Professional Documents

Culture Documents

1M08-AQUA-AZ-725-J-501-Part A - Rev 1

1M08-AQUA-AZ-725-J-501-Part A - Rev 1

Uploaded by

mannshiCopyright:

Available Formats

You might also like

- B2 Study GuideDocument2 pagesB2 Study GuideTito GitanoNo ratings yet

- DNV Comparison of Offshore Structural StandardsDocument219 pagesDNV Comparison of Offshore Structural StandardsNils Antoine Freund100% (3)

- Cmu Block Wall DetailDocument2 pagesCmu Block Wall DetailAbdulBari100% (1)

- JAW - 00-K - 11a - 040 - PP - 176 - Commissioning ITP-LV DISTRIBUTION BOARD (MCC) 00BJA10 & 00BJB10 - Rev.0Document13 pagesJAW - 00-K - 11a - 040 - PP - 176 - Commissioning ITP-LV DISTRIBUTION BOARD (MCC) 00BJA10 & 00BJB10 - Rev.0MedrouaNo ratings yet

- 4) Well Control EquipmentDocument77 pages4) Well Control Equipmentoswaldo58100% (3)

- York Yoea36fs36adhDocument20 pagesYork Yoea36fs36adhjean_carlos_abreu_rNo ratings yet

- Backwash Tank DesignDocument289 pagesBackwash Tank DesignmannshiNo ratings yet

- Aln IcDocument272 pagesAln Ic8506070700No ratings yet

- Specification - Water Spray Fixed SystemsDocument23 pagesSpecification - Water Spray Fixed SystemsJaseelKanhirathinkalNo ratings yet

- B - Design Criteria For Civil and StructuresDocument29 pagesB - Design Criteria For Civil and StructuresS ParamNo ratings yet

- S-0000-13A0-001 - 2B - 0001 - FC - Specification For Painting and Color CodingDocument57 pagesS-0000-13A0-001 - 2B - 0001 - FC - Specification For Painting and Color CodingWoon Czen NgNo ratings yet

- CB MX71ZZ El Rep 0001 000Document56 pagesCB MX71ZZ El Rep 0001 000alemdar.muhendislik25No ratings yet

- 00 Ytc MR - Tre 001 EngDocument81 pages00 Ytc MR - Tre 001 EngJessica RodriguezNo ratings yet

- Part V-PRD-1-MMS-PLA-01-0001-0 - Maintenance & Inspection Plan For Offshore Structures (Rev.0)Document66 pagesPart V-PRD-1-MMS-PLA-01-0001-0 - Maintenance & Inspection Plan For Offshore Structures (Rev.0)Son DDarrellNo ratings yet

- Calculation: Box CulvertDocument154 pagesCalculation: Box CulvertRaditya AzkaLaodeNo ratings yet

- Utf Stup STR Cal DDD Vto 001 r0Document20 pagesUtf Stup STR Cal DDD Vto 001 r0zbricks.postNo ratings yet

- 8015 0151 SC03 00 000 CN MS 00003 - 01Document33 pages8015 0151 SC03 00 000 CN MS 00003 - 01Mohanad GanemNo ratings yet

- SSP-CRCO-SS05-SYSW-PRO-00119 - 04 - PAT Procedure For 750V DC Earth SwitchDocument31 pagesSSP-CRCO-SS05-SYSW-PRO-00119 - 04 - PAT Procedure For 750V DC Earth Switchabu bakar100% (1)

- 123-ODE-ELE-A-RA-000001 - Revb - Outer Dowsing OWF - Concept Electrical System ReportDocument101 pages123-ODE-ELE-A-RA-000001 - Revb - Outer Dowsing OWF - Concept Electrical System ReportAshiqRahimanNo ratings yet

- AGP-GPS-ANOGP-L02-0001-C01 - Electrical Design Basis PDFDocument26 pagesAGP-GPS-ANOGP-L02-0001-C01 - Electrical Design Basis PDFRubénNo ratings yet

- Utf Stup STR Cal DDD Gau 001 r0Document23 pagesUtf Stup STR Cal DDD Gau 001 r0zbricks.postNo ratings yet

- Nger Ko Nccal 00 39083Document36 pagesNger Ko Nccal 00 39083Osas AsemotaNo ratings yet

- MS For Cable Glanding and TerminationDocument11 pagesMS For Cable Glanding and TerminationNijo JoseNo ratings yet

- Uu00 P NNSG 000 0512Document34 pagesUu00 P NNSG 000 0512khalid benessalahNo ratings yet

- H-10207 00 0ea00-001f Ec-Cscs Cubicles Equipment Technical Specification - BDocument16 pagesH-10207 00 0ea00-001f Ec-Cscs Cubicles Equipment Technical Specification - Bnguyen rinNo ratings yet

- j910 Dm02 P0eaf 660001 Erection Instruction Portal Reclaimer 01abDocument58 pagesj910 Dm02 P0eaf 660001 Erection Instruction Portal Reclaimer 01abrajaramkodaiNo ratings yet

- Earthing & Bonding - Principles & SpecificationDocument20 pagesEarthing & Bonding - Principles & SpecificationKumaresh100% (1)

- CounterDocument93 pagesCountera.agila03No ratings yet

- PDPII - May 2011 - Dhanaraj - 10644Document96 pagesPDPII - May 2011 - Dhanaraj - 10644Utibe basseyNo ratings yet

- CAA 2009-359 Appendix 1Document62 pagesCAA 2009-359 Appendix 1Shamendu Roy RohitNo ratings yet

- Planta Potosí Solar-Mexico 300 Mwac: Lightning Risk AssessmentDocument34 pagesPlanta Potosí Solar-Mexico 300 Mwac: Lightning Risk AssessmentJosue Crespo GonzalezNo ratings yet

- Evaluation of Centrifugal Contactor Hydraulic and Mass Transfer Performance For Caustic-Side Solvent Extraction of CesiumDocument44 pagesEvaluation of Centrifugal Contactor Hydraulic and Mass Transfer Performance For Caustic-Side Solvent Extraction of CesiumKuang-Chuan WongNo ratings yet

- INTEGRATION RENEWABLE ENERGY DIST. System (1994 (Document124 pagesINTEGRATION RENEWABLE ENERGY DIST. System (1994 (Jose ValdiviesoNo ratings yet

- CHW2204-00-EL-SPE-7301 Rev0 Specification For Electrical SystemDocument20 pagesCHW2204-00-EL-SPE-7301 Rev0 Specification For Electrical SystemphongtttNo ratings yet

- Client: Dhamra LNG Terminal Private LimitedDocument13 pagesClient: Dhamra LNG Terminal Private LimitedbalajikrishnanNo ratings yet

- BRS1-SP-E-BRS-0014.RD1 Cathodic Protection SpecificationDocument31 pagesBRS1-SP-E-BRS-0014.RD1 Cathodic Protection SpecificationABDELKADERNo ratings yet

- BZOF-MT-PRO-00035 - 0 DATA Logger Recording ProcedureDocument25 pagesBZOF-MT-PRO-00035 - 0 DATA Logger Recording ProcedureManik KNo ratings yet

- Transient Analysis ReportDocument29 pagesTransient Analysis Reportmani rNo ratings yet

- SDA-S17893-BNYC1-PX-1206-00001 C01 Bonny Equipment Sizing Calculation ReportDocument37 pagesSDA-S17893-BNYC1-PX-1206-00001 C01 Bonny Equipment Sizing Calculation ReportsegunNo ratings yet

- Earthworks Technical SpecificationDocument48 pagesEarthworks Technical SpecificationFeng XueNo ratings yet

- 6305 EL MCA 7050 A00 - AC&DC Maitenes DischargeDocument29 pages6305 EL MCA 7050 A00 - AC&DC Maitenes Dischargevicesuza87No ratings yet

- 31-MBD-127 Inlet Separator-Rev.0 (On Pile)Document53 pages31-MBD-127 Inlet Separator-Rev.0 (On Pile)Didi Hadi RiantoNo ratings yet

- RLP-1000-PM-SP-001 - IFI - Scope of Work For Detailed Engineering & Design For Storage Tanks, In-Plant Piping, Supports & Structural SteelDocument45 pagesRLP-1000-PM-SP-001 - IFI - Scope of Work For Detailed Engineering & Design For Storage Tanks, In-Plant Piping, Supports & Structural SteelAdewaleNo ratings yet

- MultiDocument452 pagesMultia.agila03No ratings yet

- VD-LINE-WP57-SUB-ATM-0001-017 - ERECTION AND INSTALLATION PROCEDURE ATM TANK - Rev.1Document18 pagesVD-LINE-WP57-SUB-ATM-0001-017 - ERECTION AND INSTALLATION PROCEDURE ATM TANK - Rev.1tomy.jipNo ratings yet

- Nger Ko Nccal 00 39083Document35 pagesNger Ko Nccal 00 39083Osas AsemotaNo ratings yet

- Mq15-08-Te-3340-Fs0001 - 0 2023Document684 pagesMq15-08-Te-3340-Fs0001 - 0 2023hugoNo ratings yet

- Balon2 CodeDocument136 pagesBalon2 CodeAshwini YadavNo ratings yet

- Civil Design CriteriaDocument13 pagesCivil Design CriteriaFikriansyahIndraSaputraNo ratings yet

- 1100-CV-DBS-001 - IFB - R0 - Civil Structure Design Criteria SignedDocument28 pages1100-CV-DBS-001 - IFB - R0 - Civil Structure Design Criteria SignedRianto FelissimoNo ratings yet

- PH12-3A-24-22-P011 Rev A - 160MVA TX StabilityDocument19 pagesPH12-3A-24-22-P011 Rev A - 160MVA TX Stabilityaravindhana1a1No ratings yet

- Specification - Automatic Wet Sprinkler SystemsDocument22 pagesSpecification - Automatic Wet Sprinkler SystemsJaseelKanhirathinkalNo ratings yet

- Assessment of Damage and Failure Mechanisms For Offshore Structures and Pipelines in Gustav An DikeDocument142 pagesAssessment of Damage and Failure Mechanisms For Offshore Structures and Pipelines in Gustav An DikeEduardo Jose Sanchez LoboNo ratings yet

- CMM86503 - V1 Turret Chain Stopper Calculation PDFDocument24 pagesCMM86503 - V1 Turret Chain Stopper Calculation PDFTran LinhNo ratings yet

- Utf Stup STR Cal DDD Div 001 r00Document21 pagesUtf Stup STR Cal DDD Div 001 r00zbricks.postNo ratings yet

- Hydrant Water Tank Foundation Design Calc - Ebocha1Document39 pagesHydrant Water Tank Foundation Design Calc - Ebocha1Levi UbaNo ratings yet

- Next Generation SDH/SONET: Evolution or Revolution?From EverandNext Generation SDH/SONET: Evolution or Revolution?Rating: 2.5 out of 5 stars2.5/5 (2)

- Autonomous Software-Defined Radio Receivers for Deep Space ApplicationsFrom EverandAutonomous Software-Defined Radio Receivers for Deep Space ApplicationsJon HamkinsNo ratings yet

- Intermittent Convex Integration for the 3D Euler Equations: (AMS-217)From EverandIntermittent Convex Integration for the 3D Euler Equations: (AMS-217)No ratings yet

- Design Thrust BlockDocument4 pagesDesign Thrust BlockmannshiNo ratings yet

- Thust Block DesignDocument15 pagesThust Block DesignmannshiNo ratings yet

- Thrust Block Dimensions: Sand 200Document2 pagesThrust Block Dimensions: Sand 200mannshiNo ratings yet

- 1M05 (B) TECTON-C-010 (REV-AB-1) SHEET No.1 OF 3-ModelDocument1 page1M05 (B) TECTON-C-010 (REV-AB-1) SHEET No.1 OF 3-ModelmannshiNo ratings yet

- Backwash Tank DesignDocument289 pagesBackwash Tank DesignmannshiNo ratings yet

- Graduation Project: Structure Analysis Unit "3" Supervisors: Dr:Osman Ramadan Dr:Hatem OsmanDocument26 pagesGraduation Project: Structure Analysis Unit "3" Supervisors: Dr:Osman Ramadan Dr:Hatem OsmanmannshiNo ratings yet

- High Rise Building Calculation SheetDocument29 pagesHigh Rise Building Calculation SheetmannshiNo ratings yet

- High Rise Building Calculation SheetDocument25 pagesHigh Rise Building Calculation SheetmannshiNo ratings yet

- Design of Column: P .35 Fcu Ac+.67fy As Fcu 250 kg/cm2 Fy 3600 kg/cm2Document4 pagesDesign of Column: P .35 Fcu Ac+.67fy As Fcu 250 kg/cm2 Fy 3600 kg/cm2mannshiNo ratings yet

- Graduation Project: Structure Analysis Unit "3" Supervisors: Dr:Osman Ramadan Dr:Hatem OsmanDocument26 pagesGraduation Project: Structure Analysis Unit "3" Supervisors: Dr:Osman Ramadan Dr:Hatem OsmanmannshiNo ratings yet

- Frames Systems Case Study AnalysisDocument15 pagesFrames Systems Case Study AnalysismannshiNo ratings yet

- Area Handing OverDocument6 pagesArea Handing OveronspsnonsNo ratings yet

- Material List: Produced On 13/11/2020 With Xpress Selection V9.0.1 - Database DIL 16.0.2Document11 pagesMaterial List: Produced On 13/11/2020 With Xpress Selection V9.0.1 - Database DIL 16.0.2Sicologo CimeNo ratings yet

- Pfs PPT 2Document27 pagesPfs PPT 2api-303720407No ratings yet

- Concreto Construccion CivilDocument4 pagesConcreto Construccion CivilMarcela Campos100% (1)

- Single Home BOQ PDFDocument3 pagesSingle Home BOQ PDFDexter Lex F. SatanaNo ratings yet

- Composite Steel JoistsDocument10 pagesComposite Steel Joistsv2299100% (1)

- 2019 0124 Fairfield Auditor Rebid Dwgs VOL 2 PDFDocument41 pages2019 0124 Fairfield Auditor Rebid Dwgs VOL 2 PDFShradha Arun SasanNo ratings yet

- Combined Footings PDFDocument2 pagesCombined Footings PDFLisa100% (1)

- 527 A014.1Document1 page527 A014.1Jinxian XuNo ratings yet

- Construction Techniques in A High Rise BuildingDocument32 pagesConstruction Techniques in A High Rise Buildingtaruntaru15379% (19)

- Atgc MP Ipa 04Document268 pagesAtgc MP Ipa 04Pradeep AnuradhaaNo ratings yet

- Gypsum Board Shaftwall Arch Spec en 09260 09211623Document15 pagesGypsum Board Shaftwall Arch Spec en 09260 09211623can_cer087No ratings yet

- Btrs System Technical Summary PDFDocument2 pagesBtrs System Technical Summary PDFpaulina7shiNo ratings yet

- Load Calculation SheetDocument9 pagesLoad Calculation SheetNaveen RevannaNo ratings yet

- BIM For Masonry Modeling Buildings in Autodesk RevitDocument101 pagesBIM For Masonry Modeling Buildings in Autodesk RevitMSNo ratings yet

- Question Bank On Structural Design 2Document3 pagesQuestion Bank On Structural Design 2Govind TivadiNo ratings yet

- ECA Presentation - Group ADocument33 pagesECA Presentation - Group AChungHuiPingNo ratings yet

- Pedal Powered RefrigeratorDocument7 pagesPedal Powered RefrigeratorPrashant KumarNo ratings yet

- Day 3-5 Introduction To Nonlinear Modeling Using Perform 3D PDFDocument21 pagesDay 3-5 Introduction To Nonlinear Modeling Using Perform 3D PDFMIHDI PALAPUZ100% (2)

- Index PDFDocument7 pagesIndex PDFganesh gundNo ratings yet

- Navaneetha Content 1Document5 pagesNavaneetha Content 1Pavithran ParameshwaranNo ratings yet

- Emerson ACDocument20 pagesEmerson ACMorryNo ratings yet

- OJTDocument36 pagesOJTRachelle AtienzaNo ratings yet

- CH 8Document80 pagesCH 8Jasmine KaurNo ratings yet

- BeshywapDocument5 pagesBeshywapAldinNo ratings yet

- Structural Framing Systems: The Trussed Tube Bundled Tube SystemDocument1 pageStructural Framing Systems: The Trussed Tube Bundled Tube SystemTanuja SidduNo ratings yet

- GHHDocument198 pagesGHHkala1989100% (1)

1M08-AQUA-AZ-725-J-501-Part A - Rev 1

1M08-AQUA-AZ-725-J-501-Part A - Rev 1

Uploaded by

mannshiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1M08-AQUA-AZ-725-J-501-Part A - Rev 1

1M08-AQUA-AZ-725-J-501-Part A - Rev 1

Uploaded by

mannshiCopyright:

Available Formats

PROJECT 7 MIGD R.O.

DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK

Document No: 1M08-AQUA-AZ-725-J-501 1 1 of 36

CALCULATION REPORT FOR BACK WASH TANK

PART A : ROOF SUPPORTING STRUCTURE

1 02/10/10 Re Issued for Approval Thiyagarajan Dr BVSB RAJA

0 24/08/10 Issued for Approval Thiyagarajan Dr BVSB RAJA

DATE PREPARED BY CHECKED BY APPROVED BY

Rev STATUS

DD/MM/YY (name & sign) (name & sign) (name & sign)

DOCUMENT REVISIONS

Sections changed in last revision are identified by a vertical line in the right margin

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

PROJECT 7 MIGD R.O. DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK

Document No: 1M08-AQUA-AZ-725-J-501 1 2 of 36

DATE DETAILS OF REVISION REV NO

24/08/10 Issued for Approval 0

02/10/2010 Re Issued for Approval 1

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

PROJECT 7 MIGD R.O. DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK

Document No: 1M08-AQUA-AZ-725-J-501 1 3 of 36

INDEX

1.0 GENERAL NOTES ………………………………………………………………………………………………. 4

1.1 SCOPE …………………………………………………………………………………………………………… 4

1.2 DESIGN PHILOSOPHY …………………………………………………………………………………… 4

1.3 DESIGN SPECIFICATION, CODES AND STANDARDS ………………………………… 5

1.4 UNITS OF MEASUREMENT ………………………………………………………………………… 5

1.5 MATERIALS …………………………………………………………………………………………………… 5

2.0 GENERAL GEOMETRY ………………………………………………………………………………………. 7

2.1 MODEL FOR SOFTWARE CALCULATIONS (STAAD SKETCHES) …………………… 7

2.1.1 ISOMETRIC VIEW OF THE FRAME …………………………………………………………… 7

2.1.2 SUPPORT NUMBERS ……………………………………………………………………………… 8

2.1.3 NODE NUMBERS, BEAM NUMBERS AND MEMBER PROPERTIES ……………. 8

3.0 LOAD ANALYSIS ………………………………………………………………………………………………… 12

3 1 PRIMARY LOAD CASE

3.1 …………………………………………………………………………………… 12

3.1.1 DEAD LOAD (DL) (LOAD CASE 11) ………………………………………………………. 12

3.1.2 LIVE LOAD (LL) (LOAD CASE 13) …………………………………………………………… 14

3.1.3 SEISMIC LOAD (EQ) (LOAD CASE 1 & 2) ……………………………………………. 15

4.0 LOAD COMBINATIONS …………………………………………… 17

4.1 LOAD COMBINATION LIST FOR LIMIT STATE OF STRENGTH …………… 17

4.2 LOAD COMBINATION LIST FOR LIMIT STATE OF SERVICEABILITY …………… 17

5.0 MEMBER DESIGN ……………………………………………………………………………………………….. 18

5.1 DESIGN FORCE FOR COLUMN ………………………………………………………………….. 18

5.2 COLUMN DESIGN FROM STAAD ………………………………………………………………. 19

5.3 BEAM DESIGN ……………………………………………………………………………………………. 21

5.3.1 CALCULATION OF SERVICE BM …………………………………………………………… 21

5.3.2 FOR RB1 ………………………………………………………………………………………………. 22

5.3.3 FOR RB2 ………………………………………………………………………………………………. 27

6.0 STAAD INPUT ……………………………………………………………………………………………………….. 32

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

PROJECT 7 MIGD R.O. DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK

Document No: 1M08-AQUA-AZ-725-J-501 1 4 of 36

1.0 GENERAL NOTES

1.1 SCOPE

The scope of this calculation is to evaluate the loads, perform structural analysis, stability check, and

design of the back wash tank roof supporting structures.

1.2 DESIGN PHILOSOPHY

1) The roof slab of the tank shall be of hollow core slab. Since the tank is circular in shape,

some places the precast RCC slab is proposed to achieve the curved boundary.

It is indicated in the roof plan (Drawing No. 725-C-503)

2) The provision for supporting hollow core slab at the top of the beam is given by having an

inverted "T" in the precast beam cross section.

3) The precast beam has been supported over the corbel in the cast in situ column.

4) The entire roofing system is connected to the shell wall thro slit arrangement in shell top.

5) The most of the horizontal shear due roof shall be resisted by concrete shell as like the

shear wall in the high rise building. Hence the connection between Shell and roof beam can be

assumed as pinned connection.

6) The load from the hollow core slab will be distributed as in one way slab. Hence the other

direction the same tie beam is provided to ensure the stability of the structure.

7) The slope for drainage on the roof is given by light weight screed concrete.

The density of light weight concrete should not be more than 10 kN/Cu.m.

8) The roof structure is modeled and analysed in Staad. The bottom of the column will have a fixed

connection with the raft slab and the bottom of shell will have pinned connection in the base slab

i.e no moment tranfer allowed from wall to base slab.

9) The seismic analysis is done as per UBC 97 as mentioned in FEWA specification and the

structural frame is designed as per BS 8110-1: 1997.

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

PROJECT 7 MIGD R.O. DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK

Document No: 1M08-AQUA-AZ-725-J-501 1 5 of 36

1.3 DESIGN SPECIFICATION, CODES AND STANDARDS

1 BS 8110-1:1997

Structural use of Concrete: Code of practice for Design and Construction

2 BS 8110-2:1985 Structural use of Concrete: Code of Practice for Special Circumstances

3 BS 8110-3:1985 Structural use of Concrete: Design charts for Singly Reinforced Beams,

Doubly Reinforced Beams, and Rectangular Columns

4 BS 8007: 1987 Code of practice for Design of Concrete Structures for Retaining Aqueous

Liquids

5 BS 8004: 1986 Code of practice for foundation.

6 BS 6399-3: 1988 Code of Practice for Imposed Roof Loads

7 UBC 97 Uniform Building Code

8 ACI 350.03-06 Seismic design of Liquid-Containing Concrete Structures and Commentary

Project Standard Drawings and Specification

1 1M08-AQUA-AZ-725-C-001 Backwash Tank and Pump Station - Civil guide drawing.

2 1M08-AQUA-AZ-725-C-002 Backwash Tank GCP10BB001 - Civil Guide drawing.

3 1M08-AQUA-AZ-722-P-001 Backwash Pumps CCP11AP001 / GCP12AP001 -

Piping Arrangement

1.4 UNITS OF MEASUREMENT

The International System units (S.I.) are used in this calculation as per ISO: 1000

In particular the following units & symbols are considered for calculation.

Length m, mm

Area m2, mm2

Volume mm3,m3

Force kN,N

Moment kNm

Mass kg.

o

Temperature C

Pressure kPa=kN/m2, MPa=N/mm2

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

PROJECT 7 MIGD R.O. DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK

Document No: 1M08-AQUA-AZ-725-J-501 1 6 of 36

1.5 MATERIALS

Concrete

Characteristic Strength of Cast-In-Situ Concrete (C50) fCU = 35 N/mm2

Specific weight c = 25 kN/m3

Reinforcement

Yield Strength of High Yield Strength Deformed bars (HYSD)

as per Table 1 of IS:1786, (Grade - Fe415) fy = 460 N/mm2

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

PROJECT 7 MIGD R.O. DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK

Document No: 1M08-AQUA-AZ-725-J-501 1 7 of 36

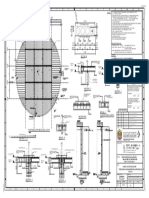

2.0 GENERAL GEOMETRY

2.1 MODEL FOR SOFTWARE CALCULATIONS (STAAD SKETCHES)

2.1.1 ISOMETRIC VIEW OF THE FRAME

Diameter of the tank = 16.0 m

No of columns = 4.0 Nos

A

1

ISOMETRIC VIEW

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

PROJECT 7 MIGD R.O. DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK

Document No: 1M08-AQUA-AZ-725-J-501 1 8 of 36

2.1.2 SUPPORT NUMBERS

213 218

214 219

2.1.3 NODE NUMBERS, BEAM NUMBERS AND BEAM PROPERTIES

MEMBER PROPERTIES

MEMBER MEMBER SIZE

SL.NO MARK WIDTH (MM) DEPTH (mm)

1 R1 350 800

2 R2 600 600

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

PROJECT 7 MIGD R.O. DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK

Document No: 1M08-AQUA-AZ-725-J-501 1 9 of 36

322 329

623:R3 633:R3

316 323 330 337

522:R2 523:R2 524:R2

622:R3 632:R3

317 324 331 338

512:R2 513:R2 514:R2

621:R3 631:R3

325 332

PLAN AT ROOF LEVEL

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

PROJECT 7 MIGD R.O. DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK

Document No: 1M08-AQUA-AZ-725-J-501 1 10 of 36

322 323 324 325

623:R3 622:R3 621:R3

2067:R1 2068:R1

213 214

ELEVATION ALONG GRID A

329 330 331 332

633:R3 632:R3 631:R3

2095:R1 2096:R1

218 219

ELEVATION ALONG GRID B

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

PROJECT 7 MIGD R.O. DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK

Document No: 1M08-AQUA-AZ-725-J-501 1 11 of 36

317 324 331 338

512:R2 513:R2 514:R2

2068:R1 2096:R1

214 219

ELEVATION ALONG GRID 1

316 323 330 337

522:R2 523:R2 524:R2

2067:R1 2095:R1

213 218

ELEVATION ALONG GRID 2

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

PROJECT 7 MIGD R.O. DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK

Document No: 1M08-AQUA-AZ-725-J-501 1 12 of 36

3.0 LOAD ANALYSIS

3.1 PRIMARY LOAD CASE

SL.NO Load Case No Load Case Description

1 1 EQX Seismic Load in X Direction

2 2 EQZ Seismic Load in Z Direction

3 3 DL Dead Load of Structural Members

4 4 LL Live Load

3.1.1 DEAD LOAD (DL) (LOAD CASE 3)

This load case includes self weight of structure and dead weight of Hollow core slab, screed etc.

a) Self weight of all main members is generated by STAAD-pro 2007, with a gravity multiplier

equal to 1.00.

b) Since the hollow core slab is used as roof slab, the loading given as one way distribution.

Self weight of hollow core slab = 3.00 KN/m2

C/C of Column = 7.40 m

Outer beam Length = 4.30 m

UDL over the beam = 3 x (7.4 + 4.3) / 2

17.55 kN/m

Thickness of screed concrete = 0.10 m

Weight of screed concrete = 1.00 KN/m2

UDL over the beam = 1 x (7.4 + 4.3) / 2

5.85

Total UDL over intermediate beam = 23.40 KN/m Say 24.00 KN/m

Total UDL over end Span = 11.70 KN/m Say 12.00 KN/m

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

PROJECT 7 MIGD R.O. DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK

Document No: 1M08-AQUA-AZ-725-J-501 1 13 of 36

-12.0 kN/m

633 -12.0 kN/m

-12.0 kN/m 524

-24.0 kN/m

523

623 -12.0 kN/m

632

-12.0 kN/m

522

-12.0 kN/m

2095 514

622

-24.0 kN/m

631

513

-12.0 kN/m

2067

-12.0 kN/m

512

621

2096

2068

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

PROJECT 7 MIGD R.O. DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK

Document No: 1M08-AQUA-AZ-725-J-501 1 14 of 36

3.1.2 LIVE LOAD (LL) (LOAD CASE 4)

This load include live loads on Roofs

Live load on Roof

Intensity of live load considered = 1.50 kN/m2 (Ref. Cl. 4.3 of BS 6399-3 : 1988)

C/C of Column = 7.40 m

Outer beam Length = 4.30 m

UDL over the beam = 1.5 x (7.4 + 4.3) / 2

Total UDL over intermediate beam = 8.78 KN/m Say 9.00 KN/m

Total UDL over end Span = 4.39 KN/m Say 4.50 KN/m

-4.5 kN/m

633 -4.5 kN/m

-4.5 kN/m 524

-9.0 kN/m

523

623 -4.5 kN/m

632

-4.5 kN/m

522

-4.5 kN/m

2095 514

622

-9.0 kN/m

631

513

-4.5 kN/m

2067

-4.5 kN/m

512

621

2096

2068

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

PROJECT 7 MIGD R.O. DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK

Document No: 1M08-AQUA-AZ-725-J-501 1 15 of 36

3.1.3 SEISMIC LOAD (EQ) (LOADCASES 1 & 2)

Seismic loads are calculated based on UBC 97. Detailed analysis is done by STAAD PRO by

defining various parameters based on the following.

Seismic zone = 2A (Ref. Design Basis)

Seismic zone factor Z = 0.15 (Ref. Table 16.I UBC 1997)

Importance factor I = 1.25

Reduction factor R = 3.5

Soil profile type (Stiff Soil Profile) = SD (Ref. Table 16.J, UBC 1997)

Full Dead load with 25% for live load (Intensity below 3kN/m2 ) are considered to be active during

seismic condition.

The seismic weight is automatically calculated by Staad itself.

9.4 kN

9.4 kN

9.4 kN

58.7 kN

9.4 kN

9.4 kN

58.7 kN

58.7 kN

9.4 kN

9.4 kN

58.7 kN

9.4 kN

0 kN

0 kN

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

PROJECT 7 MIGD R.O. DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK

Document No: 1M08-AQUA-AZ-725-J-501 1 16 of 36

58.7 kN

9.4 kN

9.4 kN

58.7 kN

9.4 kN

58.7 kN

9.4 kN

9.4 kN

58.7 kN

9.4 kN

9.4 kN

9.4 kN

0 kN

0 kN

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

PROJECT 7 MIGD R.O. DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK

Document No: 1M08-AQUA-AZ-725-J-501 1 17 of 36

4.0 LOAD COMBINATIONS

The Load Combination is taken from UBC 97.

Load 1 2 3 4

Case

EQX EQZ DL LL

101 1.4

102 1.2 1.6

103 1 1.2

104 1 0.9

105 -1 0.9

106 1 1.2

107 1 0.9

108 -1 0.9

201 1

202 1 1

203 0 714

0.714 1

204 0.714 0.9

205 -0.714 0.9

206 0.714 1 0.75

207 0.714 1

208 0.714 0.9

209 -0.714 0.9

210 0.714 1 0.75

4.1 LOAD COMBINATION LIST FOR LIMIT STATE OF STRENGTH

Load combinations for static load - 101 to 102

Load combinations for EQX - 103 to 105

Load combinations for EQZ - 106 to 108

4.2 LOAD COMBINATION LIST FOR LIMIT STATE OF SERVICEABILITY

Load combinations for crack width - 201 to 210

Load list for design of column

101 to 108

Load list for design of Roof beam

101 to 108

Load list for design of Tie beam

101 to 108

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

PROJECT 7 MIGD R.O. DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK

Document No: 1M08-AQUA-AZ-725-J-501 1 18 of 36

5.0 MEMBER DESIGN

5.1 DESIGN FORCE FOR COLUMN

d Fx Fy Fz Mx My Mz

Beam L/C

(m) (kN) (kN) (kN) (kNm) (kNm) (kNm)

Max Fx 2095 102 0.0 474.6 0.0 0.0 0.0 0.0 0.0

Min Fx 2068 104 6.6 225.2 0.1 0.0 0.1 0.0 0.0

Max Fy 2067 103 0.0 368.7 0.1 0.0 -0.1 0.0 0.6

Min Fy 2067 105 0.0 276.6 -0.1 0.0 0.1 0.0 -0.6

Max Fz 2067 108 0.0 276.6 0.0 0.1 -0.1 -0.6 0.0

Min Fz 2067 106 0.0 368.7 0.0 -0.1 0.1 0.6 0.0

Max Mx 2067 106 0.0 368.7 0.0 -0.1 0.1 0.6 0.0

Min Mx 2067 108 00

0.0 276 6

276.6 00

0.0 01

0.1 01

-0.1 -0.6

06 00

0.0

Max My 2067 106 0.0 368.7 0.0 -0.1 0.1 0.6 0.0

Min My 2067 108 0.0 276.6 0.0 0.1 -0.1 -0.6 0.0

Max Mz 2067 103 0.0 368.7 0.1 0.0 -0.1 0.0 0.6

Min Mz 2067 105 0.0 276.6 -0.1 0.0 0.1 0.0 -0.6

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

PROJECT 7 MIGD R.O. DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK

Document No: 1M08-AQUA-AZ-725-J-501 1 19 of 36

5.2 COLUMN DESIGN FROM STAAD

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

PROJECT 7 MIGD R.O. DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK

Document No: 1M08-AQUA-AZ-725-J-501 1 20 of 36

Area of Reinforcement Reqd. = 1440 sq.mm

Provided Reinforcement = 8-Y25

Provided area of Reinforcement = 3928 sq.mm HENCE OK

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

PROJECT 7 MIGD R.O. DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK

Document No: 1M08-AQUA-AZ-725-J-501 1 21 of 36

5.3 BEAM DESIGN

5.3.1 CALCULATION OF SERVICE BENDING MOMENT

Descriptions RB1 RB2

Node C/C (m) 7.40 3.60

Eff. Span (m) 6.50 3.45

Dead Load (kN) 24.00 12.00

Selfweight (kN) 21.11 21.11

Live Load (kN) 9.00 4.50

Total Load (kN) 54.11 37.61

BM (kN.m) 285.78 55.96

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

PROJECT 7 MIGD R.O. DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK

Document No: 1M08-AQUA-AZ-725-J-501 1 22 of 36

5.3.2 FOR RB-1

MATERIAL DATA

Characteristic strength of concrete fcu = 35 N/mm2

Characteristic strength of reinforcement fy = 460 N/mm2

Characteristic strength of shear reinf. fyv = 460 N/mm2

GEOMETRY DATA

Equivalent width of Beam B= 350 mm

Depth of Beam D= 800 mm

Clear cover cc = 50 mm

Dia of first layer reinf. d1 = 25 mm

Dia of second layer reinf. d2 = 25 mm

Effective depth bottom reinf

reinf. d= 713 mm

Effective depth at top reinf. d' = 63 mm

FORCE DATA

Max force details for Member No. 523, 513, 622, 632

d Fx Fy Fz Mx My Mz

Beam L/C

(m) (kN) (kN) (kN) (kNm) (kNm) (kNm)

Max Fx 622 105 0.0 0.0 62.3 0.0 0.0 0.0 0.0

Min Fx 622 103 0.0 0.0 83.1 0.0 0.0 0.0 0.0

Max Fy 513 102 0.0 0.0 189.7 0.0 0.0 0.0 0.0

Min Fy 513 102 7.4 0.0 -189.7 0.0 0.0 0.0 0.0

Max Fz 622 106 0.0 0.0 83.1 0.0 0.0 -0.1 0.0

Min Fz 622 108 0.0 0.0 62.3 0.0 0.0 0.1 0.0

Max Mx 523 105 0.0 0.0 102.3 0.0 0.0 -0.1 0.0

Min Mx 523 103 0.0 0.0 136.4 0.0 0.0 0.1 0.0

Max My 622 108 0.0 0.0 62.3 0.0 0.0 0.1 0.0

Min My 622 106 0.0 0.0 83.1 0.0 0.0 -0.1 0.0

Max Mz 513 101 0.0 0.0 159.1 0.0 0.0 0.0 0.0

Min Mz 513 102 3.7 0.0 0.0 0.0 0.0 0.0 -350.9

Max. Bottom moment = 350.90 kNm.

Max. Shear force = 189.70 kN

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

PROJECT 7 MIGD R.O. DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK

Document No: 1M08-AQUA-AZ-725-J-501 1 23 of 36

Design for Main reinforcement

Partial Safety Factor for Steel m = 1.050 (Refer Table 2.2 of BS 8110 Part 1)

Design Strength of Steel fd = Yield Strength / Partial Safety Factor

= 0.95 fy

Minimum% of reinforcement = 0.20 % (Refer Table 3.25 of BS 8110-1)

Minimum area of reinforcement reqd. Ast min = 499 mm2

% of Redistribution assumed = 0%

Ratio = (BM After distribution / BM before) b = 1

Constant K' = 0.156 (If redistribution < 10%)

2

K' = 0.402 (b - 0.4) - 0.18 (b - 0.4) = 0.176 (If redistribution > 10%)

In the present case K' = 0.156

M

K u

2

f cu Bd

K= 0.056

Here K < K', Hence no compression reinforcement are required

Case 1 : K < K' Case 1 : K > K'

k k'

z d 0 .5 0 .25 z d 0 .5 0 .25

0 .9 0 .9

As

M u ( K K ' ) f cu bd 2

As '

0 . 95 f y Z 0 . 95 f y ( d d ' )

K ' f cu bd 2

As As '

0 . 95 f y ( d d ' )

Lever arm z= 664.61 mm

Maximum Lever arm zmax = 0.95d

zmax = 676.88 mm

z < zmax, Hence OK

Neutral axis depth x = (d -z) / 0.45 x= 106.42 mm

As = Mu / 0.95 fy z

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

PROJECT 7 MIGD R.O. DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK

Document No: 1M08-AQUA-AZ-725-J-501 1 24 of 36

Top reinforcement

Flexural reinforcement required As = 0 mm2 0.00 %

Provided Reinforcement = 3 -Y 20 + 3 -Y 20

Provided area of Reinforcement = 1885 mm2 > Ast min > As

HENCE OK

Percentage of Steel provided pro = 0.756 %

Bottom reinforcement

Flexural reinforcement required As = 1208 mm2 0.48 %

Provided Reinforcement = 3 -Y 25 + 3 -Y 25

Provided area of Reinforcement = 2945 mm2 > Ast min > As

HENCE OK

Percentage of Steel provided pro = 1.181 %

Design for Shear (As per Cl. 3.4.5 of BS 8110-1 : 1997)

Maximum Shear Force Vu = 189.7 kN

Nominal Shear Stress = Vu / b * d = 0.761 N/mm2

max 0.8 f cu

Which is the lesser

= 5.000 N/mm2

Maximum Shear Stress cmax 4.73 N/mm2

1/3

100 As

1/ 4 1/3

400 f cu

Design shear stress c 0 . 79

bv d d 25

c 0.65 N/mm2

The following are the condition for the shear design

1 < 0.5 c, No shear reinforcement is required.

2 0.5c < < (c +0.4), Minimum links for whole length of beam.

3 (c+0.4) < < cmax, Shear reinforcement is required.

This beam is falling in condition 2

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

PROJECT 7 MIGD R.O. DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK

Document No: 1M08-AQUA-AZ-725-J-501 1 25 of 36

For Condition 2 For Condition 3

0 .4 bv S v bv S v ( c )

A sv Asv

0 . 95 f yv 0.95 f yv

Minimum design shear stress S 0.40 N/mm2

Min. diameter of stirrups = 8 mm

Providing 8 mm dia. 2 legged Stirupps,

Area of shear reinforcement Asv = 100.5 mm2

bv = 350 mm

dv = 700 mm

Spacing of the stirrups, reqd. Sv = 313.8 mm

Max spacing of stirrups shall not exceed 0.75d

Max. 0 75d = 534 4

534.4 mm (Cl 3 4 5 5 of BS 8110)

(Cl.3.4.5.5

Providing 2 legged 8 mm dia. Stirrups at 150 mm spacing at support

Providing 2 legged 8 mm dia. Stirupps at 250 mm spacing at Mid span

Check for Crack width

2 2

S d1 d1

acr cc

2 2 2

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

PROJECT 7 MIGD R.O. DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK

Document No: 1M08-AQUA-AZ-725-J-501 1 26 of 36

Overall depth of Beam h= 800 mm

Effective depth of Beam d= 738 mm

Width of Beam b= 400 mm

C/C of Bar S= 138 mm

Applied Service Moment Ms = 285.8 kN.m

Distance acr = 80.4 mm

Modulus of elasticity

Ec = 13.5 kN.mm2

Modulus of elasticity of Steel Es = 200.0 kN.mm2

Modulus ratio = 14.81

% of Reinforcement provided = 1.181 %

2 0.5

Depth to neutral axis, "x" = (- +(() + 2.) .d

x = 325.92 mm

Lever arm,

arm "z"

z = (d - x/3) z = 628 86 mm

628.86

Reinforcement stress " fs " = Ms/(As*Z) fs = 154.29 N/mm2

Concrete stress " fc " = (fs*As)/(0.5*b*x) fC = 7.97 N/mm2

Strain at soffit of concrete beam 1 = (fs/Es)*(h-x)/(d-x)

= 0.000889

Strain due to stiffening effect of concrete between cracks

For crack widths of 0.2mm 2 = b.(h-x)2/(3.Es.As.(d-x))

= 0.000124

Average strain for calculation of crack width m = 1 - 2

= 0.000765

3 a cr m

w

Calculated crack width a c min

1 2 cr

h x

w= 0.164 mm

< 0.2mm, Hence OK

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

PROJECT 7 MIGD R.O. DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK

Document No: 1M08-AQUA-AZ-725-J-501 1 27 of 36

5.3.3 FOR RB-2

MATERIAL DATA

Characteristic strength of concrete fcu = 35 N/mm2

Characteristic strength of reinforcement fy = 460 N/mm2

Characteristic strength of shear reinf. fyv = 460 N/mm2

GEOMETRY DATA

Equivalent width of Beam B= 350 mm

Depth of Beam D= 800 mm

Clear cover cc = 50 mm

Dia of first layer reinf. d1 = 25 mm

Dia of second layer reinf. d2 = 25 mm

Effective depth bottom reinf

reinf. d= 713 mm

Effective depth at top reinf. d' = 63 mm

FORCE DATA

Max force details for Member No. 623 633 621 631 522 512 524 514

d Fx Fy Fz Mx My Mz

Beam L/C

(m) (kN) (kN) (kN) (kNm) (kNm) (kNm)

Max Fx 631 106 0.0 58.6 40.4 0.0 0.0 0.1 0.0

Min Fx 631 108 0.0 -58.6 30.3 0.0 0.0 -0.1 0.0

Max Fy 623 102 0.0 0.0 53.4 0.0 0.0 0.0 0.0

Min Fy 623 102 3.6 0.0 -53.4 0.0 0.0 0.0 0.0

Max Fz 524 106 0.0 0.0 40.4 0.1 0.0 -0.4 0.0

Min Fz 524 108 0.0 0.0 30.3 -0.1 0.0 0.4 0.0

Max Mx 512 108 0.0 0.0 30.3 0.1 0.0 0.0 0.0

Min Mx 512 106 0.0 0.0 40.4 -0.1 0.0 0.0 0.0

Max My 524 108 0.0 0.0 30.3 -0.1 0.0 0.4 0.0

Min My 524 106 0.0 0.0 40.4 0.1 0.0 -0.4 0.0

Max Mz 522 102 0.0 0.0 53.4 0.0 0.0 0.0 0.0

Min Mz 623 102 1.8 0.0 0.0 0.0 0.0 0.0 -48.0

Max. Bottom moment = 48.00 kNm.

Max. Shear force = 53.40 kN

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

PROJECT 7 MIGD R.O. DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK

Document No: 1M08-AQUA-AZ-725-J-501 1 28 of 36

Design for Main reinforcement

Partial Safety Factor for Steel m = 1.050 (Refer Table 2.2 of BS 8110 Part 1)

Design Strength of Steel fd = Yield Strength / Partial Safety Factor

= 0.95 fy

Minimum% of reinforcement = 0.20 % (Refer Table 3.25 of BS 8110-1)

Minimum area of reinforcement reqd. Ast min = 499 mm2

% of Redistribution assumed = 0%

Ratio = (BM After distribution / BM before) b = 1

Constant K' = 0.156 (If redistribution < 10%)

2

K' = 0.402 (b - 0.4) - 0.18 (b - 0.4) = 0.176 (If redistribution > 10%)

In the present case K' = 0.156

M

K u

2

f cu Bd

K= 0.008

Here K < K', Hence no compression reinforcement are required

Case 1 : K < K' Case 1 : K > K'

k k'

z d 0 .5 0 .25 z d 0 .5 0 .25

0 .9 0 .9

As

M u ( K K ' ) f cu bd 2

As '

0 . 95 f y Z 0 . 95 f y ( d d ' )

K ' f cu bd 2

As As '

0 . 95 f y ( d d ' )

Lever arm z= 706.34 mm

Maximum Lever arm zmax = 0.95d

zmax = 676.88 mm

z > z max, Hence Take z = zmax

Neutral axis depth x = (d -z) / 0.45 x= 79.17 mm

As = Mu / 0.95 fy z

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

PROJECT 7 MIGD R.O. DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK

Document No: 1M08-AQUA-AZ-725-J-501 1 29 of 36

Top reinforcement

Flexural reinforcement required As = 0 mm2 0.00 %

Provided Reinforcement = 3 -Y 16 + 3 -Y 16

Provided area of Reinforcement = 1206 mm2 > Ast min > As

HENCE OK

Percentage of Steel provided pro = 0.484 %

Bottom reinforcement

Flexural reinforcement required As = 156 mm2 0.06 %

Provided Reinforcement = 3 -Y 20 + 3 -Y 20

Provided area of Reinforcement = 1885 mm2 > Ast min > As

HENCE OK

Percentage of Steel provided pro = 0.756 %

Design for Shear (As per Cl. 3.4.5 of BS 8110-1 : 1997)

Maximum Shear Force Vu = 53.4 kN

Nominal Shear Stress = Vu / b * d = 0.214 N/mm2

max 0.8 f cu

Which is the lesser

= 5.000 N/mm2

Maximum Shear Stress cmax 4.73 N/mm2

1/3

100 As

1/ 4 1/3

400 f cu

Design shear stress c 0 . 79

bv d d 25

c 0.56 N/mm2

The following are the condition for the shear design

1 < 0.5 c, No shear reinforcement is required.

2 0.5c < < (c +0.4), Minimum links for whole length of beam.

3 (c+0.4) < < cmax, Shear reinforcement is required.

This beam is falling in condition 1

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

PROJECT 7 MIGD R.O. DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK

Document No: 1M08-AQUA-AZ-725-J-501 1 30 of 36

For Condition 2 For Condition 3

0 .4 bv S v bv S v ( c )

A sv Asv

0 . 95 f yv 0.95 f yv

Minimum design shear stress S 0.40 N/mm2

Min. diameter of stirrups = 8 mm

Providing 8 mm dia. 2 legged Stirupps,

Area of shear reinforcement Asv = 201.1 mm2

bv = 350 mm

dv = 700 mm

Spacing of the stirrups, reqd. Sv = 627.6 mm

Max. spacing of stirrups shall not exceed 0.75d = 534.4 mm (Cl.3.4.5.5 of BS 8110)

Providing 2 legged 8 mm dia. Stirrups at 200 mm spacing at support

Providing 2 legged 8 mm dia. Stirrups at 200 mm spacing at Mid span

Check for Crack width

2 2

S d1 d1

acr cc

2 2 2

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

PROJECT 7 MIGD R.O. DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK

Document No: 1M08-AQUA-AZ-725-J-501 1 31 of 36

Overall depth of Beam h= 800 mm

Effective depth of Beam d= 738 mm

Width of Beam b= 350 mm

C/C of Bar S= 140 mm

Applied Service Moment Ms = 56.0 kN.m

Distance acr = 81.3 mm

Modulus of elasticity

Ec = 13.5 kN.mm2

Modulus of elasticity of Steel Es = 200.0 kN.mm2

Modulus ratio = 14.81

% of Reinforcement provided = 0.756 %

2 0.5

Depth to neutral axis, "x" = (- +(() + 2.) .d

x = 276.07 mm

Lever arm,

arm "z"

z = (d - x/3) z = 645 48 mm

645.48

Reinforcement stress " fs " = Ms/(As*Z) fs = 45.99 N/mm2

Concrete stress " fc " = (fs*As)/(0.5*b*x) fC = 1.79 N/mm2

Strain at soffit of concrete beam 1 = (fs/Es)*(h-x)/(d-x)

= 0.000261

Strain due to stiffening effect of concrete between cracks

For crack widths of 0.2mm 2 = b.(h-x)2/(3.Es.As.(d-x))

= 0.000184

Average strain for calculation of crack width m = 1 - 2

= 0.000077

3 a cr m

w

Calculated crack width a c min

1 2 cr

h x

w= 0.02 mm

< 0.2mm, Hence OK

-ve Sign indicates no crack

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

PROJECT 7 MIGD R.O. DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK

Document No: 1M08-AQUA-AZ-725-J-501 1 32 of 36

6.0 STAAD INPUT

STAAD SPACE

START JOB INFORMATION

ENGINEER DATE 24-Aug-09

JOB NAME Back wash tank

JOB CLIENT Tecton Engg

JOB NO BVSB/1010

ENGINEER NAME KV

CHECKER NAME BSK

APPROVED NAME NK

END JOB INFORMATION

INPUT WIDTH 79

UNIT METER KN

JOINT COORDINATES

213 0.05 8.40001 0.0500992; 214 0.05 8.40001 7.45; 218 7.45 8.4 0.0500992;

219 7

7.45

45 8

8.4

477.45;

45; 316 -3

-3.547

547 15 0

0.05;

05; 317 -3

-3.547

547 15 7

7.45;

45; 322 0

0.05

05 15 -3

-3.547;

547;

323 0.05 15 0.0500992; 324 0.05 15 7.45; 325 0.05 15 11.047;

329 7.45 15 -3.547; 330 7.45 15 0.0500992; 331 7.45 15 7.45;

332 7.45 15 11.047; 337 11.047 15 0.0500992; 338 11.047 15 7.45;

MEMBER INCIDENCES

512 317 324; 513 324 331; 514 331 338; 522 316 323; 523 323 330; 524 330 337;

621 324 325; 622 323 324; 623 322 323; 631 331 332; 632 330 331; 633 329 330;

2067 213 323; 2068 214 324; 2095 218 330; 2096 219 331;

DEFINE MATERIAL START

ISOTROPIC CONCRETE

E 2.17185e+007

POISSON 0.17

DENSITY 24

ALPHA 1e-005

DAMP 0.05

END DEFINE MATERIAL

MEMBER PROPERTY AMERICAN

2067 2068 2095 2096 PRIS YD 0.6 ZD 0.6

512 TO 514 522 TO 524 PRIS YD 0.8 ZD 0.35

621 TO 623 631 TO 633 PRIS YD 0.8 ZD 0.35

CONSTANTS

MATERIAL CONCRETE ALL

SUPPORTS

213 214 218 219 FIXED

316 317 322 325 329 332 337 338 PINNED

************************************************************

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

PROJECT 7 MIGD R.O. DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK

Document No: 1M08-AQUA-AZ-725-J-501 1 33 of 36

*******************SEISMIC DEFINITION**********************

***********************************************************

MEMBER RELEASE

513 514 523 524 621 622 631 632 START MZ

512 513 522 523 622 623 632 633 END MZ

DEFINE REFERENCE LOADS

LOAD R1 LOADTYPE Dead TITLE REF DEAD LOAD

SELFWEIGHT Y -1

MEMBER LOAD

513 523 UNI GY -24

512 514 522 524 621 TO 623 631 TO 633 UNI GY -12

LOAD R2 LOADTYPE Live REDUCIBLE TITLE REF LIVE LOAD

MEMBER LOAD

513 523 UNI GY -9

512 514 522 524 621 TO 623 631 TO 633 UNI GY -4.5

END DEFINE REFERENCE LOADS

DEFINE UBC LOAD

ZONE 0.15

0 15 I 1

1.25

25 RWX 3

3.5

5 RWZ 3

3.5

5 STYP 4

REFERENCE LOAD Y

R1 1.0 R2 0.25

***********************************************************

**********************PRIMARY LOADS************************

***********************************************************

LOAD 1 LOADTYPE None TITLE EQX

UBC LOAD X 1

*

*

*

LOAD 2 LOADTYPE None TITLE EQZ

UBC LOAD Z 1

*

*

*

LOAD 3 LOADTYPE None TITLE DEAD LOAD

SELFWEIGHT Y -1

MEMBER LOAD

513 523 UNI GY -24

512 514 522 524 621 TO 623 631 TO 633 UNI GY -12

*

*

*

LOAD 4 LOADTYPE None TITLE LIVE LOAD

MEMBER LOAD

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

PROJECT 7 MIGD R.O. DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK

Document No: 1M08-AQUA-AZ-725-J-501 1 34 of 36

513 523 UNI GY -9

512 514 522 524 621 TO 623 631 TO 633 UNI GY -4.5

*

*

*

********************************************************************

***************LOAD COMBINATION AS PER UBC 1997 **************

********************************************************************

*ULTIMATE LIMIT STATE

*a) 1.4D

*b) 1.2D + 1.6L + 0.5 (Lr or S)

*c) 1.2D + 1.6 (Lr or S) + (f1L or 0.8W)

*d) 1.2D + 1.3W + f1L + 0.5 (Lr or S)

*e) 1.2D + 1.0E + (f1L + f2S)

*f) 0.9D ± (1.0E or 1.3W)

LOAD COMB 101 1.4D

3 1.4

LOAD COMB 102 1

1.2DL+1.6LL

2DL+1 6LL

3 1.2 4 1.6

*FOR EQX

LOAD COMB 103 1.2DL+1.0EQX

3 1.2 1 1.0

LOAD COMB 104 0.9DL+1.0E

3 0.9 1 1.0

LOAD COMB 105 0.9DL-1.0E

3 0.9 1 -1.0

*FOR EQZ

LOAD COMB 106 1.2DL+1.0EQX

3 1.2 2 1.0

LOAD COMB 107 0.9DL+1.0E

3 0.9 2 1.0

LOAD COMB 108 0.9DL-1.0E

3 0.9 2 -1.0

*SERVICEABILITY LIMIT STATE

*a) D - (12-7)

*b) D + L + (Lr or S) - (12-8)

*c) D+( W or E / 1.4) - (12-9)

*d) 0.9D ± (E / 1.4) - (12-10)

*e) D+0.75{L+(Lr or S)+ (W or E / 1.4) - (12-11)

LOAD COMB 201 DL

3 1.0

LOAD COMB 202 DL+LL

3 1.0 4 1.0

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

PROJECT 7 MIGD R.O. DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK

Document No: 1M08-AQUA-AZ-725-J-501 1 35 of 36

*EQX

LOAD COMB 203 DL+0.714EQX

3 1.0 1 0.714

LOAD COMB 204 0.9DL+0.714EQX

3 0.9 1 0.714

LOAD COMB 205 0.9DL-0.714EQX

3 0.9 1 -0.714

LOAD COMB 206 DL+0.75LL+0.714EQX

3 1.0 4 0.75 1 0.714

*EQZ

LOAD COMB 207 DL+0.714EQZ

3 1.0 2 0.714

LOAD COMB 208 0.9DL+0.714EQZ

3 0.9 2 0.714

LOAD COMB 209 0.9DL-0.714EQZ

3 0.9 2 -0.714

LOAD COMB 210 DL+0.75LL+0.714EQZ

31

1.0

040

0.75

75 2 0

0.714

714

PERFORM ANALYSIS PRINT ALL

**********************************

******COLUMN DESIGN***************

**********************************

LOAD LIST 101 TO 108

START CONCRETE DESIGN

CODE BS8110

CLEAR 0.05 2067 2068 2095 2096

FC 35000 2067 2068 2095 2096

FYMAIN 460000 2067 2068 2095 2096

FYSEC 460000 2067 2068 2095 2096

ELY 1.2 MEMB 2067 2068 2095 2096

ELZ 1.2 MEMB 2067 2068 2095 2096

TRACK 2 ALL

DESIGN COLUMN 2067 2068 2095 2096

END CONCRETE DESIGN

*

*********************************

*****MIDDLE BEAM DESIGN*********

*********************************

LOAD LIST 101 TO 108

START CONCRETE DESIGN

CODE BS8110

CLEAR 0.05 MEMB 513 523 622 632

FC 35000 513 523 622 632

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

PROJECT 7 MIGD R.O. DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK

Document No: 1M08-AQUA-AZ-725-J-501 1 36 of 36

FYMAIN 460000 513 523 622 632

FYSEC 460000 513 523 622 632

TRACK 2 513 523 622 632

DESIGN BEAM 513 523 622 632

END CONCRETE DESIGN

*

*********************************

*****END BEAM DESIGN*************

*********************************

LOAD LIST 101 TO 108

START CONCRETE DESIGN

CODE BS8110

CLEAR 0.05 MEMB 623 633 621 631 522 512 524 514

FC 35000 623 633 621 631 522 512 524 514

FYMAIN 460000 623 633 621 631 522 512 524 514

FYSEC 460000 623 633 621 631 522 512 524 514

TRACK 2 623 633 621 631 522 512 524 514

DESIGN BEAM 623 633 621 631 522 512 524 514

END CONCRETE DESIGN

*

PERFORM ANALYSIS PRINT ALL

FINISH

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

PROJECT 7 MIGD R.O. DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK Document No: 1M08-AQUA-AZ-725-J-501 1 A1 of A3

ATTACHMENT - A

CHOICE OF HOLLOW CORE SLAB

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

PROJECT 7 MIGD R.O. DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK Document No: 1M08-AQUA-AZ-725-J-501 1 A2 of A3

SELECTION OF HOLLOW CORE SLAB

LOADING

Density of light weight concrete c = 10 kN/Cu.m

Thickness of Screed concrete D= 0.10 m

Load intensity due to screed concrete Id = 1.0 kN/m2

Live Load intensity Il = 1.5 kN/m2

Total imposed load Itotal = 2.5 kN/m2

Choose HC 20x120 with 7-11.1mm wire from manufacture catalogue

Weight of grount / m2 area Ig = 0.1 kN/m2

Selfweight of hollow core slab (excluding grout) = 2.85 kN/m

Weight of grout for 1.2m wide = 0.12 kN/m

Live Load for 1.2m wide = 1.80 kN/m

Total Load = 4.77 kN/m

Effective Span = 9.66 m

Service Beding Moment = 4.77 x 9.66 ^ 2 / 8

Service Beding Moment = 55.64 kN.m

Allowable Service Beding Moment = 61.57 kN.m

> The actual service BM, Hence OK

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

PROJECT 7 MIGD R.O. DESALINATION PLANTS AT AL-ZAWRAH

CLIENT FEDERAL ELECTRICITY AND WATER AUTHORITY

Project No: 1M08 (B) Rev. No. Sheet

CALCULATION REPORT FOR FOR BACK

WASH TANK Document No: 1M08-AQUA-AZ-725-J-501 1 A3 of A3

TECTON ENGINEERING CONSTRUCTION L.L.C, P.O.BOX. NO. 6039, AJMAN, U.A.E

You might also like

- B2 Study GuideDocument2 pagesB2 Study GuideTito GitanoNo ratings yet

- DNV Comparison of Offshore Structural StandardsDocument219 pagesDNV Comparison of Offshore Structural StandardsNils Antoine Freund100% (3)

- Cmu Block Wall DetailDocument2 pagesCmu Block Wall DetailAbdulBari100% (1)

- JAW - 00-K - 11a - 040 - PP - 176 - Commissioning ITP-LV DISTRIBUTION BOARD (MCC) 00BJA10 & 00BJB10 - Rev.0Document13 pagesJAW - 00-K - 11a - 040 - PP - 176 - Commissioning ITP-LV DISTRIBUTION BOARD (MCC) 00BJA10 & 00BJB10 - Rev.0MedrouaNo ratings yet

- 4) Well Control EquipmentDocument77 pages4) Well Control Equipmentoswaldo58100% (3)

- York Yoea36fs36adhDocument20 pagesYork Yoea36fs36adhjean_carlos_abreu_rNo ratings yet

- Backwash Tank DesignDocument289 pagesBackwash Tank DesignmannshiNo ratings yet

- Aln IcDocument272 pagesAln Ic8506070700No ratings yet

- Specification - Water Spray Fixed SystemsDocument23 pagesSpecification - Water Spray Fixed SystemsJaseelKanhirathinkalNo ratings yet

- B - Design Criteria For Civil and StructuresDocument29 pagesB - Design Criteria For Civil and StructuresS ParamNo ratings yet

- S-0000-13A0-001 - 2B - 0001 - FC - Specification For Painting and Color CodingDocument57 pagesS-0000-13A0-001 - 2B - 0001 - FC - Specification For Painting and Color CodingWoon Czen NgNo ratings yet

- CB MX71ZZ El Rep 0001 000Document56 pagesCB MX71ZZ El Rep 0001 000alemdar.muhendislik25No ratings yet

- 00 Ytc MR - Tre 001 EngDocument81 pages00 Ytc MR - Tre 001 EngJessica RodriguezNo ratings yet

- Part V-PRD-1-MMS-PLA-01-0001-0 - Maintenance & Inspection Plan For Offshore Structures (Rev.0)Document66 pagesPart V-PRD-1-MMS-PLA-01-0001-0 - Maintenance & Inspection Plan For Offshore Structures (Rev.0)Son DDarrellNo ratings yet

- Calculation: Box CulvertDocument154 pagesCalculation: Box CulvertRaditya AzkaLaodeNo ratings yet

- Utf Stup STR Cal DDD Vto 001 r0Document20 pagesUtf Stup STR Cal DDD Vto 001 r0zbricks.postNo ratings yet

- 8015 0151 SC03 00 000 CN MS 00003 - 01Document33 pages8015 0151 SC03 00 000 CN MS 00003 - 01Mohanad GanemNo ratings yet

- SSP-CRCO-SS05-SYSW-PRO-00119 - 04 - PAT Procedure For 750V DC Earth SwitchDocument31 pagesSSP-CRCO-SS05-SYSW-PRO-00119 - 04 - PAT Procedure For 750V DC Earth Switchabu bakar100% (1)

- 123-ODE-ELE-A-RA-000001 - Revb - Outer Dowsing OWF - Concept Electrical System ReportDocument101 pages123-ODE-ELE-A-RA-000001 - Revb - Outer Dowsing OWF - Concept Electrical System ReportAshiqRahimanNo ratings yet

- AGP-GPS-ANOGP-L02-0001-C01 - Electrical Design Basis PDFDocument26 pagesAGP-GPS-ANOGP-L02-0001-C01 - Electrical Design Basis PDFRubénNo ratings yet

- Utf Stup STR Cal DDD Gau 001 r0Document23 pagesUtf Stup STR Cal DDD Gau 001 r0zbricks.postNo ratings yet

- Nger Ko Nccal 00 39083Document36 pagesNger Ko Nccal 00 39083Osas AsemotaNo ratings yet

- MS For Cable Glanding and TerminationDocument11 pagesMS For Cable Glanding and TerminationNijo JoseNo ratings yet

- Uu00 P NNSG 000 0512Document34 pagesUu00 P NNSG 000 0512khalid benessalahNo ratings yet

- H-10207 00 0ea00-001f Ec-Cscs Cubicles Equipment Technical Specification - BDocument16 pagesH-10207 00 0ea00-001f Ec-Cscs Cubicles Equipment Technical Specification - Bnguyen rinNo ratings yet

- j910 Dm02 P0eaf 660001 Erection Instruction Portal Reclaimer 01abDocument58 pagesj910 Dm02 P0eaf 660001 Erection Instruction Portal Reclaimer 01abrajaramkodaiNo ratings yet

- Earthing & Bonding - Principles & SpecificationDocument20 pagesEarthing & Bonding - Principles & SpecificationKumaresh100% (1)

- CounterDocument93 pagesCountera.agila03No ratings yet

- PDPII - May 2011 - Dhanaraj - 10644Document96 pagesPDPII - May 2011 - Dhanaraj - 10644Utibe basseyNo ratings yet

- CAA 2009-359 Appendix 1Document62 pagesCAA 2009-359 Appendix 1Shamendu Roy RohitNo ratings yet

- Planta Potosí Solar-Mexico 300 Mwac: Lightning Risk AssessmentDocument34 pagesPlanta Potosí Solar-Mexico 300 Mwac: Lightning Risk AssessmentJosue Crespo GonzalezNo ratings yet

- Evaluation of Centrifugal Contactor Hydraulic and Mass Transfer Performance For Caustic-Side Solvent Extraction of CesiumDocument44 pagesEvaluation of Centrifugal Contactor Hydraulic and Mass Transfer Performance For Caustic-Side Solvent Extraction of CesiumKuang-Chuan WongNo ratings yet

- INTEGRATION RENEWABLE ENERGY DIST. System (1994 (Document124 pagesINTEGRATION RENEWABLE ENERGY DIST. System (1994 (Jose ValdiviesoNo ratings yet

- CHW2204-00-EL-SPE-7301 Rev0 Specification For Electrical SystemDocument20 pagesCHW2204-00-EL-SPE-7301 Rev0 Specification For Electrical SystemphongtttNo ratings yet

- Client: Dhamra LNG Terminal Private LimitedDocument13 pagesClient: Dhamra LNG Terminal Private LimitedbalajikrishnanNo ratings yet

- BRS1-SP-E-BRS-0014.RD1 Cathodic Protection SpecificationDocument31 pagesBRS1-SP-E-BRS-0014.RD1 Cathodic Protection SpecificationABDELKADERNo ratings yet

- BZOF-MT-PRO-00035 - 0 DATA Logger Recording ProcedureDocument25 pagesBZOF-MT-PRO-00035 - 0 DATA Logger Recording ProcedureManik KNo ratings yet

- Transient Analysis ReportDocument29 pagesTransient Analysis Reportmani rNo ratings yet

- SDA-S17893-BNYC1-PX-1206-00001 C01 Bonny Equipment Sizing Calculation ReportDocument37 pagesSDA-S17893-BNYC1-PX-1206-00001 C01 Bonny Equipment Sizing Calculation ReportsegunNo ratings yet

- Earthworks Technical SpecificationDocument48 pagesEarthworks Technical SpecificationFeng XueNo ratings yet

- 6305 EL MCA 7050 A00 - AC&DC Maitenes DischargeDocument29 pages6305 EL MCA 7050 A00 - AC&DC Maitenes Dischargevicesuza87No ratings yet

- 31-MBD-127 Inlet Separator-Rev.0 (On Pile)Document53 pages31-MBD-127 Inlet Separator-Rev.0 (On Pile)Didi Hadi RiantoNo ratings yet

- RLP-1000-PM-SP-001 - IFI - Scope of Work For Detailed Engineering & Design For Storage Tanks, In-Plant Piping, Supports & Structural SteelDocument45 pagesRLP-1000-PM-SP-001 - IFI - Scope of Work For Detailed Engineering & Design For Storage Tanks, In-Plant Piping, Supports & Structural SteelAdewaleNo ratings yet

- MultiDocument452 pagesMultia.agila03No ratings yet

- VD-LINE-WP57-SUB-ATM-0001-017 - ERECTION AND INSTALLATION PROCEDURE ATM TANK - Rev.1Document18 pagesVD-LINE-WP57-SUB-ATM-0001-017 - ERECTION AND INSTALLATION PROCEDURE ATM TANK - Rev.1tomy.jipNo ratings yet

- Nger Ko Nccal 00 39083Document35 pagesNger Ko Nccal 00 39083Osas AsemotaNo ratings yet

- Mq15-08-Te-3340-Fs0001 - 0 2023Document684 pagesMq15-08-Te-3340-Fs0001 - 0 2023hugoNo ratings yet

- Balon2 CodeDocument136 pagesBalon2 CodeAshwini YadavNo ratings yet

- Civil Design CriteriaDocument13 pagesCivil Design CriteriaFikriansyahIndraSaputraNo ratings yet

- 1100-CV-DBS-001 - IFB - R0 - Civil Structure Design Criteria SignedDocument28 pages1100-CV-DBS-001 - IFB - R0 - Civil Structure Design Criteria SignedRianto FelissimoNo ratings yet

- PH12-3A-24-22-P011 Rev A - 160MVA TX StabilityDocument19 pagesPH12-3A-24-22-P011 Rev A - 160MVA TX Stabilityaravindhana1a1No ratings yet

- Specification - Automatic Wet Sprinkler SystemsDocument22 pagesSpecification - Automatic Wet Sprinkler SystemsJaseelKanhirathinkalNo ratings yet

- Assessment of Damage and Failure Mechanisms For Offshore Structures and Pipelines in Gustav An DikeDocument142 pagesAssessment of Damage and Failure Mechanisms For Offshore Structures and Pipelines in Gustav An DikeEduardo Jose Sanchez LoboNo ratings yet

- CMM86503 - V1 Turret Chain Stopper Calculation PDFDocument24 pagesCMM86503 - V1 Turret Chain Stopper Calculation PDFTran LinhNo ratings yet

- Utf Stup STR Cal DDD Div 001 r00Document21 pagesUtf Stup STR Cal DDD Div 001 r00zbricks.postNo ratings yet

- Hydrant Water Tank Foundation Design Calc - Ebocha1Document39 pagesHydrant Water Tank Foundation Design Calc - Ebocha1Levi UbaNo ratings yet

- Next Generation SDH/SONET: Evolution or Revolution?From EverandNext Generation SDH/SONET: Evolution or Revolution?Rating: 2.5 out of 5 stars2.5/5 (2)

- Autonomous Software-Defined Radio Receivers for Deep Space ApplicationsFrom EverandAutonomous Software-Defined Radio Receivers for Deep Space ApplicationsJon HamkinsNo ratings yet

- Intermittent Convex Integration for the 3D Euler Equations: (AMS-217)From EverandIntermittent Convex Integration for the 3D Euler Equations: (AMS-217)No ratings yet

- Design Thrust BlockDocument4 pagesDesign Thrust BlockmannshiNo ratings yet

- Thust Block DesignDocument15 pagesThust Block DesignmannshiNo ratings yet

- Thrust Block Dimensions: Sand 200Document2 pagesThrust Block Dimensions: Sand 200mannshiNo ratings yet

- 1M05 (B) TECTON-C-010 (REV-AB-1) SHEET No.1 OF 3-ModelDocument1 page1M05 (B) TECTON-C-010 (REV-AB-1) SHEET No.1 OF 3-ModelmannshiNo ratings yet

- Backwash Tank DesignDocument289 pagesBackwash Tank DesignmannshiNo ratings yet

- Graduation Project: Structure Analysis Unit "3" Supervisors: Dr:Osman Ramadan Dr:Hatem OsmanDocument26 pagesGraduation Project: Structure Analysis Unit "3" Supervisors: Dr:Osman Ramadan Dr:Hatem OsmanmannshiNo ratings yet

- High Rise Building Calculation SheetDocument29 pagesHigh Rise Building Calculation SheetmannshiNo ratings yet

- High Rise Building Calculation SheetDocument25 pagesHigh Rise Building Calculation SheetmannshiNo ratings yet

- Design of Column: P .35 Fcu Ac+.67fy As Fcu 250 kg/cm2 Fy 3600 kg/cm2Document4 pagesDesign of Column: P .35 Fcu Ac+.67fy As Fcu 250 kg/cm2 Fy 3600 kg/cm2mannshiNo ratings yet

- Graduation Project: Structure Analysis Unit "3" Supervisors: Dr:Osman Ramadan Dr:Hatem OsmanDocument26 pagesGraduation Project: Structure Analysis Unit "3" Supervisors: Dr:Osman Ramadan Dr:Hatem OsmanmannshiNo ratings yet

- Frames Systems Case Study AnalysisDocument15 pagesFrames Systems Case Study AnalysismannshiNo ratings yet

- Area Handing OverDocument6 pagesArea Handing OveronspsnonsNo ratings yet

- Material List: Produced On 13/11/2020 With Xpress Selection V9.0.1 - Database DIL 16.0.2Document11 pagesMaterial List: Produced On 13/11/2020 With Xpress Selection V9.0.1 - Database DIL 16.0.2Sicologo CimeNo ratings yet

- Pfs PPT 2Document27 pagesPfs PPT 2api-303720407No ratings yet

- Concreto Construccion CivilDocument4 pagesConcreto Construccion CivilMarcela Campos100% (1)

- Single Home BOQ PDFDocument3 pagesSingle Home BOQ PDFDexter Lex F. SatanaNo ratings yet

- Composite Steel JoistsDocument10 pagesComposite Steel Joistsv2299100% (1)

- 2019 0124 Fairfield Auditor Rebid Dwgs VOL 2 PDFDocument41 pages2019 0124 Fairfield Auditor Rebid Dwgs VOL 2 PDFShradha Arun SasanNo ratings yet

- Combined Footings PDFDocument2 pagesCombined Footings PDFLisa100% (1)

- 527 A014.1Document1 page527 A014.1Jinxian XuNo ratings yet

- Construction Techniques in A High Rise BuildingDocument32 pagesConstruction Techniques in A High Rise Buildingtaruntaru15379% (19)

- Atgc MP Ipa 04Document268 pagesAtgc MP Ipa 04Pradeep AnuradhaaNo ratings yet

- Gypsum Board Shaftwall Arch Spec en 09260 09211623Document15 pagesGypsum Board Shaftwall Arch Spec en 09260 09211623can_cer087No ratings yet

- Btrs System Technical Summary PDFDocument2 pagesBtrs System Technical Summary PDFpaulina7shiNo ratings yet

- Load Calculation SheetDocument9 pagesLoad Calculation SheetNaveen RevannaNo ratings yet

- BIM For Masonry Modeling Buildings in Autodesk RevitDocument101 pagesBIM For Masonry Modeling Buildings in Autodesk RevitMSNo ratings yet

- Question Bank On Structural Design 2Document3 pagesQuestion Bank On Structural Design 2Govind TivadiNo ratings yet

- ECA Presentation - Group ADocument33 pagesECA Presentation - Group AChungHuiPingNo ratings yet

- Pedal Powered RefrigeratorDocument7 pagesPedal Powered RefrigeratorPrashant KumarNo ratings yet

- Day 3-5 Introduction To Nonlinear Modeling Using Perform 3D PDFDocument21 pagesDay 3-5 Introduction To Nonlinear Modeling Using Perform 3D PDFMIHDI PALAPUZ100% (2)

- Index PDFDocument7 pagesIndex PDFganesh gundNo ratings yet

- Navaneetha Content 1Document5 pagesNavaneetha Content 1Pavithran ParameshwaranNo ratings yet

- Emerson ACDocument20 pagesEmerson ACMorryNo ratings yet

- OJTDocument36 pagesOJTRachelle AtienzaNo ratings yet

- CH 8Document80 pagesCH 8Jasmine KaurNo ratings yet

- BeshywapDocument5 pagesBeshywapAldinNo ratings yet

- Structural Framing Systems: The Trussed Tube Bundled Tube SystemDocument1 pageStructural Framing Systems: The Trussed Tube Bundled Tube SystemTanuja SidduNo ratings yet

- GHHDocument198 pagesGHHkala1989100% (1)