Professional Documents

Culture Documents

Competency Based Learning Material

Competency Based Learning Material

Uploaded by

Riemmar MoicoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Competency Based Learning Material

Competency Based Learning Material

Uploaded by

Riemmar MoicoCopyright:

Available Formats

COMPETENCY BASED LEARNING MATERIAL

Sector : Electrical and Electronics

Qualification Title : Electrical Installation and Maintenance NC II

Unit of Competency : install wiring devices of floor and wall mounted outlets, lighting fixture/switches and

auxiliary Outlet

Module Title : install wiring devices of floor and wall mounted outlets, lighting fixture/switches and

auxiliary Outlet

Nominal duration : 56 hour

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

How to use this Competency-Based Learning Material

Welcome!

Welcome to the module in Installing Wiring Devices of Floor and Wall Mounted Outlets, Lighting

Fixtures/Switches, and Auxiliary Outlets. This module contains training materials and activities for you to

complete.

The unit of competency Install Wiring Devices of Floor and Wall Mounted Outlets, Lighting Fixtures/Switches,

and Auxiliary Outlets contains knowledge, skills and attitudes required for Electrical and Installation Maintenance

NC II.

You are required to go through a series of learning activities in order to complete each learning outcomes of the

module. In each learning outcome there are Information Sheets, Resource Sheets and Reference Materials for

further reading to help you better understand the required activities. Follow these activities on your own and answer

self-check at the end of each learning outcome. Get the answer key from your instructor and check your work

honestly. If you have questions please don’t hesitate to ask your facilitator for assistance.

Remember to:

This learning material was prepared to help you achieve the required competency, in ELECTRICAL

INSTALLATION & MAINTENANCE. This will be the source of information for you to acquire knowledge and

skills in this particular trade, with minimum supervision or help from your instructor.

In doing the activities to complete the requirements of this module, please be guided by the following:

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

Talk to you trainer and agree on how you will both organize the training of this unit. Read through the

learning guide carefully. It is divided into sections which cover all the skill and knowledge you need to

successfully complete in this module.

Work through all the information and complete the activities in each section. Read information sheets and

complete the self- check. Suggested references are included to supplement the materials provided in this

module.

Most probably your trainer will also be your supervisor or manager. He/she is there to support you and

show you the correct way to do things. Ask for help.

Your trainer will tell you about the important things you need to consider when you are completing

activities and it is important that you listen and take notes.

You will be given plenty of opportunity to ask questions and practice on the job. Make sure you practice

your new skills during regular work shifts. This way you will improve both your speed and memory and

also your confidence. Talk to more experience workmates and ask for their guidance.

Use the self-check questions at the end of each section to test your own progress.

When you are ready, ask your trainer to watch you perform the activities outline in this module.

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

As you work through the activities, ask for written feedback on your progress. Your trainer keeps

feedback/pre-assessment reports for this reason. When you have this learning material and feel confident

that you have sufficient knowledge and skills your trainer will arrange and appointment with a registered

assessor to assess you. The results of the assessment will be recorded in you competency Achievement

Record.

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

Electrical Installation and Maintenance NC III

No. Unit of Competency Module Title Code

Perform roughing-in Performing roughing-in

activities, wiring and activities, wiring and

cabling works for single- cabling works for single-

1. phase distribution, phase distribution, ELC74130

power, lighting and power, lighting and 1

auxiliary systems auxiliary systems

Install electrical Installing electrical

protective devices for protective devices for

distribution, power, distribution, power,

2. lighting, auxiliary, lighting, auxiliary, ELC74130

lightning protection and lightning protection and 2

grounding systems grounding systems

Install wiring Installing wiring

devices of floor and devices of floor and

wall mounted wall mounted

3. outlets, lighting outlets, lighting ELC74130

fixtures/switches, fixtures/switches, 3

and auxiliary and auxiliary

outlets outlets

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

MODULE CONTENT

Sector : ELECTRICAL AND ELECTRONICS

Qualification Title : Electrical Installation and Maintenance NCII

Unit of Competency : install wiring devices of floor and wall mounted outlets, lighting fixture/switches

and auxiliary Outlet

Module Title : install wiring devices of floor and wall mounted outlets, lighting fixture/switches and

auxiliary Outlet

Nominal duration : 56 hours

Introduction

This unit covers the knowledge, skills and attitudes on selecting and installing wiring devices, installing

lighting fixtures/switches and notifying completion of work of floor and wall mounted outlets and auxiliary

outlets

Learning outcomes:

At the end of this module, you MUST be able to:

1. Select wiring devices

2. Install wiring devices

3. Install lighting fixture/ switches

4. Notify completion of work

Assessment Criteria:

Working drawings are interpreted to produce component to specifications

Working devices are selected according to operation requirements.

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

LEARNING OUTCOME SUMMARY

Learning Outcome #1 Types of technical drawings

Contents:

1. identify different kinds of technical drawings

2. Interpret Technical drawing

3. Prepare changes on electrical/ electronic schematics and diagram

Assessment Criteria

Components, assemblies, or objects are recognized as required.

Dimensions of the key features of the objects depicted in the drawing are

correctly identified.

Symbols used in the drawing are identified and interpreted correctly.

Drawings are checked and validated against job requirements or

equipment in accordance with standard operating procedure.

Condition

Students/ trainees must be provided with the following.

1. Workplace

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

2. Competency Based Learning Material (CBLM)

3. Work Piece

4. Drawing instrument

Assessment Method

1. Direct observation

2. Written test

3. Demonstration with oral questioning

LEARNING EXPERIENCE

Learning outcome 1: Select wheels and accessories

Learning Activities Special Instructions

1. Read Information sheet 4.1-1 on identify

different types of technical drawing

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

Answer Self-check 4.1-1 then compare You must achieve the given passing score

answers with Answer key 4.1-1 before proceeding to the next activity.

Answer Self-check 4.1-1.2 then check You must perform the given activity based

the out-put using given rubrics on the requirements.

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

Information Sheet 3.1.1-1

INSTALL WIRING DEVICES OF FLOOR AND WALL MOUNTED OUTLETS,

LIGHTING FIXTURE/SWITCHES AND AUXILLIARY OUTLET

Personal Protective Equipment

Learning objectives

After reading this information sheet you must be able to

1. Identify safety equipment

2. Awareness in hazards on job

_____________________________________________________________________________-

Personal Protective Equipment (PPE)

Basic PPE consists of:

1. Cotton protective clothing with long sleeves

2. Helmet or hard hat

3. Goggles for eye protection

4. Gloves (leather or rubber)

5. Hearing protectors

6. Safety footwear

Personal Protective Equipment (PPE) refers to items

typically worn by a worker to provide protection from

recognized hazards. Depending on the job task to be

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

performed, PPE for the electric power industry generally includes safety glasses, face shields,

hard hats, safety shoes, insulating (rubber) gloves with leather protectors, insulating sleeves,

and flame-resistant (FR) clothing. Additional PPE, such as fall protection equipment,

respirators, chemical-resistant or cut-resistant gloves, and chaps, may be required, depending on

the results of the hazard assessment required under 1910.132 or on additional "269"

requirements (for example, when working with brush chippers, chain saws, or stump cutters).

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

Prior to requiring workers to wear PPE, employers are required to:

Perform hazard assessments, as required, and determine the PPE needed to

protect workers.

Provide training on the proper use of PPE for working on or near exposed energized parts.

Discuss PPE needs during required job briefings.

Inspect and test certain PPE such as insulating (rubber) gloves and sleeves (29 CFR

1910.137) to ensure that they are not damaged or defective, and will provide the

needed protection.

https://www.osha.gov/SLTC/etools/electric_power/personal_protective_equipment.html

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

a system of belts or restraints to hold a person to

prevent falling or injury.

A safety harness is a form of personal

protective equipment (PPE) that is

designed to catch a person in case of

falling while working at height.

Electrical Hazards

What is ELECTRICAL HAZARD?

An electrical hazard is a dangerous condition where a worker can or does make electrical

contact with energized equipment or a conductor. From that contact, the person may sustain an

injury from shock, and there is a potential for the worker to receive an arc flash (electrical

explosion) burn, thermal burn or blast injury.

Electricity can either be "static" or "dynamic". Dynamic electricity is the uniform motion of

electrons through condition (electric current). Static electricity is the accumulation of charge

on surfaces as a result of contact and friction with another surface.

According to the Electrical Safety Authority (ESA) there were 83¹ electrocutions in Ontario

from 2001 through 2010. According to ESA, the most common cause of occupational

electrocution is using an improper procedure (60%)

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

SELF CHECK 3.1.1-1

Personal Protective Equipment

DIRECTION: Identify what being asked by the following questions.

1. What is safety harness?

2. What is electrical hazards?

3. Give a 4 Personal Protective Equipment (PPE)?

4. Why we need Personal Protective Equipment (PPE)?

5. What are primarily cost of hazard?

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

ANSWER KEY 3.1.1-1

Personal Protective Equipment

1. A system of belts or restraints to hold a person to prevent falling or injury.

2. The person may sustain an injury from shock.

3. 1. Safety googles

2. Safety gloves

3. Helmet or Hardhat

4. Safety shoes

4. Provide protection from recognized hazards.

5. Receive an arc flash (electrical explosion) burn, thermal burn or blast injury

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

Task sheet 3.1.1.1

Personal Protective Equipment

Performance Objective:

Demonstrate the standard operating procedures in applying personal protective

equipment

Supplies/Materials :

Hard Hat or

Helmet Goggles

Safety shoes

Gloves

Steps and Procedure

Demonstrate the Proper wearing of PPE.

Assessment Method:

Demonstration

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

PERFORMANCE CRITERIA CHECKLIST 3.1.1-1

Personal Protective Equipment

JOB SHEET NO. 3.1.1-1 Completed

Personal Protective Equipment

Performance Criteria: YES NO

1. Wear the PPE Properly

2. Check the standard of the materials

3. Uses PPE appropriate

4. Punctually used PPE in appropriate location

in job

RESULTS NOT YET

COMPLETED COMPLETED

Comments:

Learner has satisfied the above performance criteria:

Learner’s signature:

Trainer’s signature:

Date:

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

Read Information Sheet 3.1.2-1

Materials Specification

Learning objectives

After reading this information sheet you must be able to

1. Identify the materials.

2. Awareness in materials and its specification

3. Know how to notify materials specification.

A fish tape is used to pull

stranded or solid wire

through metal or PVC

Fish Tape

conduit. Cable lube is

available to assist you in

pulling the wires through the

pipe.

A standard tape measure is

used for all kinds of field

measurements, such as

Tape setting heights for switches

Measure and outlets, centering

lighting fixture boxes, and

marking surfaces for cutouts.

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

A voltage tester is used for a

quick safety check to make

sure there's no voltage in an

electrical wire or device

Non-Contact before you start working on

Voltage it. Non- contact voltage

Tester testers are the simplest and

safest types of testers

because they can detect

electricity just by being near

an outlet slot or wire.

A hammer is used to secure

boxes equipped with nail-on

brackets to wall studs and

other framing members in a

Hammer

home. You’ll also need one

to drive wire staples when

installing new electrical

cable.

Tongue-and-groove pliers are

used to remove knockouts

Tongue-and- from metal electrical boxes,

Groove Pliers tighten cable clamps, and

adjust expansion-type ceiling

fan boxes.

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

Side-Cutting

Diagonal Wire strippers are used to cut

Pliers and strip insulation from

electrical wire. They have a

variety of holes for stripping

different standard sizes of

wire and include cutting teeth

for trimming the wire ends.

Side-Cutting Diagonal cutting pliers,

Diagonal sometimes called side snips

Pliers or dikes, are used to cut wire.

They are specially designed

with a cutting edge that goes

down to the tip of the pliers,

allowing you to get into tight

areas to trim wires. Some

types can also detect live

wires for safety.

Linesman Linesman pliers are

Pliers electrician do-it-all pliers.

They cut wires, twist wires

together, and grip wires for

pulling. They have a squared-

off end that is great for

twisting wires together, a

center cutting blade for

cutting wire, and a grip area

between the handles for

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

pulling wire.

A small level, such as a

torpedo level, fits easily in a

tool pouch and is used to

Torpedo make sure your work is level

Level and plumb. A great

installation starts with level

boxes and straight switch and

outlet covers.

Electrical work involves a lot

of dark places, from attics

and basements to wall and

ceiling cavities to the insides

Flashlight

of electrical boxes. A

flashlight is needed as much

for safety as it is for

convenience.

Allen wrenches are used to

Allen Wrench tighten hex-head screws. You

Set (Hex Set) need both metric and

standard sets.

Utility Knife A utility knife, or box cutter,

is handy for cutting sheathing

from non-

metallic (Romex) cable, to

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

cut off electrical tape, and to

open cardboard boxes.

Electricians keep

screwdrivers with them at all

times, for removing and

installing cover plates,

Phillips outlets, switches, and many

Screwdrivers other devices. It's best to

have a few different lengths

of Phillips screwdrivers as

well as #1, #2, and #3 tip

sizes.

As with Phillips

screwdrivers, you will likely

Straight- need more than one size of

Blade straight- blade screwdrivers.

Screwdrivers If you have to choose just

one, pick a medium blade. It

will suit most projects.

A voltmeter is used to read

voltage levels and verify that

circuits are indeed “live.” or

Voltmeter or off. Multi meters can read

Multimeter voltage levels as well as

amperage (current),

resistance, and DC voltage

and amperage

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

Wire crimpers are used to

Wire crimp lugs or terminals onto

Crimpers wires. Many can also be used

to strip wire insulation.

pliers having tapered ends,

Long Nose

forworking in a small space

Pliers

or with a small object.

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

Task Sheet 3.1.2-1

MATERIAL SPECIFICATION

1.

2.

3.

4.

5.

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

ANSWER KEY 3.1.2-1

1. VOLTAGE TESTER

2. SIDE CUTTING PLIER

3. LONG NOSE PLIER

4. MULTI-TESTER

5. UTILITY KNIFE

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

Task Sheet 3.1.2-1 Materials Specification

Performance Objective: Demonstrate the Materials Specification

Supplies/Materials : Hard Hat or

Helmet Goggles

Safety shoes

Gloves

Steps and Procedure

Demonstrate the Proper wearing of PPE.

Assessment Method: Demonstration /

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

PERFORMANCE CRITERIA CHECKLIST 3.1.2-

Completed

1

Materials Specification

Performance Criteria: YES NO

1. Identify Each materials

2. Check the standard of the materials

3. Awareness in materials and its specification

4. Know how to notify materials specification.

NOT YET

COMPLETED

COMPLETED

Comments:

Learner has satisfied the above performance criteria:

Learner’s signature:

Trainer’s signature:

Date:

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

Information Sheet 3.1.3-1

Types and uses of electrical wiring devices, tools and equipment

Learning objectives

After reading this information sheet you must be able to

1. Identify the types and uses of electrical wiring devices, tools and equipment

2. Awareness in uses of electrical wiring devices, tools and equipment

3. Know how to notify of electrical wiring devices, tools and equipment

WIRING MATERIALS AND INSTALLATION METHODS IN ELECTRICAL CONSTRUCTION WORKS

Electrical wiring needs expertise attention to every building projects. It directly related to the

safety of human beings and utilities / equipment people handle. The scope of electrical wiring

shall cover supply, installation, testing and commissioning of all conduits and accessories,

wiring, switches, socket outlets, spur outlets, junction boxes / pull boxes, GI pull wires, ceiling

roses making connections etc. Unless otherwise indicated wiring shall consist of PVC insulated,

copper conductor wires installed in heavy gauge steel galvanized conduits.

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

CONDUITS

1.1 GALVANIZED STEEL CONDUITS AND FITTING

1. Conduit Type: In general interior and exterior wires ways shall be Electrical Metallic

Tubing (EMT). The conduit shall be straight, have a circular cross section sufficiently

accurate to accept approved couplings and fittings. Wall thickness shall be uniform

through and welding of seams shall be continuous and thoroughly done. The interior

surface shall be free from injurious defects.

2. Number of conductors in tubing: The numbers of conductors in a single tubing shall

not exceed the percentage fill specified in the NEC.

3. Coupling Connector, Bends: Coupling and connector used with tubing shall be made

up tight. Bends in the tubing shall be so made that the tubing will not be injured and that

the internal diameter of the tubing will not be effectively reduced.

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

1.2 RIGID AND FLEXIBLE PVC CONDUIT

1. Conduit Type: PVC conduit shall be of the grey / black, round, heavy gauge, polyvinyl

chloride (PVC) conduit.The PVC conduit and fittings such as bends lock units, reducers,

coupler check nuts, bushes etc.. Unless otherwise specified minimum size of conduits

shall be 20 mm diameter. The conduits shall be suitable to use in an ambient temperature

of 60 degree centigrade and shall not be installed in areas that receive direct sun

light. Ready Made bends shall be used.

2. Number of conductors in tubing: The number of conductors in a single tubing shall

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

not exceed the percentage fill specified in the NEC code.

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

3. Coupling Connector, Bends: Coupling and connector used with tubing shall be made

up tight. Bends in the tubing shall be so made that the tubing will not be injured and that

the internal diameter of the tubing will not be effectively reduced.

2. WIRES, CABLES AND CORDS

1. Wires: Unless otherwise specified all wires shall be PVC insulated single core, stranded

copper conductor conforming to BS 6004. All wires shall be colored as follows:

1. Phase A of 1: Red Color of wire

2. Phase B of 2: Yellow Color of wire

3. Phase C of 3: Blue Color of wire

4. Neutral: Black

5. Ground: Yellow Green or Green (One color only to be used for the

complete Installation).

The size of wires shall be as indicated in the drawings.

2. Telephone Cables: The telephone cable used for telephone socket outlet shall be twin pairs

22 AWG, PVC insulated copper conductor wires, UL approved. The telephone cables used as

main feeder connecting the telephone junction boxes to main telephone junction boxes shall be

multi-pairs type, as specified on drawings.

3. Flexible Cords: The cords to connect short extension to the luminaries, immersion heaters,

equipment etc. shall be heat resisting PVC insulated to BS 6500 - 1969 with copper

conductors.

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

3. WIRING ACCESSORIES

1. Unless otherwise specified all wiring accessories shall be Standard British type. The exact

type & model shall be as specified in the drawings, bill of quantities or herein in the specific.

2. Outlet, Pull box, Junction Boxes and Fittings.

Each outlet, junction or pull box shall be of proper type, class and construction to suit the

specific conditions encountered. Outlet pull box or junction boxes shall be conforming

with IEE regulations and other applicable requirements that have been established by the

various agencies, codes and authorities.

OUTLET, PULL AND JUNCTION BOXES IN GENERAL, BE AS FOLLOWS:

1.1 Outlets for light points, convenient socket outlets, power outlets, switch boxes,

pull / junction boxes shall be code gauge 46 mm deep galvanized steel, and shall be of

shapes and size to suit their respective locations and installations and shall be provided

with covers to suit their function and installation.

1.2 Outlet boxes shall be equipped with fixtures or straps where required. All outlet

boxes shall be provided with brass ground terminals.

1.3 All junction boxes/pull boxes shall have suitable covers.

1.4 Surface mounted outlet and junction boxes in the outdoor locations shall be of

cast iron metal with threaded hubs.

1.5 The surface mounted indoor boxes shall be sheet steel painted purpose made for

surface installation.

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

2. LIGHTING SWITCHES

For internal use shall be of the grid assembly pattern with rocker operated switch units

suitable for operation with inductive loads. Switches shall be either, one way, two way or

intermediate as indicated in the drawings and shall be rated 20 Amps.

Switch plates shall be champagne, charcoal or satin chrome cover finish, MK make Accent

type for all offices area.

Switch plates shall be Matt chrome cover finish, MK make ALBANY range for all services

area, including toilets, kitchen, guard room, pump room, electric room etc. and metal clad

cover finish shall be used in the factory, storage area, finished product, etc. where

Electrical Metal Tube (EMT) pipes are used, as shown and described on drawings.

For internal surface installation switches shall be provided with matching steel box and

shall be with metal clad finish.

External outdoor switches shall be covered with weather proof flap. EGA tube make.

Pull cord switches shall be of white molded plastic suitable for surface mounted and shall

be supplied with matching patterns. These shall be manufactured by MK Co. Ltd.

(England) or approved equivalent

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

3. CONVENIENT SOCKET OUTLETS

For flush indoor installation shall be 13 A, 3 pin switched socket outlet with indicator and

manufactured to British Standard. Finishing to be Matt chrome cover finish, MK make

ALBANY range for all services area, including toilets, kitchen, guard room, pump room,

electric room etc. and metal clad cover finish shall be used in the factory, storage, finished

product, etc. where Electrical Metal Tube (EMT) pipes are used, as shown and described on

drawings.

4. TELEPHONE OUTLETS

Telephone outlets shall be suitable for surface or flush installation with American standard

socket outlet. The finish of the switch plates shall be Matt chrome cover finish, MK make

ALBANY range for all services area, including toilets, kitchen, guard room, pump room,

electric room etc. and metal clad cover finish shall be used in the factory, storage area,

finished product, etc. where Electrical Metal Tube (EMT) pipes are used, as shown and

described on drawings.

5. SPUR UNITS

Spur units shall be 20A or 45A, DP switch type with pilot lamp. For flush installation

shall be switched and fitted with neon indicator and cord outlet on the front

plate. Finish to be as specified elsewhere.

6. DP SWITCH OUTLET

The DP switch outlet shall be suitable for flush or surface type of installation. The capacity

as indicated on the drawings. The finish shall be Matt chrome cover finish, Mk make

ALBANY range for all services area, including toilets, kitchen, guard room, pump room,

electric room etc. and metal clad cover finish shall be used in the factory, storage area,

finished products, etc. where Electrical metal Tube (EMT) pipes are used, as shown and

described on drawings.

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

7. CONNECTOR OUTLETS

Connector outlets shall comprise flush overlapping plates of white molded plastic suitable

for attachment to standard recessed steel boxes. These shall be fitted in three terminals a

clamping device for outgoing flexible cable.

WIRING INSTALLATION

The wiring installation shall be in conformity with IEE regulation and/or approved

equivalent standards.

Unless otherwise specified all wiring shall be in rigid PVC conduit embedded in wall,

or ceiling or concealed in the false ceiling.

The size of conduits shall be selected in accordance with the IEE regulations and the

minimum size of the conduit shall be 20 mm dia unless otherwise indicated or

approved.

Factory made conduit bends shall be used where required. Conduits shall be kept at

minimum of 100 mm from the pipes of other non-electrical services.

Separate conduits and runways shall be used for:

1. Lighting system.

2. Power outlets.

3. Emergency light.

4. Telephone system.

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

5. Fire alarm system.

6. Sound / public address system.

7. Television system.

8. Computer system.

Wiring for short extensions to outlets in hung ceiling or to equipment, motors etc. shall

be installed in flexible conduits. Otherwise rigid conduits shall be used.

Conduits run on surfaces shall be supported on galvanized / PVC saddles which in turn

are properly screwed to the wall or ceiling. Saddles shall be at intervals of not more than

60 cm. Fixing screws shall be with round cheese head or and rustproof materials.

Exposed conduits shall be neatly run parallel or at right angles to the wall of the

building. Pull boxes must be provided at the right angles and at a distance of not

exceeding 20 meter length.

Conduits embedded into the walls shall be fixed by means of staples at not more than 60

cm intervals. Chase in the wall shall be neatly made and refilled after laying the conduit

and brought to the finish of the wall.

Conduits buried in concrete structure shall be put in position and securely fastened to

the reinforcement and got approved by the consultant before the concrete is poured.

Proper care shall be taken to ensure that the conduits and boxes are neither dislocated

nor choked at the time of pouring the concrete.

Suitable fish wires shall be drawn in all conduits before they are embedded.

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

Inspection boxes shall be provided for periodical inspection to facilitate draw and removal

of cables. Such inspection boxes shall be flush with the wall in the case of recessed

conduits.

Inspection boxes shall be spaced at not more than 12 meters apart or two 90 degree solid

bends or equal.

Use of PVC conduits in places where ambient temperature is 60 degree c or above is

prohibited. PVC conduits shall not be used in outdoor system. Conduits shall be free from

sharp edges and burrs and grease or oil shall not be used for the purpose of pulling the wire.

The entire system of conduits must be completely installed and rendered electrically

continuous before the conductors are pulled in.

All PVC conduits shall be jointed with plain PVC couples using approved PVC jointing

materials as recommended by the manufacturer. All joints shall be water tight. Junction

between conduit and adaptable boxes, back outlet boxes, switch outlet boxes and the like

must be provided with entry spouts and smooth PVC bushes.

A ground wire of not less than 2.5 sq. mm copper shall be run inside each conduit. The

wire shall be insulated and color coded.

4. BRANCH CIRCUIT WIRING

All final branch circuits for lighting and appliances, shall be single conductor cables run

inside conduits.

Branch circuit conductor sizes shall be as shown in the schedule of quantities and drawing

and conforming the requirements of the IEE regulations.

Home runs indicated in the drawings for the final branch circuits shall be kept in a

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

separate conduit upto the panel board via switches wherever called for. No other wiring

shall be bunched in the same conduit.

Flexible cords for connection to appliances, fans and pendants shall be 250/440V grade,

three or four cores, with tinned stranded copper wires, insulated, twisted and sheathed with

strengthening cord. Color of sheath shall be subject to the architect approval.

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

For each lot of wires the contractor shall supply a certificate issued by the manufacturer

stating its origin, date of manufacture, constitution and standard to which it complies and

the test certificates.

Looping system of wiring shall be used. Wires shall not be jointed. Where joints are

unavoidable, these shall be made through approved mechanical connector.

5.CONTROL SWITCHES

Control switches shall be connected in the phase conductors only and shall be ‘ON’ when

knob is down. Switches shall be fixed in galvanized steel boxes. Chromium plated screws

shall be used.

220 V (230 V) power supply wiring shall be distinctly separate form any other different

voltage system and lighting wiring.

Though the circuit wiring is indicated on the drawing, contractor shall check and be responsible for

the connection.

Each circuit phase wire from the distribution boards should be followed with a separate

neutral wire of the same size as the circuit wire.

Each light point and outlet shall be identified with their circuit number and panel board

number with a label pasted on them.

6.TESTING OF ELECTRICAL WIRING SYSTEM

The entire installation shall be tested in accordance with IEE regulations for:

1. Insulation resistance.

2. Earth continuity.

3. Polarity of single pole switches.

A test certificate shall be submitted in standard performa as directed by the Supervising

enginee

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

Self Check 3.1.3-1

Types and uses of electrical wiring devices, tools and equipment

1. What is the use of conduit?

a) To protect the lights

b) To protect and cover the wires

c) To protect the appliances

d) To protect the rats

2. What is the main use of a switch?

a) To generate power

b) To power a generator

c) To power on or power off a certain component

d) To control ampere rating

3. What is the use of circuit Breaker?

a) Serves as a protective device against short circuit

b) Trips off when there is over current(reaches the maximum allowable

current)

c) Serves as a pilot control device

d) All of the above

4. What is the use of earth or grounding system?

a) Protection of user and the system against short circuits

b) Serves as current generator

c) To know the voltage rating

d) Saves power

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

5. What is the use of copper wires?

a) Serves as conductor that allows current flow

b) Blocks current flow

c) Transfers resistance flow

d) Arrests voltage regulation

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

Answer Key 3.1.3-1

Types and uses of electrical wiring devices, tools and equipment

1. B

2. C

3. B

4. A

5. A

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

INFORMATION SHEET No. 3.1.4-1

Install wiring devices

Procedures in interpreting job requirements of wiring devices

Learning Objectives:

After reading this Information Sheet, you must be able to:

1. Define wiring device according to electrical code

2. Identify the types of wiring devices and its classification

3. Guidelines in selecting wiring devices

Introduction

Wiring devices are defined as single discrete units of electrical distribution systems which are

intended to carry but not utilize electric energy. Wiring devices are electrical devices used to

control and to provide connection points for low voltage outlets, lighting systems and appliances

(e.g., wall switches and receptacles). The Philippine Electrical Code (PEC) and National

Electrical Code (NEC) defines device as a unit of an electrical system that is intended to carry or

control but not utilize electric energy.

Types and Classification of Wiring Devices

This covers a wide assortment of system components that include, however not

limited to the following:

1. Switches and Plates

2. Relays and Conductors

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

3. Receptacles and Plates

4. Conductors

5. Fuses and Circuit Breakers

6. Outlets (Floor Outlet, Grounding Type Convenience Outlet or otherwise

known as Special Purpose Outlet or SPO)

Guidelines for wiring device application designs.

Selecting and applying wiring devices. Receptacles, switches, plates, and others

are available in a wide range of sizes, ratings, and styles with specific features and

characteristics to meet most design/application requirements.

Grades of wiring devices, manufacturer's catalogs use a variety of terms to

indicate the quality or grade of wiring devices offered.

For example, the term "economy," "competitive," "intermediate," or "residential"

are sometimes used to indicate that the device is economically priced or designed for

light-duty applications. Terms such as "specification" or "super-specification" would

indicate devices that are of better quality, designed for greater reliability and usually

higher priced.

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

However, none of these terms has an official status with standardizing agencies

such as Underwriters Laboratories (UL), Factory-Mutual (FM), Electrical Testing

Laboratories (ETL), or the National Electrical Manufacturers Association (NEMA).

Presently, UL lists wiring devices for only two grades, standard and hospital

grade. All devices, whether termed intermediate, economy, or specification must

meet identical UL requirements (although as mentioned above, specification grade

devices are of better quality construction).

Above all, the Philippine Electrical Code must be the basis for the guidelines for

wiring devices and application designs.

How to select wiring devices?

Here the steps in selecting wiring devices:

1. Select a known industry manufacturer.

2. Look for a multi- year product warranty.

3. Make sure that there is an easy and clear way to contact the manufacturers support.

4. Check for a connected equipment damage warranty.

5. Always ask for manufacturer’s manual

6. Select wiring devices which are well-made and durable.

7. Select materials that easy to use and install.

8. Select wiring devices according to the job requirements

9. Telephone Etiquette in Taking and Processing Orders

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

Terminology

Block diagram: a diagram of a system in which the principal parts or functions are represented

by blocks connected by lines that show the relationships of the blocks.

Figure 1-Block diagram

Circuit drawing (diagram): a simplified conventional graphical representation of an electrical circuit.

Duplex receptacle Single-pole switch SYMBOL LEGEND 1 × 4 fluorescent light fixture Electrical panel

EMT run Armoured cable run (B/X) 4x4 junction box 10' 12' 21 mm 21 mm

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

Figure 2-Circuit drawing

Line diagram: a one-line diagram or single-line diagram is a simplified notation for

representing an electrical system. The one-line diagram is similar to a block diagram except that

electrical elements such as switches, circuit breakers, transformers, and capacitors are shown by

standardized schematic symbols.

Figure 3-One-line diagram

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

Pictorial diagram: a diagram that represents the elements of a system using abstract, graphic

drawings or realistic pictures.

Schematic diagram: a diagram that uses lines to represent the wires and symbols to represent

components. It is used to show how the circuit functions.

Figure 4—Schematic diagram

Wiring diagram (or pictorial): a simplified conventional pictorial representation of an

electrical circuit. It shows the components of the circuit as simplified shapes, and how to make

the connections between the devices. A wiring diagram usually gives more information about the

relative position and arrangement of devices and terminals on the devices.

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

Figure 5-Wiring diagram

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

SELF CHECK 3.1.4-1

Procedures in interpreting job requirements of wiring devices

1. A simplified conventional graphical representation of an electrical circuit.

a. one line diagram c. pictural diagram

b. circuit diagram d. wiring daigram

2. A diagram of a system in which the principal parts or functions are represented by blocks

connected by lines that show the relationships of the blocks.

a. schematic diagram c. block diagram

b. pictural diagram d. wiring diagram

3. A simplified conventional pictorial representation of an electrical circuit. It shows the

components of the circuit as simplified shapes, and how to make the connections

between the devices. A wiring diagram usually gives more information about the relative

position and arrangement of devices and terminals on the devices.

a. schematic diagram c. block diagram

b. pictural diagram d. wiring daigram

4. A diagram that uses lines to represent the wires and symbols to represent components.

It is used to show how the circuit functions.

a. schematic diagram c. block diagram

b. pictural diagram d. wiring daigram

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

5. A diagram that represents the elements of a system using abstract, graphic drawings or

realistic pictures.

a. schematic diagram c. block diagram

b. pictural diagram d. wiring diagram

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

ANSWER KEY 3.1.1

1.B

2.C

3.D

4.A

5.B

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

TASK SHEET 3.1.4-1

Procedures in interpreting job requirements of wiring devices

Performance Objective:

Demonstrate the Procedures in interpreting job requirements of wiring devices

Supplies/Materials :

Sacket

Bulb

Set of pliers

Switches

Screw

driver Wires

Tester

Breaker

Equipment :

NA

Steps and Procedure

Demonstrate the procedures in interpreting job requirements of wiring devices

Assessment Method:

Demonstration

CBLM on EIM - Date Developed: Document No.

NC II install wiring

devices of floor and June 2022 Issued by:

wall mounted outlets,

lighting fixture/switches

and auxiliary Outlet

Developed by: Revision #

Denmar C. Pingol 01

PERFORMANCE CRITERIA CHECKLIST Completed

3.1.4-1

Procedures in interpreting job

requirements of wiring devices

Performance Criteria: YES NO

1. Proper uses of PPE

2. Define wiring device according to electrical code

3. Identify the types of wiring devices and

its classification

4. Guidelines in selecting wiring devices

5. Check wiring devices based on job requirements

6. Uses the materials, devices based on job

requirements

7. Interprets layout/ wiring diagram

RESULTS COMPLETE NOT YET

D COMPLETE

D

Comments:

Learner has satisfied the above performance criteria:

Learner’s signature:

Trainer’s signature:

Date:

CBLM on EIM - Date Developed: Document No.

NC II install wiring devices

of floor and wall mounted June 2022 Issued by:

outlets, lighting

fixture/switches and

auxiliary Outlet

Developed by: Revision # 01

Denmar C. Pingol

You might also like

- Diagrama Elétrico Hyundai 210LC-7Document17 pagesDiagrama Elétrico Hyundai 210LC-7Guemep Guemep82% (11)

- CBLM Lo.1 Eim NciiDocument53 pagesCBLM Lo.1 Eim NciiJohn Lester M. Dela Cruz79% (29)

- Ultimate Guide: Wiring, 8th Updated EditionFrom EverandUltimate Guide: Wiring, 8th Updated EditionRating: 3.5 out of 5 stars3.5/5 (4)

- CBLM Final1Document115 pagesCBLM Final1Victor Rosales89% (72)

- CBLM Rogh-In PDFDocument64 pagesCBLM Rogh-In PDFmyco saura80% (5)

- 4 - Final Competency Based Learning MaterialsDocument40 pages4 - Final Competency Based Learning MaterialsVictor Rosales89% (47)

- Eim CBLMDocument53 pagesEim CBLMlast jam100% (4)

- Parts Book Hd465-7r - Lepbh467r4Document710 pagesParts Book Hd465-7r - Lepbh467r4Royan Firdaus100% (1)

- Abc of Power Modules: Functionality, Structure and Handling of a Power ModuleFrom EverandAbc of Power Modules: Functionality, Structure and Handling of a Power ModuleNo ratings yet

- 4 - CBLMDocument48 pages4 - CBLMMitchille GetizoNo ratings yet

- 3 EimDocument115 pages3 EimCzar Ina100% (2)

- CBLM ElectricalDocument33 pagesCBLM ElectricalCharis Abad100% (1)

- CBLM Final1Document118 pagesCBLM Final1Seniorito LouiesitoNo ratings yet

- Competency-Based Learning Material: SectorDocument22 pagesCompetency-Based Learning Material: SectorTommy Dela Cruz100% (1)

- CBLM Final1 PDFDocument115 pagesCBLM Final1 PDFGlenn Etnomla100% (3)

- Competency Based Learning Material - ToRRES (FINAL)Document46 pagesCompetency Based Learning Material - ToRRES (FINAL)j4240300No ratings yet

- CBLM KimDocument34 pagesCBLM KimVALDEZ, MELVINE G.No ratings yet

- Core 3 Install Wiring Devices For Floor and Wall Mounted Outlets Lighting Fixtures Switches and Auxilliary OutletsDocument81 pagesCore 3 Install Wiring Devices For Floor and Wall Mounted Outlets Lighting Fixtures Switches and Auxilliary OutletsSuigen JM MontejoNo ratings yet

- Competency Based Learning Material - ToRRES (FINAL)Document32 pagesCompetency Based Learning Material - ToRRES (FINAL)j4240300No ratings yet

- CBLM or Learning MaterialsDocument16 pagesCBLM or Learning MaterialsMhen Maugan100% (1)

- Competency Based Learning Material: Electrical Installation AND Maintenance NC IiDocument59 pagesCompetency Based Learning Material: Electrical Installation AND Maintenance NC IiTimothy John Natal Mandia100% (2)

- CBLMDocument33 pagesCBLMIris Daphne BadoyNo ratings yet

- Module 1 - EIM Prepare Electrical Power and HydraulicDocument58 pagesModule 1 - EIM Prepare Electrical Power and HydraulicNoel Bua-ay100% (1)

- 1 CBLM-ROGH-IN ActivitiesDocument77 pages1 CBLM-ROGH-IN ActivitiesEarl TrinidadNo ratings yet

- CBLM For Eim TMDocument57 pagesCBLM For Eim TMrommel montilla100% (2)

- Competency Based Learning Materials: Electrical and Installation Maintenance NC IiDocument3 pagesCompetency Based Learning Materials: Electrical and Installation Maintenance NC Iielmer olmedilloNo ratings yet

- EIM-Institutional Assessment ToolsDocument22 pagesEIM-Institutional Assessment Toolslast jam100% (1)

- Template CES MOIDocument9 pagesTemplate CES MOIT Jah NepNo ratings yet

- Template CES Preliminary PageDocument2 pagesTemplate CES Preliminary PageT Jah NepNo ratings yet

- CBLM or Learning MaterialsDocument38 pagesCBLM or Learning MaterialsMaximalistaNo ratings yet

- PTS TemplateDocument52 pagesPTS TemplateRhony BayocbocNo ratings yet

- Mi CBLM COMPETENCY BASED LEARNING MATERIALDocument74 pagesMi CBLM COMPETENCY BASED LEARNING MATERIALMelanie SegoviaNo ratings yet

- CBLM Eim Module 1Document49 pagesCBLM Eim Module 1John B. BataraNo ratings yet

- CBLM Eim Module 1Document47 pagesCBLM Eim Module 1Jude Metante100% (1)

- Cometa Exemplar Uc5 CommonDocument76 pagesCometa Exemplar Uc5 CommonArnel Lajo FulgencioNo ratings yet

- How To Use This Competency-Based Learning Materials: Sector: Qualification Title Unit of Competencies Module TitleDocument9 pagesHow To Use This Competency-Based Learning Materials: Sector: Qualification Title Unit of Competencies Module TitleJoemar BalagotNo ratings yet

- CBLM 6 Terminate Connect Electrical Wiring Electronic CircuitsDocument39 pagesCBLM 6 Terminate Connect Electrical Wiring Electronic CircuitsDivina LayaNo ratings yet

- Sag EimDocument3 pagesSag EimFERDINAND BANAGANo ratings yet

- Sag-Electrical Installation and Maintenance NciiDocument3 pagesSag-Electrical Installation and Maintenance NciiCris Licsi Mantes75% (4)

- 4 Final Competency Based Learning MaterialsDocument34 pages4 Final Competency Based Learning MaterialsAnn NadiahanNo ratings yet

- Form 1.4 Training Needs Training Needs (Learning Outcomes) Module Title/Module of InstructionDocument1 pageForm 1.4 Training Needs Training Needs (Learning Outcomes) Module Title/Module of InstructionEmil D. Padullon100% (1)

- Sag - Electrical Installation and Maintenance NC IIDocument3 pagesSag - Electrical Installation and Maintenance NC IIMichael ScottNo ratings yet

- Learning Activity Sheet No. 3: 2. Estimate The Materials Needed For The JobDocument4 pagesLearning Activity Sheet No. 3: 2. Estimate The Materials Needed For The JobGenly Nasol NibreaNo ratings yet

- 6 CBLM Lo 1 Eim NciiDocument54 pages6 CBLM Lo 1 Eim NciiReynole DulaganNo ratings yet

- Core-3 FileDocument58 pagesCore-3 FileCharisse InaanuranNo ratings yet

- Terminate and Connect Electrical WiringDocument18 pagesTerminate and Connect Electrical WiringArnold BalanoNo ratings yet

- CBLM Eim Module 2Document148 pagesCBLM Eim Module 2John B. Batara100% (1)

- Competency-Based Learning Materials: Information and Communication Technology Computer Hardware Servicing NC IiDocument53 pagesCompetency-Based Learning Materials: Information and Communication Technology Computer Hardware Servicing NC IiVincent Bumas-ang AcapenNo ratings yet

- GEnova FinalsDocument9 pagesGEnova Finalsjoey catotoNo ratings yet

- CSS Module 3 Terminate and Connect of Electrical Wiring and Electronic CircuitsDocument18 pagesCSS Module 3 Terminate and Connect of Electrical Wiring and Electronic CircuitsHenry PescasioNo ratings yet

- EIM Self Assessment Guide NewDocument3 pagesEIM Self Assessment Guide NewRicalyn BelarminoNo ratings yet

- CSS Terminating and Connerting Electrical Wiring and Electronic CircuitsDocument19 pagesCSS Terminating and Connerting Electrical Wiring and Electronic CircuitsRalfh Pescadero De GuzmanNo ratings yet

- Electricity Module 1Document15 pagesElectricity Module 1Reinier Paclibar FederizoNo ratings yet

- TASK SHEET Study GuideDocument10 pagesTASK SHEET Study GuideJohn Raymund MabansayNo ratings yet

- EIM Module For New NormalDocument23 pagesEIM Module For New NormalJohn B. BataraNo ratings yet

- Competency-Based Learning Materials: Information and Communication Technology Computer Hardware Servicing NC IIDocument53 pagesCompetency-Based Learning Materials: Information and Communication Technology Computer Hardware Servicing NC IIVincent Bumas-ang AcapenNo ratings yet

- Competency Based Learning Material: Technical Education and Skills Development AuthorityDocument51 pagesCompetency Based Learning Material: Technical Education and Skills Development Authoritymico alilayaNo ratings yet

- Moi-3-VDocument5 pagesMoi-3-VJohn Lester M. Dela CruzNo ratings yet

- SAG - Electrical Installation and Maintenance NC IIDocument4 pagesSAG - Electrical Installation and Maintenance NC IIMark MarasiganNo ratings yet

- CBLM Competency Elect Install and Maint NC IIDocument51 pagesCBLM Competency Elect Install and Maint NC IIRoderick Rosanes100% (1)

- Form 1.4Document1 pageForm 1.4Jayson Deocareza Dela TorreNo ratings yet

- Candidate's Name: Assessor's Name: Qualification: Units of Competency To Be AssessedDocument2 pagesCandidate's Name: Assessor's Name: Qualification: Units of Competency To Be AssessedRiemmar MoicoNo ratings yet

- Sample Observation Checklist With Questioning DemonstrationDocument3 pagesSample Observation Checklist With Questioning DemonstrationRiemmar MoicoNo ratings yet

- KM 14. East Service Rd. Western Bicutan, Taguig City, 1630, PhilippinesDocument23 pagesKM 14. East Service Rd. Western Bicutan, Taguig City, 1630, PhilippinesRiemmar MoicoNo ratings yet

- po4-competency-based-learning-material-drFT - MoicoDocument36 pagespo4-competency-based-learning-material-drFT - MoicoRiemmar MoicoNo ratings yet

- Session Plan: 2. Install Wiring DevicesDocument4 pagesSession Plan: 2. Install Wiring DevicesRiemmar MoicoNo ratings yet

- Po1 Data Gathering Instrument For TraineeDocument3 pagesPo1 Data Gathering Instrument For TraineeRiemmar MoicoNo ratings yet

- Competency Based Learning Material: Technological University of The Philippines-Taguig CampusDocument40 pagesCompetency Based Learning Material: Technological University of The Philippines-Taguig CampusRiemmar MoicoNo ratings yet

- Catálogo DPS DCDocument3 pagesCatálogo DPS DCHedlund ErikNo ratings yet

- High Speed GearboxesDocument6 pagesHigh Speed Gearboxeskh_chu_1100% (1)

- Loadwise 502 RCI Operators ManualDocument13 pagesLoadwise 502 RCI Operators ManualM RefaiNo ratings yet

- Control ValveDocument58 pagesControl ValveNIKHIL SHINDENo ratings yet

- UntitledDocument31 pagesUntitledJulio CruzNo ratings yet

- Compact Linear Fresnel ReflectorDocument3 pagesCompact Linear Fresnel Reflectorjeff whoNo ratings yet

- Catalogue Evap-Cond-Cdu - HD 2Document3 pagesCatalogue Evap-Cond-Cdu - HD 2Dimensi LainNo ratings yet

- Stylus C79 D78 Parts List and Diagram PDFDocument6 pagesStylus C79 D78 Parts List and Diagram PDFDeniskoffNo ratings yet

- 【Installation】Ground Mounting System from Fasten Solar PDFDocument16 pages【Installation】Ground Mounting System from Fasten Solar PDFSukhbat DashnyamNo ratings yet

- 5M Maintenance ManualDocument351 pages5M Maintenance ManualRobin GhekiereNo ratings yet

- Types of Micro Computer - Desktop Computer - Laptop - Smartphones - Tablet - PDA (Personal Digital Assistant) - Server Microcomputer - WorkstationDocument2 pagesTypes of Micro Computer - Desktop Computer - Laptop - Smartphones - Tablet - PDA (Personal Digital Assistant) - Server Microcomputer - WorkstationNjumboketNo ratings yet

- Inclination Sensor CorrectionDocument3 pagesInclination Sensor CorrectionFrank SmithNo ratings yet

- CIJ - Raise A Hallelujah - TECH & SUPPORTDocument1 pageCIJ - Raise A Hallelujah - TECH & SUPPORTAdber John SantosNo ratings yet

- EP500 Standard Electropneumatic Positioner: Installation and Maintenance InstructionsDocument28 pagesEP500 Standard Electropneumatic Positioner: Installation and Maintenance InstructionsAlan ValdezNo ratings yet

- Wiringaccessoriesandlighting 180824142012Document30 pagesWiringaccessoriesandlighting 180824142012Ravi BhakeraoNo ratings yet

- WOLCK EYDFA With WDM-Datasheet & ManualDocument14 pagesWOLCK EYDFA With WDM-Datasheet & ManualWOLCK Liwen LeiNo ratings yet

- BOD Incubator PDFDocument1 pageBOD Incubator PDFp RAJAVELUNo ratings yet

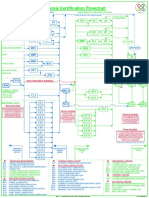

- GOC Functional Certification Flow ChartDocument1 pageGOC Functional Certification Flow ChartKAABECHE SlimaneNo ratings yet

- Ams 120Document1 pageAms 120Osorio LuisNo ratings yet

- BCSD Ordering HandbookDocument12 pagesBCSD Ordering Handbookgabrielsilva2042No ratings yet

- ITQ Manual100&3000Document17 pagesITQ Manual100&3000Yunus SiagianNo ratings yet

- Color Mark Contrast Sensor BZJ211 in Pakistan - Fiaz Electrical SolutionsDocument9 pagesColor Mark Contrast Sensor BZJ211 in Pakistan - Fiaz Electrical SolutionsZafar HussainNo ratings yet

- Power Circuit Breakers Insulated Case Circuit Breakers PDFDocument61 pagesPower Circuit Breakers Insulated Case Circuit Breakers PDFThar LayNo ratings yet

- Westinghouse Lighting VB-15 Series Roadway Spec Sheet 6-79Document2 pagesWestinghouse Lighting VB-15 Series Roadway Spec Sheet 6-79Alan MastersNo ratings yet

- Mini Project LVL 3Document4 pagesMini Project LVL 3Batrisyialya RusliNo ratings yet

- Parts List Manual: I A C TS20C/V200TSDocument108 pagesParts List Manual: I A C TS20C/V200TSMarcos CabreraNo ratings yet

- LM24 SR 2.0 US 4Nm 19559Document2 pagesLM24 SR 2.0 US 4Nm 19559Multiservici Campo EliasNo ratings yet

- Model: PLS00572 Double-Face LED Moving Wash/Beam LightDocument12 pagesModel: PLS00572 Double-Face LED Moving Wash/Beam LightledaggettNo ratings yet