Professional Documents

Culture Documents

Cable For 3-Phase: Classification of Cables

Cable For 3-Phase: Classification of Cables

Uploaded by

anvOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cable For 3-Phase: Classification of Cables

Cable For 3-Phase: Classification of Cables

Uploaded by

anvCopyright:

Available Formats

Classification

of Cables

Cables for underground

service may be classified in

two ways according to (i) the

type of insulating material

used in their manufacture (ii)

the voltage for

CLASSIFICATION OF

CABLES

Cables for underground

service may be classified in

two ways according to

(i) the type of

insulating material used in

their manufacture

(ii) the voltage for

which they are manufactured.

However, the latter method of

classification is generally

preferred, according to which

cables can be divided into the

following groups:

Low-tension (L.T.) cables —

upto 1000 V

High-tension (H.T.) cables —

upto 11,000 V

Super-tension (S.T.) cables —

from 22 kV to 33 kV

Extra high-tension (E.H.T.)

cables — from 33 kV to 66 kV

Extra super voltage cables —

beyond 132 kV

A cable may have one or

more than one core

depending upon the type of

service for which it is

intended. It may be

(i) single-core

(ii) (ii) two-core

(iii) (iii) three-core

(iv) (iv) four-core etc.

For a 3-phase service, either

3-single-core cables or three-

core cable can be used

depending upon the operating

voltage and load demand.

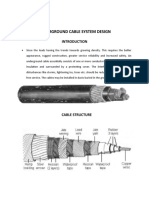

Fig. shows the constructional

details of a single-core low

tension cable. The cable has

ordinary construction because

the stresses developed in the

cable for low voltages (up to

6600 V) are generally small. It

consists of one circular core

of tinned stranded copper (or

aluminium) insulated by

layers of impregnated paper.

The insulation is surrounded

by a lead sheath which

prevents the entry of moisture

into the inner parts. In order

to protect the lead sheath

from corrosion, an overall

serving of compounded

fibrous material (jute etc.) is

provided. Single-core cables

are not usually armoured in

order to avoid excessive

sheath losses. The principal

advantages of single-core

cables are simple

construction and availability of

larger copper section.

Cable For 3-Phase

In practice, underground

cables are generally required

to deliver 3-phase power. For

the purpose, either three-core

cable or three single core

cables may be used. For

voltages upto 66 kV, 3-core

cable (i.e., multi-core

construction) is preferred due

to economic reasons.

However, for voltages beyond

66 kV, 3-core-cables become

too large and unwieldy and,

therefore, single-core cables

areused. The following types

of cables are generally used

for 3-phase service :

1. Belted cables — upto 11

kV

2. Screened cables — from

22 kV to 66 kV

3. Pressure cables — beyond

66 kV.

1. Belted Cables

These cables are used for

voltages upto 11kV but in

extraordinary cases, their use

may be extended upto 22kV.

Fig.3 shows the

constructional details of a 3-

core belted cable. The cores

are insulated from each other

by layers of impregnated

paper.

Leadsheath

Thicknessof

insulation

between

conductorand

sheath

Paperbelt

Thicknessofinsulation

betweenconductors

Another layer of impregnated

paper tape, called paper belt

is wound round the grouped

insulated cores. The gap

between the insulated cores

is filled with fibrous insulating

material (jute etc.) so as to

give circular cross-section to

the cable. The cores are

generally stranded and may

be of non circular shape to

make better use of available

space. The belt is covered

with lead sheath to protect the

cable against ingress of

moisture and mechanical

injury. The lead sheath is

covered with one or more

layers of armouring with an

outer serving (not shown in

the figure).The belted type

construction is suitable only

for low and medium voltages

as the electro static stresses

developed in the cables for

these voltages are more or

less radial i.e., across the

insulation. However, for high

voltages (beyond 22 kV), the

tangential stresses also

become important. These

stresses act along the layers

of paper insulation. As the

insulation resistance of paper

is quite small along the

layers, therefore, tangential

stresses set up leakage

current along the layers of

paper insulation. The leakage

current causes local heating,

resulting in the risk of

breakdown of insulation at

any moment. In order to

overcome this difficulty,

screened cables are used

where leakage currents are

conducted to earth through

metallic screens.

2.Screened Cables

These cables are meant for

use up to 33 kV, but in

particular cases their use may

be extended to operating

voltages up to 66 kV. Two

principal types of screened

cables are H-type cables and

S.L. type cables.

(i)H-type Cables

This type of cable was first

designed by H. Hochstetler

and hence the name. Fig.

shows the constructional

details of a typical 3-core, H-

type cable. Each core is

insulated by layers of

impregnated paper. The

insulation on each core is

covered with a metallic

screen which usually consists

of a perforated aluminum foil.

The cores are laid in such a

way that metallic screens

Make contact with one

another. An additional

conducting belt (copper

woven fabric tape) is

Wrapped round the three

cores. The cable has no

insulating belt but lead

sheath, bedding, armouring

and serving follow as usual. It

is easy to see that each core

screen is in electrical contact

with the conducting belt and

the lead sheath. As all the

four screens (3 core screens

and one conducting belt) and

the lead sheath are at earth

potential, therefore, the

electrical stresses are purely

radial and consequently

dielectric losses are reduced.

Two principal advantages are

claimed for H-type cables.

Firstly, the perforations in the

metallic screens assist in the

complete impregnation of the

cable with the compound and

thus the possibility of air

pockets or voids (vacuous

spaces) in the dielectric is

eliminated. The voids if

present tend to reduce the

breakdown strength of the

cable and may cause

considerable damage to the

paper insulation. Secondly,

the metallic screens increase

the heat dissipating power of

the cable.

(Ii) s.l. Type cables

Fig. shows the constructional

details of a 3-core S.L.

(separate lead) type cable. It

is basically H-type cable but

the screen round each core

insulation is covered by its

own lead sheath. There is no

overall lead sheath but only

armouring and serving are

provided. The S.L. type

cables have two main

advantages over H-type

cables. Firstly, the separate

sheaths minimize the

possibility of core-to-core

breakdown. Secondly,

bending of cables becomes

easy due to the elimination of

overall lead sheath. However,

the disadvantage is that the

three lead sheaths of S.L.

cable are much thinner than

the single sheath of H-cable

and, therefore, call for greater

care in manufacture

3. Pressure cables

For voltages beyond 66 kV,

solid type cables are

unreliable because there is a

danger of breakdown of

insulation due to the presence

of voids. When the operating

voltages are greater than 66

kV, pressure cables are used.

In such cables, voids are

eliminated by increasing the

pressure of compound and for

this reason they are called

pressure cables. Two types of

pressure cables viz oil-filled

cables and gas pressure

cables are commonly used.

(i)Oil-filled cables.

In such types of cables,

channels or ducts are

provided in the cable for oil

circulation. The oil under

pressure (it is the same oil

used for impregnation) is kept

constantly supplied to the

channel by means of external

reservoirs placed at suitable

distances (say 500 m) along

the route of the cable. Oil

under pressure compresses

the layers of paper insulation

and is forced in to any voids

that may have formed

between the layers. Due to

the elimination of voids, oil-

filled cables can be used for

higher voltages, the range

being from 66 kV up to 230

kV. Oilfilled cables are of

three types viz., single-core

conductor channel, single-

core sheath channel and

three-core filler-space

channels.

Fig. shows the constructional

details of a single-core

conductor channel, oil filled

cable. The oil channel is

formed at the center by

stranding the conductor wire

around a hollow cylindrical

steel spiral tape. The oil

under pressure is supplied to

the channel by means of

external reservoir. As the

channel is made of spiral

steel tape, it allows the oil to

percolate between copper

strands to the wrapped

insulation. The oil pressure

compresses the layers of

paper insulation and prevents

the possibility of void

formation. The system is so

designed that when the oil

gets expanded due to

increase in cable

temperature, the extra oil

collects in the reservoir.

However, when the cable

temperature falls during light

load conditions, the oil from

the reservoir flows to the

channel. The disadvantage of

this type of cable is that the

channel is at the middle of the

cable and is at full

voltage w.r.t. earth, so that a

very complicated system of

joints is necessary. Fig.

shows the constructional

details of a single core sheath

channel oil-filled cable. In this

type of cable, the conductor is

solid similar to that of solid

cable and is paper insulated.

However, oil ducts are

provided in them etallic

sheath as shown. In the 3-

core oil-filler cable shown in

Fig. the oil ducts are located

in the filler spaces. These

channels are composed of

perforated metalribbon tubing

and are at earth potential.

(ii)Gas Pressure Cable

The voltage required to set up

ionization inside a void

increases as the pressure is

increased. Therefore, if

ordinary cable is subjected to

a sufficiently high pressure,

the ionization can be

altogether eliminated. At the

same time, the increased

pressure produces radial

compression which tends to

close any voids. This is the

underlying principle of gas

pressure cables.

Fig Shows the section of

external pressure cable

designed by Hochstetler,

Vogal and Bowden. The

construction of the cable is

similar to that of an ordinary

solid type except that it is of

triangular shape and

thickness of lead sheath is

75% that of solid cable. The

triangular section reduces the

weight and gives low thermal

resistance but the main

reason for triangular shape is

that the lead sheath acts as a

pressure membrane. The

sheath is protected by a thin

metal tape. The cable is laid

in a gas-tight steel pipe. The

pipe is filled with dry nitrogen

gas at 12 to 15 atmospheres.

The gas pressure produces

radial compression and

closes the voids that may

have formed between the

layers of paper insulation.

Such cables can carry more

load current and operate at

higher voltages than a normal

cable. Moreover,

maintenance cost is small

and the nitrogen gas helps in

quenching any flame.

However, it has the

disadvantage that the overall

cost is very high.

Dielectric Stress

In Cable

Under operating conditions,

the insulation of a cable is

subjected to electrostatic

forces. This is known as

dielectric stress. The

dielectric stress at any point

in a cable is in fact the

potential gradient (or electric

intensity) at that point.

Consider a single core cable

with core diameter d and

internal sheath diameter D.

As proved in Art 8, the electric

intensity at a point x metres

from the centre of the cable is

By definition, electric intensity

is equal to potential gradient.

Therefore, potential gradient

g at a point x meters from the

Centre of cable is

It is clear from exp. (iii) that

potential gradient varies

inversely as the distance x.

Therefore, potential gradient

will be maximum when x is

minimum i.e., when x = d/2 or

at the surface of the

conductor. On the other hand,

potential gradient will be

minimum at x = D/2 or at

sheath surface. Maximum

potential gradient is

The variation of stress in the

dielectric is shown in Fig.14. It

is clear that dielectric stress is

maximum at the conductor

surface and its value goes on

decreasing as we move away

from the conductor. It may be

noted that maximum stress is

an important consideration in

the design of a cable. For

instance, if a cable is to be

operated at such a voltage

that maximum stress is 5

kV/mm, then the insulation

used must have a dielectric

strength of at least 5 kV/mm,

otherwise breakdown of the

cable will become inevitable.

Most Economical

Size of Conductor

It has already been shown

that maximum stress in a

cable occurs at the surface of

the conductor. For safe

working of the cable,

dielectric strength of the

insulation should be more

than the maximums tress.

Rewriting the expression for

maximum stress, we get,

The values of working voltage

V and internal sheath

diameter D have to be kept

fixed at certain values due to

design considerations. This

leaves conductor diameter d

to be the only variable in exp.

(i). For given values of V and

D, the most economical

conductor diameter will be

one for which gmax has a

minimum value. The value of

gmax will be minimum when d

loge D/d is maximum i.e.

Study Material, Lecturing

Notes, Assignment,

Reference, Wiki description

explanation, brief detail

Transmission and Distribution

: Insulators and Cables :

Classification of Cables |

You might also like

- Weld SurveillanceDocument33 pagesWeld SurveillancecanakyuzNo ratings yet

- It Is Quite Another Electricity: Transmitting by One Wire and Without GroundingFrom EverandIt Is Quite Another Electricity: Transmitting by One Wire and Without GroundingRating: 4.5 out of 5 stars4.5/5 (2)

- LANXESS-Release Agents 01-2017Document20 pagesLANXESS-Release Agents 01-2017Phuong The NguyenNo ratings yet

- Electrical Characteristics of CablesDocument32 pagesElectrical Characteristics of CablesSupakint Suteepichatpunt100% (1)

- Underground Power Cables Catalogue 03-2010Document48 pagesUnderground Power Cables Catalogue 03-2010Edgar Sierra Rodriguez100% (1)

- 60-500 KV High Voltage-Gallery PDFDocument33 pages60-500 KV High Voltage-Gallery PDFuzakcilNo ratings yet

- Republic of Iraq Minstrey of Higher Education and Scientific Research University of BabylonDocument18 pagesRepublic of Iraq Minstrey of Higher Education and Scientific Research University of Babylonمهيمن الابراهيميNo ratings yet

- UG CablesDocument42 pagesUG CablesRenuka KutteNo ratings yet

- Chapter Eight (Cables)Document40 pagesChapter Eight (Cables)Magarsaa Qana'iiNo ratings yet

- Underground Cables - 010954Document23 pagesUnderground Cables - 010954lawrence momanyiNo ratings yet

- Unit 4Document71 pagesUnit 4Vairaperumal KNo ratings yet

- Lecture 11 Underground CablesDocument8 pagesLecture 11 Underground CablesKenean YeshitelaNo ratings yet

- Power1 Chapter-8 PDFDocument40 pagesPower1 Chapter-8 PDFEnyew50% (2)

- EE458Document36 pagesEE458ArishaNo ratings yet

- Underground Cables (Done)Document17 pagesUnderground Cables (Done)Sk Munwar BabuNo ratings yet

- Underground Power Cables: Jatinder Singh 1241084 B.Tech Ee-7 Ctiemt, Shahpur, JalandharDocument42 pagesUnderground Power Cables: Jatinder Singh 1241084 B.Tech Ee-7 Ctiemt, Shahpur, JalandharGopinath B L NaiduNo ratings yet

- Underground CableDocument23 pagesUnderground CableVinay KumarNo ratings yet

- 2.2 Underground Cables1Document37 pages2.2 Underground Cables1Aayu JainNo ratings yet

- Basic Math For Cable TerminationDocument17 pagesBasic Math For Cable TerminationAbraham JyothimonNo ratings yet

- Types of Wires and CablesDocument23 pagesTypes of Wires and CablesTanya100% (1)

- Insulators: Dr.S.Prabhakar Karthikeyan Smieee, PDF (Cpri) Associate Professor, SELECT VIT University, VelloreDocument31 pagesInsulators: Dr.S.Prabhakar Karthikeyan Smieee, PDF (Cpri) Associate Professor, SELECT VIT University, Velloresahale sheraNo ratings yet

- Topic 4 - CablesDocument20 pagesTopic 4 - CablesVictorNo ratings yet

- Birla Vishvakarma MahavidyalayaDocument22 pagesBirla Vishvakarma MahavidyalayaRajeshNo ratings yet

- Under Ground Cable Ps-2Document15 pagesUnder Ground Cable Ps-2Md. Ruhul AminNo ratings yet

- Nexans MV Cables UK Brochure - 1Document48 pagesNexans MV Cables UK Brochure - 1Ra'fat HerzallahNo ratings yet

- Types of Wires Cable PDFDocument21 pagesTypes of Wires Cable PDFRájDèép TrìpâţhíNo ratings yet

- Paper Insulated Distribution CablesDocument10 pagesPaper Insulated Distribution Cablesdeepak2628No ratings yet

- 5 Electrical Installations - RevisedDocument52 pages5 Electrical Installations - RevisedKrupa DungraniNo ratings yet

- 1 - Insulators String Efficiency ProblemDocument71 pages1 - Insulators String Efficiency ProblemVeera Vamsi Yejju100% (1)

- Underground Cable System DesignDocument25 pagesUnderground Cable System DesignJayvee BustardeNo ratings yet

- Under Ground CableDocument37 pagesUnder Ground CableTanushree BiswasNo ratings yet

- Cabling: Presented by Wisdom, Patsika, GreenDocument31 pagesCabling: Presented by Wisdom, Patsika, GreenShione T MundawararaNo ratings yet

- Insulation of CablesDocument31 pagesInsulation of CablesnandhakumarmeNo ratings yet

- Cable: Electrical System TN-S Grand Coulee Dam Fire Test Sweden FireDocument7 pagesCable: Electrical System TN-S Grand Coulee Dam Fire Test Sweden FireSanjeev GuptaNo ratings yet

- Practical 7Document6 pagesPractical 7Mahipalsinh RajputNo ratings yet

- CableDocument6 pagesCablekelvinyeohNo ratings yet

- Udeme Udoh Report On Armoured Cable His UseDocument7 pagesUdeme Udoh Report On Armoured Cable His UseUdeme UdohNo ratings yet

- Introduction of CablesDocument14 pagesIntroduction of CablesRanganath SriNo ratings yet

- Under Ground Cables: Figure Show The General Construction of A Single Core CableDocument18 pagesUnder Ground Cables: Figure Show The General Construction of A Single Core CableJalaj GargNo ratings yet

- Underground Cables: Atmiya Institute of Technology & ScienceDocument35 pagesUnderground Cables: Atmiya Institute of Technology & ScienceLaveen Raghunam100% (2)

- Notes11 CablesDocument15 pagesNotes11 CablesVivek RamachandranNo ratings yet

- Submision of Building ServicesDocument24 pagesSubmision of Building ServiceskusumchitikaNo ratings yet

- Ee413 Ehv and Uhv Ac Transmission Unit 3 UNIT III INSULATORS AND CABLESDocument33 pagesEe413 Ehv and Uhv Ac Transmission Unit 3 UNIT III INSULATORS AND CABLESDr G VijayakumarNo ratings yet

- Notes 11: CablesDocument15 pagesNotes 11: CablesAbhishek SinghNo ratings yet

- Under Ground CablesDocument18 pagesUnder Ground Cablessreenivasroyal883% (23)

- Sace Tmax XT: Circuit-Breaker Terminals and ConnectionDocument28 pagesSace Tmax XT: Circuit-Breaker Terminals and ConnectionPiyakarn BeeNo ratings yet

- Underground Cables: Gcek, Electrical EngineeringDocument54 pagesUnderground Cables: Gcek, Electrical Engineeringsushilkumarbhoi2897No ratings yet

- High Voltage CablesDocument10 pagesHigh Voltage CableskhadijabugtiNo ratings yet

- Classification of Cables SlidesDocument19 pagesClassification of Cables Slidessaravan1891100% (4)

- Ps-I Unit-4Document35 pagesPs-I Unit-4Tushar kumarNo ratings yet

- Electrical Wires and Cables TypesDocument10 pagesElectrical Wires and Cables TypesMarlo AristorenasNo ratings yet

- Bilal Lateef. Beem-F19-024 Assignment#07 Mechanical Design of Overhead LinesDocument10 pagesBilal Lateef. Beem-F19-024 Assignment#07 Mechanical Design of Overhead LinesBilal Latif BhuttaNo ratings yet

- Vanshi Dhar PDFDocument6 pagesVanshi Dhar PDFKhadse PriyankaNo ratings yet

- Cable (Sizing and Calculation)Document31 pagesCable (Sizing and Calculation)Ajaysingh SolankiNo ratings yet

- T&D Lab Manual 4th Sem EeDocument20 pagesT&D Lab Manual 4th Sem Ee993276757067% (6)

- 7 - Underground CableDocument60 pages7 - Underground Cablealamin shawonNo ratings yet

- Cable Construction Part 1Document5 pagesCable Construction Part 1Jesus RodriguezNo ratings yet

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsFrom EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNo ratings yet

- CISA Exam - Testing Concept-Network Physical Media (Fiber Optic/ UTP/STP/Co-axial) (Domain-4)From EverandCISA Exam - Testing Concept-Network Physical Media (Fiber Optic/ UTP/STP/Co-axial) (Domain-4)No ratings yet

- How to Install Electric Bells, Annunciators, and AlarmsFrom EverandHow to Install Electric Bells, Annunciators, and AlarmsNo ratings yet

- Textile Processing ChemicalsDocument104 pagesTextile Processing ChemicalsIftakharul IslamNo ratings yet

- MASS TRANSFER - 4.weekDocument47 pagesMASS TRANSFER - 4.weekAlexNo ratings yet

- Flexural Behavior of Ultra-High-Performance Fiber-Reinforced Concrete Beams Reinforced With GFRP and Steel RebarsDocument17 pagesFlexural Behavior of Ultra-High-Performance Fiber-Reinforced Concrete Beams Reinforced With GFRP and Steel Rebarsmohamed ellithyNo ratings yet

- Comdiflex Spiral Wound Gaskets Technical CatalogueDocument7 pagesComdiflex Spiral Wound Gaskets Technical CatalogueSugianto BarusNo ratings yet

- Subject: Method Statement For Shuttering WorksDocument5 pagesSubject: Method Statement For Shuttering WorksRounak MaheshwariNo ratings yet

- Ilovepdf MergedDocument45 pagesIlovepdf MergedameeshaNo ratings yet

- Kelvin Probe Force Microscopy: SynonymsDocument8 pagesKelvin Probe Force Microscopy: SynonymsRaj TokasNo ratings yet

- 1934 enDocument1 page1934 enAlexandre Colin CorreaNo ratings yet

- Annisa Indah Kirana - Tugas Evaporasi PDFDocument5 pagesAnnisa Indah Kirana - Tugas Evaporasi PDFANNISA KIRANANo ratings yet

- Internship Report PDFDocument5 pagesInternship Report PDFSanjay BombNo ratings yet

- Hardness Conversion or Equivalence Table For Many Different ScalesDocument7 pagesHardness Conversion or Equivalence Table For Many Different ScalessureshjeevaNo ratings yet

- Vf2cm Transfer - 4wd - Awd Transfer System PrecautionDocument1 pageVf2cm Transfer - 4wd - Awd Transfer System PrecautionWILIAM VENTURANo ratings yet

- H432-01-Periodic Table, Elements and Physical Chemistry/a Level Chemistry A H432 - H432-01 - QS13Document5 pagesH432-01-Periodic Table, Elements and Physical Chemistry/a Level Chemistry A H432 - H432-01 - QS13Altay ShawNo ratings yet

- MMJ 300/500 V: Installation CablesDocument2 pagesMMJ 300/500 V: Installation CablesQC ĐNNo ratings yet

- Saic Q 1060Document3 pagesSaic Q 1060Arjun RawatNo ratings yet

- Management Corner: MILESTONE Heater Fouling ControlDocument6 pagesManagement Corner: MILESTONE Heater Fouling ControlUmer PirachaNo ratings yet

- Pararrayos Tipo BalestroDocument3 pagesPararrayos Tipo BalestroBladimir Michel100% (1)

- OctinoxateDocument7 pagesOctinoxatebagusdwiNo ratings yet

- Materials ConcreteDocument3 pagesMaterials ConcreteKarlo BosecNo ratings yet

- Mil PRF 61002BDocument27 pagesMil PRF 61002BAbdullah PalNo ratings yet

- Synthesis of Nanomaterials Using Various TopDocument18 pagesSynthesis of Nanomaterials Using Various TopDevayush ShuklaNo ratings yet

- PSA 50 Paper PDFDocument5 pagesPSA 50 Paper PDFshashi kant kumarNo ratings yet

- 6321ZTAA - 0001 - A1408224 - E (Honda)Document18 pages6321ZTAA - 0001 - A1408224 - E (Honda)utp0159146No ratings yet

- 欧盟CLP化学品分类名单Document644 pages欧盟CLP化学品分类名单Yang YangNo ratings yet

- Greige Woven Glass Fabrics: Standard Specification ForDocument17 pagesGreige Woven Glass Fabrics: Standard Specification ForTuyên RùaNo ratings yet

- BCE 222 - Mechanics of Deformable Bodies First Examination: I - Add or Imultiply)Document3 pagesBCE 222 - Mechanics of Deformable Bodies First Examination: I - Add or Imultiply)Icy IzzyNo ratings yet

- (Dislocations in Solids 14) John Hirth (Eds.) - A Tribute To F.R.N. Nabarro (2008, Elsevier Science)Document551 pages(Dislocations in Solids 14) John Hirth (Eds.) - A Tribute To F.R.N. Nabarro (2008, Elsevier Science)Hariom PrakashNo ratings yet

- Chapter 1 HeatDocument10 pagesChapter 1 HeatJikni NobleNo ratings yet