Professional Documents

Culture Documents

Raffmetal: UNI EN 1676 and 1706

Raffmetal: UNI EN 1676 and 1706

Uploaded by

swaroop NalamCopyright:

Available Formats

You might also like

- Operation & Maintenance Manual 319 Compact Excavator: S/N 563311001 & AboveDocument136 pagesOperation & Maintenance Manual 319 Compact Excavator: S/N 563311001 & Abovejose breno vieira silva50% (2)

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706satheeskumar VikramasingarajNo ratings yet

- Cu ZN 15 TombacDocument2 pagesCu ZN 15 TombacPetrus UngureanuNo ratings yet

- EN47100Document2 pagesEN47100tsonjayaNo ratings yet

- EN71000 From ReinferdenDocument2 pagesEN71000 From ReinferdenJason WuNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Hareth MRAIDINo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Sachin JawaleNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Amandeep SinghNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Raj RajeshNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Martin DuarteNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Hareth MRAIDINo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Jonathan Getial CruzNo ratings yet

- En 44100Document2 pagesEn 44100hiren_mistry55No ratings yet

- BS en 1706 - En44100 PDFDocument2 pagesBS en 1706 - En44100 PDFDhamodaran RNo ratings yet

- Kme STOL76 C19010 enDocument1 pageKme STOL76 C19010 enMattia Terri TerrandoNo ratings yet

- c68700 Aluminum BrassDocument1 pagec68700 Aluminum Brassm_f_deathNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Raj RajeshNo ratings yet

- ML 13 FC AlSi (Cu) non-EN AB Standard AlloyDocument2 pagesML 13 FC AlSi (Cu) non-EN AB Standard Alloygtarq09No ratings yet

- Copper Cu-Dhp / Sf-Cu: Page 1/2Document2 pagesCopper Cu-Dhp / Sf-Cu: Page 1/2gemilanglpNo ratings yet

- Navy M BronzeDocument1 pageNavy M BronzeDeepak KumarNo ratings yet

- CuNiSi AlloyDocument6 pagesCuNiSi AlloyJdjoNo ratings yet

- 6060 PropertiesDocument3 pages6060 Propertiesinterpon07No ratings yet

- CuZn40 01 2019 PDFDocument7 pagesCuZn40 01 2019 PDFMisaelNo ratings yet

- En 1706 Aluminum and Aluminum Alloys Castings en 1676 Aluminum Alloyed Ingots For RemeltingDocument1 pageEn 1706 Aluminum and Aluminum Alloys Castings en 1676 Aluminum Alloyed Ingots For RemeltingBahar ÇolakNo ratings yet

- A.S.T.M. B584-09a: WWW - Okendo.mxDocument4 pagesA.S.T.M. B584-09a: WWW - Okendo.mxShariq KhanNo ratings yet

- C2700Document6 pagesC2700Andrew TanNo ratings yet

- AISI 1035 cs46Document2 pagesAISI 1035 cs46Russell ShacklefordNo ratings yet

- Copper Alloy: Leaded Gun Metal Cusn5Zn5Pb5-CDocument1 pageCopper Alloy: Leaded Gun Metal Cusn5Zn5Pb5-CPankaj KumbhareNo ratings yet

- CuZn30 PDFDocument2 pagesCuZn30 PDFavinashchauhan2695No ratings yet

- AmuDocument2 pagesAmuavinashchauhan2695No ratings yet

- Cusn8 Industrial RolledDocument4 pagesCusn8 Industrial RolledPrakash MakadiaNo ratings yet

- Tigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-ADocument1 pageTigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-AsatnamNo ratings yet

- ASM Material Data Sheet PDFDocument2 pagesASM Material Data Sheet PDFtiele_barcelosNo ratings yet

- CuZn33 CatalogueDocument9 pagesCuZn33 CataloguefedericoNo ratings yet

- Arsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!Document2 pagesArsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!David LluguinNo ratings yet

- Tigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28Document1 pageTigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28satnamNo ratings yet

- Alloy 276 Spec SheetDocument3 pagesAlloy 276 Spec SheetJAYA BHARATHA REDDYNo ratings yet

- Cu-HCP: C10300 Industrial RolledDocument7 pagesCu-HCP: C10300 Industrial RolledpierocarnelociNo ratings yet

- Aisi 304Document2 pagesAisi 304Rohit100% (1)

- Datasheet Sanicro 72hpDocument2 pagesDatasheet Sanicro 72hpphillipskincaidNo ratings yet

- LFBCW510L TN enDocument4 pagesLFBCW510L TN endrgilleNo ratings yet

- PNA 400_Cu-OF_C10200-E.NDocument2 pagesPNA 400_Cu-OF_C10200-E.Ntatto198No ratings yet

- Ex EN 43100 AlSi10Mg (B) non-EN AB Standard AlloyDocument2 pagesEx EN 43100 AlSi10Mg (B) non-EN AB Standard Alloygtarq09No ratings yet

- MSrinivas - STEELS FOR CRITICAL APPLICATIONSDocument46 pagesMSrinivas - STEELS FOR CRITICAL APPLICATIONSamit gajbhiye100% (1)

- Haynes: Hastelloy W AlloyDocument4 pagesHaynes: Hastelloy W AlloyLuiz FernandoNo ratings yet

- High Tensile: Voestalpine High Performance Metals (Australia) Pty LTDDocument5 pagesHigh Tensile: Voestalpine High Performance Metals (Australia) Pty LTDSinan YıldızNo ratings yet

- Cuzn37 Industrial RolledDocument6 pagesCuzn37 Industrial RolledcvgfgNo ratings yet

- DS Mold 2311 1Document4 pagesDS Mold 2311 1marjan banooNo ratings yet

- CZLLCW511L TN enDocument4 pagesCZLLCW511L TN endrgilleNo ratings yet

- Cu DHPDocument3 pagesCu DHPLUIGINo ratings yet

- Material Data Sheet: Manganese Bronze (High Strength Yellow Brass)Document1 pageMaterial Data Sheet: Manganese Bronze (High Strength Yellow Brass)Fred Duarte CaldeiraNo ratings yet

- 2205 Technical Data Sheet: Chemistry Mechanical PropertiesDocument6 pages2205 Technical Data Sheet: Chemistry Mechanical PropertiesJandri JacobNo ratings yet

- Datasheet Sandvik 2rk65 en v2019!06!19 14 - 54 Version 1Document13 pagesDatasheet Sandvik 2rk65 en v2019!06!19 14 - 54 Version 1mauferesNo ratings yet

- Sandvik 25.22.2.Lmn: (Welding Wire)Document3 pagesSandvik 25.22.2.Lmn: (Welding Wire)Anonymous w6TIxI0G8lNo ratings yet

- Cu Ofe c10100 Pna 203 - enDocument2 pagesCu Ofe c10100 Pna 203 - enNitin KumarNo ratings yet

- Cu ZN 15Document2 pagesCu ZN 15wjjt6chgtmNo ratings yet

- Steel PropertiesDocument22 pagesSteel PropertiesMOHD SALMANNo ratings yet

- Bronze C86300 SpecificationsDocument2 pagesBronze C86300 SpecificationsDoss MartinNo ratings yet

- Material Data Sheet: Manganese Bronze (High Strength Yellow Brass)Document1 pageMaterial Data Sheet: Manganese Bronze (High Strength Yellow Brass)Fred Duarte CaldeiraNo ratings yet

- 25724-830-V1A-MHCB-00049 Inf. TecnicaDocument3 pages25724-830-V1A-MHCB-00049 Inf. TecnicaNelson Cuevas AvendanoNo ratings yet

- Choosing The Best Integration Approach Among RFC Adapter, ABAP Proxy, and Enterprise ServicesDocument7 pagesChoosing The Best Integration Approach Among RFC Adapter, ABAP Proxy, and Enterprise ServicesLord SethNo ratings yet

- Install GuideDocument2 pagesInstall GuideffdfNo ratings yet

- Lab 4 WindTunnel Cylinder HandoutDocument7 pagesLab 4 WindTunnel Cylinder HandoutSteelcoverNo ratings yet

- Zorrozaurre Master Plan: Press ReleaseDocument4 pagesZorrozaurre Master Plan: Press ReleasegmaNo ratings yet

- Fundamentals of Surveying Part 3 - PartialDocument10 pagesFundamentals of Surveying Part 3 - PartialRanier Andrei VillanuevaNo ratings yet

- Aerated Concrete Production Using Various Raw MaterialsDocument5 pagesAerated Concrete Production Using Various Raw Materialskinley dorjee100% (1)

- Python L1 Assignments Topgear Hima 284446Document10 pagesPython L1 Assignments Topgear Hima 284446subhani shaik100% (1)

- Airport BussinesDocument56 pagesAirport Bussinesjonmrx001No ratings yet

- 4824 Kimbrell-4824 TherrienDocument25 pages4824 Kimbrell-4824 TherrienzazaNo ratings yet

- Visvesvaraya Technological University: Department of Civil EngineeringDocument5 pagesVisvesvaraya Technological University: Department of Civil EngineeringAkshay HalyalNo ratings yet

- Environmental Degradation PDFDocument10 pagesEnvironmental Degradation PDFMuhammad UsmanNo ratings yet

- Failure Cause Value MappingDocument54 pagesFailure Cause Value MappingHuỳnh Thanh Tuấn0% (1)

- Distributor - Perkins Extended Life Coolant PresentationDocument11 pagesDistributor - Perkins Extended Life Coolant PresentationPritish147No ratings yet

- KeTTHA - Incentives For Renewable Energy, Energy Efficiency & Green Buildings in MalaysiaDocument22 pagesKeTTHA - Incentives For Renewable Energy, Energy Efficiency & Green Buildings in MalaysiamicrefeeNo ratings yet

- PXE Lot or PXE LiteDocument10 pagesPXE Lot or PXE Lite1E : Empowering IT Efficiency100% (1)

- TRUST2G TELKOMSEL-NOKBSC-BSC-day-PM 16365-2019 01 03-10 34 04 795Document137 pagesTRUST2G TELKOMSEL-NOKBSC-BSC-day-PM 16365-2019 01 03-10 34 04 795Dayat Hidayat HidayatNo ratings yet

- Dewa Asset ManagemntDocument7 pagesDewa Asset ManagemntDC VashistNo ratings yet

- Quickspecs: HP Ipaq Hx2100 Series Pocket PCDocument9 pagesQuickspecs: HP Ipaq Hx2100 Series Pocket PCnongNo ratings yet

- Week One Homework Problems: Fundamentals of ! Fluid PowerDocument2 pagesWeek One Homework Problems: Fundamentals of ! Fluid PowertprakashtceNo ratings yet

- 3.4 - Burning in A KilnDocument4 pages3.4 - Burning in A KilnIrshad Hussain100% (1)

- Grizzly FeederDocument1 pageGrizzly FeederAmr N KhNo ratings yet

- Discover Media PQ Gen.2 April - 2018 - enDocument5 pagesDiscover Media PQ Gen.2 April - 2018 - enMir MihailescuNo ratings yet

- Online ChattingDocument24 pagesOnline ChattingAmruthaprashanthNo ratings yet

- ENGLISHDocument13 pagesENGLISHpierocarnelociNo ratings yet

- SPE-200168-MS (Aramco - Gas Choking)Document11 pagesSPE-200168-MS (Aramco - Gas Choking)Alfonso RamosNo ratings yet

- Penomoran Ordner QC Head Office ContohDocument2 pagesPenomoran Ordner QC Head Office ContohGultom Juliana LiliesNo ratings yet

- Tute4 NewDocument4 pagesTute4 NewMicheal LordyNo ratings yet

- Design and Estimation of 1MW Utility ScaDocument15 pagesDesign and Estimation of 1MW Utility ScaRodney ZephaniaNo ratings yet

Raffmetal: UNI EN 1676 and 1706

Raffmetal: UNI EN 1676 and 1706

Uploaded by

swaroop NalamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Raffmetal: UNI EN 1676 and 1706

Raffmetal: UNI EN 1676 and 1706

Uploaded by

swaroop NalamCopyright:

Available Formats

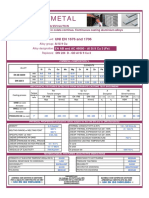

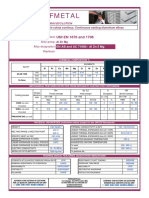

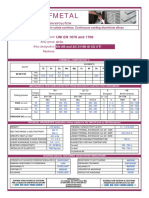

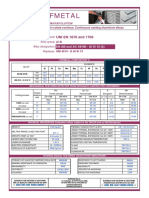

RAFFMETAL

THE ALUMINIUM EVOLUTION

g di alluminio in colata continua. Continuous casting

Leghe g aluminium alloys

y

Standard: UNI EN 1676 and 1706

Alloy group: Al Si 9 Cu

Alloy designation: EN AB and AC 46100 - Al Si 11 Cu 2 (Fe)

Replaces: UNI 7363 - SG Al Si 132

CHEMICAL COMPOSITION %

ELEMENTS

ALLOY Individual Global

Si Fe Cu Mn Mg Cr Ni Zn Pb Sn Ti impurities impurities

min 10,0

, 0,45

, 1,5

,

EN AB 46100

max 12,0 1,0 2,5 0,55 0,30 0,15 0,45 1,7 0,25 0,15 0,20 0,05 0,25

min 11,0 0,70 1,75

UNI 7363 - SG Al Si 132

max 12,5 1,0 2,50 0,5 0,30 - 0,30 1,40 0,15 0,10 0,20 2,20

MECHANICAL FEATURES DETECTED FROM SEPARATE CASTING TEST SPECIMENS

Rm Sp 0,2 A HB

Temper Tensile strenght Yield strenght Elongation Brinell hardness

gp

Casting process designat

g

ions EN 1706 UNI 7363 EN 1706 UNI 7363 EN 1706 UNI 7363 EN 1706 UNI 7363

Mpa N/mm2 Mpa N/mm2 % % HBW HB

SAND (as cast)

Annealed

SHELL (as cast)

Annealed

PRESSURE DIE (as cast) F 240 265-295 140 155-195 1 1,5-2,5 80 85-100

PHYSICAL PROPERTIES (indicative values subject to the UNI EN and ex UNI Standards)

DENSITY 2.67 Kg/dm³ THERMAL CONDUCTIVITY at 20°C 120 - 130 W/(m K)

565 Ԩ LINEAR THERMAL EXPANSION from 20 t 100Ԩ 19.7x10-6/°C

MELTING RANGE or MELTING POINT

585 Ԩ LINEAR THERMAL EXPANSION from 20 t 200Ԩ 20.5x10-6/°C

SPECIFIC HEAT (at 100)° 0.23 cal/g °C LINEAR THERMAL EXPANSION from 20 t 300Ԩ 21.3x10-6/°C

LATENT HEAT OF MELTING 93 cal/g SUGGESTED MAXIMUM TEMPERATURE 750 Ԩ

LINEAR SHRINKAGE ˜0.7 % SUGGESTED CASTING TEMPERATURE

ELECTRIC CONDUCTIVITY 14 - 18 MS/m °in sand

MODULUS OF ELASTICITY 7600 Kg/mm² °in shell

°in pressure die 600-700 Ԩ

TECHNOLOGICAL FEATURES, QUALITATIVE INDICATIONS

STRENGTH AT ELEVATED TEMPERATURE(to 200°C MEDIUM RESISTANCE TO HOT TEARING SMALL

GENERAL RESISTANCE TO CORROSION MEDIUM PRESSURE TIGHTNESS SUFFICIENT

MACHINABILITY SUFFICIENT WELDABILITY SUFFICIENT

CASTABILITY GOOD DECORATIVE ANODISING LOW

POLISHING MEDIUM PROTECTIVE ANODISING

Raffmetal S.p.a.

via malpaga, 82 25070 Casto (BS)

tel:0365.890.100 fax 0365.899.327

qualita@raffmetal.it

q @

vendite@raffmetal.it

You might also like

- Operation & Maintenance Manual 319 Compact Excavator: S/N 563311001 & AboveDocument136 pagesOperation & Maintenance Manual 319 Compact Excavator: S/N 563311001 & Abovejose breno vieira silva50% (2)

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706satheeskumar VikramasingarajNo ratings yet

- Cu ZN 15 TombacDocument2 pagesCu ZN 15 TombacPetrus UngureanuNo ratings yet

- EN47100Document2 pagesEN47100tsonjayaNo ratings yet

- EN71000 From ReinferdenDocument2 pagesEN71000 From ReinferdenJason WuNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Hareth MRAIDINo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Sachin JawaleNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Amandeep SinghNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Raj RajeshNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Martin DuarteNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Hareth MRAIDINo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Jonathan Getial CruzNo ratings yet

- En 44100Document2 pagesEn 44100hiren_mistry55No ratings yet

- BS en 1706 - En44100 PDFDocument2 pagesBS en 1706 - En44100 PDFDhamodaran RNo ratings yet

- Kme STOL76 C19010 enDocument1 pageKme STOL76 C19010 enMattia Terri TerrandoNo ratings yet

- c68700 Aluminum BrassDocument1 pagec68700 Aluminum Brassm_f_deathNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Raj RajeshNo ratings yet

- ML 13 FC AlSi (Cu) non-EN AB Standard AlloyDocument2 pagesML 13 FC AlSi (Cu) non-EN AB Standard Alloygtarq09No ratings yet

- Copper Cu-Dhp / Sf-Cu: Page 1/2Document2 pagesCopper Cu-Dhp / Sf-Cu: Page 1/2gemilanglpNo ratings yet

- Navy M BronzeDocument1 pageNavy M BronzeDeepak KumarNo ratings yet

- CuNiSi AlloyDocument6 pagesCuNiSi AlloyJdjoNo ratings yet

- 6060 PropertiesDocument3 pages6060 Propertiesinterpon07No ratings yet

- CuZn40 01 2019 PDFDocument7 pagesCuZn40 01 2019 PDFMisaelNo ratings yet

- En 1706 Aluminum and Aluminum Alloys Castings en 1676 Aluminum Alloyed Ingots For RemeltingDocument1 pageEn 1706 Aluminum and Aluminum Alloys Castings en 1676 Aluminum Alloyed Ingots For RemeltingBahar ÇolakNo ratings yet

- A.S.T.M. B584-09a: WWW - Okendo.mxDocument4 pagesA.S.T.M. B584-09a: WWW - Okendo.mxShariq KhanNo ratings yet

- C2700Document6 pagesC2700Andrew TanNo ratings yet

- AISI 1035 cs46Document2 pagesAISI 1035 cs46Russell ShacklefordNo ratings yet

- Copper Alloy: Leaded Gun Metal Cusn5Zn5Pb5-CDocument1 pageCopper Alloy: Leaded Gun Metal Cusn5Zn5Pb5-CPankaj KumbhareNo ratings yet

- CuZn30 PDFDocument2 pagesCuZn30 PDFavinashchauhan2695No ratings yet

- AmuDocument2 pagesAmuavinashchauhan2695No ratings yet

- Cusn8 Industrial RolledDocument4 pagesCusn8 Industrial RolledPrakash MakadiaNo ratings yet

- Tigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-ADocument1 pageTigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-AsatnamNo ratings yet

- ASM Material Data Sheet PDFDocument2 pagesASM Material Data Sheet PDFtiele_barcelosNo ratings yet

- CuZn33 CatalogueDocument9 pagesCuZn33 CataloguefedericoNo ratings yet

- Arsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!Document2 pagesArsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!David LluguinNo ratings yet

- Tigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28Document1 pageTigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28satnamNo ratings yet

- Alloy 276 Spec SheetDocument3 pagesAlloy 276 Spec SheetJAYA BHARATHA REDDYNo ratings yet

- Cu-HCP: C10300 Industrial RolledDocument7 pagesCu-HCP: C10300 Industrial RolledpierocarnelociNo ratings yet

- Aisi 304Document2 pagesAisi 304Rohit100% (1)

- Datasheet Sanicro 72hpDocument2 pagesDatasheet Sanicro 72hpphillipskincaidNo ratings yet

- LFBCW510L TN enDocument4 pagesLFBCW510L TN endrgilleNo ratings yet

- PNA 400_Cu-OF_C10200-E.NDocument2 pagesPNA 400_Cu-OF_C10200-E.Ntatto198No ratings yet

- Ex EN 43100 AlSi10Mg (B) non-EN AB Standard AlloyDocument2 pagesEx EN 43100 AlSi10Mg (B) non-EN AB Standard Alloygtarq09No ratings yet

- MSrinivas - STEELS FOR CRITICAL APPLICATIONSDocument46 pagesMSrinivas - STEELS FOR CRITICAL APPLICATIONSamit gajbhiye100% (1)

- Haynes: Hastelloy W AlloyDocument4 pagesHaynes: Hastelloy W AlloyLuiz FernandoNo ratings yet

- High Tensile: Voestalpine High Performance Metals (Australia) Pty LTDDocument5 pagesHigh Tensile: Voestalpine High Performance Metals (Australia) Pty LTDSinan YıldızNo ratings yet

- Cuzn37 Industrial RolledDocument6 pagesCuzn37 Industrial RolledcvgfgNo ratings yet

- DS Mold 2311 1Document4 pagesDS Mold 2311 1marjan banooNo ratings yet

- CZLLCW511L TN enDocument4 pagesCZLLCW511L TN endrgilleNo ratings yet

- Cu DHPDocument3 pagesCu DHPLUIGINo ratings yet

- Material Data Sheet: Manganese Bronze (High Strength Yellow Brass)Document1 pageMaterial Data Sheet: Manganese Bronze (High Strength Yellow Brass)Fred Duarte CaldeiraNo ratings yet

- 2205 Technical Data Sheet: Chemistry Mechanical PropertiesDocument6 pages2205 Technical Data Sheet: Chemistry Mechanical PropertiesJandri JacobNo ratings yet

- Datasheet Sandvik 2rk65 en v2019!06!19 14 - 54 Version 1Document13 pagesDatasheet Sandvik 2rk65 en v2019!06!19 14 - 54 Version 1mauferesNo ratings yet

- Sandvik 25.22.2.Lmn: (Welding Wire)Document3 pagesSandvik 25.22.2.Lmn: (Welding Wire)Anonymous w6TIxI0G8lNo ratings yet

- Cu Ofe c10100 Pna 203 - enDocument2 pagesCu Ofe c10100 Pna 203 - enNitin KumarNo ratings yet

- Cu ZN 15Document2 pagesCu ZN 15wjjt6chgtmNo ratings yet

- Steel PropertiesDocument22 pagesSteel PropertiesMOHD SALMANNo ratings yet

- Bronze C86300 SpecificationsDocument2 pagesBronze C86300 SpecificationsDoss MartinNo ratings yet

- Material Data Sheet: Manganese Bronze (High Strength Yellow Brass)Document1 pageMaterial Data Sheet: Manganese Bronze (High Strength Yellow Brass)Fred Duarte CaldeiraNo ratings yet

- 25724-830-V1A-MHCB-00049 Inf. TecnicaDocument3 pages25724-830-V1A-MHCB-00049 Inf. TecnicaNelson Cuevas AvendanoNo ratings yet

- Choosing The Best Integration Approach Among RFC Adapter, ABAP Proxy, and Enterprise ServicesDocument7 pagesChoosing The Best Integration Approach Among RFC Adapter, ABAP Proxy, and Enterprise ServicesLord SethNo ratings yet

- Install GuideDocument2 pagesInstall GuideffdfNo ratings yet

- Lab 4 WindTunnel Cylinder HandoutDocument7 pagesLab 4 WindTunnel Cylinder HandoutSteelcoverNo ratings yet

- Zorrozaurre Master Plan: Press ReleaseDocument4 pagesZorrozaurre Master Plan: Press ReleasegmaNo ratings yet

- Fundamentals of Surveying Part 3 - PartialDocument10 pagesFundamentals of Surveying Part 3 - PartialRanier Andrei VillanuevaNo ratings yet

- Aerated Concrete Production Using Various Raw MaterialsDocument5 pagesAerated Concrete Production Using Various Raw Materialskinley dorjee100% (1)

- Python L1 Assignments Topgear Hima 284446Document10 pagesPython L1 Assignments Topgear Hima 284446subhani shaik100% (1)

- Airport BussinesDocument56 pagesAirport Bussinesjonmrx001No ratings yet

- 4824 Kimbrell-4824 TherrienDocument25 pages4824 Kimbrell-4824 TherrienzazaNo ratings yet

- Visvesvaraya Technological University: Department of Civil EngineeringDocument5 pagesVisvesvaraya Technological University: Department of Civil EngineeringAkshay HalyalNo ratings yet

- Environmental Degradation PDFDocument10 pagesEnvironmental Degradation PDFMuhammad UsmanNo ratings yet

- Failure Cause Value MappingDocument54 pagesFailure Cause Value MappingHuỳnh Thanh Tuấn0% (1)

- Distributor - Perkins Extended Life Coolant PresentationDocument11 pagesDistributor - Perkins Extended Life Coolant PresentationPritish147No ratings yet

- KeTTHA - Incentives For Renewable Energy, Energy Efficiency & Green Buildings in MalaysiaDocument22 pagesKeTTHA - Incentives For Renewable Energy, Energy Efficiency & Green Buildings in MalaysiamicrefeeNo ratings yet

- PXE Lot or PXE LiteDocument10 pagesPXE Lot or PXE Lite1E : Empowering IT Efficiency100% (1)

- TRUST2G TELKOMSEL-NOKBSC-BSC-day-PM 16365-2019 01 03-10 34 04 795Document137 pagesTRUST2G TELKOMSEL-NOKBSC-BSC-day-PM 16365-2019 01 03-10 34 04 795Dayat Hidayat HidayatNo ratings yet

- Dewa Asset ManagemntDocument7 pagesDewa Asset ManagemntDC VashistNo ratings yet

- Quickspecs: HP Ipaq Hx2100 Series Pocket PCDocument9 pagesQuickspecs: HP Ipaq Hx2100 Series Pocket PCnongNo ratings yet

- Week One Homework Problems: Fundamentals of ! Fluid PowerDocument2 pagesWeek One Homework Problems: Fundamentals of ! Fluid PowertprakashtceNo ratings yet

- 3.4 - Burning in A KilnDocument4 pages3.4 - Burning in A KilnIrshad Hussain100% (1)

- Grizzly FeederDocument1 pageGrizzly FeederAmr N KhNo ratings yet

- Discover Media PQ Gen.2 April - 2018 - enDocument5 pagesDiscover Media PQ Gen.2 April - 2018 - enMir MihailescuNo ratings yet

- Online ChattingDocument24 pagesOnline ChattingAmruthaprashanthNo ratings yet

- ENGLISHDocument13 pagesENGLISHpierocarnelociNo ratings yet

- SPE-200168-MS (Aramco - Gas Choking)Document11 pagesSPE-200168-MS (Aramco - Gas Choking)Alfonso RamosNo ratings yet

- Penomoran Ordner QC Head Office ContohDocument2 pagesPenomoran Ordner QC Head Office ContohGultom Juliana LiliesNo ratings yet

- Tute4 NewDocument4 pagesTute4 NewMicheal LordyNo ratings yet

- Design and Estimation of 1MW Utility ScaDocument15 pagesDesign and Estimation of 1MW Utility ScaRodney ZephaniaNo ratings yet