Professional Documents

Culture Documents

Student Workbook: Coupled Tanks Experiment For Labview Users

Student Workbook: Coupled Tanks Experiment For Labview Users

Uploaded by

Tahir KhAnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Student Workbook: Coupled Tanks Experiment For Labview Users

Student Workbook: Coupled Tanks Experiment For Labview Users

Uploaded by

Tahir KhAnCopyright:

Available Formats

student workbook

Coupled Tanks Experiment for LabVIEW ™ Users

Standardized for ABET * Evaluation Criteria

Developed by:

Jacob Apkarian, Ph.D., Quanser

Hervé Lacheray, M.A.SC., Quanser

Amin Abdossalami, M.A.SC., Quanser

Quanser educational solutions

are powered by:

Captivate. Motivate. Graduate.

© 2013 Quanser Inc., All rights reserved.

Quanser Inc.

119 Spy Court

Markham, Ontario

L3R 5H6

Canada

info@quanser.com

Phone: 1-905-940-3575

Fax: 1-905-940-3576

Printed in Markham, Ontario.

For more information on the solutions Quanser Inc. offers, please visit the web site at:

http://www.quanser.com

This document and the software described in it are provided subject to a license agreement. Neither the software nor this document may be

used or copied except as specified under the terms of that license agreement. All rights are reserved and no part may be reproduced, stored in

a retrieval system or transmitted in any form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior

written permission of Quanser Inc.

ACKNOWLEDGEMENTS

Quanser, Inc. would like to thank the following contributors:

Dr. Hakan Gurocak, Washington State University Vancouver, USA, for his help to include embedded outcomes assessment, and

Dr. K. J. Åström, Lund University, Lund, Sweden for his immense contributions to the curriculum content.

COUPLED TANKS Workbook - Student Version 2

CONTENTS

1 Introduction 4

2 Modeling 5

2.1 Background 5

2.2 Pre-Lab Questions 10

3 Tank 1 Level Control 11

3.1 Background 11

3.2 Pre-Lab Questions 14

3.3 Lab Experiments 15

3.4 Results 18

4 Tank 2 Level Control 19

4.1 Background 19

4.2 Pre-Lab Questions 21

4.3 Lab Experiments 22

4.4 Results 26

5 System Requirements 27

5.1 Overview of Files 28

5.2 Calibrating the pressure sensor measurements 28

5.3 Setup for Tank 1 Level Control Simulation 28

5.4 Setup for Tank 1 Level Control 29

5.5 Setup for Tank 2 Level Control Simulation 29

5.6 Setup for Tank 2 Level Control 30

6 Lab Report 31

6.1 Template for Tank 1 Level Control Report 31

6.2 Template for Tank 2 Level Control Report 32

6.3 Tips for Report Format 33

COUPLED TANKS Workbook - Student Version v 1.2

1 INTRODUCTION

The Coupled Tanks plant is a "Two-Tank" module consisting of a pump with a water basin and two tanks. The two

tanks are mounted on the front plate such that flow from the first (i.e. upper) tank can flow, through an outlet orifice

located at the bottom of the tank, into the second (i.e. lower) tank. Flow from the second tank flows into the main

water reservoir. The pump thrusts water vertically to two quick-connect orifices "Out1" and "Out2". The two system

variables are directly measured on the Coupled-Tank rig by pressure sensors and available for feedback. They are

namely the water levels in tanks 1 and 2. A more detailed description is provided in [2]. To name a few, industrial

applications of such Coupled-Tank configurations can be found in the processing system of petro-chemical, paper

making, and/or water treatment plants.

During the course of this experiment, you will become familiar with the design and pole placement tuning of Proportional-

plus-Integral-plus-Feedforward-based water level controllers. In the present laboratory, the Coupled-Tank system

is used in two different configurations, namely configuration #1 and configuration #2, as described in [2]. In config-

uration #1, the objective is to control the water level in the top tank, i.e., tank #1, using the outflow from the pump.

In configuration #2, the challenge is to control the water level in the bottom tank, i.e. tanks #2, from the water flow

coming out of the top tank. Configuration #2 is an example of state coupled system.

Topics Covered

• How to mathematically model the Coupled-Tank plant from first principles in order to obtain the two open-loop

transfer functions characterizing the system, in the Laplace domain.

• How to linearize the obtained non-linear equation of motion about the quiescent point of operation.

• How to design, through pole placement, a Proportional-plus-Integral-plus-Feedforward-based controller for the

Coupled-Tank system in order for it to meet the required design specifications for each configuration.

• How to implement each configuration controller(s) and evaluate its/their actual performance.

Prerequisites

In order to successfully carry out this laboratory, the user should be familiar with the following:

1. See the system requirements in Section 5 for the required hardware and software.

2. Transfer function fundamentals, e.g., obtaining a transfer function from a differential equation.

3. Familiar with designing PID controllers.

4. Basics of LabVIEW™ .

COUPLED TANKS Workbook - Student Version 4

2 MODELING

2.1 Background

2.1.1 Configuration #1 System Schematics

A schematic of the Coupled-Tank plant is represented in Figure 2.1, below. The Coupled-Tank system's nomen-

clature is provided in Appendix A. As illustrated in Figure 2.1, the positive direction of vertical level displacement is

upwards, with the origin at the bottom of each tank (i.e. corresponding to an empty tank), as represented in Figure

3.2.

Figure 2.1: Schematic of Coupled Tank in Configuration #1.

2.1.2 Configuration #1 Nonlinear Equation of Motion (EOM)

In order to derive the mathematical model of your Coupled-Tank system in configuration #1, it is reminded that the

pump feeds into Tank 1 and that tank 2 is not considered at all. Therefore, the input to the process is the voltage to

the pump VP and its output is the water level in tank 1, L1 , (i.e. top tank).

The purpose of the present modelling session is to provide you with the system's open-loop transfer function, G1(s),

which in turn will be used to design an appropriate level controller. The obtained Equation of Motion, EOM, should

be a function of the system's input and output, as previously defined.

COUPLED TANKS Workbook - Student Version v 1.2

Therefore, you should express the resulting EOM under the following format:

∂L1

= f (L1 , Vp )

∂t

where f denotes a function.

In deriving the Tank 1 EOM the mass balance principle can be applied to the water level in tank 1, i.e.,

∂L1

At1 = Fi1 − Fo1 (2.1)

∂t

where At1 is the area of Tank 1. Fi1 and Fo1 are the inflow rate and outflow rate, respectively. The volumetric inflow

rate to tank 1 is assumed to be directly proportional to the applied pump voltage, such that:

Fi1 = Kp Vp

Applying Bernoulli's equation for small orifices, the outflow velocity from tank 1, vo1 , can be expressed by the following

relationship:

√

vo1 = 2gL1

2.1.3 Configuration #1 EOM Linearization and Transfer Func-

tion

In order to design and implement a linear level controller for the tank 1 system, the open-loop Laplace transfer

function should be derived. However by definition, such a transfer function can only represent the system's dynamics

from a linear differential equation. Therefore, the nonlinear EOM of tank 1 should be linearized around a quiescent

point of operation. By definition, static equilibrium at a nominal operating point (Vp0 , L10 ) is characterized by the

Tank 1 level being at a constant position L10 due to a constant water flow generated by constant pump voltage Vp0 .

In the case of the water level in tank 1, the operating range corresponds to small departure heights, L11 , and small

departure voltages, Vp1 , from the desired equilibrium point (Vp0 , L10 ). Therefore, L1 and Vp can be expressed as

the sum of two quantities, as shown below:

L1 = L10 + L11 , Vp = Vp0 + Vp1 (2.2)

The obtained linearized EOM should be a function of the system's small deviations about its equilibrium point

(Vp0 , L10 ). Therefore, one should express the resulting linear EOM under the following format:

∂

L11 = f (L11 , Vp1 ) (2.3)

∂t

where f denotes a function.

Example: Linearizing a Two-Variable Function

Here is an example of how to linearize a two-variable nonlinear function called f (z). Variable z is defined

z ⊤ = [z1 z2 ]

and f (z) is to be linearized about the operating point

z0 ⊤ = [a b]

COUPLED TANKS Workbook - Student Version 6

The linearized function is

( ) ( )

∂f (z) ∂f (z)

fz = f (z0 ) + (z1 − a) + (z2 − b)

∂z1 ∂z2

z=z0 z=z0

For a function, f , of two variables, L1 and Vp , a first-order approximation for small variations at a point (L1 , Vp ) =

(L10 , Vp0 ) is given by the following Taylor's series approximation:

( ) ( )

∂2 ∂ ∂

f (L1 , Vp ) ∼

= f (L10 , Vp0 ) + f (L10 , Vp0 ) + (L1 − L10 ) f (L10 , Vp0 ) (Vp − Vp0 ) (2.4)

∂L1 ∂Vp ∂L1 ∂Vp

Transfer Function

From the linear equation of motion, the system's open-loop transfer function in the Laplace domain can be defined

by the following relationship:

L11 (s)

G1 (s) = (2.5)

Vp1 (s)

The desired open-loop transfer function for the Coupled-Tank's tank 1 system is the following:

Kdc1

G1 (s) = (2.6)

τ1 s + 1

where Kdc1 is the open-loop transfer function DC gain, and τ1 is the time constant.

As a remark, it is obvious that linearized models, such as the Coupled-Tank tank 1's voltage-to-level transfer function,

are only approximate models. Therefore, they should be treated as such and used with appropriate caution, that is

to say within the valid operating range and/or conditions. However for the scope of this lab, Equation 2.5 is assumed

valid over the pump voltage and tank 1 water level entire operating range, Vp_peak and L1_max , respectively.

2.1.4 Configuration #2 System Schematics

A schematic of the Coupled-Tank plant is represented in Figure 2.2, below. The Coupled-Tank system's nomen-

clature is provided in Appendix A. As illustrated in Figure 2.2, the positive direction of vertical level displacement is

upwards, with the origin at the bottom of each tank (i.e. corresponding to an empty tank), as represented in Figure

2.2.

2.1.5 Configuration #2, Nonlinear Equation of Motion (EOM)

This section explains the mathematical model of your Coupled-Tank system in configuration #2, as described in

Reference [1]. It is reminded that in configuration #2, the pump feeds into tank 1, which in turn feeds into tank 2.

As far as tank 1 is concerned, the same equations as the ones explained in Section 2.1.2 and Section 2.1.3 will

apply. However, the water level Equation Of Motion (EOM) in tank 2 still needs to be derived. The input to the tank

2 process is the water level, L1 , in tank 1 (generating the outflow feeding tank 2) and its output variable is the water

level, L2 , in tank 2 (i.e. bottom tank). The purpose of the present modelling session is to guide you with the system's

open-loop transfer function, G2 (s), which in turn will be used to design an appropriate level controller. The obtained

EOM should be a function of the system's input and output, as previously defined.

Therefore, you should express the resulting EOM under the following format:

∂L2

= f (L2 , L1 )

∂t

COUPLED TANKS Workbook - Student Version v 1.2

Figure 2.2: Schematic of Coupled Tank in configuration #1.

where f denotes a function.

In deriving the tank #2 EOM the mass balance principle can be applied to the water level in tank 2 as follows

∂L2

At2 = Fi2 − Fo2

∂t

where At2 is the area of tank 2. Fi2 and Fo2 are the inflow rate and outflow rate, respectively.

The volumetric inflow rate to tank 2 is equal to the volumetric outflow rate from tank 1, that is to say:

Fi2 = Fo1

Applying Bernoulli's equation for small orifices, the outflow velocity from tank 2, vo2 , can be expressed by the following

relationship:

√

vo2 = 2gL2

2.1.6 Configuration #2 EOM Linearization and Transfer Func-

tion

In order to design and implement a linear level controller for the tank 2 system, the Laplace open-loop transfer

function should be derived. However by definition, such a transfer function can only represent the system's dynamics

from a linear differential equation. Therefore, the nonlinear EOM of tank 2 should be linearized around a quiescent

point of operation.

COUPLED TANKS Workbook - Student Version 8

In the case of the water level in tank 2, the operating range corresponds to small departure heights, L11 and L21 ,

from the desired equilibrium point (L10 , L20 ). Therefore, L2 and L1 can be expressed as the sum of two quantities,

as shown below:

L2 = L20 + L21 , L1 = L10 + L11 (2.7)

The obtained linearized EOM should be a function of the system's small deviations about its equilibrium point

(L20 , L10 ). Therefore, you should express the resulting linear EOM under the following format:

∂

L21 = f (L11 , L21 ) (2.8)

∂t

where f denotes a function.

For a function, f , of two variables, L1 and L2 , a first-order approximation for small variations at a point (L1 , L2 ) =

(L10 , L20 ) is given by the following Taylor's series approximation:

( ) ( )

∂2 ∂ ∂

f (L1 , L2 ) ∼

= f (L10 , L20 ) + f (L10 , L20 ) + (L1 − L10 ) f (L10 , L20 ) (L2 − L20 ) (2.9)

∂L1 ∂L2 ∂L1 ∂L2

Transfer Function

From the linear equation of motion, the system's open-loop transfer function in the Laplace domain can be defined

by the following relationship:

L21 (s)

G2 (s) = (2.10)

L11 (s)

the desired open-loop transfer function for the Coupled-Tank's tank 2 system, such that:

Kdc2

G2 (s) = (2.11)

τ2 s + 1

where Kdc2 is the open-loop transfer function DC gain, and τ2 is the time constant.

As a remark, it is obvious that linearized models, such as the Coupled-Tank's tank 2 level-to-level transfer function,

are only approximate models. Therefore, they should be treated as such and used with appropriate caution, that is to

say within the valid operating range and/or conditions. However for the scope of this lab, Equation 2.10 is assumed

valid over tank 1 and tank 2 water level entire range of motion, L1_max and L2_max , respectively.

COUPLED TANKS Workbook - Student Version v 1.2

2.2 Pre-Lab Questions

Answer the following questions:

1. Using the notations and conventions described in Figure 2 derive the Equation Of Motion (EOM) characterizing

the dynamics of tank 1. Is the tank 1 system's EOM linear?

Hint: The outflow rate from tank 1, Fo1 , can be expressed by:

Fo1 = Ao1 vo1 (2.12)

2. The nominal pump voltage Vp0 for the pump-tank 1 pair can be determined at the system's static equilibrium.

By definition, static equilibrium at a nominal operating point (Vp0 , L10 ) is characterized by the water in tank

1 being at a constant position level L10 due to the constant inflow rate generated by Vp0 . Express the static

equilibrium voltage Vp0 as a function of the system's desired equilibrium level L10 and the pump flow constant

Kp . Using the system's specifications given in the Coupled Tanks User Manual ([2]) and the desired design

requirements in Section 3.1.1, evaluate Vp0 parametrically.

3. Linearize tank 1 water level's EOM found in Question #1 about the quiescent operating point (Vp0 , L10 ).

4. Determine from the previously obtained linear equation of motion, the system's open-loop transfer function in

the Laplace domain as defined in Equation 2.5 and Equation 2.6. Express the open-loop transfer function DC

gain, Kdc1 , and time constant, τ1 , as functions of L10 and the system parameters. What is the order and type

of the system? Is it stable? Evaluate Kdc1 and τ1 according to system's specifications given in the Coupled

Tanks User Manual ([2]) and the desired design requirements in Section 3.1.1.

5. Using the notations and conventions described in Figure 2.2, derive the Equation Of Motion (EOM) character-

izing the dynamics of tank 2. Is the tank 2 system's EOM linear?

Hint: The outflow rate from tank 2, Fo2 , can be expressed by:

Fo2 = Ao2 vo2 (2.13)

6. The nominal water level L10 for the tank1-tank2 pair can be determined at the system's static equilibrium. By

definition, static equilibrium at a nominal operating point (L10 , L20 ) is characterized by the water in tank 2 being

at a constant position level L20 due to the constant inflow rate generated from the top tank by L10 . Express

the static equilibrium level L10 as a function of the system's desired equilibrium level L20 and the system's

parameters. Using the system's specifications given in the Coupled Tanks User Manual ([2]) and the desired

design requirements in Section 4.1.1, evaluate L10 .

7. Linearize tank 2 water level's EOM found in Question #5 about the quiescent operating point (L10 , L20 ).

8. Determine from the previously obtained linear equation of motion, the system's open-loop transfer function in

the Laplace domain, as defined in Equation 2.10 and Equation 2.11. Express the open-loop transfer function

DC gain, Kdc2 , and time constant, τ2 , as functions of L10 , L20 , and the system parameters. What is the order

and type of the system? Is it stable? Evaluate Kdc2 and τ2 according to system's specifications given in the

Coupled Tanks User Manual ([2]) and the desired design requirements in Section 4.1.1.

COUPLED TANKS Workbook - Student Version 10

3 TANK 1 LEVEL CONTROL

3.1 Background

3.1.1 Specifications

In configuration #1, a control is designed to regulate the water level (or height) of tank #1 using the pump voltage. The

control is based on a Proportional-Integral-Feedforward scheme (PI-FF). Given a ±1 cm square wave level setpoint

(about the operating point), the level in tank 1 should satisfy the following design performance requirements:

1. Operating level in tank 1 at 15 cm: L10 = 15 cm.

2. Percent overshoot less than 10%: P O1 ≤ 11 %.

3. 2% settling time less than 5 seconds: ts_1 ≤ 5.0 s.

4. No steady-state error: ess = 0 cm.

3.1.2 Tank 1 Level Controller Design: Pole Placement

For zero steady-state error, tank 1 water level is controlled by means of a Proportional-plus-Integral (PI) closed-loop

scheme with the addition of a feedforward action, as illustrated in Figure 3.1, below, the voltage feedforward action

is characterized by:

√

Vp_f f = Kf f _1 Lr_1 (3.1)

and

Vp = Vp1 + Vp_f f (3.2)

As it can be seen in Figure 3.1, the feedforward action is necessary since the PI control system is designed to

compensate for small variations (a.k.a. disturbances) from the linearized operating point (Vp0 , L10 ). In other words,

while the feedforward action compensates for the water withdrawal (due to gravity) through tank 1 bottom outlet

orifice, the PI controller compensates for dynamic disturbances.

Figure 3.1: Tank 1 Water Level PI-plus-Feedforward Control Loop.

COUPLED TANKS Workbook - Student Version v 1.2

The open-loop transfer function G1 (s) takes into account the dynamics of the tank 1 water level loop, as characterized

by Equation 2.5. However, due to the presence of the feedforward loop, G1 (s) can also be written as follows:

L1 (s)

G1 (s) = (3.3)

Vp1 (s)

3.1.3 Second-Order Response

The block diagram shown in Figure 3.2 is a general unity feedback system with compensator, i.e., controller C(s)

and a transfer function representing the plant, P (s). The measured output, Y (s), is supposed to track the reference

signal R(s) and the tracking has to match to certain desired specifications.

Figure 3.2: Unity feedback system.

The output of this system can be written as:

Y (s) = C(s) P (s) (R(s) − Y (s))

By solving for Y (s), we can find the closed-loop transfer function:

Y (s) C(s) P (s)

=

R(s) 1 + C(s) P (s)

The input-output relation in the time-domain for a proportional-integral (PI) controller is

Ki (r − y)

u = Kp (r − y) + (3.4)

s

where Kp is the proportional gain and Ki is the integral gain.

In fact, when a first order system is placed in series with PI compensator in the feedback loop as in Figure 3.2, the

resulting closed-loop transfer function can be expressed as:

Y (s) ωn2

= 2 (3.5)

R(s) s + 2ζ ωn s + ωn2

where ωn is the natural frequency and ζ is the damping ratio. This is called the standard second-order transfer

function. Its response properties depend on the values of ωn and ζ.

Peak Time and Overshoot

Consider a second-order system as shown in Equation 3.5 subjected to a step input given by

R0

R(s) = (3.6)

s

with a step amplitude of R0 = 1.5. The system response to this input is shown in Figure 3.3, where the red trace is

the response (output), y(t), and the blue trace is the step input r(t).

COUPLED TANKS Workbook - Student Version 12

Figure 3.3: Standard second-order step response.

The maximum value of the response is denoted by the variable ymax and it occurs at a time tmax . For a response

similar to Figure 3.3, the percent overshoot is found using

100 (ymax − R0 )

PO = (3.7)

R0

From the initial step time, t0 , the time it takes for the response to reach its maximum value is

tp = tmax − t0 (3.8)

This is called the peak time of the system.

In a second-order system, the amount of overshoot depends solely on the damping ratio parameter and it can be

calculated using the equation ( )

− √π ζ

1−ζ 2

P O = 100 e (3.9)

The peak time depends on both the damping ratio and natural frequency of the system and it can be derived as

π

tp = √ (3.10)

ωn 1 − ζ 2

Tank 1 level response 2% Settling Time can be expressed as follows:

4

ts = (3.11)

ζω

Generally speaking, the damping ratio affects the shape of the response while the natural frequency affects the

speed of the response.

COUPLED TANKS Workbook - Student Version v 1.2

3.2 Pre-Lab Questions

1. Analyze tank 1 water level closed-loop system at the static equilibrium point (Vp0 , L10 ) and determine and

evaluate the voltage feedforward gain, Kf f _1 , as defined by Equation 3.1.

2. Using tank 1 voltage-to-level transfer function G1 (s) determined in Section 2.2 and the control scheme block

diagram illustrated in Figure 3.1, derive the normalized characteristic equation of the water level closed-loop

system.

Hint#1: The feedforward gain Kf f _1 does not influence the system characteristic equation. Therefore, the

feedforward action can be neglected for the purpose of determining the denominator of the closed-loop transfer

function. Block diagram reduction can be carried out.

Hint#2: The system's normalized characteristic equation should be a function of the PI level controller gains,

Kp_1 , and Ki_1 , and system's parameters, Kdc_1 and τ1 .

3. By identifying the controller gains Kp_1 and Ki_1 , fit the obtained characteristic equation to the second-order

standard form expressed below:

s2 + 2ζ1 ωn1 s + ωn1

2

=0 (3.12)

Determine Kp_1 and Ki1 as functions of the parameters ωn1 , ζ1 , Kdc_1 , and τ1 using Equation 3.5.

4. Determine the numerical values for Kp_1 and Ki_1 in order for the tank 1 system to meet the closed-loop desired

specifications, as previously stated.

COUPLED TANKS Workbook - Student Version 14

3.3 Lab Experiments

3.3.1 Objectives

• Tune through pole placement the PI-plus-feedforward controller for the actual water level in tank 1 of the

Coupled-Tank system.

• Implement the PI-plus-feedforward control loop for the actual Coupled-Tank's tank 1 level.

• Run the obtained PI-plus-feedforward level controller and compare the actual response against the controller

design specifications.

• Run the system's simulation simultaneously, at every sampling period, in order to compare the actual and

simulated level responses.

3.3.2 Tank 1 Level Control Simulation

Experimental Setup

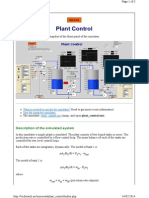

The Coupled Tanks -Tank1 Level Control simulation VI shown in Figure 3.4 is used to perform tank 1 level control

simulation exercises in this laboratory.

Figure 3.4: VI used to run PI-FF control Simulation on Coupled Tanks system in configuration #1.

IMPORTANT: Before you can conduct these simulations, you need to make sure that the lab files are configured

according to your setup. If they have not been configured already, then you need to go to Section 5 to configure the

lab files first.

Follow this procedure:

1. In Coupled Tanks.lvproj, open Coupled Tanks- Tank1 Level Control Simulation.vi. The model implements the

system's simulation Proportional-plus-Integral (PI) closed-loop with feedforward action, as studied in Section

3.1.2. To familiarize yourself with the diagram, it is suggested that you open the model subsystems to get a

better idea of their composing blocks as well as take note of the I/O connections.

2. To generate a square wave that goes between 14 and 16 cm for the tank 1 level reference, go to the Amplitude

Command (cm) section and set the controls to the following:

• Amplitude = 1 cm

COUPLED TANKS Workbook - Student Version v 1.2

• Frequency = 0.02 Hz

• Offset = 15 cm

The total level setpoint for tank 1 should result to be a square wave of ±1cm around the desired equilibrium

level L10

3. Enter the proportional, integral, and feedforward control gains found in Section 3.2 in the kp_1, ki_1, and kff_1

controls in the Control Parameters section on the front panel. Have your lab assistant check your values.

4. Run the VI.

5. The VI should start the Coupled Tanks simulation filling tank 1 up to its operating level L10 . Then after a 15-

second settling delay (in order to stabilize the system at its operating point), the water level in tank 1 should start

tracking the desired ±1cm square wave setpoint around the desired operating level L10 . The corresponding

commanded pump voltage, which is proportional to the control effort spent, can also be monitored and plotted

on-line.

6. Attach plots showing the Implemented Tank 1 Level Control response and the input voltage.

7. Assess the actual performance of the level response and compare it to the design requirements. Measure

your response actual percent overshoot and settling time. Are the design specifications satisfied? Explain. If

your level response does not meet the desired design specifications, review your PI-plus-Feedforward gain

calculations and/or alter the closed-loop pole locations until they do. If you are still unable to achieve the

required performance level, ask your T.A. for advice. Does the response satisfy the specifications given in

Section 3.1.1?

Hint: Use the graph cursors in the Measure tab to take measurements.

3.3.3 Tank 1 Level Control Implementation

Experimental Setup

The Coupled Tanks Tank1 Level Control VI shown in Figure 3.5 is used to perform tank 1 level control exercises in

this laboratory. This VI interfaces with the pump and pressure sensors of the Coupled Tanks system.

Note that a first-order low-pass filter with a cut-off frequency of 2.5 Hz is added to the output signal of the tank 1 level

pressure sensor. This filter is necessary to attenuate the high-frequency noise content of the level measurement.

Such a measurement noise is mostly created by the sensor's environment consisting of turbulent flow and circulating

air bubbles. Although introducing a short delay in the signals, low-pass filtering allows for higher controller gains in

the closed-loop system, and therefore for higher performance. Moreover, as a safety watchdog, the controller will

stop if the water level in either tank 1 or tank 2 goes beyond 27 cm.

IMPORTANT: Before you can conduct these experiments, you need to make sure that the lab files are configured

according to your setup. If they have not been configured already, then you need to go to Section 5 to configure the

lab files first.

Follow this procedure:

1. In Coupled Tanks.lvproj, open Coupled Tanks Tank1 Level Control.vi. The model implements the system's

actual Proportional-plus-Integral (PI) closed-loop with feedforward action. To familiarize yourself with the dia-

gram, it is suggested that you open the model subsystems to get a better idea of their composing blocks as

well as take note of the I/O connections.

2. To generate a square wave that goes between 14 and 16 cm for the tank 1 level reference, go to the Amplitude

Command (cm) section and set the controls to the following:

• Amplitude = 1 cm

• Frequency = 0.02 Hz

• Offset = 15 cm

COUPLED TANKS Workbook - Student Version 16

Figure 3.5: VI used to run PI-FF control on Coupled Tanks system in configuration #1.

The total level setpoint for tank 1 should result to be a square wave of ±1 cm around the desired equilibrium

level L10

3. Enter the proportional, integral, and feedforward control gains found in Section 3.2 in the Kp, Ki, and Kff controls

in the Control Parameters section on the front panel. Have your lab assistant check your values.

4. Run the VI. The pump should start running and filling up tank 1 to its operating level, L10 . After a settling delay,

the water level in tank 1 should begin tracking the ±1 cm square wave setpoint (about operating level L10 ).

5. Attach plots showing the Implemented Tank 1 Level Control response and the input voltage.

6. Assess the actual performance of the level response and compare it to the design requirements. Measure

your response actual percent overshoot and settling time. Are the design specifications satisfied? Explain. If

your level response does not meet the desired design specifications, review your PI-plus-Feedforward gain

calculations and/or alter the closed-loop pole locations until they do. If you are still unable to achieve the

required performance level, ask your lab instructors for advice. Does the response satisfy the specifications

given in Section 3.1.1?

Hint: Use the graph cursors in the Measure tab to take measurements.

7. Specifically discuss in your lab report the following points:

• How does your actual tank 1 level compare to the simulated response?

• From the plot of the actual level response, measure your system settling time and percentage overshoot.

Are the values in agreement with the design specifications? If not exactly, find some of the possible

reasons.

• Include in your lab report your final values for Kp_1 , Ki_1 , and Kf f _1 as well as the resulting response plot

of the actual and theoretical L1 versus Lr_1 . Also include from the same run the corresponding plot of Vp .

Ensure to properly document all your results and observations before moving on the the next section.

• You can now proceed to the next section, which deals with the actual implementation of your PI-plus-

Feedforward level controller for tank 2 of the Coupled-Tank system in configuration #2.

COUPLED TANKS Workbook - Student Version v 1.2

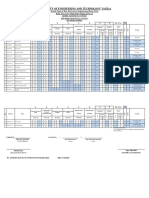

3.4 Results

Fill out Table 3.1 with your answers from your control lab results - both simulation and implementation.

Description Symbol Value Units

Pre Lab Questions

Tank 1 Control Gains

√

Feed Forward Control Gain Kf f1 V/ cm

Proportional Control Gain kp1 V/cm

Integral Control Gain ki1 V/(cm-s)

Tank 2 Control Simulation

Steady-state error ess cm

Settling time ts1 s

Percent overshoot P O1 %

Tank 2 Control Implementation

Steady-state error ess cm

Settling time ts1 s

Percent overshoot P O1 %

Table 3.1: Results

COUPLED TANKS Workbook - Student Version 18

4 TANK 2 LEVEL CONTROL

4.1 Background

4.1.1 Specifications

In configuration #2, the pump feeds tank 1 and tank 1 feeds tank 2. The designed closed-loop system is to control

the water level in tank 2 (i.e. the bottom tank) from the water flow coming out of tank 1, located above it. Similarly

to configuration #1, the control scheme is based on a Proportional-plus-Integral-plus-Feedforward law.

In response to a desired ± 1 cm square wave level setpoint from tank 2 equilibrium level position, the water height

behaviour should satisfy the following design performance requirements:

1. Tank 2 operating level at 15 cm: L20 = 15 cm.

2. Percent overshoot should be less than or equal to 10%: P O2 ≤ 10.0 %.

3. 2% settling time less than 20 seconds: ts,2 ≤ 20.0 s.

4. No steady-state error: ess,2 = 0 cm.

4.1.2 Tank 2 Level Controller Design: Pole Placement

For zero steady-state error, tank 1 water level is controlled by means of a Proportional-plus-Integral (PI) closed-loop

scheme with the addition of a feedforward action, as illustrated in Figure 4.1, below.

In the block diagram depicted in Figure 4.1, the water level in tank 1 is controlled by means of the closed-loop system

previously designed in Section 3.1. This is represented by the tank 1 closed-loop transfer function defined below:

L1 (s)

T1 (s) = (4.1)

Lr_1 (s)

Such a subsystem represents an inner (or nested) level loop. In order to achieve a good overall stability with such

a configuration, the inner level loop (i.e. tank 1 closed-loop system) must be much faster than the outer level loop.

This constraint is met by the previously stated controller design specifications, where ts_1 ≤ ts_2 .

However for the sake of simplicity in the present analysis, the water level dynamics in tank 1 are neglected. There-

fore, it is assumed hereafter that:

L1 (t) = Lr_1 (t) i.e. T1 (s) = 1 (4.2)

Furthermore as depicted in Figure 4.1, the level feedforward action is characterized by:

Lf f _1 = Kf f _2 Lr_2 (4.3)

and

L1 = L11 + Lf f _1 (4.4)

COUPLED TANKS Workbook - Student Version v 1.2

The level feedforward action, as seen in Figure 4.1, is necessary since the PI control system is only designed to

compensate for small variations (a.k.a. disturbances) from the linearized operating point L10 , L20 . In other words,

while the feedforward action compensates for the water withdrawal (due to gravity) through tank 2's bottom outlet

orifice, the PI controller compensates for dynamic disturbances.

Figure 4.1: Tank 2 Water Level PI-plus-Feedforward Control Loop.

The open-loop transfer function G2 (s) takes into account the dynamics of the tank 2 water level loop, as characterized

by Equation 2.10. However, due to the presence of the feedforward loop and the simplifying assumption expressed

by Equation 4.2, G2 (s) can also be written as follows:

L2 (s)

G2 (s) = (4.5)

L1 (s)

COUPLED TANKS Workbook - Student Version 20

4.2 Pre-Lab Questions

1. Analyze tank 2 water level closed-loop system at the static equilibrium point (L10 , L20 ) and determine and

evaluate the voltage feedforward gain, Kf f _2 , as defined by Equation 4.3.

2. Using tank 2 voltage-to-level transfer function G2 (s) determined in Section 2 and the control scheme block

diagram illustrated in Figure 4.1, derive the normalized characteristic equation of the water level closed-loop

system.

Hint#1: Block diagram reduction can be carried out.

Hint#2: The system's normalized characteristic equation should be a function of the PI level controller gains,

Kp_2 , and Ki_2 , and system's parameters, Kdc_2 and τ2 .

3. By identifying the controller gains Kp_2 and Ki_2 , fit the obtained characteristic equation to the standard second-

order equation: s2 + 2ζ2 ωn2 s + ωn2

2

= 0. Determine Kp_2 and Ki2 as functions of the parameters ωn2 , ζ2 , Kdc_2 ,

and τ2 .

4. Determine the numerical values for Kp_2 and Ki_2 in order for the tank 2 system to meet the closed-loop desired

specifications, as previously stated.

COUPLED TANKS Workbook - Student Version v 1.2

4.3 Lab Experiments

4.3.1 Objectives

• Tune through pole placement the PI-plus-Feedforward controller for the actual water level of the Coupled-Tank

system's tank 2.

• Implement the PI-plus-Feedforward control loop for the actual tank 2 water level.

• Run the obtained Feedforward-plus-PI level controller and compare the actual response against the controller

design specifications.

• Run the system's simulation simultaneously, at every sampling period, in order to compare the actual and

simulated level responses.

• Investigate the effect of the nested PI-plus-Feedforward level control loop implemented for tank 2.

4.3.2 Tank 2 Level Control Simulation

Experimental Setup

The Coupled Tanks -Tank2 Level Control simulation VI shown in Figure 4.2 is used to perform tank 2 level control

simulation exercises in this laboratory.

Figure 4.2: VI used to run PI-FF control Simulation on Coupled Tanks system in configuration #2.

IMPORTANT: Before you can conduct these simulations, you need to make sure that the lab files are configured

according to your setup. If they have not been configured already, then you need to go to Section 5 to configure the

lab files first.

Follow this procedure:

1. In Coupled Tanks.lvproj, open Coupled Tanks- Tank2 Level Control Simulation.vi. The model implements the

system's simulation Proportional-plus-Integral (PI) closed-loop with feedforward action, as studied in Section

4.1.2. As mentioned in the pre-lab assignments, the tank 2 water level control loop is based on tank 1 level

controller, as developed and tuned in the previous sections. The level controller diagram for the Coupled-Tank

in configuration #2 also interfaces directly with your Coupled-Tank hardware. To familiarize yourself with the

diagram, it is suggested that you open the model subsystems to get a better idea of their composing blocks as

well as take note of the I/O connections.

COUPLED TANKS Workbook - Student Version 22

2. To generate a square wave that goes between 14 and 16 cm for the tank 2 level reference, go to the Amplitude

Command (cm) section and set the controls to the following:

• Amplitude = 1 cm

• Frequency = 0.02 Hz

• Offset = 15 cm

The total level setpoint for tank 2 should result to be a square wave of ±1cm around the desired equilibrium

level L20

3. Enter the proportional, integral, and feedforward control gains found in Section 4.2 in the kp_2, ki_2, and kff_2

controls in the Control Parameters section on the front panel. Keep in the the PI-plus-feedforward controller

gains for tank 1 of the Coupled-Tank system in configuration #1, as previously implemented. Those are kp_1,

ki_1, and kff_1 controls in the Control Parameters section on the front panel. Have your lab assistant check

your values.

4. Run the VI.

5. The VI should start the Coupled Tanks simulation filling tank1 and tank 2 up to their operating levels L10 and

L20 , respectively. Then after a 35-second settling delay (in order to stabilize the system at its operating point),

the water level in tank 2 should start tracking the desired ±1cm square wave setpoint around the desired

operating level L20 . The corresponding commanded pump voltage, which is proportional to the control effort

spent, can also be monitored and plotted on-line.

6. Attach plots showing the Implemented Tank 2 Level Control response and the input voltage.

7. Assess the actual performance of the level response and compare it to the design requirements. Measure

your response actual percent overshoot and settling time. Are the design specifications satisfied? Explain. If

your level response does not meet the desired design specifications, review your PI-plus-Feedforward gain

calculations and/or alter the closed-loop pole locations until they do. If you are still unable to achieve the

required performance level, ask your lab instructor for advice. Does the response satisfy the specifications

given in Section 2.1.4?

Hint: Use the graph cursors in the Measure tab to take measurements.

4.3.3 Tank 2 Level Control Implementation

Experimental Setup

The Coupled Tanks Tank2 Level Control VI shown in Figure 4.3 is used to perform tank 2 level control exercises

in this laboratory. This VI interfaces with the pump and pressure sensors of the Coupled Tanks system. It should

be noted that two simple low-pass filters cut-off frequency 2.5 Hz are added to the output signal of the tank 1 and

tank 2 level pressure sensors. These filters are necessary to attenuate the high-frequency noise content of the level

measurements. Such a measurement noise is mostly created by the sensors environment made of turbulent flow

and circulating air bubbles. Although introducing a short delay in the signals, low-pass filtering allows for higher

controller gains in the closed-loop system, and therefore for higher performance. Moreover, as a safety watchdog,

the controller will stop if the water level in either tank 1 or tank 2 goes beyond 27cm.

IMPORTANT: Before you can conduct these experiments, you need to make sure that the lab files are configured

according to your setup. If they have not been configured already, then you need to go to Section 5 to configure the

lab files first.

Follow this procedure:

1. In Coupled Tanks.lvproj, open Coupled Tanks Tank2 Level Control.vi. The model implements the system's

actual Proportional-plus-Integral (PI) closed-loop with feedforward action, as studied in Assignment #3. To

familiarize yourself with the diagram, it is suggested that you open the model subsystems to get a better idea

of their composing blocks as well as take note of the I/O connections.

COUPLED TANKS Workbook - Student Version v 1.2

Figure 4.3: VI used to run PI-FF control on Coupled Tanks system in configuration #2.

2. To generate a square wave that goes between 14 and 16 cm for the tank 2 level reference, go to the Amplitude

Command (cm) section and set the controls to the following:

• Amplitude = 1 cm

• Frequency = 0.02 Hz

• Offset = 15 cm

The total level setpoint for tank 2 should result to be a square wave of ±1cm around the desired equilibrium

level L20

3. Enter the proportional, integral, and feedforward control gains found in Section 4.2 in the kp_2, ki_2, and kff_2

controls in the Control Parameters section on the front panel. Keep in the the PI-plus-feedforward controller

gains for tank 1 of the Coupled-Tank system in configuration #1, as previously implemented. Those are kp_1,

ki_1, and kff_1 controls in the Control Parameters section on the front panel. Have your lab assistant check

your values.

4. Run the VI.

5. The VI should start the gear pump thrusting water filling tank1 and tank 2 up to their operating levels L20 .

Then after a 35-second settling delay (in order to stabilize the system at its operating point), the water level in

tank 2 should start tracking the desired ±1cm square wave setpoint around the desired operating level L20 .

The corresponding commanded pump voltage, which is proportional to the control effort spent, can also be

monitored and plotted on-line.

6. Attach plots showing the Implemented Tank 2 Level Control response and the input voltage.

7. Assess the actual performance of the level response and compare it to the design requirements. Measure

your response actual percent overshoot and settling time. Are the design specifications satisfied? Explain. If

your level response does not meet the desired design specifications, review your PI-plus-Feedforward gain

calculations and/or alter the closed-loop pole locations until they do. If you are still unable to achieve the

required performance level, ask your lab instructor for advice. Does the response satisfy the specifications

given in Section 2.1.4?

Hint: Use the graph cursors in the Measure tab to take measurements.

8. Specifically discuss in your lab report the following points:

• How does your actual tank 2 level compare to the simulated response?

COUPLED TANKS Workbook - Student Version 24

• From the plot of the actual level response, measure your system settling time and percentage overshoot.

Are the values in agreement with the design specifications? If not exactly, find some of the possible

reasons.

• Include in your lab report your final values for Kp_2 , Ki_2 , and Kf f _2 as well as the resulting response plot

of the actual and theoretical L2 versus Lr_2 . Also include from the same run the corresponding plot of Vp .

Ensure to properly document all your results and observations before moving on the the next section.

• You can now proceed to the next section, which deals with the actual implementation of your PI-plus-

Feedforward level controller for tank 2 of the Coupled-Tank system in configuration #2.

COUPLED TANKS Workbook - Student Version v 1.2

4.4 Results

Fill out Table 4.1 with your answers from your control lab results - both simulation and implementation.

Description Symbol Value Units

Pre Lab Questions

Tank 2 Control Gains

Feed Forward Control Gain Kf f2 cm/cm

Proportional Control Gain kp2 cm/cm

Integral Control Gain ki2 1/(s)

Tank 2 Control Simulation

Steady-state error ess cm

Settling time ts2 s

Percent overshoot P O2 %

Tank 2 Control Implementation

Steady-state error ess cm

Settling time ts2 s

Percent overshoot P O2 %

Table 4.1: Results

COUPLED TANKS Workbook - Student Version 26

5 SYSTEM REQUIREMENTS

Required Software

Make sure LabVIEW™ is installed with the following required add-ons:

1. LabVIEW™

2. NI-DAQmx

3. NI LabVIEW™ Control Design and Simulation Module

4. Quanser Rapid Control Prototyping Toolkitr

Note: Make sure the Quanser Rapid Control Prototyping (RCP) Toolkit is installed after LabVIEW. See the RCP

Toolkit Quick Start Guide for more information.

Required Hardware

• Data acquisition (DAQ) device that is compatible with Quanser Rapid Control Prototyping Toolkitr . This in-

cludes Quanser DAQ boards such as Q2-USB, Q8-USB, QPID, and QPIDe and some National Instruments

DAQ devices.

• Quanser Coupled Tanks.

• Quanser VoltPAQ-X1 power amplifier, or equivalent.

Before Starting Lab

Before you begin this laboratory make sure:

• LabVIEW™ is installed on your PC.

• DAQ device has been successfully tested (e.g., using the test software in the Quick Start Guide).

• Coupled Tanks and amplifier are connected to your DAQ board as described Reference [2].

COUPLED TANKS Workbook - Student Version v 1.2

5.1 Overview of Files

File Name Description

Coupled Tanks User Manual.pdf This manual describes the hardware of the Coupled Tanks

system and explains how to setup and wire the system for

the experiments.

Coupled Tanks Workbook (Student).pdf This laboratory guide contains pre-lab questions and lab

experiments demonstrating how to design and implement

controllers for on the Coupled Tanks plant using Lab-

VIEW™ .

Coupled Tanks.lvproj LabVIEW project that contains all the LabVIEW™ Virtual

Instrument (VI) files required for running the Quanser Cou-

pled Tanks labs.

Coupled Tanks -Calibration.vi VI that is used to calibrate the pressure sensor measure-

ments on the Coupled Tanks system.

Coupled Tanks -Tank1 Level Simula- VI that simulates Tank1 level controller (configuration 1)for

tion.vi the Coupled Tanks system.

Coupled Tanks -Tank2 Level Simula- VI that simulates Tank2 level controller (configuration 2)

tion.vi for the Coupled Tanks system.

Coupled Tanks -Tank1 Level Control.vi VI that implements the PI Tank1 level controller (configu-

ration 1) on the Coupled Tanks system using LabVIEW™

.

Coupled Tanks -Tank2 Level Control.vi VI that implements the Tank2 level controller on the Cou-

pled Tanks system using LabVIEW™ .

Table 5.1: Files supplied with the Coupled Tanks

5.2 Calibrating the pressure sensor measurements

Follow these steps:

1. Load the LabVIEW™ software.

2. Open the LabVIEW Project COUPLEDTANK.lvproj.

3. Open the LabVIEW VI called Coupled Tanks- Calibration.

4. Follow the steps in the VI to calibrate both pressure sensors. The sensors should measure about 0V when

empty and about 4.1V when filled up to 25cm.

5.3 Setup for Tank 1 Level Control Simulation

Follow these steps:

1. Load the LabVIEW™ software.

2. Open the LabVIEW Project COUPLEDTANK.lvproj.

3. Open the LabVIEW VI called Coupled Tanks- Tank 1 Control Simulation, shown in Figure 3.4.

4. Ensure the PI-FF control gains the kp_1, ki_1, and kff_1 on the VI front panel are set to the value found in the

Pre-Lab Questions in Section 3.2.

COUPLED TANKS Workbook - Student Version 28

5.4 Setup for Tank 1 Level Control

Follow these steps to get the system ready for this lab:

1. Setup the Coupled Tanks as detailed in the Coupled Tanks User Manual ([2]).

2. If using the VoltPAQ-X1, make sure the Gain switch is set to 3.

3. Open COUPLEDTANK.lvproj project as outlined in Section 5.3.

4. Open Coupled Tanks- Tank1 Level Control.vi shown in Figure 3.5.

5. As discussed in Section 5.3, set the PI gains according to the Pre-Lab Exercise values.

6. Configure DAQ: Ensure the HIL Initialize block is configured for the DAQ device that is installed in your system.

To do this, go to the block diagram (CTRL-E) and double click on the HIL Initialize Express VI shown in Figure

5.1.

Figure 5.1: HIL Initialize Express VI

7. Under the Main tab, select the data acquisition device that is installed on your system in the Board type section.

For example, in Figure 5.2 the Q2-USB is chosen.

Figure 5.2: Select DAQ board that will be used to control system

5.5 Setup for Tank 2 Level Control Simulation

Follow these steps:

1. Load LabVIEW™ and open COUPLEDTANK.lvproj.

2. Open the Coupled Tanks- Tank2 Level Control Simulation VI, shown in Figure 4.2.

3. Make sure the control gains are set to the values found in Section 4.2.

4. Ensure the PI-FF control gains the kp_2, ki_2, and kff_2 on the VI front panel are set to the value found in the

Pre-Lab Questions in Section 4.2.

COUPLED TANKS Workbook - Student Version v 1.2

5.6 Setup for Tank 2 Level Control

Follow these steps to get the system ready for this lab:

1. Go through step 1-4 in Section 5.4 to setup the Coupled Tankssystem and open COUPLEDTANK.lvproj.

2. Open Coupled Tanks-Tank 2 Level Control.vi shown in Figure 4.3.

3. Make sure the control gains are set as dictated in Section 5.5.

4. Configure DAQ: Ensure the HIL Initialize Express VI is configured as explained in Section 5.4.

COUPLED TANKS Workbook - Student Version 30

6 LAB REPORT

This laboratory contains two groups of experiments, namely,

1. Tank 1 Level control, and

2. Tank 2 Level control.

For each experiment, follow the outline corresponding to that experiment to build the content of your report. Also,

in Section 6.3 you can find some basic tips for the format of your report.

6.1 Template for Tank 1 Level Control Report

I. PROCEDURE

1. Simulation

• Briefly describe the main goal of the simulation.

• Briefly describe the simulation procedure in Step 6 in Section 3.3.2.

2. Implementation

• Briefly describe the main goal of this experiment.

• Briefly describe the experimental procedure in Step 5 in Section 3.3.3.

II. RESULTS

Do not interpret or analyze the data in this section. Just provide the results.

1. Response plot from step 6 in Section 3.3.2, Tank1 level control simulation.

2. Response plot from step 5 in Section 3.3.3, Tank 1 level control implementation.

3. Provide applicable data collected in this laboratory (from Table 3.1).

III. ANALYSIS

Provide details of your calculations (methods used) for analysis for each of the following:

1. Peak time, percent overshoot, steady-state error, and input voltage in Step 7 in Section 3.3.2.

2. Peak time, percent overshoot, steady-state error, and input voltage in Step 6 in Section 3.3.3.

IV. CONCLUSIONS

Interpret your results to arrive at logical conclusions for the following:

1. Whether the controller meets the specifications in Step 7 in Section 3.3.2, Tank1 level control simulation.

2. Whether the controller meets the specifications in Step 6 in Section 3.3.3, Tank1 level control implementation.

COUPLED TANKS Workbook - Student Version v 1.2

6.2 Template for Tank 2 Level Control Report

I. PROCEDURE

1. Simulation

• Briefly describe the main goal of the simulation.

• Briefly describe the simulation procedure in Step 6 in Section 4.3.2.

2. Implementation

• Briefly describe the main goal of this experiment.

• Briefly describe the experimental procedure in Step 6 in Section 4.3.3.

II. RESULTS

Do not interpret or analyze the data in this section. Just provide the results.

1. Response plot from step 6 in Section 4.3.2, Tank2 level control simulation.

2. Response plot from step 6 in Section 4.3.3, Tank2 level control implementation.

3. Provide applicable data collected in this laboratory (from Table 4.1).

III. ANALYSIS

Provide details of your calculations (methods used) for analysis for each of the following:

1. Peak time, percent overshoot, steady-state error, and input voltage in Step 7 in Section 4.3.2.

2. Peak time, percent overshoot, steady-state error, and input voltage in Step 7 in Section 4.3.3.

IV. CONCLUSIONS

Interpret your results to arrive at logical conclusions for the following:

1. Whether the controller meets the specifications in Step 7 in Section 4.3.3, Tank2 level control implementation.

COUPLED TANKS Workbook - Student Version 32

6.3 Tips for Report Format

PROFESSIONAL APPEARANCE

• Has cover page with all necessary details (title, course, student name(s), etc.)

• Each of the required sections is completed (Procedure, Results, Analysis and Conclusions).

• Typed.

• All grammar/spelling correct.

• Report layout is neat.

• Does not exceed specified maximum page limit, if any.

• Pages are numbered.

• Equations are consecutively numbered.

• Figures are numbered, axes have labels, each figure has a descriptive caption.

• Tables are numbered, they include labels, each table has a descriptive caption.

• Data are presented in a useful format (graphs, numerical, table, charts, diagrams).

• No hand drawn sketches/diagrams.

• References are cited using correct format.

COUPLED TANKS Workbook - Student Version v 1.2

REFERENCES

[1] Quanser Inc. Coupled Tank User Manual, 2012.

COUPLED TANKS Workbook - Student Version 34

Process control plants for teaching and research

Coupled Tanks Magnetic Levitation

These plants are ideal for intermediate level teaching. They are also suitable for research

relating to traditional or modern control applications of process control. For more

information please contact info@quanser.com

©2013 Quanser Inc. All rights reserved.

INFO@QUANSER.COM +1-905-940-3575 QUANSER.COM

Solutions for teaching and research. Made in Canada.

You might also like

- Lab 1 Control SystemDocument39 pagesLab 1 Control SystemMuhd Ikram ShabryNo ratings yet

- Master Resource Book in MathDocument1,040 pagesMaster Resource Book in MathService Provider100% (3)

- Ron Larson Laurie Boswell: Florida EditionDocument19 pagesRon Larson Laurie Boswell: Florida EditionSayed Miko50% (2)

- User Manual: Couple Tank ExperimentDocument22 pagesUser Manual: Couple Tank ExperimentRUBEN DARIO TAMAYO BALLIVIANNo ratings yet

- QNET HVAC Workbook StudentDocument23 pagesQNET HVAC Workbook StudentJoão PauloNo ratings yet

- CPB 30004 - CHAPTER 1 - INTRO Sept 2014Document52 pagesCPB 30004 - CHAPTER 1 - INTRO Sept 2014Ashwin MNo ratings yet

- Ferris WheelDocument20 pagesFerris WheelKOOPER FRUITTENo ratings yet

- Coupled Tanks - Workbook (Instructor)Document66 pagesCoupled Tanks - Workbook (Instructor)Rehman ButtNo ratings yet

- Coupled Tanks - Workbook (Student)Document34 pagesCoupled Tanks - Workbook (Student)Yash AgarwalNo ratings yet

- Experiment # 5 5. Coupled Water Tanks: 5.1. ObjectivesDocument28 pagesExperiment # 5 5. Coupled Water Tanks: 5.1. ObjectivesStefany CorreaNo ratings yet

- Aim of The ExperimentDocument10 pagesAim of The Experimentadssf fdgddNo ratings yet

- Coupled TanksDocument32 pagesCoupled TanksbgizachewNo ratings yet

- Coupled Tank (Task)Document17 pagesCoupled Tank (Task)Anaya KhanNo ratings yet

- A Calculated Implementation of A Control SystemDocument16 pagesA Calculated Implementation of A Control SystemmayrtNo ratings yet

- Tutorial Sol CH 20Document6 pagesTutorial Sol CH 20Abraham wisdomNo ratings yet

- Experiment 6: Level Control of A Coupled Water TankDocument10 pagesExperiment 6: Level Control of A Coupled Water Tankilet09No ratings yet

- 2 DOF Helicopter Courseware Sample For MATLAB UsersDocument10 pages2 DOF Helicopter Courseware Sample For MATLAB UsersMoazam AliNo ratings yet

- PDC Lab 8Document9 pagesPDC Lab 8Mustafa BarwaniwalaNo ratings yet

- Techteach - No Simview Plant Control IndexDocument3 pagesTechteach - No Simview Plant Control IndexDiabloNo ratings yet

- KNC 1101 Chemical Engineering Laboratory I Experiment ManualDocument36 pagesKNC 1101 Chemical Engineering Laboratory I Experiment ManualIzzatiHazwaniNo ratings yet

- Cascade ControlDocument20 pagesCascade Controlthesimpleguy6No ratings yet

- Two Tank MPCDocument39 pagesTwo Tank MPCEdo RossNo ratings yet

- Tutorial For Pressure Relief Valve Load Analysis Using CAEPIPEDocument6 pagesTutorial For Pressure Relief Valve Load Analysis Using CAEPIPEAtanasioNo ratings yet

- Rotary Pendulum Workbook - Instructor - PDFDocument60 pagesRotary Pendulum Workbook - Instructor - PDFLillyane RodriguesNo ratings yet

- 4 On Off Level ControlDocument4 pages4 On Off Level ControlAdrian AmadorNo ratings yet

- Design of State Feedback Controller and Observer Using MatlabDocument6 pagesDesign of State Feedback Controller and Observer Using MatlabYashwant MosesNo ratings yet

- Lab ReportDocument13 pagesLab ReportHemal MenukaNo ratings yet

- Application of Fuzzy Controller in Drum Water-Level Control: Zhuo Wang Qiang WangDocument3 pagesApplication of Fuzzy Controller in Drum Water-Level Control: Zhuo Wang Qiang WangGnana Prakash JanarthananNo ratings yet

- Simo MisoDocument13 pagesSimo MisoAndres RodriguezNo ratings yet

- 2 DOF Robot Workbook - QUARC (Student) PDFDocument33 pages2 DOF Robot Workbook - QUARC (Student) PDFRobcib UpmNo ratings yet

- Water Mixing Tank Problem Richard E. Rangel Alarcon, M.EDocument8 pagesWater Mixing Tank Problem Richard E. Rangel Alarcon, M.Eelias muñozNo ratings yet

- Control Lab ReportDocument11 pagesControl Lab ReportMariamMunirAhmad100% (1)

- ET401 Lab Self-Regulating Single Tank Level Control: Modeling and Tuning Profs Sarnacki, Owen, Olivari, Tefft Fall 2019Document4 pagesET401 Lab Self-Regulating Single Tank Level Control: Modeling and Tuning Profs Sarnacki, Owen, Olivari, Tefft Fall 2019essameldinNo ratings yet

- 6 Process Modeling Equations: Kpe τ ps +1 Kpe τ S+1 θ τDocument5 pages6 Process Modeling Equations: Kpe τ ps +1 Kpe τ S+1 θ τGarabigNo ratings yet

- Experiment (1) Calibration and Characteristics of A Motorized ValveDocument41 pagesExperiment (1) Calibration and Characteristics of A Motorized ValveKhalid M MohammedNo ratings yet

- Series & Parallel PumpDocument14 pagesSeries & Parallel PumpDivaan Raj Karunakaran100% (3)

- Jeas 1121 8737Document7 pagesJeas 1121 8737monse369No ratings yet

- Lab+IV Quanser PDFDocument7 pagesLab+IV Quanser PDFZakNo ratings yet

- PH SystemsDocument12 pagesPH Systemslux0008No ratings yet

- Rotary Pendulum Workbook (Student) PDFDocument39 pagesRotary Pendulum Workbook (Student) PDFLillyane RodriguesNo ratings yet

- Pwp711 Lab 1Document7 pagesPwp711 Lab 1Tumelo ArnatNo ratings yet

- Coupled Tank - MPCDocument6 pagesCoupled Tank - MPCMutiara PurnamaNo ratings yet

- LLE Operating ManualDocument6 pagesLLE Operating ManualMenwer AttarakihNo ratings yet

- Fixed Bed Adsorption Column M7Document3 pagesFixed Bed Adsorption Column M7Mayank VashishthaNo ratings yet

- SRV02 WorkbookDocument88 pagesSRV02 WorkbookMikayel Aghajanyan0% (1)

- Lab 2Document14 pagesLab 2Madhumita KumarNo ratings yet

- Lab ManualDocument75 pagesLab ManualaathiraNo ratings yet

- Control System: AssessmentDocument9 pagesControl System: AssessmentAbdullahNo ratings yet

- Apc&sct Cie-1Document3 pagesApc&sct Cie-1Dhanush M HNo ratings yet

- Flexible Joint Workbook - InstructorDocument57 pagesFlexible Joint Workbook - InstructorGabriel SaldanhaNo ratings yet

- Prelab 3 Response of First and Second Order SystemsDocument7 pagesPrelab 3 Response of First and Second Order SystemsDean Joyce AlborotoNo ratings yet

- Coupled TanksDocument32 pagesCoupled TanksAnkur MondalNo ratings yet

- PCVLDocument16 pagesPCVLabmuqeet2No ratings yet

- Kpe τ ps +1 Kpe τ S+1 θ τ: 6 Process Modeling EquationsDocument6 pagesKpe τ ps +1 Kpe τ S+1 θ τ: 6 Process Modeling EquationsGarabigNo ratings yet

- Two Tank Non-Interacting Liquid Level Control Comparison Using Fuzzy and PSO ControllerDocument8 pagesTwo Tank Non-Interacting Liquid Level Control Comparison Using Fuzzy and PSO Controlleramna aftabNo ratings yet

- Manual For The Distillation Column: Jørgen K. Johnsen June 21, 2005Document12 pagesManual For The Distillation Column: Jørgen K. Johnsen June 21, 2005Abdul Gafoor ShaikhNo ratings yet

- مختبر سيطرهDocument66 pagesمختبر سيطرهKaesar SabahNo ratings yet

- LAB 2: Disturbance Cancellation of Proportional and Integral ControllerDocument4 pagesLAB 2: Disturbance Cancellation of Proportional and Integral Controllerparveet1999No ratings yet

- 02 Labsheet 2 DMC H Rev CDocument11 pages02 Labsheet 2 DMC H Rev Czul hilmiNo ratings yet

- Level Process Station: Instrumentation and Process ControlDocument164 pagesLevel Process Station: Instrumentation and Process Controlgeorge kbeNo ratings yet

- Classical and Modern Control with Worked Examples: International Series on Systems and Control, Volume 2From EverandClassical and Modern Control with Worked Examples: International Series on Systems and Control, Volume 2No ratings yet

- Investigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsFrom EverandInvestigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsNo ratings yet

- Classical and Modern Control with Worked Examples: Pergamon International Library of Science, Technology, Engineering and Social Studies: International Series on Systems and Control, Volume 2From EverandClassical and Modern Control with Worked Examples: Pergamon International Library of Science, Technology, Engineering and Social Studies: International Series on Systems and Control, Volume 2No ratings yet

- Lec4 PDFDocument15 pagesLec4 PDFTahir KhAnNo ratings yet

- RESULT SHEET OF FIFTH SEMESTER (FALL SEMESTER-2021) EXAMINATIONS IN BSC ELECTRONICS ENGINEERING-E19-CHAKWALDocument2 pagesRESULT SHEET OF FIFTH SEMESTER (FALL SEMESTER-2021) EXAMINATIONS IN BSC ELECTRONICS ENGINEERING-E19-CHAKWALTahir KhAnNo ratings yet

- Lec2 PDFDocument18 pagesLec2 PDFTahir KhAnNo ratings yet

- PID Cascade For HVAC System ControlDocument6 pagesPID Cascade For HVAC System ControlTahir KhAnNo ratings yet

- E. Ambikairajah Australia: Part B: Transform MethodsDocument47 pagesE. Ambikairajah Australia: Part B: Transform MethodsTahir KhAnNo ratings yet

- Lec 5Document18 pagesLec 5Tahir KhAnNo ratings yet

- E. Ambikairajah Australia: Part A: Signal ProcessingDocument152 pagesE. Ambikairajah Australia: Part A: Signal ProcessingTahir KhAnNo ratings yet

- DSP9 PDFDocument66 pagesDSP9 PDFTahir KhAnNo ratings yet

- E. Ambikairajah Australia: Part B: Transform MethodsDocument49 pagesE. Ambikairajah Australia: Part B: Transform MethodsTahir KhAnNo ratings yet

- E. Ambikairajah Australia: Part A: Chapter 3 (C) : Digital Signal ProcessingDocument52 pagesE. Ambikairajah Australia: Part A: Chapter 3 (C) : Digital Signal ProcessingTahir KhAnNo ratings yet

- E. Ambikairajah Australia: Chapter 3 (B) : Digital Signal ProcessingDocument121 pagesE. Ambikairajah Australia: Chapter 3 (B) : Digital Signal ProcessingTahir KhAnNo ratings yet

- DSP2 PDFDocument92 pagesDSP2 PDFTahir KhAnNo ratings yet

- E. Ambikairajah Australia: Introduction To Z-TransformDocument71 pagesE. Ambikairajah Australia: Introduction To Z-TransformTahir KhAnNo ratings yet

- DLD lAB FINALDocument4 pagesDLD lAB FINALTahir KhAnNo ratings yet

- B.SC MathematicsDocument37 pagesB.SC MathematicsMarikannan GNo ratings yet

- Questions That Students Recollected Post The Test. DisclaimerDocument38 pagesQuestions That Students Recollected Post The Test. DisclaimerSothku Sravan100% (1)

- Module Seven Honors Guided NotesDocument5 pagesModule Seven Honors Guided NotesJazmyn DavisNo ratings yet

- Lecture Notes On: Department of Computer Science & Engineering Jaipur Engineering College & Research Centre, JaipurDocument32 pagesLecture Notes On: Department of Computer Science & Engineering Jaipur Engineering College & Research Centre, JaipurKunallNo ratings yet

- Presentation PPT Financial EngineeringDocument21 pagesPresentation PPT Financial EngineeringYassine MerizakNo ratings yet

- Choice of The Weight FunctionDocument1 pageChoice of The Weight FunctionCosmo FanaNo ratings yet

- Basic Cash Formulas Manual April 2009 - 2.8Document123 pagesBasic Cash Formulas Manual April 2009 - 2.8horns2034No ratings yet

- 08 Exponential ExpressionsDocument10 pages08 Exponential ExpressionsFranz Julian Arenasa PiscosNo ratings yet

- Component InterfacesDocument29 pagesComponent InterfacesSatish SriramojiNo ratings yet

- MATH 106 MidtermDocument24 pagesMATH 106 MidtermSandro SerdiñaNo ratings yet

- Std11 Maths EM 1Document271 pagesStd11 Maths EM 1Hariprasad ManoharanNo ratings yet

- Transform Calculus Module 1: Laplace Transform: Basic ConceptsDocument7 pagesTransform Calculus Module 1: Laplace Transform: Basic ConceptsYellasiri Sangeetha100% (1)

- Lesson 5.6 Algebra TwoDocument6 pagesLesson 5.6 Algebra Twohoudini4No ratings yet

- PlotDocument34 pagesPlottjjy7k2fctNo ratings yet

- Ravi Pyspark RDD Tutorial 1665758938Document20 pagesRavi Pyspark RDD Tutorial 1665758938Sree KrithNo ratings yet

- Functions SLDocument22 pagesFunctions SLarvindshukla123No ratings yet

- Block-2 MCSE-004 Unit-1Document20 pagesBlock-2 MCSE-004 Unit-1Himanshu RawatNo ratings yet

- Probability Theory Lecture Notes 03Document3 pagesProbability Theory Lecture Notes 03Xing QiuNo ratings yet

- Logical FunctionsDocument14 pagesLogical FunctionsHamham LidasanNo ratings yet

- Principles of Communication Systems by Taub and Schilling - Text PDFDocument119 pagesPrinciples of Communication Systems by Taub and Schilling - Text PDFMurugeswari EswariNo ratings yet

- BTECH CSE 4th SemesterDocument18 pagesBTECH CSE 4th SemesterAdityaNo ratings yet

- SMK Sentosa Yearly Lesson Plan 2019 Mathematics Form 2Document17 pagesSMK Sentosa Yearly Lesson Plan 2019 Mathematics Form 2IffahJusohNo ratings yet

- P1 Complete BookDocument403 pagesP1 Complete Bookasheralt3791No ratings yet

- j.1467-9787.1966.tb01311.x Quandt BaumolDocument14 pagesj.1467-9787.1966.tb01311.x Quandt Baumolsaid basalimNo ratings yet

- IP Assignment 1 2022Document17 pagesIP Assignment 1 2022TemphuNo ratings yet

- fx-220 PLUS fx-85MS fx-82MS fx-300MS fx-350MS: (2nd Edition / S-V.P.A.M.)Document52 pagesfx-220 PLUS fx-85MS fx-82MS fx-300MS fx-350MS: (2nd Edition / S-V.P.A.M.)Nicat NezirovNo ratings yet

- Multi Variable Calculus NotesDocument105 pagesMulti Variable Calculus NotesmuhammadtalNo ratings yet