Professional Documents

Culture Documents

Epoxy Curing Agents For Fast Cure Civil Engineering Applications

Epoxy Curing Agents For Fast Cure Civil Engineering Applications

Uploaded by

Nissim Hazar CasanovaCopyright:

Available Formats

You might also like

- Organic Chemistry 9Th Edition Mcmurry Solutions Manual Full Chapter PDFDocument36 pagesOrganic Chemistry 9Th Edition Mcmurry Solutions Manual Full Chapter PDFmaria.topolosky417100% (11)

- Charpy Impact Test - Lab ReportDocument18 pagesCharpy Impact Test - Lab ReportChitra Nadia100% (1)

- Evonik-Ancamine 2791Document2 pagesEvonik-Ancamine 2791Tangtang GuoNo ratings yet

- EXP-MN-SM085-En-R0 - Safety Valves and Burst DiscsDocument55 pagesEXP-MN-SM085-En-R0 - Safety Valves and Burst Discsbali100% (7)

- Ancamide 2634 Curing Agent: Epoxy Curing Agents and ModifiersDocument7 pagesAncamide 2634 Curing Agent: Epoxy Curing Agents and ModifiersNissim Hazar CasanovaNo ratings yet

- BOATEXDocument1 pageBOATEXDianWidodoNo ratings yet

- Evonik Ancamine2811Document2 pagesEvonik Ancamine2811kishanptlNo ratings yet

- Anquamine 728: Curing AgentDocument4 pagesAnquamine 728: Curing AgentGreg PanganNo ratings yet

- Evonik-Ancamine 2726 EUDocument7 pagesEvonik-Ancamine 2726 EUkishanptlNo ratings yet

- Civil Engineering / Coatings Epikure Curing Agent 8545-W-52 Versatile Waterborne Amine Curing Agent For Civil Engineering and Floor CoatingsDocument4 pagesCivil Engineering / Coatings Epikure Curing Agent 8545-W-52 Versatile Waterborne Amine Curing Agent For Civil Engineering and Floor CoatingsDonnaNo ratings yet

- Evonik-Amicure PACMDocument5 pagesEvonik-Amicure PACMuzzy2No ratings yet

- DION IMPACT 9102 SeriesDocument5 pagesDION IMPACT 9102 SeriesLENEEVERSONNo ratings yet

- The World Quality Leader in Cashew Liquid Technology: Coating Products PortfolioDocument8 pagesThe World Quality Leader in Cashew Liquid Technology: Coating Products Portfolioمحمد عزتNo ratings yet

- Evonik-Ancamide 221-X70 - EUDocument5 pagesEvonik-Ancamide 221-X70 - EUMOHAMED100% (1)

- ANCAMINE® 2422 Curing Agent: DescriptionDocument7 pagesANCAMINE® 2422 Curing Agent: DescriptionSastra MahachemNo ratings yet

- Ancamide 2445 TdsDocument7 pagesAncamide 2445 Tdsnc5r8fkp6zNo ratings yet

- Ancamide 261A: Curing AgentDocument11 pagesAncamide 261A: Curing AgentBERKAT RAJA SEMESTANo ratings yet

- Evonik-Ancamine 2410Document10 pagesEvonik-Ancamine 2410Shivam NagarkarNo ratings yet

- Evonik-Ancamide 261A EUDocument7 pagesEvonik-Ancamide 261A EUNimerksNo ratings yet

- Ancamide 261a UsDocument11 pagesAncamide 261a UsdamiendamNo ratings yet

- Ancamine 1934 UsDocument3 pagesAncamine 1934 UsNIKESH PRAKASHNo ratings yet

- Evonik-Chemresist Pages PDFDocument16 pagesEvonik-Chemresist Pages PDFessaessa1980No ratings yet

- Evonik-Ancamine 2280 - EUDocument5 pagesEvonik-Ancamine 2280 - EUOswaldo Manuel Ramirez MarinNo ratings yet

- Luxafloor ECO: Water Borne Epoxy Floor CoatingDocument2 pagesLuxafloor ECO: Water Borne Epoxy Floor CoatinglivefreakNo ratings yet

- Atlac 590 002126 - 1520269898Document2 pagesAtlac 590 002126 - 1520269898Jainam ShahNo ratings yet

- 93 Sinopec Extreme Pressure Lithium Complex GreaseDocument3 pages93 Sinopec Extreme Pressure Lithium Complex GreaseAmadeus CocaNo ratings yet

- Swancor 901-3: Epoxy Vinyl Ester ResinsDocument2 pagesSwancor 901-3: Epoxy Vinyl Ester Resinswongpengchiong7205No ratings yet

- Acrolon 218 HS Acrylic PolyurethaneDocument4 pagesAcrolon 218 HS Acrylic PolyurethaneJohn ReevesNo ratings yet

- Crystic Gelcoat Ls 98pa Gelcoat en Nov17Document2 pagesCrystic Gelcoat Ls 98pa Gelcoat en Nov17ghariharan95No ratings yet

- Stycas 2850Document2 pagesStycas 2850die6o_brNo ratings yet

- Selection & Specification Data Substrates & Surface PreparationDocument2 pagesSelection & Specification Data Substrates & Surface PreparationJuanNo ratings yet

- TDS 2800000925 en - USDocument2 pagesTDS 2800000925 en - USIsrael HernandezNo ratings yet

- Ancamine 2739 TdsDocument8 pagesAncamine 2739 Tdsnc5r8fkp6zNo ratings yet

- Epoxy Backing Grout Epigen 0301: Typical Applications ProfileDocument2 pagesEpoxy Backing Grout Epigen 0301: Typical Applications ProfileDianWidodoNo ratings yet

- Araldite Epoxy Resin Cy 230 and Hy 951 HardenerDocument6 pagesAraldite Epoxy Resin Cy 230 and Hy 951 Hardenersonu50% (2)

- Araldite Epoxy Resin Cy 230 and Hy 951 HardenerDocument6 pagesAraldite Epoxy Resin Cy 230 and Hy 951 HardenerVaibhav AnuseNo ratings yet

- Molykote PG-641 Grease - PDSDocument2 pagesMolykote PG-641 Grease - PDSabc xyzNo ratings yet

- Blucem Hb55: Product Code Bc-20-00-000S R01/2017 Page 1 of 4Document4 pagesBlucem Hb55: Product Code Bc-20-00-000S R01/2017 Page 1 of 4Rajiv SingalNo ratings yet

- Tds Exxon 6101XRDocument2 pagesTds Exxon 6101XRindahNo ratings yet

- Royalthane 450GLDocument2 pagesRoyalthane 450GLSyed FaridNo ratings yet

- PolaneSolarReflective 1Document2 pagesPolaneSolarReflective 1cenoscottpatrickNo ratings yet

- Hetron 922 Infusion Resin 45 en A4Document1 pageHetron 922 Infusion Resin 45 en A4uzzy2No ratings yet

- Somentor Rolling Oils: Asia PacificDocument4 pagesSomentor Rolling Oils: Asia PacificFajar EkoNo ratings yet

- Sherglass FFDocument4 pagesSherglass FFJhose BonillaNo ratings yet

- Ancamine 2740 TdsDocument5 pagesAncamine 2740 Tdsnc5r8fkp6zNo ratings yet

- Acrolon 218 HsDocument4 pagesAcrolon 218 HsKARENNo ratings yet

- CarbolineDocument18 pagesCarbolineimaduddinshaNo ratings yet

- Epigen 0907: High Strength Epoxy AdhesiveDocument2 pagesEpigen 0907: High Strength Epoxy AdhesiveAfzal ImamNo ratings yet

- 838 Silicone Adhesive SealantDocument3 pages838 Silicone Adhesive SealantMario Vargas VegaNo ratings yet

- Exxon 6101Document2 pagesExxon 6101M. Kürşad ArslanNo ratings yet

- Belzona 1121: Product Specification SheetDocument2 pagesBelzona 1121: Product Specification SheetQuy RomNo ratings yet

- Ancamide 2573 TDSDocument1 pageAncamide 2573 TDSnc5r8fkp6zNo ratings yet

- 670.bull.2022 (22.0)Document3 pages670.bull.2022 (22.0)Francisco RodríguezNo ratings yet

- Ancamine 2726 TdsDocument1 pageAncamine 2726 Tdsnc5r8fkp6zNo ratings yet

- Evonik Sunmide CX 1151 UploadDocument6 pagesEvonik Sunmide CX 1151 UploadEpox by Epx polymers pvt ltdNo ratings yet

- 22 - Water-Borne Road Marking Resin - Eagacryl 6050 - 2019 EditionDocument4 pages22 - Water-Borne Road Marking Resin - Eagacryl 6050 - 2019 Editionleonardo16No ratings yet

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 Hshector gomezNo ratings yet

- Interbond 201 Temperate Eng A4 20171106Document4 pagesInterbond 201 Temperate Eng A4 20171106Purwanto ritzaNo ratings yet

- EMULSION TECHNICAL DATA SHEET (7 Revised 1212)Document1 pageEMULSION TECHNICAL DATA SHEET (7 Revised 1212)kabiru isahNo ratings yet

- Epoxy Coating K Sir 88Document2 pagesEpoxy Coating K Sir 88ANIBALLOPEZVEGANo ratings yet

- Rubber Nanocomposites: Preparation, Properties, and ApplicationsFrom EverandRubber Nanocomposites: Preparation, Properties, and ApplicationsNo ratings yet

- Ancamide 2634 Curing Agent: Epoxy Curing Agents and ModifiersDocument7 pagesAncamide 2634 Curing Agent: Epoxy Curing Agents and ModifiersNissim Hazar CasanovaNo ratings yet

- Epoxy Curing Agents and ModifiersDocument3 pagesEpoxy Curing Agents and ModifiersNissim Hazar CasanovaNo ratings yet

- Epoxy Curing Agents and ModifiersDocument4 pagesEpoxy Curing Agents and ModifiersNissim Hazar CasanovaNo ratings yet

- Epoxy Curing Agents and Modifiers: Ancamine® 1637-LV Curing AgentDocument1 pageEpoxy Curing Agents and Modifiers: Ancamine® 1637-LV Curing AgentNissim Hazar CasanovaNo ratings yet

- Epoxy Curing Agents and Modifiers: Ancamide® 260A Curing AgentDocument1 pageEpoxy Curing Agents and Modifiers: Ancamide® 260A Curing AgentNissim Hazar CasanovaNo ratings yet

- Krasol LBD2000Document1 pageKrasol LBD2000Nissim Hazar CasanovaNo ratings yet

- Epoxy Civil EngineeringDocument20 pagesEpoxy Civil EngineeringNissim Hazar CasanovaNo ratings yet

- AkzoNobel EBS 481 FQ tcm54-30339Document1 pageAkzoNobel EBS 481 FQ tcm54-30339Nissim Hazar CasanovaNo ratings yet

- Chemical ResistanceDocument14 pagesChemical ResistanceNissim Hazar CasanovaNo ratings yet

- Resinas para MetalDocument7 pagesResinas para MetalNissim Hazar CasanovaNo ratings yet

- Types of Methods of Powder Production:: Physico Chemical Processes Are As UnderDocument11 pagesTypes of Methods of Powder Production:: Physico Chemical Processes Are As UnderDevashish JoshiNo ratings yet

- HDL-PSG3442-300 Filtro Solberg - Filtro de Descarga de Equipo PDFDocument1 pageHDL-PSG3442-300 Filtro Solberg - Filtro de Descarga de Equipo PDFYacila AlvaradoNo ratings yet

- Ferraris Et Al IJED PIAR ARG 2 20212Document24 pagesFerraris Et Al IJED PIAR ARG 2 20212khaled emadNo ratings yet

- German Problems 2014 Thu Nghiem 1Document447 pagesGerman Problems 2014 Thu Nghiem 1Hảo ĐặngNo ratings yet

- The Following Text Is For Questions Number 1 and 2Document8 pagesThe Following Text Is For Questions Number 1 and 2ayip7miftahNo ratings yet

- Identification of Synthetic Cannabinoids 5F-Adb and Xlr-11 in Seized Sample in Penang, MalaysiaDocument6 pagesIdentification of Synthetic Cannabinoids 5F-Adb and Xlr-11 in Seized Sample in Penang, Malaysia049 VIMAL CHANDERNo ratings yet

- EYEC-Faculty of Chemical and Process Engineering - Monograph-2016Document234 pagesEYEC-Faculty of Chemical and Process Engineering - Monograph-2016ORDONEZENo ratings yet

- Material Specifications For Cartridge Valves and Manifolds: Better Performance Comes From Working TogetherDocument2 pagesMaterial Specifications For Cartridge Valves and Manifolds: Better Performance Comes From Working TogetherMiguel VlntìnNo ratings yet

- 0smoregulation in Fresh Water FishesDocument4 pages0smoregulation in Fresh Water FishesKazi AfrozNo ratings yet

- DAF-P&ID Mi For deDocument1 pageDAF-P&ID Mi For deali mohammedNo ratings yet

- Chem 26.1 Experiment 6 Atq Questions, Data SheetDocument4 pagesChem 26.1 Experiment 6 Atq Questions, Data SheetdeleonmatthewreiNo ratings yet

- June 2010 (v2) QP - Paper 1 CIE Chemistry IGCSEDocument16 pagesJune 2010 (v2) QP - Paper 1 CIE Chemistry IGCSERedCazorlaNo ratings yet

- BS-1377 Part-6 Standrard Test For Con Solidation PermeabilitDocument65 pagesBS-1377 Part-6 Standrard Test For Con Solidation PermeabilitAshraf Tomizeh100% (1)

- 101 DR Fixit Pidiproof LW+Document2 pages101 DR Fixit Pidiproof LW+beshnu garanaikNo ratings yet

- Alkanes ClassDocument27 pagesAlkanes ClassRyan JamesNo ratings yet

- Materials of Construction: Conventional ConverterDocument2 pagesMaterials of Construction: Conventional ConverterChrispine M BakulumaNo ratings yet

- PONTERAS (Alcohols, Phenols, Ethers)Document3 pagesPONTERAS (Alcohols, Phenols, Ethers)KARYLLE JUNE PONTERASNo ratings yet

- Excercise QuestionsDocument13 pagesExcercise QuestionsSavarinathan Maria RayappanNo ratings yet

- GESTRA Guide PDFDocument244 pagesGESTRA Guide PDFmkarahanNo ratings yet

- Coli. Arabinose Must First Be Converted Into Ribulose-5-Phosphate Before It Can BeDocument5 pagesColi. Arabinose Must First Be Converted Into Ribulose-5-Phosphate Before It Can BeDiego LeonardoNo ratings yet

- Spectrophotometric Determination of The Total Phenolic ContentDocument4 pagesSpectrophotometric Determination of The Total Phenolic ContentevitajulieNo ratings yet

- Recruitment, Result, Application Form, Admit Card: Prasar Bharati Previous Question Papers - Get Free Exam Sample PaperDocument7 pagesRecruitment, Result, Application Form, Admit Card: Prasar Bharati Previous Question Papers - Get Free Exam Sample PaperchowNo ratings yet

- MasterTop BSFDocument3 pagesMasterTop BSFnawazkhan23No ratings yet

- Matter and Materials: Natural ScienceDocument39 pagesMatter and Materials: Natural ScienceLu-Anne BrownNo ratings yet

- Iaea 89Document48 pagesIaea 89Imtiyaz AliNo ratings yet

- Class 12th Chemistry Project On Settling of CementDocument19 pagesClass 12th Chemistry Project On Settling of CementSuhail Ahmed100% (5)

- Lesson 1C - PhysDocument10 pagesLesson 1C - PhysEvamae Lincuna Moral ApacNo ratings yet

Epoxy Curing Agents For Fast Cure Civil Engineering Applications

Epoxy Curing Agents For Fast Cure Civil Engineering Applications

Uploaded by

Nissim Hazar CasanovaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Epoxy Curing Agents For Fast Cure Civil Engineering Applications

Epoxy Curing Agents For Fast Cure Civil Engineering Applications

Uploaded by

Nissim Hazar CasanovaCopyright:

Available Formats

Epoxy Curing Agents for Fast Cure

Civil Engineering Applications

Facility owners and applicators often demand

a quick return to service when re-coating or

repairing facility surfaces, and coating formu-

lators need to meet these requirements.

Air Products can help. We offer formulators the

most comprehensive line of fast cure amine-

based epoxy curing agents in the industry.

A Full Line of Fast Cure Products

Highlighted on the table on the reverse side

are some of the modified aliphatic and modified

cycloaliphatic products we recommend when

formulating for rapid cure and property devel-

opment at ambient or low-temperature condi-

tions. These products offer good performance

in a number of civil engineering and coating

applications, including industrial and decorative

flooring, concrete coatings and adhesives,

secondary containment linings and repair

mortars. The products can also be used

as accelerators for other amine-based

curing agents.

For more detailed information about our latest

fast cure developments, see the enclosed

product data sheets and the product table

on the reverse side.

19889/Odorski 1 5/15/01, 12:41 PM

Performance Properties thickness. In addition, set time is highly

and Fast Cure temperature-dependent and increases at

lower temperatures.

A number of product performance properties

are key indicators of a product’s fast cure Gel time is an indicator of pot life, the time the

ability. Thin film set time, for instance, is an applicator has to apply the formulated product

indicator of the time needed for an applied after mixing. The actual pot life of the formulated

epoxy to cure before it can be put into service. epoxy system depends on the modifiers and

Although greatly influenced by the choice of fillers added, the size of the mixing container,

curing agent, system set time also depends on and the mixing temperature.

fillers and additives as well as the applied

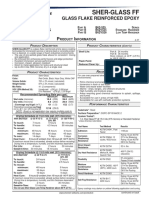

Air Products’ Epoxy Curing Agents for Fast Cure

Civil Engineering and Coatings Applications

77° F 40° F

Thin Film Thin Film Mixed 77° F Low Temp.

Set Time Set Time Gel Time Viscosity Viscosity Color Use Level Cure 60° Cure Film

(hr) (hr) (min) (cP) (cP) (Gardner) (phr) Gloss Appearance Comments

Modified Aliphatics

Ancamine® 1637LV 2.5 6.5 16 1,500 8,350 6 26 61 Fair Low cost-in-use. DOT noncorrosive.

Ancamine 1768 1.5 5.0 10 220 2,820 2 50 36 Poor Low viscosity. Low cost-in-use.

Ancamine 1856 1.8 3.5 9 3,000 10,800 5 40 NT Fair Very good cure under damp,

low-temperature conditions.

Ancamine 2089M 2.0 5.0 15 100 2,540 2 40 101 Very Good Very low viscosity. Very good

blush resistance.

Ancamine 2205 1.0 2.5 6 3,600 4 50 73 Poor The fastest cure at ambient and

low temperatures.

Ancamine 2432 2.0 8.0 27 300 2,100 3 46 109 Good Outstanding chemical resistance.

Good set time/pot life balance.

Ancamine 2481 2.7 8.5 18 1,000 4,470 2 47 119 Very Good Very good film appearance.

Low cost-in-use.

Modified Cycloaliphatics

Ancamine 2074 4.5 14.0 32 60 1,030 1 50 NT Good Low viscosity. Low color.

Very good color stability.

Ancamine 2368 5.3 16.0 32 200 1,400 2 52 119 Good Low viscosity. High strength and modulus.

Low cost-in-use.

Ancamine 2423 3.5 9.5 17 1,200 4,280 1 60 126 Good Excellent organic acid resistance.

Low color.

Ancamine 2489 3.0 10.0 32 80 860 1–2 44 126 Very Good Very low viscosity and mixed viscosity.

Good set time/pot life balance. Low color.

Ancamine 2505 3.5 13.0 31 495 2,900 8 58 129 Excellent Excellent blush resistance.

Low cost-in-use.

Air Products and Chemicals, Inc., Performance Chemicals Division, 7201 Hamilton Boulevard, Allentown, PA 18195-1501

Tel: 800-345-3148 or 610-481-6799, Fax: 610-481-4381, Web: www.airproducts.com/epoxyadditives

© Air Products and Chemicals, Inc., 1999 (19889) Printed in U.S.A. Pub. No. 125-9920

19889/Odorski 2 5/15/01, 12:41 PM

You might also like

- Organic Chemistry 9Th Edition Mcmurry Solutions Manual Full Chapter PDFDocument36 pagesOrganic Chemistry 9Th Edition Mcmurry Solutions Manual Full Chapter PDFmaria.topolosky417100% (11)

- Charpy Impact Test - Lab ReportDocument18 pagesCharpy Impact Test - Lab ReportChitra Nadia100% (1)

- Evonik-Ancamine 2791Document2 pagesEvonik-Ancamine 2791Tangtang GuoNo ratings yet

- EXP-MN-SM085-En-R0 - Safety Valves and Burst DiscsDocument55 pagesEXP-MN-SM085-En-R0 - Safety Valves and Burst Discsbali100% (7)

- Ancamide 2634 Curing Agent: Epoxy Curing Agents and ModifiersDocument7 pagesAncamide 2634 Curing Agent: Epoxy Curing Agents and ModifiersNissim Hazar CasanovaNo ratings yet

- BOATEXDocument1 pageBOATEXDianWidodoNo ratings yet

- Evonik Ancamine2811Document2 pagesEvonik Ancamine2811kishanptlNo ratings yet

- Anquamine 728: Curing AgentDocument4 pagesAnquamine 728: Curing AgentGreg PanganNo ratings yet

- Evonik-Ancamine 2726 EUDocument7 pagesEvonik-Ancamine 2726 EUkishanptlNo ratings yet

- Civil Engineering / Coatings Epikure Curing Agent 8545-W-52 Versatile Waterborne Amine Curing Agent For Civil Engineering and Floor CoatingsDocument4 pagesCivil Engineering / Coatings Epikure Curing Agent 8545-W-52 Versatile Waterborne Amine Curing Agent For Civil Engineering and Floor CoatingsDonnaNo ratings yet

- Evonik-Amicure PACMDocument5 pagesEvonik-Amicure PACMuzzy2No ratings yet

- DION IMPACT 9102 SeriesDocument5 pagesDION IMPACT 9102 SeriesLENEEVERSONNo ratings yet

- The World Quality Leader in Cashew Liquid Technology: Coating Products PortfolioDocument8 pagesThe World Quality Leader in Cashew Liquid Technology: Coating Products Portfolioمحمد عزتNo ratings yet

- Evonik-Ancamide 221-X70 - EUDocument5 pagesEvonik-Ancamide 221-X70 - EUMOHAMED100% (1)

- ANCAMINE® 2422 Curing Agent: DescriptionDocument7 pagesANCAMINE® 2422 Curing Agent: DescriptionSastra MahachemNo ratings yet

- Ancamide 2445 TdsDocument7 pagesAncamide 2445 Tdsnc5r8fkp6zNo ratings yet

- Ancamide 261A: Curing AgentDocument11 pagesAncamide 261A: Curing AgentBERKAT RAJA SEMESTANo ratings yet

- Evonik-Ancamine 2410Document10 pagesEvonik-Ancamine 2410Shivam NagarkarNo ratings yet

- Evonik-Ancamide 261A EUDocument7 pagesEvonik-Ancamide 261A EUNimerksNo ratings yet

- Ancamide 261a UsDocument11 pagesAncamide 261a UsdamiendamNo ratings yet

- Ancamine 1934 UsDocument3 pagesAncamine 1934 UsNIKESH PRAKASHNo ratings yet

- Evonik-Chemresist Pages PDFDocument16 pagesEvonik-Chemresist Pages PDFessaessa1980No ratings yet

- Evonik-Ancamine 2280 - EUDocument5 pagesEvonik-Ancamine 2280 - EUOswaldo Manuel Ramirez MarinNo ratings yet

- Luxafloor ECO: Water Borne Epoxy Floor CoatingDocument2 pagesLuxafloor ECO: Water Borne Epoxy Floor CoatinglivefreakNo ratings yet

- Atlac 590 002126 - 1520269898Document2 pagesAtlac 590 002126 - 1520269898Jainam ShahNo ratings yet

- 93 Sinopec Extreme Pressure Lithium Complex GreaseDocument3 pages93 Sinopec Extreme Pressure Lithium Complex GreaseAmadeus CocaNo ratings yet

- Swancor 901-3: Epoxy Vinyl Ester ResinsDocument2 pagesSwancor 901-3: Epoxy Vinyl Ester Resinswongpengchiong7205No ratings yet

- Acrolon 218 HS Acrylic PolyurethaneDocument4 pagesAcrolon 218 HS Acrylic PolyurethaneJohn ReevesNo ratings yet

- Crystic Gelcoat Ls 98pa Gelcoat en Nov17Document2 pagesCrystic Gelcoat Ls 98pa Gelcoat en Nov17ghariharan95No ratings yet

- Stycas 2850Document2 pagesStycas 2850die6o_brNo ratings yet

- Selection & Specification Data Substrates & Surface PreparationDocument2 pagesSelection & Specification Data Substrates & Surface PreparationJuanNo ratings yet

- TDS 2800000925 en - USDocument2 pagesTDS 2800000925 en - USIsrael HernandezNo ratings yet

- Ancamine 2739 TdsDocument8 pagesAncamine 2739 Tdsnc5r8fkp6zNo ratings yet

- Epoxy Backing Grout Epigen 0301: Typical Applications ProfileDocument2 pagesEpoxy Backing Grout Epigen 0301: Typical Applications ProfileDianWidodoNo ratings yet

- Araldite Epoxy Resin Cy 230 and Hy 951 HardenerDocument6 pagesAraldite Epoxy Resin Cy 230 and Hy 951 Hardenersonu50% (2)

- Araldite Epoxy Resin Cy 230 and Hy 951 HardenerDocument6 pagesAraldite Epoxy Resin Cy 230 and Hy 951 HardenerVaibhav AnuseNo ratings yet

- Molykote PG-641 Grease - PDSDocument2 pagesMolykote PG-641 Grease - PDSabc xyzNo ratings yet

- Blucem Hb55: Product Code Bc-20-00-000S R01/2017 Page 1 of 4Document4 pagesBlucem Hb55: Product Code Bc-20-00-000S R01/2017 Page 1 of 4Rajiv SingalNo ratings yet

- Tds Exxon 6101XRDocument2 pagesTds Exxon 6101XRindahNo ratings yet

- Royalthane 450GLDocument2 pagesRoyalthane 450GLSyed FaridNo ratings yet

- PolaneSolarReflective 1Document2 pagesPolaneSolarReflective 1cenoscottpatrickNo ratings yet

- Hetron 922 Infusion Resin 45 en A4Document1 pageHetron 922 Infusion Resin 45 en A4uzzy2No ratings yet

- Somentor Rolling Oils: Asia PacificDocument4 pagesSomentor Rolling Oils: Asia PacificFajar EkoNo ratings yet

- Sherglass FFDocument4 pagesSherglass FFJhose BonillaNo ratings yet

- Ancamine 2740 TdsDocument5 pagesAncamine 2740 Tdsnc5r8fkp6zNo ratings yet

- Acrolon 218 HsDocument4 pagesAcrolon 218 HsKARENNo ratings yet

- CarbolineDocument18 pagesCarbolineimaduddinshaNo ratings yet

- Epigen 0907: High Strength Epoxy AdhesiveDocument2 pagesEpigen 0907: High Strength Epoxy AdhesiveAfzal ImamNo ratings yet

- 838 Silicone Adhesive SealantDocument3 pages838 Silicone Adhesive SealantMario Vargas VegaNo ratings yet

- Exxon 6101Document2 pagesExxon 6101M. Kürşad ArslanNo ratings yet

- Belzona 1121: Product Specification SheetDocument2 pagesBelzona 1121: Product Specification SheetQuy RomNo ratings yet

- Ancamide 2573 TDSDocument1 pageAncamide 2573 TDSnc5r8fkp6zNo ratings yet

- 670.bull.2022 (22.0)Document3 pages670.bull.2022 (22.0)Francisco RodríguezNo ratings yet

- Ancamine 2726 TdsDocument1 pageAncamine 2726 Tdsnc5r8fkp6zNo ratings yet

- Evonik Sunmide CX 1151 UploadDocument6 pagesEvonik Sunmide CX 1151 UploadEpox by Epx polymers pvt ltdNo ratings yet

- 22 - Water-Borne Road Marking Resin - Eagacryl 6050 - 2019 EditionDocument4 pages22 - Water-Borne Road Marking Resin - Eagacryl 6050 - 2019 Editionleonardo16No ratings yet

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 Hshector gomezNo ratings yet

- Interbond 201 Temperate Eng A4 20171106Document4 pagesInterbond 201 Temperate Eng A4 20171106Purwanto ritzaNo ratings yet

- EMULSION TECHNICAL DATA SHEET (7 Revised 1212)Document1 pageEMULSION TECHNICAL DATA SHEET (7 Revised 1212)kabiru isahNo ratings yet

- Epoxy Coating K Sir 88Document2 pagesEpoxy Coating K Sir 88ANIBALLOPEZVEGANo ratings yet

- Rubber Nanocomposites: Preparation, Properties, and ApplicationsFrom EverandRubber Nanocomposites: Preparation, Properties, and ApplicationsNo ratings yet

- Ancamide 2634 Curing Agent: Epoxy Curing Agents and ModifiersDocument7 pagesAncamide 2634 Curing Agent: Epoxy Curing Agents and ModifiersNissim Hazar CasanovaNo ratings yet

- Epoxy Curing Agents and ModifiersDocument3 pagesEpoxy Curing Agents and ModifiersNissim Hazar CasanovaNo ratings yet

- Epoxy Curing Agents and ModifiersDocument4 pagesEpoxy Curing Agents and ModifiersNissim Hazar CasanovaNo ratings yet

- Epoxy Curing Agents and Modifiers: Ancamine® 1637-LV Curing AgentDocument1 pageEpoxy Curing Agents and Modifiers: Ancamine® 1637-LV Curing AgentNissim Hazar CasanovaNo ratings yet

- Epoxy Curing Agents and Modifiers: Ancamide® 260A Curing AgentDocument1 pageEpoxy Curing Agents and Modifiers: Ancamide® 260A Curing AgentNissim Hazar CasanovaNo ratings yet

- Krasol LBD2000Document1 pageKrasol LBD2000Nissim Hazar CasanovaNo ratings yet

- Epoxy Civil EngineeringDocument20 pagesEpoxy Civil EngineeringNissim Hazar CasanovaNo ratings yet

- AkzoNobel EBS 481 FQ tcm54-30339Document1 pageAkzoNobel EBS 481 FQ tcm54-30339Nissim Hazar CasanovaNo ratings yet

- Chemical ResistanceDocument14 pagesChemical ResistanceNissim Hazar CasanovaNo ratings yet

- Resinas para MetalDocument7 pagesResinas para MetalNissim Hazar CasanovaNo ratings yet

- Types of Methods of Powder Production:: Physico Chemical Processes Are As UnderDocument11 pagesTypes of Methods of Powder Production:: Physico Chemical Processes Are As UnderDevashish JoshiNo ratings yet

- HDL-PSG3442-300 Filtro Solberg - Filtro de Descarga de Equipo PDFDocument1 pageHDL-PSG3442-300 Filtro Solberg - Filtro de Descarga de Equipo PDFYacila AlvaradoNo ratings yet

- Ferraris Et Al IJED PIAR ARG 2 20212Document24 pagesFerraris Et Al IJED PIAR ARG 2 20212khaled emadNo ratings yet

- German Problems 2014 Thu Nghiem 1Document447 pagesGerman Problems 2014 Thu Nghiem 1Hảo ĐặngNo ratings yet

- The Following Text Is For Questions Number 1 and 2Document8 pagesThe Following Text Is For Questions Number 1 and 2ayip7miftahNo ratings yet

- Identification of Synthetic Cannabinoids 5F-Adb and Xlr-11 in Seized Sample in Penang, MalaysiaDocument6 pagesIdentification of Synthetic Cannabinoids 5F-Adb and Xlr-11 in Seized Sample in Penang, Malaysia049 VIMAL CHANDERNo ratings yet

- EYEC-Faculty of Chemical and Process Engineering - Monograph-2016Document234 pagesEYEC-Faculty of Chemical and Process Engineering - Monograph-2016ORDONEZENo ratings yet

- Material Specifications For Cartridge Valves and Manifolds: Better Performance Comes From Working TogetherDocument2 pagesMaterial Specifications For Cartridge Valves and Manifolds: Better Performance Comes From Working TogetherMiguel VlntìnNo ratings yet

- 0smoregulation in Fresh Water FishesDocument4 pages0smoregulation in Fresh Water FishesKazi AfrozNo ratings yet

- DAF-P&ID Mi For deDocument1 pageDAF-P&ID Mi For deali mohammedNo ratings yet

- Chem 26.1 Experiment 6 Atq Questions, Data SheetDocument4 pagesChem 26.1 Experiment 6 Atq Questions, Data SheetdeleonmatthewreiNo ratings yet

- June 2010 (v2) QP - Paper 1 CIE Chemistry IGCSEDocument16 pagesJune 2010 (v2) QP - Paper 1 CIE Chemistry IGCSERedCazorlaNo ratings yet

- BS-1377 Part-6 Standrard Test For Con Solidation PermeabilitDocument65 pagesBS-1377 Part-6 Standrard Test For Con Solidation PermeabilitAshraf Tomizeh100% (1)

- 101 DR Fixit Pidiproof LW+Document2 pages101 DR Fixit Pidiproof LW+beshnu garanaikNo ratings yet

- Alkanes ClassDocument27 pagesAlkanes ClassRyan JamesNo ratings yet

- Materials of Construction: Conventional ConverterDocument2 pagesMaterials of Construction: Conventional ConverterChrispine M BakulumaNo ratings yet

- PONTERAS (Alcohols, Phenols, Ethers)Document3 pagesPONTERAS (Alcohols, Phenols, Ethers)KARYLLE JUNE PONTERASNo ratings yet

- Excercise QuestionsDocument13 pagesExcercise QuestionsSavarinathan Maria RayappanNo ratings yet

- GESTRA Guide PDFDocument244 pagesGESTRA Guide PDFmkarahanNo ratings yet

- Coli. Arabinose Must First Be Converted Into Ribulose-5-Phosphate Before It Can BeDocument5 pagesColi. Arabinose Must First Be Converted Into Ribulose-5-Phosphate Before It Can BeDiego LeonardoNo ratings yet

- Spectrophotometric Determination of The Total Phenolic ContentDocument4 pagesSpectrophotometric Determination of The Total Phenolic ContentevitajulieNo ratings yet

- Recruitment, Result, Application Form, Admit Card: Prasar Bharati Previous Question Papers - Get Free Exam Sample PaperDocument7 pagesRecruitment, Result, Application Form, Admit Card: Prasar Bharati Previous Question Papers - Get Free Exam Sample PaperchowNo ratings yet

- MasterTop BSFDocument3 pagesMasterTop BSFnawazkhan23No ratings yet

- Matter and Materials: Natural ScienceDocument39 pagesMatter and Materials: Natural ScienceLu-Anne BrownNo ratings yet

- Iaea 89Document48 pagesIaea 89Imtiyaz AliNo ratings yet

- Class 12th Chemistry Project On Settling of CementDocument19 pagesClass 12th Chemistry Project On Settling of CementSuhail Ahmed100% (5)

- Lesson 1C - PhysDocument10 pagesLesson 1C - PhysEvamae Lincuna Moral ApacNo ratings yet