Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

67 viewsDefine Work

Define Work

Uploaded by

carlos juarezThis document contains questions and answers about work systems and productivity. Some key points:

- Work involves physical and mental effort to accomplish tasks. Time is the most common measure of work as most workers are paid hourly wages.

- Productivity is a measure of output relative to inputs like labor, capital, and technology. Capital and technology are generally more important than labor for improving productivity.

- Work systems can involve manual labor, worker-machine systems, or automation. Setting standards and measuring work helps evaluate jobs and payment systems.

- Sequential work flows involve processing steps in order. Bottlenecks and starving/blocking can occur. Batch processing groups work units but causes delays between batches.

Copyright:

© All Rights Reserved

Available Formats

Download as TXT, PDF, TXT or read online from Scribd

You might also like

- Airbus ISI IN-SERVICE RELIABILITY DATA REPORTINGDocument26 pagesAirbus ISI IN-SERVICE RELIABILITY DATA REPORTINGandrinjoNo ratings yet

- Meggitt Wheels and Brakes SyllabusDocument1 pageMeggitt Wheels and Brakes Syllabusben folds100% (1)

- Answers To ProblemsDocument23 pagesAnswers To ProblemsYuvahraani Ravichandran100% (4)

- Aircraft Cabin Interior System - AssignmentDocument2 pagesAircraft Cabin Interior System - AssignmentDamon Leong0% (1)

- Fire Code 2013 PDFDocument1,033 pagesFire Code 2013 PDFKo PaukNo ratings yet

- Ch01 Introduction SDocument5 pagesCh01 Introduction Sa.mNo ratings yet

- Assignment o Tom at I OnDocument22 pagesAssignment o Tom at I OnphyrdowsNo ratings yet

- Benefit Cost Ratio Analysis and Payback PeriodDocument20 pagesBenefit Cost Ratio Analysis and Payback Periodfadhillah ivanNo ratings yet

- Steady State Analysis of PMSG PDFDocument16 pagesSteady State Analysis of PMSG PDF1balamanianNo ratings yet

- MCQDocument21 pagesMCQSangeetha MothilalNo ratings yet

- Automobile Air Condition System Using Exahust GasDocument19 pagesAutomobile Air Condition System Using Exahust GasEr. Ramji TripathiNo ratings yet

- Chapter 5 KeyDocument11 pagesChapter 5 KeyBeliz GüneyNo ratings yet

- Lecture 5 Reliability Tools & TechniquesDocument77 pagesLecture 5 Reliability Tools & TechniquesNaji HayderNo ratings yet

- Engineering Economics FINAL Exam 2008 No SLTNDocument3 pagesEngineering Economics FINAL Exam 2008 No SLTNRetno Tri HastutiNo ratings yet

- IS 16046 (PT 1,2)Document1 pageIS 16046 (PT 1,2)poseidonNo ratings yet

- Advance Welding - Syllabus (KME-055)Document3 pagesAdvance Welding - Syllabus (KME-055)Shashank DwivediNo ratings yet

- Chapter 8Document4 pagesChapter 8Min ZenNo ratings yet

- Assembly Line Design FinalDocument21 pagesAssembly Line Design FinalManas RaneNo ratings yet

- Chapter 4 - Lecture Notes PDFDocument23 pagesChapter 4 - Lecture Notes PDFHerna Kartika AfandiNo ratings yet

- Case Study Adaptive Cruise ControlDocument15 pagesCase Study Adaptive Cruise ControlsarathkumarNo ratings yet

- A320 Loss of ControlDocument54 pagesA320 Loss of ControltugayyoungNo ratings yet

- 105 Tool Box Talk (Bangla)Document111 pages105 Tool Box Talk (Bangla)Jubair Ibna JubarajNo ratings yet

- Assignment 1Document7 pagesAssignment 1Ann Coleen KayNo ratings yet

- Test in The Safety PDFDocument35 pagesTest in The Safety PDFJaber Al JafarNo ratings yet

- Workshop SafetyDocument60 pagesWorkshop SafetyAkuru AdinoyNo ratings yet

- Chap 4 - (Determination of State of Damage)Document34 pagesChap 4 - (Determination of State of Damage)Muket AgmasNo ratings yet

- 3021 - 07 Predetermined Time SystemsDocument37 pages3021 - 07 Predetermined Time Systemssunilkjain6105100% (1)

- Applications of Artificial Intelligence in Mechanical EngineeringDocument44 pagesApplications of Artificial Intelligence in Mechanical EngineeringAtif RaziNo ratings yet

- TQM KahootDocument5 pagesTQM KahootGEJENDHIRAN SNo ratings yet

- Foreign Object DebrisDocument22 pagesForeign Object Debrishari sasongkoNo ratings yet

- An Introduction To Fault Tree Analysisi (FTA)Document18 pagesAn Introduction To Fault Tree Analysisi (FTA)erwingontekNo ratings yet

- Ergonomics Product Design PDFDocument2 pagesErgonomics Product Design PDFTiffany0% (2)

- Event Tree AnalysisDocument16 pagesEvent Tree AnalysisAMOL RASTOGI 19BCM0012No ratings yet

- 1 Introduction PDFDocument60 pages1 Introduction PDFAnmolNo ratings yet

- 23 14 SA V1 S1 - Agv Ass2Document5 pages23 14 SA V1 S1 - Agv Ass2Gaurav KhandelwalNo ratings yet

- Project Management: Discussion QuestionsDocument36 pagesProject Management: Discussion QuestionsMarlett SJ UnoNo ratings yet

- Lathe MachineDocument9 pagesLathe MachineSteven Josh bernalNo ratings yet

- Quiz QuestionaireDocument4 pagesQuiz QuestionaireDHARMAARJUN K 1828010No ratings yet

- 2.0 NetworkDocument24 pages2.0 NetworkChinta QaishyNo ratings yet

- Assignment 2: Problem 1Document3 pagesAssignment 2: Problem 1musicslave960% (1)

- (MCQ'S) Production Planning and Control 4 - Last Moment TuitionsDocument6 pages(MCQ'S) Production Planning and Control 4 - Last Moment TuitionsHVFTOOLS HVFNo ratings yet

- Occupational Health and Safety Test 1 - MemorandumDocument8 pagesOccupational Health and Safety Test 1 - MemorandumJimmy MerlaNo ratings yet

- Disable Activation - CMDDocument1 pageDisable Activation - CMDعرفأن توفيقNo ratings yet

- N Jobs and M - Machine ProblemDocument9 pagesN Jobs and M - Machine ProblemHarsha KasaragodNo ratings yet

- Segway (2 Wheel Balancing Vehicle) : Project Report: in Partial Fulfilment For The Award of TheDocument31 pagesSegway (2 Wheel Balancing Vehicle) : Project Report: in Partial Fulfilment For The Award of ThemadhurNo ratings yet

- Safety ManagementDocument33 pagesSafety ManagementJaypee Bucatcat100% (3)

- Chartered Engineer Royal Aeronautical Society Ceng Chartered Engineer MraesDocument42 pagesChartered Engineer Royal Aeronautical Society Ceng Chartered Engineer MraesManju ShreeNo ratings yet

- Solutions of Right Triangle (Lecture)Document20 pagesSolutions of Right Triangle (Lecture)May-ann PangisbanNo ratings yet

- ICAO DOC 9870 App PDFDocument10 pagesICAO DOC 9870 App PDFpasargad135106No ratings yet

- Emergency Response Plan SampleDocument22 pagesEmergency Response Plan SampleHubert Lindenthaler100% (1)

- Welcome To The Course: Work StudyDocument81 pagesWelcome To The Course: Work StudyAnantbhushan NavelkarNo ratings yet

- Bank of Essay QuestionsDocument2 pagesBank of Essay Questionssiti hasanahNo ratings yet

- CHAPTER-1 Introduction To Aircraft DrawingDocument12 pagesCHAPTER-1 Introduction To Aircraft DrawingGhifaris VashaNo ratings yet

- Ch02 Manual WorkDocument41 pagesCh02 Manual Workfaisalf155mNo ratings yet

- Chapter 13Document10 pagesChapter 13Bryan Andrés Peláez0% (1)

- Work Centre Cumulative LoadDocument42 pagesWork Centre Cumulative LoadMalvika KapoorNo ratings yet

- C0362015022 PDFDocument8 pagesC0362015022 PDFtheijesNo ratings yet

- Charts/Diagram PurposeDocument103 pagesCharts/Diagram Purposemchiranthan3No ratings yet

- Chapter 5: Motion StudyDocument44 pagesChapter 5: Motion StudyBaleje JeremyNo ratings yet

- PPC 2 MarksDocument23 pagesPPC 2 MarksRavi Rajan100% (1)

- Azure VMDocument3 pagesAzure VMcarlos juarezNo ratings yet

- Azure VMsDocument2 pagesAzure VMscarlos juarezNo ratings yet

- CLP - MFDM™Document2 pagesCLP - MFDM™carlos juarezNo ratings yet

- Quiz FinalDocument5 pagesQuiz Finalcarlos juarezNo ratings yet

- Question AnswerDocument4 pagesQuestion Answercarlos juarezNo ratings yet

- RBACDocument3 pagesRBACcarlos juarezNo ratings yet

- Deposit Liquidity Waiting Periods: Securitization SecurityDocument2 pagesDeposit Liquidity Waiting Periods: Securitization Securitycarlos juarezNo ratings yet

- UsabilityDocument3 pagesUsabilitycarlos juarezNo ratings yet

- RTMSDocument12 pagesRTMSRodney MacansantosNo ratings yet

- WSP - Do Not Offload - WSP - Do Not Offload - WSP - Do Not Offload - WSPDocument1 pageWSP - Do Not Offload - WSP - Do Not Offload - WSP - Do Not Offload - WSPTrần ToànNo ratings yet

- DLT 5187.2-2004Document43 pagesDLT 5187.2-2004Erlito SuperalNo ratings yet

- Đề Thi Học Kỳ 1 - Môn Tiếng Anh Lớp 12 - THPT Chuyên Thái Nguyên - File Word Có Lời Giải (Đề Hay)Document12 pagesĐề Thi Học Kỳ 1 - Môn Tiếng Anh Lớp 12 - THPT Chuyên Thái Nguyên - File Word Có Lời Giải (Đề Hay)Huyền KhánhNo ratings yet

- Wheels - Four Wheel Alignment PDFDocument5 pagesWheels - Four Wheel Alignment PDFFlorin CostinNo ratings yet

- Limited Slip Differentials: Type-Rs Type-MzDocument4 pagesLimited Slip Differentials: Type-Rs Type-MzBart Verger RodriguezNo ratings yet

- Mondeo5EU2019 Cel151Document78 pagesMondeo5EU2019 Cel151zajacmarcinNo ratings yet

- Japan Airlines 8054 ANC 1977Document77 pagesJapan Airlines 8054 ANC 1977GFNo ratings yet

- NPA Written Assessment AURLTD106Document26 pagesNPA Written Assessment AURLTD106madhu8966No ratings yet

- Ferdinand Magellan's Fatal Voyage of Discovery: Story, Timeline & Facts - HistoryExtraDocument13 pagesFerdinand Magellan's Fatal Voyage of Discovery: Story, Timeline & Facts - HistoryExtraFredNo ratings yet

- Front Track Roller Frame - Install CAT D9TDocument5 pagesFront Track Roller Frame - Install CAT D9Tiwan nawiNo ratings yet

- Paris Charges SUVs More - B1 News LessonDocument7 pagesParis Charges SUVs More - B1 News LessonBarbariskovna IriskaNo ratings yet

- Motor Insurance - Goods Carrying Comprehensive PolicyDocument3 pagesMotor Insurance - Goods Carrying Comprehensive PolicyPawan KumarNo ratings yet

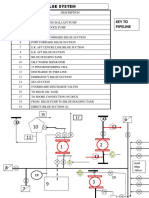

- Key To Pipeline: Bilge SystemDocument23 pagesKey To Pipeline: Bilge SystemvivekNo ratings yet

- Electric Drives: ELL332 Semester II Academic Year 2022-23Document28 pagesElectric Drives: ELL332 Semester II Academic Year 2022-23amogh agrawalNo ratings yet

- CDI4 Traffic-Mgmnt-and-Accident-Invst-w-Driving-HandoutsDocument52 pagesCDI4 Traffic-Mgmnt-and-Accident-Invst-w-Driving-HandoutsKUYA JM PAIRESNo ratings yet

- Baldwin FUELWATER SEPARATOR SPIN-ONSDocument12 pagesBaldwin FUELWATER SEPARATOR SPIN-ONSahmedalgaloNo ratings yet

- Referensi Unaccompanied 1Document38 pagesReferensi Unaccompanied 1Tegar Dwi PriambodoNo ratings yet

- Ca Panel2009 2010 - 0Document62 pagesCa Panel2009 2010 - 0Ritwik BatraNo ratings yet

- Contest Cars 400 Great Models (IMRAN HOSSAIN) (Z-Library)Document108 pagesContest Cars 400 Great Models (IMRAN HOSSAIN) (Z-Library)gla488No ratings yet

- Parts-Catalogue Adv-160 2023Document108 pagesParts-Catalogue Adv-160 2023Hamizul HassanNo ratings yet

- D375A-5, 18188 (Report)Document19 pagesD375A-5, 18188 (Report)asim ghoshNo ratings yet

- Husqvarna GTH 27V48LS OwnMan (EN)Document44 pagesHusqvarna GTH 27V48LS OwnMan (EN)Gisell ZapataNo ratings yet

- Rasier 19pt Inspection FormDocument1 pageRasier 19pt Inspection Formladysvictoria22No ratings yet

- Proton Waja 2000 MYhhDocument3 pagesProton Waja 2000 MYhhWadea BotrosNo ratings yet

- OEG Offshore - 10ft Half Height (With Side Door) - DatasheetDocument1 pageOEG Offshore - 10ft Half Height (With Side Door) - DatasheetDaniel WallNo ratings yet

- 4.LOBBY FLOOR PLAN-Layout1Document1 page4.LOBBY FLOOR PLAN-Layout1farouk 2017No ratings yet

- Dokumen - Tips - Sname Ship Design ConstructionDocument419 pagesDokumen - Tips - Sname Ship Design ConstructionCarlos SotoNo ratings yet

- DHP85, M65D: Hydraulic Pile Driving RigDocument17 pagesDHP85, M65D: Hydraulic Pile Driving Rigsasa100% (1)

- Bds en 15273 2 2013 Railway Applications Gauges Part 2 RolliDocument314 pagesBds en 15273 2 2013 Railway Applications Gauges Part 2 RolliДимитър Жеков100% (1)

Define Work

Define Work

Uploaded by

carlos juarez0 ratings0% found this document useful (0 votes)

67 views26 pagesThis document contains questions and answers about work systems and productivity. Some key points:

- Work involves physical and mental effort to accomplish tasks. Time is the most common measure of work as most workers are paid hourly wages.

- Productivity is a measure of output relative to inputs like labor, capital, and technology. Capital and technology are generally more important than labor for improving productivity.

- Work systems can involve manual labor, worker-machine systems, or automation. Setting standards and measuring work helps evaluate jobs and payment systems.

- Sequential work flows involve processing steps in order. Bottlenecks and starving/blocking can occur. Batch processing groups work units but causes delays between batches.

Original Description:

Original Title

Define work

Copyright

© © All Rights Reserved

Available Formats

TXT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document contains questions and answers about work systems and productivity. Some key points:

- Work involves physical and mental effort to accomplish tasks. Time is the most common measure of work as most workers are paid hourly wages.

- Productivity is a measure of output relative to inputs like labor, capital, and technology. Capital and technology are generally more important than labor for improving productivity.

- Work systems can involve manual labor, worker-machine systems, or automation. Setting standards and measuring work helps evaluate jobs and payment systems.

- Sequential work flows involve processing steps in order. Bottlenecks and starving/blocking can occur. Batch processing groups work units but causes delays between batches.

Copyright:

© All Rights Reserved

Available Formats

Download as TXT, PDF, TXT or read online from Scribd

Download as txt, pdf, or txt

0 ratings0% found this document useful (0 votes)

67 views26 pagesDefine Work

Define Work

Uploaded by

carlos juarezThis document contains questions and answers about work systems and productivity. Some key points:

- Work involves physical and mental effort to accomplish tasks. Time is the most common measure of work as most workers are paid hourly wages.

- Productivity is a measure of output relative to inputs like labor, capital, and technology. Capital and technology are generally more important than labor for improving productivity.

- Work systems can involve manual labor, worker-machine systems, or automation. Setting standards and measuring work helps evaluate jobs and payment systems.

- Sequential work flows involve processing steps in order. Bottlenecks and starving/blocking can occur. Batch processing groups work units but causes delays between batches.

Copyright:

© All Rights Reserved

Available Formats

Download as TXT, PDF, TXT or read online from Scribd

Download as txt, pdf, or txt

You are on page 1of 26

Final Exam

1.1 Define work.

an activity in which a person exerts physical and mental effort to accomplish a

given task or perform a duty

1.2 What are basic motion elements? Give some examples.

actuations of the limbs and other body parts while engaged in performing the task;

reaching for an object, grasping an object, or moving an object

1.3 What is a work element?

a series of work activities that are logically grouped together because they have a

unified function within the task

1.4 Why is time important in work?

the most frequently used measure of work is time, most workers are paid according

to the amount of time they work (hourly wages), workers must arrive at work on

time, incentive plans are based on how much time workers can save relative to the

standard time for a given task, labor and staffing requirements are computed using

workloads measured in units of time

1.5 Define work system as a physical entity.

a system consisting of humans, information, and equipment that is designed to

perform useful work

1.6 Define work system as a field of professional practice.

includes (1) work methods, (2) work measurement, (3) work management

1.7 What are some of the functions included within the scope of work management?

various organizational and administrative functions that must be accomplished to

achieve high productivity of the work system and effective supervision of workers

i) organizing workers to perform the specialized tasks that constitute the

workload in each department of the company

ii) motivating workers to perform the tasks

iii) evaluating the jobs in the organization so that each worker is paid an

appropriate wage or salary commensurate with the type of work performed

iv) appraising the performance of workers to reward better-performing workers

appropriately

v) compensating workers using a rational payment system for the work they

perform

1.8 Name the four broad categories of worker occupations. production workers

logistics workers service workers knowledge workers

1.9 Define productivity.

the level of output of a given process relative to the level of input

1.10 Labor is one input factor that determines productivity. What are two other

factors that are more important than labor in improving productivity? Define each

of these two additional input factors.

capital – the substitution of machines for human labor

technology – a fundamental change in the way some activity or function is

accomplished

1.11 What is the difference between the labor productivity ratio and the labor

productivity index?

index compares the LPR’s of a specified time period of interest and that of a

defined base period

1.12 A given task performed by a worker can be considered to consist of the basic

productive work content and excess nonproductive activities. (a) What is meant by

the term basic productive work content? (b) What is meant by the term excess

nonproductive activities?

basic productive work content – the theoretical minimum amount of work

required to accomplish a task, where the amount of work is expressed in terms of

time

excess nonproductive activities – the extra physical and mental actions

performed by the worker that do not add any value to the task, nor do they

facilitate the productive work content that does add value

1.13 What are the three categories of excess nonproductive activities, as they are

defined the in the text? excess activities caused by:

1. poor design of the product or service

2. inefficient methods, poor work layout, and interruptions

3. the human factor

Manual Work and Worker-Machine Systems

2.1 In terms of human participation, what are the three basic categories of work

systems?

1. manual work systems

2. worker-machine systems

3. automated systems

2.2 What is the general characteristic that is common to nearly all pure manual

work?

consists of moving things, almost always involves the movement and handling of

objects

2.3 What is the one best method principle?

of all the possible methods that can be used to perform a task, there is one

optimal method that minimizes the time and effort required to accomplish it

2.4 What is meant by the term normal performance? (or normal pace)

a pace of working that can be maintained by a properly trained worker throughout an

entire work shift without deleterious short-term or long-term effects on the

worker’s health or physical well- being

2.5 What is meant by the term normal time for a task?

when a work cycle is performed at 100% performance, the time taken is called the

normal time

2.6 What does PFD stand for? What is the purpose of the PFD allowance in

determining the standard time for a task?

Personal time, Fatigue, Delay allowance

accounts for rest breaks and delays in workers performance throughout the shift

2.7 What is an irregular work element?

elements performed with a frequency of less than once per cycle (i.e. changing a

knife blade, replacing parts when they become full, etc.)

2.8 Define the meaning of worker efficiency.

amount of work accomplished during the shift expressed as a proportion of the shift

hours

2.9 What is a worker-machine system?

when a worker operates powered equipment

2.10 What are the three main categories of powered machinery in worker-machine

systems?

1. portable power tools

2. mobile powered equipment

3. stationary powered machines

2.11 Define machine tool.

stationary power-driven machine that shapes or forms parts (i.e. turning, drilling,

forging, etc.)

2.12 Cycle times in worker-machine systems divide into two categories: (1) machine

time depends on operator and (2) machine time is constant and repetitive. Give an

example of each category.

(1) machine time depends on operator – can either be repetitive on nonrepetitive

(i.e. a typist typing a list of names and telephone numbers on a conventional

electric typewriter, or a trucker driving a tractor-trailer on a interstate

highway)

(2) machine time is constant and repetitive – the operator allows constant

machine time to complete work cycle

2.13 What is the difference between an external work element and an internal work

element in a worker- machine cycle?

external work elements – operator elements that are performed sequentially

internal work elements – elements are performed simultaneously with the machine

cycle

2.14 What are the factors that affect the workload calculation when determining

worker requirements?

1. worker efficiency

2. defect rate

3. learning curve phenomenon

2.15 What does availability mean?

the proportion of time the equipment is available to run relative to the total time

it could be used

2.16 What is a machine cluster?

a collection of two or more machines producing parts or products with identical

cycle times and serviced by one worker

Work Flow and Batch Processing

3.1 What does sequential operations mean?

work system in which multiple processing steps are accomplished in order to

complete a work unit, and the processing steps are performed sequentially not

simultaneously

3.2 What is a precedence constraint in sequential operations?

limitations on the order in which the operations can be performed

3.3 What is the difference between pure sequential work flow and mixed sequential

work flow?

pure sequential work flow – all work units follow the same exact sequence of

workstations and operations

mixed sequential work flow – there are variations in the work flow for

different work units, the work units are processed through different stations

3.4 Name and define the four types of part moves between workstations in

sequential operations.

1. in-sequence – a transport of the work unit from the current operation to the

neighboring operation immediately downstream, a move in the forward direction in

the sequence

2. bypassing – a move in the forward direction but beyond the neighboring

workstation by two or more stations ahead of the current station

3. backflow – a move of the work unit in the backward direction by one of more

stations

4. repeat operation – an operation that is repeated at the same workstation;

this might imply that several attempts are required to complete the operation, or

that two (or more) operations are performed at the same station and the operations

must be separated for some reason

3.5 What is a From-To chart?

table that can be used to indicate various quantitative relationships between

operations or workstations in a multistation work system quantities of work units

moving between operations or workstations = Qij flow rates of materials moving

between operations or workstations = Rfij distances between workstations = Lij

combinations of these values = RfijLij

3.6 What is a bottleneck in sequential operations?

the slowest operation which limits the overall production rate

3.7 What do the terms starving and blocking mean in terms of sequential

operations?

starving – the production rate of one of more downstream operations are

limited by the rate of an upstream operation (i.e. the bottleneck)

blocking – the production rate of one or more upstream operations are limited

by the rate of a downstream operation

3.8 What does the term batch processing mean?

processing of work units in finite quantities or amounts

3.9 What are some of the disadvantages of batch processing?

delays occur between processing steps because multiple batches are competing for

the same equipment, which results in long lead-times to complete the work units and

the accumulation of large quantities of work units

3.10 Given the disadvantages of batch production, what are the reasons why it is

so widely used in industry?

work unit differences (make changes in the methods, tooling, etc. between batches)

equipment limitations (size capacity of equipment)

material limitations (must be processed as a unit and later divided into multiple

units)

3.11 What are the two cost terms in the economic order quantity model? set up cost

Cu and holding (carrying) cost Ch

3.12 Write the equation that describes the relationship between the starting

quantity of work units Q0, the completed quantity Q, and the fraction defect rate q

of the operation processing the work units.

Q=Q0(1-q)

3.14 What is a work cell?

group of workstations dedicated to the processing of a range of work units within a

given type

3.15 What is a worker team?

a group of employees who work together to achieve common objectives

3.16 Define teamwork.

the collective skills and efforts of the team members exceed the sum of their

individual skills and efforts

3.17 What is the difference between a work-unit team and a self-managed work team?

work-unit team – have little autonomy and are basically a unit in the

traditional hierarchical structure of the little organization

self-managed work team – perform the work of the unit, plan and manage it;

higher level of worker involvement and empowerment

3.18 What is cross-training and what is its value in a worker team?

workers become trained in more than one job in the work cell, which mitigates

problems of absences and allows for job rotations to increase work variety and

employee satisfaction

3.19 Name some examples of cross-functional teams.

members are drawn from different functional departments in the organization

1. concurrent engineering teams – development and design of a new product

2. task forces – constituted to deal with an urgent problem or immediate

commercial opportunity confronting the organization

3. crisis management – form of task force intended to cope with a particular

crisis or disaster faced by the organization (i.e. loss of key personnel, floods,

hurricanes, terrorist attacks, and liability lawsuits)

4 Manual Assembly Lines

4.1 What is a manual assembly line?

production line that consists of a sequence of workstations where assembly tasks

are performed by human workers

4.2 What are the factors that favor the use of manual assembly lines?

demand for the product is high or medium

the products made on the line are identical or similar

the total work required to assemble the product can be divided into small

work elements

it is technologically impossible or economically infeasible to automate the

assembly operations

4.3 What are the reasons why manual assembly lines are so productive compared to

alternative methods of assembly?

1. specialization of labor

2. interchangeable parts

3. work flow

4. line pacing

4.4 What does the term manning level mean in the context of a manual assembly

line? number of workers assigned to that station

4.5 What are utility workers on a manual assembly line?

additional workers who are responsible for functions such as

1. helping workers who fall behind

2. relieving workers for personal break

3. maintenance and repair duties (not assigned to specific workstations)

4.6 What is starving on a manual assembly line?

assembly operator has completed the assigned task on the current work unit, but the

next unit has not yet arrived at the station

4.7 What is blocking on a manual assembly line?

the operator has completed the assigned task on the current work unit but cannot

pass the unit to the downstream station because that worker is not yet ready to

receive it

4.8 What are the three major categories of work transport in mechanized

production lines?

1. continuous transport

2. synchronous transport

3. asynchronous transport

4.9 What are the two types of line that can be designed to cope with product

variety? What is the difference between them?

single model – produces many units of one product and no variation in the product

batch model – produces products in batches

4.10 What does work content time mean?

total time of all work elements that must be performed to make one unit of the

product

4.11 What are repositioning losses as they are explained in the text?

some time is required each cycle to reposition the work, or the work unit, or both

4.12 What is the line balancing problem in the design of a manual assembly line?

virtually impossible to divide the work content time evenly among all workstations

4.13 What is a minimum rational work element in the context of manual assembly

lines?

a work element that has a specific limited objective on the assembly line, such as

adding a component to the base part, joining two components, etc

4.14 What is a precedence constraint in the context of manual assembly lines? some

elements must be done before others

4.15 What are the three types of efficiency that must be considered in designing

and operating a manual assembly line?

1. line efficiency E

2. repositioning efficiency Er

3. balancing efficiency Eb

4.16 What does tolerance time mean?

the time a work unit spends inside the boundaries of the workstation

4.17 Name the three line balancing algorithms as described in the text.

1. largest candidate rule

2. kilbridge and wester method

3. ranked positional weights method

4.18 What are some of the methods by which assembly line balancing efficiency can

be improved that are outside the scope of the line balancing algorithms?

methods analysis utility workers

preassembly of components storage buffers between stations parallel workstations

5 Logistics Operations

5.1 What is Business Logistics?

The acquisition, movement, storage, and distribution of materials and products, as

well as the planning and control of these operations in order to satisfy customer

demand.

5.2 What is the difference between external logistics and internal logistics?

External logistics are concerned with transportation and related activities that

occur outside of a facility. Internal logistics are concerned with the handling of

materials inside a given facility.

5.3 What are the basic objectives in business logistics? Provide a specified

level of customer service

Deliver the level of service at the lowest possible cost

5.4 Identify the five components of the logistics system.

1. Facilities-where materials and products are produced and stored

2. Inventory-the raw materials, work in progress, and finished products

3. Transportation and material handling-the means by which the inventory is

moved between and with facilities

4. Information system-the collection and processing of data related to

facilities, inventory, transportation and other logistics activities such as order

processing, order tracking and procurement.

5. Logistics workers-the employees who operate and coordinate the other

components of the logistics system.

5.5 With what is the procurement function in logistics concerned?

The acquisition and movement of materials from suppliers to manufacturing plants

that produce parts or assemble products

5.6 What are the four warehousing functions?

1. Receive-the activities associated with handling and controlling incoming

materials to the facility.

2. Store-involves putting the received materials into storage and recording

their respective locations.

3. Pick-order picking- the retrieval of materials from their storage locations

in response to customer orders.

4. Ship-packaging the materials for shipment to the customer, preparing the

required documentation, and loading the materials into the carrier.

5.7 What is cross-docking?

Warehousing operation in which shipments are received from suppliers and the items

are sorted and shipped to their respective destinations without being placed into

storage.

5.8 Name the five basic transportation modes: Rail Transport

Trucking Operations Air Transport

Water Transport Pipelines

5.9 What are the general characteristics of freight that is suited to rail

transport? Give examples of this freight.

Raw materials located away from waterways, agricultural products and low-value

manufactured goods. Ex: coal, ore, lumber, paper, wood products.

5.10 What are the general characteristics of freight that is suited to truck

transport? Give examples of this freight.

High-Value finished and semi-finished products, merchandise that needs to be

transported over short or medium distances. Ex: parts, subassemblies.

5.11 What are the advantages of truck transport over rail transport when the

applications are appropriate for trucking?

Door to door delivery, service availability and frequency and speed of delivery.

5.12 What are the general characteristics of freight that is suited to air

transport?

High-Value items that need to be shipped long distances and time is important.

5.13 What are the applications of pipelines?

Delivery of gasses, water, or slurries over long distances.

5.14 What are intermodal operations?

The use of more than one transportation mode to move materials and products between

suppliers and customers.

5.15 What are freight forwarders?

Companies that consolidate the small shipments of multiple customers into a large

shipment and then transport it by common carrier.

5.16 Give some examples of the distribution of information and entertainment

products by means of the Internet and similar communication-based distribution

modes.

Airline Tickets, Digital distribution of music, Satellite radio, Video-on-demand,

High speed internet access.

5.17 Define material handling:

Transportation operations that occur inside a facility.

5.18 What are the four major categories of material-handling equipment?

Material transport equipment, storage systems, unitizing equipment, identification

and tracking systems.

5.19 What are the five basic types of material transport equipment?

1. Industrial trucks

2. automated guided vehicles

3. monorails

4. conveyors

5. cranes and hoists.

5.20 Why are forklift trucks so widely used in industry?

This is due to the common use of pallets and similar unit load containers for

moving and storing materials.

5.21 What is an automated guided vehicle system? Define the term. Industrial

trucks capable of operation without human drivers.

5.22 How is a monorail different from an automated guided vehicle? Identify two

differences. Picks up its power from an electrified rail as oppose to having its

own power source Usually suspended from the ceiling

5.23 Conveyors can be classified as powered and non-powered. What is the feature

about powered conveyors that distinguishes them from rail-guided vehicles and

automated guided vehicles?

The pathway moves.

5.24 Name some of the major types of powered and non-powered conveyors. Powered-

roller conveyors, belt conveyors

Non-powered-roller conveyors, overhead trolley conveyors

5.25 What are the four conventional (non-automated) storage methods and equipment

types? Bulk storage, Rack systems, shelving, and drawer storage.

5.26 What are the two basic types of automated storage systems? Automated storage/

retrieval system, carousel storage system.

5.27 What are some of the reasons that companies automate the storage function?

Increase storage capacity, increase storage density, recover factory floor space,

improved security, reduce labor cost, improve safety, improve control over

inventory, improve stock rotation, improve customer service, increase throughput.

5.28 What is a carousel storage system?

A series of bins or baskets that suspend from an overhead chain conveyor that

revolves around an oval rail system. Think dry-cleaner.

5.29 What is unitizing equipment? Define what the term means.

Containers used to hold individual items during handling, equipment used to load

and package the containers.

5.30 What are the three drawbacks in manual data collection and entry that

automatic identification and data capture systems tend to eliminate?

Human error, time, cost of labor.

5.31 What is the unit load principle in material handling?

A load consisting of one part, of multiple parts, or multiple containers of parts.

The load should be as large so that it is practical for the transportation option

handling it.

6 Service Operations and Office Work

6.1 What are some of the factors that distinguish services from their products?

Services are intangible, experienced by the customer. Cannot predict time.

6.2 Identify the factors by which the quality of a service is judged by a

customer:

Customer interaction

“Quality of workmanship” provided

waiting time

service time

6.3 Service operations and organizations can be divided into three major

categories. Name these categories:

1. Service organizations

2. internal services

3. Product companies that also provide services

6.4 What is the difference between a facilities-based service and a field-based

service? Facilities-based services occur at the provider’s facility

Field based services occur at the customer’s location

6.5 Give some examples of high-contact services and of low-contact services: High

contact services-restaurants, hairdressers, dental offices, prisons.

Low contact services-postal and parcel delivery, news associations, government

services.

6.6 What are the differences in worker attributes between high-contact services

and low-contact services? High- good interpersonal skills and sense of pr.

Low- technical and analytical skills.

6.7 What are some of the differences between manual work and service work?

Service work usually is the flow of information whereby manual work is the flow of

materials.

6.8 In general, determining time standards for service work is more difficult for

repetitive production work. Why?

Variable service, random arrivals, customer contact, intangible work units,

undefined service, intermittent services, creative work

6.9 Define what an office is:

A place where the business-oriented activities of an organization are transacted

and/or services rendered.

6.10 Define office work:

Business functions such as design, sales, accounting, scheduling, and

administration.

6.11 What is the difference between office activities and office applications?

Office activities are physical and mental actions performed by an office worker.

Office applications are related to the business function i.e. reports.

6.12 Identify some of the differences between creative office work and routine

office work: Creative work- more intellectually difficult and requires special

skills and knowledge. Routine work- repetitive and less difficult

6.13 What are the differences between office knowledge workers and office support

personnel? Knowledge workers- creative information-processing activities

Support Personnel- provide administrative and staff assistance

6.14 Define office automation.

The aspects of a job that can be assigned to a computer.

6.15 Office automation reflects the convergence and integration of three

traditional office technologies. Name the three technologies and identify some of

the equipment in each technology.

1. Office Machine-typewriters, adding machines, dictation machines, photocopiers

2. Data Processing-computers, data storage, printers

3. Communication-telephones and teletype machines.

6.16 Define office augmentation.

The use of computer systems to enhance the abilities of a worker in low-volume

creative work.

7 Projects and Project Management

7.1 What is a project?

A temporary undertaking directed at accomplishing some major output, usually

requiring substantial resources and significant time to complete

7.2 Define project management.

Planning, scheduling, organizing, monitoring, and controlling the project

activities so that the PCTS objectives are achieved to the satisfaction of the

customer or sponsor

7.3 What is the difference between a project and a program?

A program is a very large undertaking, consisting of several projects. So, a

project is a subdivision of a program.

7.4 Identify and briefly describe the five typical phases in a project life

cycle.

1. Concept and feasibility phase - preliminary phase to assess feasibility and

relevance

2. Definition phase - problem definition step

3. Planning phase - detailed planning of the project including work breakdown

4. Execution phase - actual work on the project is accomplished, which consumes

most of the time and cost

5. Closeout - turning over the outcome or product to the customer or sponsor

5. What is the difference between project management and operations management?

Project manager - responsible for the project and the project team

Greater risk than operations manager because operations are concerned with ongoing

activities, whereas a project is unique and temporary

6. Project teams are usually cross-functional. What does cross-functional mean?

Team members are selected from a variety of departments and fields

7. What is a matrix organizational structure and why is it often applicable in

project teams?

This is when team members have functional or operational responsibilities at the

same time they are participating in the project

8. What is project planning?

Concerned with the development of a formal document that will be used to direct the

execution and control of the project

9. What are the three principle uses of the project plan?

1. Document the assumptions and decisions underlying the plan

2. Facilitate communication among those involved

3. Document the PCTS objectives

7.10 What is the work breakdown structure in project planning?

Defines and organizes the project into increasingly more detailed task descriptions

in each descending level of the project hierarchy

7.11 What is project scheduling and what is accomplished by it?

Estimating times for work packages

Determining sequence of work packages

Planning the dates to perform the work packages and meeting milestones

7.12 What is project control concerned with?

Monitoring progress of the work activities

Comparing the progress with the schedule

Taking corrective action when activities are found to be behind schedule

7.13 What are the three project scheduling techniques discussed in the text?

Gantt charts, Critical Path Method (CPM), and Program Evaluation and Review

Technique

(PERT)

7.14 What is a Gantt chart?

A graphical display of scheduled project activities on a time axis

7.15 Describe what is meant by the AON and AOA conventions for diagramming

networks. They are two arrow and node conventions of network diagrams

AON- activity-on-node, used with CPM

AOA- activity-on-arrow, originally used with PERT

7.16 What are the general objectives in both CPM and PERT?

To identify the total time duration of the longest sequence of activities in the

network

7.17 What is the critical path in a CPM or PERT network diagram? The longest path

7.18 What is meant by the term slack time in a CPM or PERT network?

Slack time is the amount of time that the activity can be delayed without delaying

the subsequent activities in the project

7.19 What is the basic difference between PERT and CPM?

CPM uses constant time estimates

PERT uses a probability distribution consisting of the most optimistic, most

likely, and most pessimistic time estimates

7.20 What is project crashing?

When you need to finish a project in less time than the time of the critical path

8 Intro. to Methods Engineering and Operations Analysis

8.1 What is methods engineering?

The analysis and design of work methods and systems including tooling equipment,

technologies, workplace layout, plant layout, and environment used in these methods

and systems.

8.2 What are the principal objectives of methods engineering?

1. To increase productivity and efficiency

2. To reduce cycle time

3. To reduce production costs

4. To reduce labor content

8.3 What is operations analysis?

The study of an operation or group of related operations for the purpose of

analyzing their efficiency and effectiveness so that improvements can be developed

relative to specified objectives.

8.4 What was the operation studied by Frank Gilbreth in his initial research on

motion study? Bricklaying

8.5 What is methods analysis?

The study of an existing method or process, usually by breaking it down into the

work elements or basic operations that comprise it.

8.6 What is methods design?

The design of a new method or the redesign of an existing method or process based

on a preceding methods analysis.

8.7 What are the six steps of the systematic approach in methods engineering?

1. Define the problem and objectives

2. Analyze the problem

3. Formulate Alternatives

4. Evaluate Alternatives and select best

5. Implement the best method

6. Audit the study

8.8 The procedure offered in the text for selecting among alternatives divides

the technical features of proposed equipment alternatives into two categories. What

are the two categories?

Must features and Desirable features.

8.9 What is a histogram?

A statistical graph consisting of bars representing different values in which the

length of each bar is proportional to the frequency or relative frequency.

8.10 What is a Pareto Chart?

A specific histogram where the data is arranged to some criteria.

8.11 What is a check sheet?

A data gathering tool generally used in the preliminary stages of the study of a

problem.

8.12 What is a defect concentration diagram?

A graphical method that has been found to be useful in analyzing the causes of

product or part defects.

8.13 What is a scatter diagram?

An x-y plot of the data taken of the two variables of interest.

8.14 What is a cause and effect diagram?

A graphical tabular chart used to list and analyze the potential causes of a given

problem.

8.15 What does “USA” stand for in the USA principle? Understand, Simplify,

Automate

8.16 What are the three phases in the automation migration strategy?

1. Manual Production

2. Automated Production

3. Automated integrated production

8.17 Why would a company want to use manual production methods instead of

automated methods at the beginning of production of a new product?

It is cheaper, quicker to set up.

9 Charting & Diagramming Techniques for Operations Analysis

9.1 What are the objectives of using charts and diagrams to study work?

1. to permit work process to be communicated and comprehended more readily

2. to allow the use of algorithms specifically designed for the particular

diagramming technique

3. to divide a given work process into its constituent elements for analysis

purposes

4. to provide a structure in the search for improvements

5. to represent a proposed new work process or method

9.2 What are the four methods indicated in the text by which the analyst develops

a description of the work process that is ultimately used to create the graphic?

The analyst is intimately familiar with the process, the analyst observes and

records information about the process, one-on-one interviews of those familiar with

the process, group interviews of those familiar with the process.

9.3 What are the two characteristics of value-added steps in a given process?

the customer considers important, physically change the product or service

9.4 Name some examples of network diagrams:

flow between operations, precedence order in manufacturing

9.5 What are the two types of operations diagrammed in an operation chart?

processing and assembly operations

inspection operations

9.6 Identify the five types of symbols used in a process chart:

O-Operation, I-Inspection, M-Move, D-Delay, S-Storage

9.7 Name the three types of process chart described in the text, and identify the

application area for each:

1. Worker Process Chart- analyzes activities of human worker.

2. Form Process Chart- analyzes the flow of paperwork forms and office

procedures

3. Flow Process Chart- analyzes the flow of materials through a sequence of

activities

9.8 What is a flow diagram?

A drawing of the facility layout but with the addition of lines representing

movement of materials or workers to specific locations in the facility.

9.9 What are some of the problem areas that can be identified using a flow

diagram? travel, congestion, delays, inefficient layout of workstations

9.10 What is an activity chart?

A listing of the work activities of one or more subjects plotted against a time

scale to indicate graphically how much time is spent of each activity.

9.11 Identify some of the types of multiple activity charts:

Right hand/Left hand, Worker-machine, Worker-multi-machine, gang activity chart

9.12 What are the three block symbols used in a basic process map?

oval- starting/ending point, rectangle- task or activity step, diamond- decision

point

10 Motion Study and Work Design

10.1 What is motion study?

Analysis of the basic hand, arm, and body movements of workers as they perform work

10.2 What is work design?

Methods and motions used to perform a task.

10.3 What is a therblig?

A basic motion element- such as: Grasp Hold, etc.

10.4 Identify some of the ineffective therbligs: search, hold

10.5 What is the term sometimes used for the kind of analysis involving therbligs

in a task? micromotion analysis

10.6 What are the general objectives of micromotion analysis?

Eliminate ineffective therbligs, avoid the use of a hand for holding parts, combine

therbligs whenever possible, simply overall method, and reduce time required for

motion.

10.7 Name some of the principles of motion economy that deal with the use of the

two hands:

Both hands should be fully utilized, two hands should begin their motions and end

their motions at the same time, the motions of the hands and arms should be

symmetrical and simultaneous, the worker’s two hands should never be idle at the

same time

10.8 Why are smooth continuous curved motions better than straight line motions

when performing manual work?

When you drastically change an objects direction, it causes the worker to attribute

more force to the object. This effectively increases energy output.

10.9 What is the lowest classification of hand and arm motions? Finger motions

only

10.10 What is the difference between eye-focus and eye-travel?

Eye-focus is only they eye adjusting to change viewing distance; eye-travel is when

the user must change line of sight.

10.11 What advantage does the use of the legs have over the use of the arms?

The legs are stronger than the arms so they should be used for heavy lifting.

10.12 What is gravity feed bin and what is its advantage over a simple tray?

Gravity feed bin uses gravity to position items so that they are easier to reach

for the worker.

10.13 What are the desirable adjustments on a chair designed for the workspace?

seat height, back height, padding, back support, motion

10.14 Why are multiple function tools better than separate tools for each function?

Less time is used to reposition the tool.

11 Facility Layout Planning and Design

11.1 Define the term facility layout.

The size and shape of a facility as well as the relative locations of the

functional areas, equipment, work stations, etc.

11.2 What are the objectives in layout planning?

1. Efficient movement of materials and people

2. Logical work flow and minimum travel distances between operations

3. Efficient utilization of space

4. Safety and satisfaction of workers and others who use the facility

5. Flexibility to meet changing future requirements

6. Advancing the operational mission of the facility

11.3 What is the difference between a process layout and a product layout?

Process- equipment is arranged according to function

Product- workstations are located along the line of flow of work units

11.4 What are some of the principal advantages of a process layout over a product

layout? High product variety, versatility

11.5 What are some of the principal advantages of a product layout over a process

layout? High production rate, high efficiency

11.6 What is a fixed-position layout?

The product remains in one location and the equipment and workers are brought to

it.

11.7 Identify the typical application areas of the three basic layout types in

terms of production quantity and product variety.

Process- variety of parts Product- same part Fixed- Large work units

11.8 What is a cellular layout?

Combines the best features of process and product layouts

11.9 What are the similarities and differences between a construction project

layout and a fixed-position layout?

Construction project layout is temporary because of a scheduled completion date

Product does remain on the site, but workers and equipment vacate upon completion

In both layouts the workers and equipment are brought to the product, but in

construction it is impossible to move the product after completion

11.10 What is the difference between the traditional office layout and the open

office concept?

Traditional – usually an approximation of a process layout in the sense that

the personnel are typically grouped according to functions or departments

Open office – the office layout consists of large open areas in which modular

furniture and partitions rather than permanent walls are used to designate and

separate workstations

11.11 What are the differences between a site layout, a block layout, and a

detailed layout?

Site layout – shows how the building will be located on the property,

indicating position and orientation relative to roads and rail sidings

Block layout – shows the arrangement and sizes of departments in the building

Detailed layout – shows how workstations and equipment are arranged in each

department

11.12 In systematic layout planning, what are the P-Q-R-S-T data requirements?

Specifically, what do P, Q, R, S, and T stand for?

P – product Q – quantity R – routing

S – supporting services

T – time issues

11.13 What are some of the charting techniques used to analyze material flows?

Operations charts, flow process charts, from-to charts

11.14 What do the closeness ratings A, E, I, O, and U mean?

A – absolutely necessary for departments to be next to each other E – especially

important

I – important O – ordinary

U – unimportant

11.15 Identify some of the factors that may influence the assignment of a

particular closeness rating to a pair of departments.

Material flow

Need for contact between personnel

Use of the same equipment sharing of common records Sharing of supervision or tech

support staff

Use of the same utilities

High noise level-emission of fumes, odors, etc

11.16 What is an activity relationship chart?

Tabular means of displaying the closeness ratings among all pairs of activities or

departments

11.17 What is an activity relationship diagram?

Graphical means of displaying the closeness ratings among pairs of activities

11.18 What is a space relationship diagram?

An extension of the activity relationship diagram in which the blocks representing

departments are now assigned areas that are proportional to the areas computed in

the previous space determination step

11.19 What are some of the modifying considerations that are likely to influence

the layout design? Personnel requirements

Material-handling methods Storage facilities

Aisle space Offices

Building features Site conditions

11.20 What are some of the practical limitations that may influence the layout

design? Budget-building codes

Safety requirement Existing building

12 Introduction to Work Measurement

12.1 What is the standard time for a task? Provide a definition.

The amount of time that should be allowed for an average worker to process one work

unit using the standard method and working at a normal pace.

12.2 What are some of the characteristics typical of industrial situation in which

time standards would be beneficial?

Low productivity, repeat orders, long production runs, repetitive work cycles,

short cycle times.

12.3 What are the functions and applications of accurately established time

standards in an organization?

define a fair day’s work

means of converting a workload into staffing requirements

an objective way to compare methods

basis for wage incentives

time data for production planning and cost estimating

12.4 Identify three basic methods to determine time standards: Estimation,

historical records, work measurement techniques

12.5 What are the five basic work measurement techniques?

1. direct time study

2. predetermined motion time systems

3. standard data systems

4. work sampling

5. computerized work measurement

12.6 What is the difference between the normal time and the standard time for a

task?

Normal time is when a worker is working at 100% pace. Standard time allows for time

lost in shift.

12.7 How does computerized work measurement reduce the time and effort of the time

study analyst?

facilitates the collection of data at the work site in direct time study and

work sampling

automatically performing routine computations that had to be done by hand

organizing the time standards files and databases

retrieving data from databases in predetermined motion time studies and

standard data systems

assisting in the preparation of the documentation required in work

measurement

12.8 What are the prerequisites for valid time standards?

Task is performed by an average worker, worker’s pace represents standard

performance, worker uses the standard method, and task is performed on a standard

work unit.

12.9 Identify the two common benchmarks of standard performance that are often

used: Walking at 3mph on level flat ground

Dealing four hands of cards from a 52 card deck in exactly 30 seconds

12.10 What are the details that should be included when defining the standard

method?

Procedure used by the worker, tools, equipment, workplace layout, irregular work

elements, working conditions, setup.

12.11 What is a PFD allowance in time standards?

The accumulated time a worker is allotted during a shift to have personal time,

fatigue time, and delay time.

12.12 What are some of the reasons why workers experience lost time during a work

shift? Restroom breaks, phone calls, fatigue, delays from management

12.13 What is a contingency allowance?

Allowances provided due to problem with the task or the production equipment used

to perform it.

12.14 What is the difference between accuracy and precision in a measurement

system?

Accuracy is how close the measured value is to the true value; Precision is the

repeatability of the measurement system.

12.15 Why is accuracy an elusive quality in work measurement?

It is impossible to scientifically determine the true value of the quantity of

interest.

12.16 What is precision in work measurement?

The expected variability within a single time study or the time standard resulting

from that study.

12.17 What is consistency in work measurement?

The variances in standard time values among different time study analysts who study

the same task.

12.18 What is the application speed ratio in work measurement?

The ratio of time required to determine a time standard relative to the standard

time itself.

13 Direct Time Study

13.1 Define direct time study:

The direct and continuous observation of a task using a stopwatch or other

timekeeping device to record the time taken to accomplish a task

13.2 Identify the five steps in the direct time study procedure:

1. define and document the standard method

2. divide the task into work elements

3. time the work elements to obtain the observed time for the task

4. evaluate the worker’s pace relative to standard performance

5. apply an allowance to the normal time to computer the standard time

13.3 Why is it so important to define and document the standard method as

precisely and thoroughly as possible?

Provides a complete description to the worker, method improvements, disputes about

method, and data for standard data system.

13.4 What is the snapback timing method when using a stopwatch during direct time

study? Timer starts at zero for each work element.

13.5 What is the continuous timing method when using a stopwatch during direct

time study? Timer continuously runs from start of task to end

13.6 Why is performance rating a necessary step in direct time study? It is used

to calculate the normal time.

13.7 Why is an allowance added to the normal time to compute the standard time?

The allowance is a PFD allowance.

13.8 What are some of the causes of variability in the observed work element times

that occur from cycle to cycle?

Variances in pace.

13.9 Why is the student t distribution rather than the normal distribution used in

the calculation of the number of work cycles to be timed?

Want to focus on the most critical element (longest element).

13.10 What is the difference between elemental performance rating and overall

performance rating? Elemental performance is the performance for each work element,

overall is for the overall task.

13.11 What are the characteristics of a well-implemented performance rating system?

Consistency among tasks, consistency among analysts, easily understood, related to

standard performance, machine-paced elements rated at 100%, performance rating

recorded during the task, and worker notification.

13.12 What are the advantages of electronic stopwatches compared to mechanical

stopwatches?

Easier to read, lighter, more accurate and precise, can be used for continuous or

snap back timing.

14 Predetermined Motion Time Systems

14.1 Define predetermined motion time system:

A database of basic motion elements and their associated normal time values,

together with a set of procedures for applying the data to analyze manual tasks and

establish standard times for the tasks.

14.2 What are the steps in applying a predetermined motion time system?

1. Synthesize the method

2. Retrieve the normal time values for each motion element

3. Evaluate the method to make improvements

4. Apply allowances to determine the standard time

14.3 What is the difference between a first-level PMTS and a higher-level PMTS?

First-level PMTS systems are more detailed where higher-level PMTS systems are very

simplified

14.4 What is a motion aggregate in a higher-level PMTS?

A combination of two or more first-level PMTS aggregates. Example: combine “reach”

and “grasp” to form “get”.

14.5 Compare the advantages of a higher-level PMTS and a first-level PMTS:

First-level PMTS: more accurate, takes more time to set standard, highly

repetitive, only short cycles, basic motions, very detailed, very flexible.

Higher-level PMTS: less accurate, less time to set standard, repetitive or

batch, longer cycle times ok, aggregates of basic motion, less detailed, less

flexible.

14.6 What is the unit of time used in methods-time measurement?

TMU(time measurement unit): 1 TMU = 0.00001 hr = 0.0006 min = 0.036 sec

14.7 What does the acronym MOST stand for? Maynard Operation Sequence Technique

14.8 What is the primary focus of MOST in terms of type of work activity? The

movement of objects

14.9 What are the motion aggregates in MOST called? Activity sequence models

14.10 What is the difference between General Move and Controlled Move in MOST?

General move is free motion where as controlled move is restricted. Ex: controlled

move- moving a lever.

15 Standard Data Systems

15.1 What is a standard data system?

A database of normal time values usually organized by work elements, that can be

used to establish time standards for tasks composed of work elements similar to

those in the database.

15.2 Which work measurement techniques should be used as the source of the data in

a standard data system if accuracy of the standards is important?

Any other

15.3 What are the general characteristics and requirements of work situations for

which a standard data system is most suited?

Less accurate standard data systems

15.4 Identify the steps in using a standard data system:

Analyze the new task and divide it into work elements, Access database to determine

normal times of work elements, add element normal times to obtain task normal time,

computer standard times for setup and production cycle.

15.5 What is the database formats commonly used in a standard data system?

Charts, tables, mathematical formulas, worksheets, and computerized databases and

retrieval systems

15.6 Identify the different work element classifications encountered in standard

data systems for work measurement:

Setup and production elements, constant and variable elements, worker-paced and

machine elements, regular and irregular elements, internal and external elements

15.7 What are the advantages of a standard data system that is based on

determining the normal time for an entire work cycle rather than individual work

elements?

Productivity in setting standards Cost savings

Setting standards before production

Avoids the need for performance rating, consistency in the standards Inputs to

other information systems

15.8 What are some of the disadvantages and limitations of standard data systems

and the reasons that a company might not want to develop such a system?

High investment costs Source of data Methods descriptions

Risk of improper applications

16 Work Sampling

16.1 Define work sampling:

The statistical technique for determining the proportions of time spent by subjects

in various defined categories of activity.

16.2 What are the characteristics of work situations for which work sampling is

most suited?

Sufficient time available to perform the study, multiple subjects, long cycle

times, non-repetitive work cycles

16.3 What are some of the common applications of work sampling?

Machine utilization, worker utilization, allowance for time standards, average unit

time, time standards

16.4 What is a biased estimate in work sampling?

An estimate that tends to consistently differ from the true value, either because

the estimating method is somehow flawed or the variable being estimated is

influenced by the act of observing it.

16.5 On what kinds of jobs or tasks is work sampling an appropriate technique for

setting time standards? Repetitive well defined tasks, short cycle times

16.6 What is meant by the term sampling stratification?

16.7 Name three advantages of work sampling:

1. Operations and activities that are too impractical or too costly to measure

by continuous observation can be measured

2. Multiple subjects can be included in a single work sampling study

3. Less time and lower cost to perform study. (see page 437)

16.8 Name three disadvantages and limitations of work sampling:

1. Not accurate

2. Not practical for studying a single subject

3. Provides less detailed information about the work elements. (see page 438)

17 Computerized Work Measurement and Standards Maintenance

17.1 What is the objective of computerizing portions of the various work

measurement procedures? Saves the observer time

17.2 What are the five steps in the conventional time study procedure, and in

which of those steps are there opportunities for computer assistance?

1. Define and document the standard method

2. Divide the task into work elements

3. Time the work elements to obtain the observed time for the task

4. Rate the workers performance to determine the normalized time

5. Apply allowances to computer the standard time

17.3 How are the personal digital assistants used in direct time study? To enter

work element descriptions

Timing the work elements Statistical record

Number of work cycles

17.4 How are personal computers used in direct time study? To do statistical

analysis and charting

Standard time computations Generation of work instructions

Interface to other programs, standards maintenance

17.5 How can PC’s and PDA’s be used in a work sampling situation? Can design the

study

Collect the data Analyze the data

Report the results

17.6 What are the two principal functions of an ideal computerized work

measurement system that is based on a predetermined motion time system and/or a

standard data system?

Work measurement, standards database

17.7 What is the computer’s job in implementing the work measurement function in

an ideal computerized work measurement system that is based on a predetermined

motion time system and/or a standard data system?

Perform the routine computations and facilitate the retrieval of data needed by the

analyst.

17.8 What is the computer’s job in implementing the standards database function in

an ideal computerized work measurement system that is based on a predetermined

motion time study and/or a standard data system?

Storage and retrieval capabilities Mass updating capabilities

Data export features Standards maintenance

17.9 What are the three ingredients required in a computerized work measurement

system that is fully automated using expert systems technology?

1. Knowledge base of an expert time study analyst

2. Computer-compatible description of the task for which the time standard is to

be set

3. Capability to apply the knowledge base to a given task description to set a

standard.

17.10 What is the typical reason that a worker may have difficulty making 100%

efficiency on a task for which a time standard has been set?

The actual method is less productive than the standard method.

17.11 What are some of the possible improvements that a worker might make to devise

a method that is more productive than the standard method?

Improvises a special tool Layout is revised

Manual elements that were external to the machine, become internal Work elements

listed as being done by one hand are done by both hands Worker changes the machine

settings (reducing cycle time)

17.12 What is meant by the term creeping changes (in work methods)?

Changes that affect the cycle time by a negligible amount. Lots of creeping changes

add up.

17.13 What is the function of a standard maintenance program? To protect the

validity of the time standards

17.14 What are the problems that result from standards erosion over time – that is,

time standards that become less and less valid over time due to creeping changes

and surreptitious methods improvements made by the worker?

Labor productivity is reduced Incentive earnings escalate Labor costs rise

Estimates become inaccurate Organization suffers a loss

19 Learning Curves

19.1 Describe the learning curve phenomenon:

The reduction in cycle time that occurs in a repetitive work activity as the number

of cycles increases

19.2 Define the term learning rate:

The proportion by which the dependent variable, usually the task time, is

multiplied every time the number of task cycles or work units doubles.

19.3 What is the rate of improvement and how is it related to the learning rate?

The proportion by which the dependent variable is reduced every time the number of

units doubles

19.4 Which value of learning rate means faster learning, 75% or 90%? 75%

19.5 Why is the basic equation in learning curve theory, y=kxm, called a log-

linear model? The equation plots as a straight line in log-log coordinates.

19.6 What is the basic difference between the Crawford equation and the Wright

equation in learning curve theory?

The Wright model uses the cumulative average time as the dependent variable in the

basic equation, Crawford uses time.

19.7 Why does the cumulative average time always have a higher value than the unit

time in the lob- linear equation?

The average includes unit time values for lower values of N and these time values

are larger.

19.8 What are the two basic parameters that are required to use either the

Crawford or the Wright learning curve equations?

The time or cost associated with the first unit, the slope m from which the

learning rate LR can be deduced.

19.9 How is the worker able to reduce the cycle time as the number of work units

increases? Worker becomes familiar with the task

Makes fewer mistakes as the task is repeated

Body motions become more efficient (rhythm and pattern) Minor adjustments are made

in the workplace layout Fewer delays that interrupt operation

19.10 How is the larger organization able to reduce the cycle time as the number of

work units increases? Methods improvements

Fine tuning of machinery Development of tooling Tech improvements Design

improvements Improved materials Better planning

19.11 What are the two ways to obtain the value of the learning rate for a given

application? Use industrial averages, analyze data from actual application.

19.12 What is the simplest way to estimate the learning rate based on actual data?

Observing the doubling effect

19.13 Why is it reasonable to believe that the learning rate for a worker-machine

system will be higher than for pure manual work?

Machine time is fixed. There is no learning involved.

19.14 What is a composite learning curve?

The situation in which a learning rate is to be determined for a large entity of

work, such as an entire product

19.15 What is remission when used in the context of an interruption in the learning

curve? When there are interruptions, the learning curve sets back.

19.16 How does product complexity affect the learning curve?