Professional Documents

Culture Documents

Bora1994 - Heat Induced Gelation of Pea

Bora1994 - Heat Induced Gelation of Pea

Uploaded by

Felipe Gomes da SilvaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bora1994 - Heat Induced Gelation of Pea

Bora1994 - Heat Induced Gelation of Pea

Uploaded by

Felipe Gomes da SilvaCopyright:

Available Formats

Heat Induced Gelation of Pea (Pisum sativum) Mixed

Globulins, Vicilin and Legumin

PUSHKAR S. BORA, CLARK J. BREKKE, and JOSEPH R. POWERS

ABSTRACT MATERIALS & METHODS

Mixed globulins (MG) were extracted from ground dry peas (Pisum Extraction of pea globulins

sntivum, B-160) with 0.5M NaCl, 50 mM potassium phosphate, pH The extraction method was that of Koyoro and Powers (1987).

7.2, and isolated by precipitation at pH 4.5. Crude vicilin and legumin Whole dry green peas (Pisum sat&urn, B-160) from a single bag, pro-

were fractionated from the MG by dialysis against 0.2M NaCl, pH 4.8, vided by Dumas Seed Co., Pullman, WA, were ground into flour using

and centrifugation, then further purified using DEAE-cellulose chro- a cyclone sample mill equipped with a 0.5 mm screen. The flour was

matography. Conditions for maximum gel hardness of heat induced extracted at room temperature (-23°C) with 0.5 M NaCl, 50 mM

MG gel, as determined with an Instron Universal Testing Machine, potassium phosphate buffer, pH 7.2, in a ratio of 6 mL buffer/g of

were heating for 20 min at pH 7.1 at 87°C. Purified vicilin, but not flour for 1 hr with constant agitation using a propeller stirrer. The

legumin, formed heat induced gels. The relationship was linear be- extract was centrifuged (19,000 X g, 15 min, 4”C), and the supernatant

tween protein (globulin) concentration and log gel hardness. At all was filtered through pads of glass wool. This filtrate was diluted with

protein concentrationsstudied, as proportion of legumin decreased,gel 5 vol of cold distilled water (4°C) and pH adjusted to 4.5 with 2N HCl

hardnessincreased. to precipitate salt soluble proteins. The protein floe was allowed to

settle overnight at 4°C. After decanting much of the supernatant,the

Key Words: pea protein, globulins, gelation, vicilin, legumin remaining suspension was centrifuged, the pellet resuspended and

washed with water, and re-centrifuged. The resulting pellet was re-

extracted twice with extraction buffer in a ratio of 5 mL buffer/g of

INTRODUCTION pellet for 1 hr at 4”C, followed by re-centrifugation. The supematants

PROTEIN GELATION is an aggregation in which polymer to pol- resulting from the re-extraction were combined and divided into three

ymer and polymer to solvent interactions (both attractive and parts. The pH of one-third of the supernatantwas adjusted to 4.5 to

repulsive) are balanced, and an ordered network or matrix ca- precipitate mixed globulins, which were recovered by centrifugation

(19,000 X g, 15 min, 4’C), washed with water, centrifuged and freeze-

pable of holding water is formed (Schmidt, 1981). The capac- dried. The remaining two-thirds of the supematantwas dialyzed against

ity of gels to act as a matrix for holding water, lipids, sugars, Mcllvaines buffer, 493 mL 0.2M Na,HPO, * 2H,O + 507 mL O.lM

flavors and other ingredients is useful in food applications and citric acid, containing 0.2M NaCl, pH 4.8 (Scholz et al., 1974), at 4°C

for development of new products (Kinsella, 1979). for 42 hr with two changesof buffer in a ratio of 10 mL of buffer per

Thermal gelation of soybean protein has been studied ex- mL of original supematant.The precipitate (legumin) was collected by

tensively (Mori et al., 1982a; Nakamura et al., 1984a, 1985a). centrifugation, suspendedin distilled water at a ratio of l:lO, agitated,

Mori et al. (1982b) and Nakamura et al. (1984b, 1985b) have re-centrifuged (19,000 X g, 15 min) and the precipitate freeze-dried.

reported the contributions of 7s and 11s soy globulins in the The supematant from dialysis was adjusted to pH 4.5 and the precip-

itate (vicilin) recovered, washed with distilled water, centrifuged and

process of gelation. Utsumi and Kinsella (1985) indicated that

freeze-dried. The freeze-dried protein samples, representing several

electrostatic interactions and disulfide bonds are involved in separateprotein extractions, were stored in screw cap glass scintillation

the formation of 11s globulin gel, mostly hydrogen bonding vials at -20°C until used.

in 7s globulin gel, and hydrogen bonding and hydrophobic

interactions in soy isolate gel. Similar studies on the involve-

ment of molecular forces in the process of gelation of soy Chromatography of legumin and vicilin fractions

protein were reported by Nakamura et al. (1986a,b) and Mori

Legumin and vicilin preparations were further purified by DEAE

et al. (1986). The 11s and 7s globulins may interact with each

cellulose column chromatographyusing 35 mM potassium phosphate,

other in gels made from soy isolate proteins (Babajimopoulos 0.075M NaCl, 0.02% sodium azide buffer, pH 8.0. Freeze-driedprotein

et al., 1983; Utsumi and Kinsella, 1985). was re-solubilized in column buffer at a concentration of 12 to 15 mgl

Pea seeds contain 20 to 30% protein, most of which are mL by sonication for 1 min and placed on the column. Vicilin and

storage proteins. The two major proteins, legumin and vicilin, legumin were eluted stepwise with buffer containing 0.15M and 0.4M

are classical globulins and represent 65 to 80% of the total NaCl, respectively (Grant and Lawrence, 1964). Eluted fractions were

buffer-extractable protein (Schroeder, 1982). Legumin and vi- isoelectrically precipitated, centrifuged, washed with distilled water,

cilin proteins are similar to the 11s and 7s proteins of soybean, centrifuged and frozen (-20°C).

respectively (Derbyshire et al., 1976), and, thus, potentially Elution patterns of mixed globulin, crude legumin and crude vicilin

samples from the DEAE column were also used as a measure of the

may be important as functional protein ingredients in proc- composition of those preparations.Thus, total protein eluting at 0.15M

essed foods. However, information on the gelation behavior of NaCl was recorded as a measure of vicilin and that at 0.4M NaCl was

such proteins is limited (Bacon et al., 1990; Gueguen and Le- as legumin content.

febvre, 1983). Our objective was to examine thermal gelation

of mixed pea globulins at various conditions and compare the

results to those for crude and column purified legumin and Denaturation temperature of mixed globulins by differential

vicilin at standardizedconditions. scanning calorimetry (DSC)

DSC was performed in a Perkin-Elmer DSC 4 fitted with a 3600

Authors Brekke and Powers are with the Dept. of Food Science Thermal Analysis Data Station. Protein samples in 35 mM phosphate

& Human Nutrition, Washington State Univ., Pullman, W A buffer, 0.4M NaCl, pH 7.2, were hermetically sealedin aluminum pans

99164-6378. Author Bore’s present address: Universidade Fed- (Perkin-Elmer kit No. 219-0062) and ‘scanned at lO”C/min over the

eral da Paraiba, Department0 de Tecnologia Q&mica e de range 25-100°C at a sensitivity of 1.0 mW using phosphatebuffer in

Alimentos, Centro de Tecnologia, Campus Universithrio I, the referencepan. The instrument was calibrated for temperatureusing

58.059 - Joao Pessoa/PB, Brasil. Address inquiries to Dr. C. J. indium (m.p. 156.6O”C). Tm was determined with data analysis pro-

Brekke. grams supplied by Perkin-Elmer.

594-JOURNAL OF FOOD SCIENCE-Volume 59, No. 3, 1994

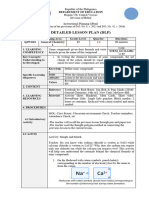

i.oT 17.4% globulin8 OS-

0.01 I

0 0.1 0.2 0.3 0.4 0.5

lieatlng The (mln) Sodium Chloride Concentration (Y)

Fig. l-Heating time and protein concentration effects on peak Fig. 3-Sodium chloride concentration and peak force of gels

force of gels prepared from pea mixed globulin at 87’C and pH made with pea mixed globulin. Gels were prepared by heating

7.2. 15% mixed globulin solutions 20 min at 87°C in 30 mM Tris-HCI,

pH 7.1, with variable concentrations of NaCI.

Table l-Composition of crude globulin fractions a8 calculated from

DEAE cellulose chromatography profiles according to Grant and

Lawrence (1964)

Legumin Vicilin

Fraction (%) (%)

Mixed globulins 35.7 84.3

Crude legumin 88.5 31.5

Crude vicilin 9.1 90.9

RESULTS & DISCUSSION

DSC OF MIXED GLOBULINS indicated one transition between

74 and 9S’C with a maximum at 86.2”C (thermogram not

shown). This was essentially the same temperature (86’C) pre-

0.0 4

5.5 6.0 6.5 7.0 7.5 8.0 viously reported for field peas by Arntfield and Murray (1981),

px of Gel although the solvent system they used was not specified. Time

Fig. 2-Effect of pH on peak force of gels prepared from pea of heating at 87°C had a marked effect on mixed globulin gel

mixed globulins. Gels were made by heating 15% mixed glob- peak force (Fig. 1). At pH 7.2, gel strength increased with

ulin solutions 20 min at 87°C in 30 mM Tris-HCI buffers. heating time up to 20 min, but heating beyond that period

caused a decreasein gel peak force. Nakamura et al. (1985a)

noted similar behavior for soybean glycinin (11s) when heated

at 100°C for different times. They also reported maximum gel

Preparation of gels strength at 20 min heating. We adopted 20 min heating time

at 87°C as our standard gelation conditions, based on observed

Gelationof proteinsampleswas carriedout accordingto the method

describedby Utsumi and Kinsella (1985). Freeze-driedprotein was maximum transition of 86.2’C and data presented in Fig. 1.

suspendedin 30 mM Tris-HCI buffer, pH 7.2, in a test tube, and the To study the effect of pH on gel formation and gel peak

suspensionwas sonicatedfor 1 min. The suspensionwas centrifuged force, and further define standard conditions, pH of the mixed

for 30 min, and the supematant (protein solution) was used for prep globulin solutions was varied from 5.95 to 8.60 (Fig. 2). We

arationof the gels. Aliquots of protein solution (25 to 3OpL) in 30 observed that at pH 5.95 no gel formed. Gel formation oc-

mM Tris-HCl buffer weretransferredto Carawayblood tubes(75 mm curred at 2 pH 6.4, with the greatest gel peak force at pH 7.1.

X 2.5 mm i.d) (FisherScientific),the tube endswere sealedwith po- Increasing pH to > 8.0 resulted in a translucent and sticky gel

lyvinylidene chloride film and O-rings,andcentrifugedat 500 X g for which was difficult to remove from the tubes.

10 min to remove air bubbles. Heating time of the tubes ranged from Sodium chloride had an adverse effect on mixed globulin

0 to 45 min in a water bath at 87°C followed by immersion in cold

water. The tubes were then held at 4°C for 24 hr, prior to gel peak gel peak force. Within the concentration range 0 to 0.5M NaCl,

force determinations.

In a secondexperiment,pH wasvariedfrom 5.95 gel strength was maximum at OM NaCl and decreased with

to 8.60, with heating for 20 min at 87°C in the water bath. All other increasing NaCl concentration (Fig. 3). Utsumi and Kinsella

procedures and conditions were as before. (1985), using soybean isolate and 11s protein, also reported a

decrease in gel strength with increase in NaCl concentration.

Wang and Damodaran (1991) noted that in the presence of

0.5M NaCl, soy 11s did not form a gel when heated at 9O”C,

Gel peak force and protein and the peak force of soy isolate gels was reduced. Conversely,

they did not observe a reduction in peak force of soy 7s gels

The gels formed in blood tubes were carefully removed by blowing when OSM NaCl was added.

on the narrow end, taking care to collect the expelled gel on a glass The make-up of the mixed globulin, crude legumin and

slide without damage,cut into 1 cm pieces, a piece laid lengthwise on crude vicilin preparations, based on elution patterns from the

the stage of an Instron Universal Testing Machine, Model 1350 (In- DEAE column was determined (Table 1). The data are based

stron Corp., Canton, MA), and the gel peak force was determined. The

speed of the plate (76 mm diam) was adjusted to 4 cm/min and the on the definition of Grant and Lawrence (1964) that vicilin

compression to 70%. Peak force refers to that obtained during the first elutes at 0.15M NaCl and legumin at 0.4M NaCl from DEAE

compression cycle (Boume, 1978). Two to five gels were used for cellulose under the conditions used. At the conditions used for

replicatedeterminations.Proteinwas determinedby the biuret method gelation, i.e. pH 7.1, 20 min at 87”C, and at the protein con-

(Gomall et al., 1949),usingbovine serumalbuminas standard. centrations studied, legumin fractions, either crude or further

Volume 59, No. 3, 1994JOURNAL OF FOOD SCIENCE-595 I

PEA GLOBULIN GEUTION. ..

REFERENCES

Arntfield, SD. and Murray, E.D. 1981. The influence of processing para-

meters on food protein functionality: I. Differential scanning calorimetry

as an indicator of protein denaturation. Can. Inst. Food Sci. Technol. J.

14: 289-294.

Babajimopoulos, M., Damodaran, S., Rizvi! S&H., and Kinsella, J.E. 1983.

Effect of various anions on the rheolopcal and gelling behavior of soy

proteins:

.r.“C Thermodynamic observations. J. Agric. Food Chem. 31: 1270-

1z 40.

Bacon, J.R., Noel, T.R., and Lambert, N. 1990. Preparation of transparent

ea protein gels: a comparison of isolation procedures. Int. J. Food Sci.

F echnol. 26: 527-537.

Bourne, M.C. 1978. Texture profile analysis. Food Technol. 32: 62-66,72.

Damodaran, S. and Kinsella, J.E. 1982. Effect of conglycinin on the ther-

mal aggregation of glycinin. J. Agric. Chem. 30: 812-817.

Derbyshire, E., Wri ht, D.J., and Boulter, D. 1976. Legumin and vicilin,

stora e proteins o le me seeds. Phytochem. 15: 3-24.

Gornal P, A.G., Bardawi

% 1, C.J., and David, M.M. 1949. Determination of

0.1 serum protein by means of the biuret reaction. J. Biol. Chem. 177: 751-

8 10 12 14 16 18 20 753.

Grant, D.R. and Lawrence, J.M. 1964. Effects of sodium dodecyl sulfate

Protein Concsntratlon (al/v) and other dissociating agents on the globulins of peas. Arch. B&hem.

Fig. bPeak force of gels from solutions of several pea protein Biophys. 108: 552-561.

Gueguen, J. and Lefehvre, J. 1983. Water retention and flow behaviors of

fractions of variable protein concentration. Gels were made by protein isolates from peas. Qual. Pl. Pl. Foods Human Nutr. 33: 201-

heating protein solutions for 20 min at 87°C at pH 7.01-7.04. W 208.

= mixed globulins, 0 = crude vicilin, Ir, = DEAE-purified vicilin. Kinsella, J.E. 1979. Functional properties of soy protein. J. Am. Oil Chem.

Sot. 56: 242-257.

Koyoro, H. and Powers, J.R. 1987. Functional properties of pea globulin

fractions. Cereal Chem. 64: 97-101.

purified by DEAE cellulose column-chromatography, did not Mori, T., Nakamura, T. and Utsumi, S. 1982a. Gelation mechanism of soy-

bean 11s globulin: Formation of soluble aggregates as transient inter-

gel. At the highest concentration, neither of these fractions mediates. J. Food Sci. 47: 26-30.

showed any evidence of a gel hard enough to measure. How- Mori, T., Nakamura, T. and Utsumi, S. 1982b. Formation of pseudoglyci-

ever, further-purified vicilin from the DEAE column formed a nins and their eel hardness. J. Aeric. Food Chem. 30: 828-831.

Mori, T, Nakamcra, T. and UtsuG, S. 1986. Behavior of intermolecular

gel of greater peak force than for gels from crude vicilin or bond formation in the late stage of heat induced gelation. J. Agric. Food

mixed globulins. While both 7s and 11s soy globulin fractions Chem. 34: 33-36.

Nakamura, T., Utsumi, S., and Mori, T. 1984a. Network structure for-

have the capacity to form gels, the pea vicilin (7s) fraction mation in thermally Induced gelation of glycinin. J. Agric. Food Chem.

had that capacity while pea legumin (11s) did not. Saio and 32: 349-352.

Nakamura, T., Utsumj, S., Kitamura, K.; Harada, K., and Mori, T. 1984b.

Watanabe (1978) reported that the 11s soy protein produced Cultivar differences m gelling characteristics of soybean glycinin. J. Agr.

a much harder gel than the 7s soy protein. Food Chem. 32: 647-651.

Nakamura, T., Utsumi, S. and Mori, T. ‘1985a. Effect of temperature on

Data for vicilin fractions and mixed globulins demonstrated the different stages of thermal gelling of glycinin. J. Agr. Food Chem.

a linear relationship (semi-log scale) between gel peak force 33: 1201-1203.

and protein concentration (Fig. 4). At equal protein concentra- Nakamura, T., Utsumi, S., and Mori, T. 1985b. Formation of pseudodv-

cinins from intermediary subunits of glycinin and their gel ‘proper&

tions, peak force of the gel from column purified vicilin was and network structure. Aaic. Biol. Chem. 49: 2733-2741.

greatest, followed by the gels made from crude vicilin and Nakamura, T., Utsumi, S.,\nd Mori, T. 1986a. Interactions during heat

induced gel&ion in mixed system of soybean 7s and 11s globulins. Agric.

mixed globulins. That is, the greater the proportion of vicilin, Biol. Chem. 50: 2429-2435.

the greater was the gel peak force. That all three lines (Fig. 4) Nakamura, T., Utsumi, S., and Mori, T., 198613.Mechanism of heat in-

duced gelation and gel properties of soybean 7s globulin. Agric. Biol.

were nearly parallel indicated that the effect of legumin on gel Chem. 50: 1287-1293.

peak force was not protein concentration dependent. The de- Saio, K. and Watanabe, T. 1978. Differences in functional properties of 7s

crease in gel peak force with increase in legumin may not be and 11s soybean proteins. J. Texture Studies 9: 135-157.

Schmidt, R.H. 1981. Gel&ion and Coagulation. Ch. 7. In Protein Func-

simply a dilution or vicilin sparing effect, but may be due to tionaltty in FoocZs,J.P. Cherry (Ed.), p. 131-147. ACS Symposium Series

protein to protein interaction. For example, with soybean 7s No. 147. Am. Chem. Sot., Washin n, DC.

Scholz, G., Richter, J., and Manteu t-P el, R. 1974. Studies on seed globulins

and 11s globulins, the 7s protein interacts electrostatically from le mes. I. Separation and purification of legumin and vi&in from

with the basic subunits of 11s globulin to form soluble com- Vicia faT a L. by zone precipitation. Biochem. Physiol. Pflanzen 166: 163-

plexes during gelation (Damodaran and Kinsella, 1982; Ut- -.-.

172

Schroeder, H.E. 1982. Quantitative studies on the cotyledonary proteins

sumi et al., 1984). However, unlike vicilin and legumin in our in the rrenus Pisum. J. Sci. Food Am. 33: 623-633.

study, the interaction of soybean 11s and 7s proteins was Utsumi, G. and Kinsella, J.E. 1985. F&ces involved in soy protein elation:

Effect of various reagents on the formation, hardness and solu5. lhty of

affected by the proportion of globulins. heat induced gels made from 7S, llS, and soy isolate. J. Food Sci. 50:

1278-1282.

Utsumi, S., Damodaran, S., and Kinsella, J.E. 1984. Heat induced inter-

CONCLUSIONS action between soybean proteins: Preferential association of 11s basic

subunits and subunits of 7s. J. Agr. Food Chem. 32: 1406-1412.

Wang, D.-H. and Damodaran, S. 1991. Thermal lation of globular pro-

VICILIN, the 7s component of pea globulin, undergoes heat teins: Influence of protein conformation on geT strength. J. Agr. Food

gelation in a model system while legumin, the 11s component, Chem. 39: 433-438.

does not gel under the same conditions. The optimal conditions MS received 6128193;revised 12/18/93; accepted l/19/94.

for gelation of a pea mixed globulin system, as assessedby

gel hardness, were pH 7.1 and heating time 20 min at 87°C.

Addition of NaCl at concentrations of 0.05M or greater re-

Author Rors gr&foUy achowledges the fellowship awarded by Cmselho Nackmal de

sulted in mixed globulin sets of reduced hardness. Legumin Desenvolvimento Cientillco e Tecnologico, Brazil and the Univmkhde Federal da Fnr&a

concentration in a range of pea globulin preparations, as esti- for study leave. The technical advice of Dr. Youling I. Xiong regarding the @ation and

mated by DEAE ion exchange chromatography elution profile, DSC studies is much appreciated Washington State University, A@iculhual Research Cen-

tar, Fullman, WA project No. 0626. /

was inversely related to gel hardness in the model system.

596-JOURNAL OF FOOD SCIENCE-Volume 59, No. 3, 1994

You might also like

- 2021 RI H2 Chem Prelims P3 AnswersDocument9 pages2021 RI H2 Chem Prelims P3 Answersclarissa yeoNo ratings yet

- Investigatory Project ExampleDocument8 pagesInvestigatory Project ExampleKyle David Lubigan Paraiso82% (88)

- LORD AC-902 LC Experimental TDSDocument2 pagesLORD AC-902 LC Experimental TDSVenkata ChadaNo ratings yet

- Effect of Heat Treatment On The Nutritional Quality of Milk ProteinsDocument4 pagesEffect of Heat Treatment On The Nutritional Quality of Milk ProteinsLộc Võ Tường100% (1)

- Effect of Heat Treatment On Dispersion Stability of Soymilk and Heat DenaturationDocument7 pagesEffect of Heat Treatment On Dispersion Stability of Soymilk and Heat DenaturationDiễm My PhạmNo ratings yet

- Plntphys00211 0097Document7 pagesPlntphys00211 0097yasmineat29No ratings yet

- Ind 23218981Document4 pagesInd 23218981stilbeneNo ratings yet

- 12 Rozdzial PDFDocument6 pages12 Rozdzial PDFVamshi NarlagiriNo ratings yet

- Hydrolysates of NativeDocument8 pagesHydrolysates of NativeAnisa TridiyaniNo ratings yet

- S. K. SATHE D. K. SALUNKHE - Isolation, Partial Characterization and Modification of The Great Northern Bean (Phaseolus Vulgaris L.) StarchDocument5 pagesS. K. SATHE D. K. SALUNKHE - Isolation, Partial Characterization and Modification of The Great Northern Bean (Phaseolus Vulgaris L.) StarchTaufik Nuraziz100% (1)

- Production of Poly (3-Hydroxybutyrate) by Fed-Batch Culture of Recombinant Escherichia Coli With A Highly Concentrated Whey SolutionDocument4 pagesProduction of Poly (3-Hydroxybutyrate) by Fed-Batch Culture of Recombinant Escherichia Coli With A Highly Concentrated Whey Solutionapi-3743140No ratings yet

- 2011 Article 160Document6 pages2011 Article 160jwalantkbhattNo ratings yet

- The Isolation and Characterisation of Jacalin Artocarpus Heterophyllus Jackfruit Lectin Based On Its Charge Properties 1995 The International JournalDocument10 pagesThe Isolation and Characterisation of Jacalin Artocarpus Heterophyllus Jackfruit Lectin Based On Its Charge Properties 1995 The International JournalsfsmNo ratings yet

- Isolation and Characterization of A Thermostable - Amylase FromDocument5 pagesIsolation and Characterization of A Thermostable - Amylase FromDương Nguyễn Thùy DungNo ratings yet

- Cristalización CuajoDocument9 pagesCristalización CuajoPablo GarcíaNo ratings yet

- Yamada 2005Document6 pagesYamada 2005Dương Nguyễn Thùy DungNo ratings yet

- Vitb1 B2Document6 pagesVitb1 B2gbahaciuNo ratings yet

- Youle 1978Document4 pagesYoule 1978Porko DioNo ratings yet

- Isolation and Purification of CellulaseDocument6 pagesIsolation and Purification of CellulaseMeshal NoorNo ratings yet

- Isolation and partial characterisation of α-amylase components evolved during early wheat germinationDocument13 pagesIsolation and partial characterisation of α-amylase components evolved during early wheat germinationDwi Surya AtmajaNo ratings yet

- Effect of Heat Treatment On Edible Yam (Dioscorea Activity: Kinetic and Thermodynamic AnalysisDocument10 pagesEffect of Heat Treatment On Edible Yam (Dioscorea Activity: Kinetic and Thermodynamic Analysisاجي تقرى100% (1)

- Experimental Work: Chapter No.3Document28 pagesExperimental Work: Chapter No.3saabiaanNo ratings yet

- Effects of Polysaccharides Upon The Functional Properties of 11 S Globulin of Broad BeansDocument8 pagesEffects of Polysaccharides Upon The Functional Properties of 11 S Globulin of Broad BeansJose perezNo ratings yet

- Potential of Taiwan Sorghum Spirits Lees For The Production of BioethanolDocument21 pagesPotential of Taiwan Sorghum Spirits Lees For The Production of Bioethanolrichardson sitohangNo ratings yet

- Jurnal Tugas TFDocument5 pagesJurnal Tugas TFDhian ZhahirahNo ratings yet

- Biochemical Studies Cocoa Bean Polyphenol Oxidase: Pat LeeDocument10 pagesBiochemical Studies Cocoa Bean Polyphenol Oxidase: Pat LeeAntra OjhaNo ratings yet

- Comparative Studies On Glucoamylases From Three Fungal SourcesDocument16 pagesComparative Studies On Glucoamylases From Three Fungal SourcesEka WahyuniNo ratings yet

- Fermentation and Recovery of L-Glutamic - Acid - FromDocument8 pagesFermentation and Recovery of L-Glutamic - Acid - FromPrachi BhoirNo ratings yet

- Ahmad 2001Document9 pagesAhmad 2001Himew BraidNo ratings yet

- TMP 633 EDocument5 pagesTMP 633 EFrontiersNo ratings yet

- B. ConggylcininDocument8 pagesB. ConggylcininKevin SanjayaNo ratings yet

- ArtigoDocument14 pagesArtigoFernanda CorreaNo ratings yet

- Variations of Peroxidase Activity in Cocoa (Theobroma Cacao L.) PDFDocument4 pagesVariations of Peroxidase Activity in Cocoa (Theobroma Cacao L.) PDFFadli Ryan ArikundoNo ratings yet

- Biochemical Changes in Experimental Soy Sauce KojiDocument13 pagesBiochemical Changes in Experimental Soy Sauce KojiTâm Dương ĐứcNo ratings yet

- AMARE GESSESSE 1998 IsozymesDocument3 pagesAMARE GESSESSE 1998 IsozymesDivyesh BhagatNo ratings yet

- Partial Characterization of Lipase From Cocoa BeanDocument6 pagesPartial Characterization of Lipase From Cocoa BeannubnubNo ratings yet

- Chin 1991Document5 pagesChin 1991Pedro RetamalNo ratings yet

- Jsfa.274055021020161117 32447 1hvsqq With Cover Page v2Document11 pagesJsfa.274055021020161117 32447 1hvsqq With Cover Page v2Afandynibandera AfandynibanderaNo ratings yet

- Electrophoresis and Fractionation of Wheat GlutenDocument14 pagesElectrophoresis and Fractionation of Wheat GlutensecucaNo ratings yet

- Kumar 2004Document12 pagesKumar 2004Annie NolascoNo ratings yet

- Or-Amylase Production in Aqueous Two-Phase Systems With: Bacillus SubtilisDocument6 pagesOr-Amylase Production in Aqueous Two-Phase Systems With: Bacillus SubtilisHong HanhNo ratings yet

- Characterization of Red Bean (Phaseolus Radiatus Var. Aurea)Document4 pagesCharacterization of Red Bean (Phaseolus Radiatus Var. Aurea)NGUYỄN HOÀNG LINHNo ratings yet

- Lactobacillus: Isolation and Characterisation of A Ropy Strain Producing The Exopolysaccharide Ke®ranDocument6 pagesLactobacillus: Isolation and Characterisation of A Ropy Strain Producing The Exopolysaccharide Ke®ranAnh Trinh XuanNo ratings yet

- Beta Amylase of Sweet PotatoDocument7 pagesBeta Amylase of Sweet PotatoJhoana Falcon100% (1)

- Cellulase Enzyme Production by Streptomyces SP Using Fruit Waste As SubstrateDocument5 pagesCellulase Enzyme Production by Streptomyces SP Using Fruit Waste As SubstrateHamka NurkayaNo ratings yet

- Hojo 1999Document11 pagesHojo 1999Berk YüzerNo ratings yet

- Experiment 2Document8 pagesExperiment 2Corina Faye RosarioNo ratings yet

- Functional Propieties of Lupin Seed (Lupinus Mutabilis) Protein... (Sathe Et Al.)Document7 pagesFunctional Propieties of Lupin Seed (Lupinus Mutabilis) Protein... (Sathe Et Al.)Lenna TrujilloNo ratings yet

- Choi Et Al.. 1998. Characterization of An Extracellular Flocculating Substance Produced by A Planktonic Cyanobacterium, Anabaena SPDocument4 pagesChoi Et Al.. 1998. Characterization of An Extracellular Flocculating Substance Produced by A Planktonic Cyanobacterium, Anabaena SPAzb 711No ratings yet

- Nutritional Composition and Solubility of Edible Bird Nest (Aerodramus Fuchiphagus)Document7 pagesNutritional Composition and Solubility of Edible Bird Nest (Aerodramus Fuchiphagus)garias indraNo ratings yet

- Amano P6 - Rice BranDocument6 pagesAmano P6 - Rice BranlaviniakartikaNo ratings yet

- Separation and Characterization of Wheat Protein Fractions by High-Performance Capillary ElectrophoresisDocument6 pagesSeparation and Characterization of Wheat Protein Fractions by High-Performance Capillary ElectrophoresisHamidatun FtpNo ratings yet

- Pnas00657 0264Document5 pagesPnas00657 0264Muhammad sherazNo ratings yet

- Han 1975 Microbial Fermentation of Rice Straw Nutritive Composition and in Vitro Digestibility of The FermentationDocument5 pagesHan 1975 Microbial Fermentation of Rice Straw Nutritive Composition and in Vitro Digestibility of The FermentationNgân NguyêñNo ratings yet

- App// D: O., Microbiology BiotechnologyDocument4 pagesApp// D: O., Microbiology BiotechnologyRoger FernandezNo ratings yet

- Comparative Prod of Amylase Enzyme From RhizopusDocument4 pagesComparative Prod of Amylase Enzyme From RhizopusIsworo RukmiNo ratings yet

- Fungal EnzymesDocument9 pagesFungal EnzymesYui Bioscience PalsanNo ratings yet

- 1.Oil-In-water Emulsion Properties of Egg YolkDocument8 pages1.Oil-In-water Emulsion Properties of Egg YolkLuis LamadridNo ratings yet

- Havea Etal, 1998Document13 pagesHavea Etal, 1998سومر صيموعةNo ratings yet

- Influence of PH and Ionic Environment On Thermal Aggregation of Whey ProteinsDocument5 pagesInfluence of PH and Ionic Environment On Thermal Aggregation of Whey ProteinsJohnatan HubsNo ratings yet

- Pemanfaatan Kulit Cempedak Sebagai Bahan Baku Pembuatan Bioetanol Dengan Proses Fermentasi Menggunakan Saccharomyces CereviseaeDocument9 pagesPemanfaatan Kulit Cempedak Sebagai Bahan Baku Pembuatan Bioetanol Dengan Proses Fermentasi Menggunakan Saccharomyces CereviseaeDianSafitriAndazi 27No ratings yet

- 9 AltintasDocument8 pages9 AltintasValentina InonizedNo ratings yet

- Vermeulen2012 Impacto Meio AmbienteDocument33 pagesVermeulen2012 Impacto Meio AmbienteFelipe Gomes da SilvaNo ratings yet

- Biofilms Based On Cassava Starch Containing Extract of Yerba Mate As Antioxidant and PlasticizerDocument10 pagesBiofilms Based On Cassava Starch Containing Extract of Yerba Mate As Antioxidant and PlasticizerFelipe Gomes da SilvaNo ratings yet

- Ultrasound-Assisted Modification of Functional Properties and BiologicalDocument15 pagesUltrasound-Assisted Modification of Functional Properties and BiologicalFelipe Gomes da SilvaNo ratings yet

- Pectina Efeitos CrossDocument12 pagesPectina Efeitos CrossFelipe Gomes da SilvaNo ratings yet

- Polysaccharide Protein Interactions: C.G. de Kruif, R. TuinierDocument9 pagesPolysaccharide Protein Interactions: C.G. de Kruif, R. TuinierFelipe Gomes da SilvaNo ratings yet

- Molecular Forces Involved in Heat-Induced Pea Protein Gelation EffectsDocument8 pagesMolecular Forces Involved in Heat-Induced Pea Protein Gelation EffectsFelipe Gomes da SilvaNo ratings yet

- Ki KBR H C Ki BR H C: Oducts B ADocument2 pagesKi KBR H C Ki BR H C: Oducts B AnaverfallNo ratings yet

- ESTIMATION OF HB CONTENTDocument2 pagesESTIMATION OF HB CONTENTSuman MandalNo ratings yet

- J of Applied Polymer Sci - 2012 - YeDocument9 pagesJ of Applied Polymer Sci - 2012 - YeBarisNo ratings yet

- AnodicProtectionofDigestersTAPPI2003 PDFDocument26 pagesAnodicProtectionofDigestersTAPPI2003 PDFabdur sufaNo ratings yet

- Smoke Sabre MSDSDocument5 pagesSmoke Sabre MSDSnsusanoNo ratings yet

- PLP Gchem1 Q1 W2 D3Document4 pagesPLP Gchem1 Q1 W2 D3ERIC BAAYNo ratings yet

- Failure Analysis of Aluminum Wires in All Aluminum Alloy Conductors - AAAC PDFDocument20 pagesFailure Analysis of Aluminum Wires in All Aluminum Alloy Conductors - AAAC PDFqaqc peleburanNo ratings yet

- MarkDocument1 pageMarkZayar LinnNo ratings yet

- Tachyhydrite Camg CL 12H O: Crystal Data: Physical PropertiesDocument1 pageTachyhydrite Camg CL 12H O: Crystal Data: Physical Propertieskittipun khamprasoetNo ratings yet

- Lab Report Experiment 1 and 2 - K2G7Document11 pagesLab Report Experiment 1 and 2 - K2G7Divagar SivaselvamNo ratings yet

- Report On Utility OperationDocument45 pagesReport On Utility OperationArham AsimNo ratings yet

- Dokumen - Tips - Drilling Fluid FundamentalsDocument4 pagesDokumen - Tips - Drilling Fluid FundamentalsjalalNo ratings yet

- Science DirectDocument13 pagesScience DirectLê DuyNo ratings yet

- Organic Chemistry JEE Main 2023 Chapterwise PYQs PDFDocument32 pagesOrganic Chemistry JEE Main 2023 Chapterwise PYQs PDFSrishant KumarNo ratings yet

- AMS-Recent Progress of High-Entropy Materials For Energy Storage and ConversionDocument44 pagesAMS-Recent Progress of High-Entropy Materials For Energy Storage and Conversionrambabu surampallyNo ratings yet

- Lactic Acid Production From Glycerol Using CaO As Solid Base CatalystDocument8 pagesLactic Acid Production From Glycerol Using CaO As Solid Base CatalystlarguedasNo ratings yet

- Intensive Revision Practice 1Document5 pagesIntensive Revision Practice 1Dee -AdilaNo ratings yet

- Ionic Bonding Dot and Cross WorksheetDocument2 pagesIonic Bonding Dot and Cross WorksheetBasra AbdillahiNo ratings yet

- Experiment 5 - Enzymes Part IiDocument6 pagesExperiment 5 - Enzymes Part IiHalleli CastilloNo ratings yet

- Chemistry Project - F-BlockDocument28 pagesChemistry Project - F-BlockTHEONLYNABILNo ratings yet

- Fiberglass (GRP) Pultruded Open-Weather Storm-And Guard-Square HandrailsDocument10 pagesFiberglass (GRP) Pultruded Open-Weather Storm-And Guard-Square HandrailsDavid Drolet TremblayNo ratings yet

- Astm G4-01 (2008)Document9 pagesAstm G4-01 (2008)Davannendran Chandran100% (1)

- Ehb Hepa 2108Document8 pagesEhb Hepa 2108Daniel JanusauskasNo ratings yet

- EDTADocument29 pagesEDTA5P4RT4NII7No ratings yet

- Logik L12IM14E Ice Cube MakerDocument36 pagesLogik L12IM14E Ice Cube MakerJan EythorNo ratings yet

- Graphene Quantum Dots From Chemistry To Applications 2018Document38 pagesGraphene Quantum Dots From Chemistry To Applications 2018endalekNo ratings yet

- 2021 Problemario QOHBDocument6 pages2021 Problemario QOHBRebeca VegaNo ratings yet