies and Trade 5 June 2012 (Students)ragul96No ratings yet

- Chapter 4Document56 pagesChapter 4Crystal Brown100% (1)

- 143 Tax - Republic of The Phil v. GMCC United Development Corporation, G.R. No. 191856, 07 December 2016Document1 page143 Tax - Republic of The Phil v. GMCC United Development Corporation, G.R. No. 191856, 07 December 2016Brandon BanasanNo ratings yet

- Group Presentation 2: Topic: Fraud, Corruption & Illegal ActivitiesDocument25 pagesGroup Presentation 2: Topic: Fraud, Corruption & Illegal ActivitiesCallie NguyenNo ratings yet

- Soc. Sci Gen EndDocument18 pagesSoc. Sci Gen EndanneNo ratings yet

- Subcontractor AgreementDocument14 pagesSubcontractor AgreementAmit ChaudharyNo ratings yet

- Fostering Tax Compliance in RDC: Lesson From Korean Case StudyDocument13 pagesFostering Tax Compliance in RDC: Lesson From Korean Case StudyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- 21.12.24 Mayor Baker LetterDocument2 pages21.12.24 Mayor Baker LetterWendy LiberatoreNo ratings yet

- 2 VHSCP009340500191 R 1917 EC69 D846621Document1 page2 VHSCP009340500191 R 1917 EC69 D846621paulettem.guy68No ratings yet

- Fdi in India PDFDocument12 pagesFdi in India PDFpnjhub legalNo ratings yet

- Tender Form For Dematerialized Equity Shares Tcs Buyback 2018Document2 pagesTender Form For Dematerialized Equity Shares Tcs Buyback 2018Ankit LatiyanNo ratings yet

- Invoice Template 1Document2 pagesInvoice Template 1PramodhNo ratings yet