Professional Documents

Culture Documents

Keyboard Plate & PCB Switches Keycaps Case: FN FN 123 FN

Keyboard Plate & PCB Switches Keycaps Case: FN FN 123 FN

Uploaded by

JeremyCopyright:

Available Formats

You might also like

- Skills Test Unit 9 Test B PDFDocument5 pagesSkills Test Unit 9 Test B PDFmajaNo ratings yet

- Double Cut LP JRDocument55 pagesDouble Cut LP JRFoo100% (1)

- NCAB Design Guidelines FlexRigid 1 2 231221Document1 pageNCAB Design Guidelines FlexRigid 1 2 231221Adrián Avellán GarcíaNo ratings yet

- ODIN LT ManualDocument7 pagesODIN LT ManualK BitcoinNo ratings yet

- Transformer Testing Diagnostics ToolDocument1 pageTransformer Testing Diagnostics ToolOsi MalickNo ratings yet

- KENR3599KENR3599Document6 pagesKENR3599KENR3599Carlos Enrique Vega OrtegaNo ratings yet

- Pocket-GT Eng02 WDocument1 pagePocket-GT Eng02 WAntônio NetoNo ratings yet

- Series 320Document6 pagesSeries 320Prathamesh GangalNo ratings yet

- 036 CerberusPRO IP4 0-92314-EnDocument2 pages036 CerberusPRO IP4 0-92314-EnvagnerNo ratings yet

- DV422 DV426 DV626UserManualDocument2 pagesDV422 DV426 DV626UserManualSonaNo ratings yet

- Dis Coupling - Misumi 1Document1 pageDis Coupling - Misumi 1SenthilNo ratings yet

- Frenic-Mega g2 Instruction Manual Inr-Si47-2392b-EDocument2 pagesFrenic-Mega g2 Instruction Manual Inr-Si47-2392b-Ejunjun kurniaNo ratings yet

- CB434D Civiles Serie CNHDocument6 pagesCB434D Civiles Serie CNHJesusAntonioQuirinoCanoNo ratings yet

- Power Tools - Montly HSE Inspection ChecklistDocument3 pagesPower Tools - Montly HSE Inspection ChecklistphitoNo ratings yet

- Manual de Usuario Obulb ProDocument1 pageManual de Usuario Obulb ProPere Civit QuiterioNo ratings yet

- Played Loud, Played Heavy These Drums RespondDocument4 pagesPlayed Loud, Played Heavy These Drums RespondaeroglideNo ratings yet

- Tractor D6G - SIS PDFDocument2 pagesTractor D6G - SIS PDFEduardo TorresNo ratings yet

- GB ES FR NL: Quick Start GuideDocument2 pagesGB ES FR NL: Quick Start Guidemick_hussNo ratings yet

- Noblex: PLL Synthesizer Stereo Radio With Compact Disc Player DigitalDocument14 pagesNoblex: PLL Synthesizer Stereo Radio With Compact Disc Player DigitalHernánSchusterNo ratings yet

- Screenshot 2023-11-22 at 10.05.09 PMDocument4 pagesScreenshot 2023-11-22 at 10.05.09 PMMicheal RajeshNo ratings yet

- Reed Adjustment Guide One PageDocument1 pageReed Adjustment Guide One PageCamillo GrassoNo ratings yet

- Brother A3 Inkjet Printer 2022Document2 pagesBrother A3 Inkjet Printer 2022HuiChan LimNo ratings yet

- Benedetto17 3Document1 pageBenedetto17 3Thierry QuesimuNo ratings yet

- Noblex nxc939bt js-15002b Mmotion-Electronics rcd3227bt Car Audio SMDocument17 pagesNoblex nxc939bt js-15002b Mmotion-Electronics rcd3227bt Car Audio SMCiclo TucumanNo ratings yet

- FT Mini Sportster v1.0 Full-SizeDocument4 pagesFT Mini Sportster v1.0 Full-SizeUdhasu NayakNo ratings yet

- Tectonic Activity and HazardsDocument8 pagesTectonic Activity and Hazardstamarashort100% (1)

- 3203 - Changing W Sub Waiting Ambulant - Rls PDFDocument1 page3203 - Changing W Sub Waiting Ambulant - Rls PDFVinay PallivalppilNo ratings yet

- LSI Sunburst Series Spec Sheet 1985Document4 pagesLSI Sunburst Series Spec Sheet 1985Alan MastersNo ratings yet

- 22.5" & Above Wheel Diameter: 2021 Product Specification Guide - HEAVY DUTYDocument2 pages22.5" & Above Wheel Diameter: 2021 Product Specification Guide - HEAVY DUTYPSNo ratings yet

- Apxbrochureusv 3 DDocument9 pagesApxbrochureusv 3 DLeandro RosaNo ratings yet

- 2.2.02 Schedule of Components: L D SD S PIR DN L/P P Rtls Code Description TotalDocument1 page2.2.02 Schedule of Components: L D SD S PIR DN L/P P Rtls Code Description TotalVinay PallivalppilNo ratings yet

- ABBManobra A LineMidi2008Document82 pagesABBManobra A LineMidi2008Claudia MartinsNo ratings yet

- 1124 MurdersRueRevised Ebook PDFDocument104 pages1124 MurdersRueRevised Ebook PDFHimi SanNo ratings yet

- 2006 Trenier RW CustomDocument7 pages2006 Trenier RW CustomBetoguitar777No ratings yet

- Series 314Document8 pagesSeries 314Prathamesh GangalNo ratings yet

- Universal Heating Cross Reference ChartsDocument2 pagesUniversal Heating Cross Reference ChartsOsopanda PandaNo ratings yet

- Turner Group, Mechanical Engineering & Applied Mechanics, School of Engineering & Applied Sciences University of PennsylvaniaDocument1 pageTurner Group, Mechanical Engineering & Applied Mechanics, School of Engineering & Applied Sciences University of Pennsylvaniaapi-482373029No ratings yet

- MAGIC-NS 2 User ManualDocument2 pagesMAGIC-NS 2 User ManualIce BoyNo ratings yet

- CP-433E, CS-423E, and CS-433E Electrical System Vibratory CompactorDocument2 pagesCP-433E, CS-423E, and CS-433E Electrical System Vibratory CompactorHector VallesNo ratings yet

- 2Document10 pages2Abstruse RonNo ratings yet

- MRT M&E Drawing3Document1 pageMRT M&E Drawing3qinxuekunNo ratings yet

- Complete Guide Modern Javascript 4thDocument324 pagesComplete Guide Modern Javascript 4thEdgar Ricárdez PeraltaNo ratings yet

- 14M Motor Grader Electrical System: Harness and Wire Electrical Schematic SymbolsDocument6 pages14M Motor Grader Electrical System: Harness and Wire Electrical Schematic SymbolsTekooMohamedNo ratings yet

- Revisions By: Electrical LegendDocument1 pageRevisions By: Electrical Legendvinhson65-1No ratings yet

- Compressor: Design FeaturesDocument5 pagesCompressor: Design FeaturesGio GioNo ratings yet

- E200 - Electrical Panel SchedulesDocument1 pageE200 - Electrical Panel SchedulesDagmawi GashawNo ratings yet

- D11N PDFDocument2 pagesD11N PDFJhon Richard Chambi PacoNo ratings yet

- LG 320gDocument2 pagesLG 320gb52v9jbNo ratings yet

- 14M - R9J SchematicDocument6 pages14M - R9J SchematicDiki PurwandiNo ratings yet

- CoaxialConnectors 2019 WEB2Document4 pagesCoaxialConnectors 2019 WEB2Divanshu JainNo ratings yet

- CoaxialConnectors 2019 WEB2Document4 pagesCoaxialConnectors 2019 WEB2Divanshu JainNo ratings yet

- Owner's Manual: SetupDocument2 pagesOwner's Manual: SetuptatfutureNo ratings yet

- Project S-302: Inking, Length Measure, Area MeasureDocument2 pagesProject S-302: Inking, Length Measure, Area MeasureNoviantoNo ratings yet

- Sony Zs Pe60Document2 pagesSony Zs Pe60Lord VarioNo ratings yet

- Sony Zs Pe60Document2 pagesSony Zs Pe60Lord VarioNo ratings yet

- RZR PRO XP (Base Model)Document5 pagesRZR PRO XP (Base Model)Andrea CalandriNo ratings yet

- 14M Electric System B9J 1-UPDocument6 pages14M Electric System B9J 1-UPIndi100% (1)

- Solids & Semiconductors (Theory)Document25 pagesSolids & Semiconductors (Theory)Avi KedarrNo ratings yet

- 14M Motor Grader Electrical System: Harness and Wire Electrical Schematic SymbolsDocument6 pages14M Motor Grader Electrical System: Harness and Wire Electrical Schematic Symbolsmanu luvungaNo ratings yet

- The Genius of Fear: Unlocking Hitchcock's Cinematic SecretsFrom EverandThe Genius of Fear: Unlocking Hitchcock's Cinematic SecretsNo ratings yet

- Exercises For ERD: Material TypeDocument3 pagesExercises For ERD: Material TypeKi KiNo ratings yet

- White Program - Inline Back To Back High - 2.4m - Iphone, Ipad and Watch + MacDocument5 pagesWhite Program - Inline Back To Back High - 2.4m - Iphone, Ipad and Watch + MacRobert SilvaNo ratings yet

- Digital Signal Processing: - Introduction, MS (Computer Engineering) NUST, Pakistan Mtjahangir17@ce - Ceme.edu - PKDocument136 pagesDigital Signal Processing: - Introduction, MS (Computer Engineering) NUST, Pakistan Mtjahangir17@ce - Ceme.edu - PKHamza ShafiqNo ratings yet

- C# Books, .NET Books, ASP - NET Books, VB - NET BooksDocument5 pagesC# Books, .NET Books, ASP - NET Books, VB - NET BooksSlavica ZivkovicNo ratings yet

- Example of Connection To Machine Controller MP2¡¡¡Document8 pagesExample of Connection To Machine Controller MP2¡¡¡Đạt Trương TuấnNo ratings yet

- Simple CalculatorDocument3 pagesSimple CalculatoramaniNo ratings yet

- User Environment Manager Datasheet FAQDocument2 pagesUser Environment Manager Datasheet FAQOscarNo ratings yet

- 3 - QMT425-T3 Linear Programming (29-74)Document46 pages3 - QMT425-T3 Linear Programming (29-74)Ashraf RadzaliNo ratings yet

- Poster Presentation For BBA V GEUDocument1 pagePoster Presentation For BBA V GEUJayant JawlaNo ratings yet

- Hsdpa Ue CatDocument2 pagesHsdpa Ue CatJason BrathNo ratings yet

- Zynq Ultrascale+ Mpsoc Product Tables and Product Selection GuideDocument8 pagesZynq Ultrascale+ Mpsoc Product Tables and Product Selection GuidedavidparelloNo ratings yet

- Microsoft SQL Server Database AdministrationDocument6 pagesMicrosoft SQL Server Database AdministrationpeddareddyNo ratings yet

- Nopcommerce Auction & Multi-StoreDocument5 pagesNopcommerce Auction & Multi-StoreamgodhaniNo ratings yet

- Government Supporting Documents GuideDocument7 pagesGovernment Supporting Documents Guidemaricar buisanNo ratings yet

- Chapter 2: Part B: AcknowledgementDocument29 pagesChapter 2: Part B: AcknowledgementVioleta GjiniNo ratings yet

- Content PDFDocument3 pagesContent PDFrafita muñozNo ratings yet

- Gutranrelation: Error SheetDocument16 pagesGutranrelation: Error SheetAhmed BadrNo ratings yet

- A Systematic Review For Enabling of Develop A Blockchain Technology in Healthcare Application TaxonomyDocument35 pagesA Systematic Review For Enabling of Develop A Blockchain Technology in Healthcare Application TaxonomyAshraf AbdouNo ratings yet

- National University of Singapore School of Computing IS2102 Enterprise Systems Architecture and Design Tutorial 2 Discussion QuestionsDocument3 pagesNational University of Singapore School of Computing IS2102 Enterprise Systems Architecture and Design Tutorial 2 Discussion QuestionsDavid HardsonNo ratings yet

- Bruxo M15Document5 pagesBruxo M15Matheus GomesNo ratings yet

- Selection of Various Types of UPS (Part-1) - Electrical Notes & ArticlesDocument1 pageSelection of Various Types of UPS (Part-1) - Electrical Notes & ArticleskakagoNo ratings yet

- Journal of Purchasing and Supply Management: Christoph G. Schmidt, Stephan M. Wagner TDocument13 pagesJournal of Purchasing and Supply Management: Christoph G. Schmidt, Stephan M. Wagner TAbdo EłNo ratings yet

- Mastering Android Studio - A Beginner's GuideDocument263 pagesMastering Android Studio - A Beginner's GuidewebmasterNo ratings yet

- BS/BSC (B.tech Hons) Engineering Technology New Curriculum 2015-2016Document179 pagesBS/BSC (B.tech Hons) Engineering Technology New Curriculum 2015-2016EngrEjazURRehmanNo ratings yet

- Ai Master Class Series - Day 8: Emotion Recognition Using OpencvDocument11 pagesAi Master Class Series - Day 8: Emotion Recognition Using OpencvAdnanNo ratings yet

- Al Hisn Ul Haseen With Sharah by Shaykh Ashiq Ilahi Madni (R.a)Document265 pagesAl Hisn Ul Haseen With Sharah by Shaykh Ashiq Ilahi Madni (R.a)Musalman Bhai50% (2)

- Tugas Preprocessing DataDocument1,374 pagesTugas Preprocessing Data2210312006No ratings yet

- Day 1 AssignmentDocument15 pagesDay 1 AssignmentChaya MahadevNo ratings yet

- Thank You For Buying My G2A Method !: How It Works?Document8 pagesThank You For Buying My G2A Method !: How It Works?WayneNo ratings yet

Keyboard Plate & PCB Switches Keycaps Case: FN FN 123 FN

Keyboard Plate & PCB Switches Keycaps Case: FN FN 123 FN

Uploaded by

JeremyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Keyboard Plate & PCB Switches Keycaps Case: FN FN 123 FN

Keyboard Plate & PCB Switches Keycaps Case: FN FN 123 FN

Uploaded by

JeremyCopyright:

Available Formats

Version 4.

0

Latest version available at neutrone.com

.com Merch available at superanked.com

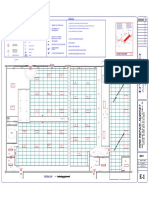

1 Keyboard 2 Case 3 Plate & PCB 4 Switches 5 Keycaps

Full Size (100%) Hard plate vs soft plate Types of switch Switch structure Keycaps profile Keycaps materials

Tenkeyless (TKL) R1 R2 R3 R4 Space ABS

Split & Ergonomic The main factor affecting Linear switches

Upper housing Impact resistant, lightweight

Separated in 2 modules, with typing feel is how hard the Move straight up and Guides the switching slide Cherry and durable. Uncoated ABS

Compact different shapes and layouts. down. No tactile

plate is during bottom out. precisely. keycaps are prone to becoming

feedback or clicking

shiny over time. Common due

noise. Rapid

Stem OEM to low cost in manufacture.

STIFF actuation.

Creates the pre-travel and the

PBT

Common materials Tactile switches

keystroke feel.

SA A more chalky feel and higher

Steel resistance to key shine than

Provide a noticeable Crosspoint contact

bump in the middle of It makes the electrical contact ABS. Heavier than ABS. Less

travel to let the user that activates the switch. common due to higher cost.

Aluminium Brass MDA

Ortho feel the response of

POM

The rows are straight and in line the operation. Coil spring Similar properties to PBT

with each other, freedom of Aluminium Sets up the pressure needed to XDA

with resistance to shine and

functionality/programmability. activate the switch and helps the heavier compared to ABS. Less

switch moving back to original common than PBT due to even

Carbon fibre Clicky switches

position. DSA higher cost of manufacture.

Compact keyboards ABS or PC Similar to tactile,

Very smooth feel due to low

but with a “click” Housing base coefficient of friction.

FR4 sound when the key The inner part forms the mounting

is activated.

Plastics

for the keyswitch’s switching

mechanism. The outer part is both

Keycaps printing

A B S, ACRY LIC, the base and mounting surface for

P OLYCA R B O N AT E

Acrylic mechanical keyboards.

Plateless Double shot injection molding

75 %

65 % 60 %

40 %

Cherry MX Operating Pre Total Actuation Graphs

This keycap type is produced when two layers of

plastic are molded into each other. With this

method, markings cannot be worn off and the

FLEX switches Force Travel Travel

86-88 Fn 123 65-68 Fn 123 59-64 Fn 123 39-41 Fn 123

characters can achieve high contrast.

Keys Keys Keys Keys Wood

PCB Red 45cN 2.0mm 4.0mm

Dye sublimation

This is a simplification. The presence and position of some Process where heat is used to impregnate a

modifiers may vary. Check carefully the keyboard layout you pick. material with a dye. Dye sublimation requires

that the dye must be darker than the material it

Keyboard profile Regular PCB Brown 55cN 2.0mm 4.0mm is being used to dye.

2-Piece construction With multiple solder points

(plated through-holes) to Pad printing

Such a kit consists of a Black 60cN 2.0mm 4.0mm Pads are dipped into ink, and then pressed onto

accommodate alternate layouts. the keycap to form a layer of ink on top of the

case and a PCB/Plate keycap. This is flexible (i.e. various colors) but

Flat

combo. PCB and plate are the ink is prone to wear.

Blue 60cN 2.2mm 4.0mm

only counted as ONE piece Tactile

position

Operating

position

Reset

position

Curved backplate Staircase Contoured keys since the plate is Screen printing with UV coat

Chiclet potentially optional. Also called as silk screen printing. The letters

Technical characteristics will be hollowed in a specially made woven mesh.

When the paint is brushed, paint will fill the

Modifiers compatibility hollow parts and print letters on keycaps. It

3-Piece construction Operation force Activation point Total travel distance can also print various colors. A UV coating will

be added on top of letters.

Hot swap PCB How hard you have to When a keypress is The distance your keycap

Standard bottom row press the key. It is recognized by the travels until it hits the

R1 R1 R1 Spacebar R1 R1 R1 R1 It allows to swap out the

On top of the Two Piece measured in centinewton keyboard. It is measured upper housing of the Laser ablation

1x1.25 1x1.25 1x1.25 1x6.25 1x1.25 1x1.25 1x1.25 1x1.25

All bottom row modifiers switch without having to solder (cN) or gram-force (gf). in millimeters. It is switch (the distance until

construction content, The transparent plastic is covered in paint,

are 1.25 wide. or desolder anything. also known as operating you bottom out). It is and a laser burns off the paint to expose the

these kits usually include position or actuation measured in millimeters. transparent plastic in the shape of the

Non-Standard bottom row a top frame for the case 0-55 cN Light point. character.

R1 R1 R1 Spacebar R1 R1 R1 R1

1x1.5 1x1 1x1.25 1x6.50 1x1.25 1x1 1x1 1x1.5

The bottom row modifiers and is commonly held in Tactile position

55-75 cN Medium

vary in size. place by screws through The point where you feel

R1 R1 R1 Spacebar R1 R1 R1 R1 Reset position Laser etching

1x1.5 1x1 1x1.5 1x6.00 1x1.5 1x1 1x1 1x1.5

the bottom case. 75-95 cN Heavy The distance at which

the bump on tactile and A laser is used to burn the required letters

clicky switches. On into the keycaps. This printing is mainly used

the key is deactivated

R1 R1 R1 R1 Spacebar R1 R1 R1 R1 95+ cN Super Heavy when released.

linear switches, there’s for white keycaps, grey keycaps, or bamboo.

1x1.25 1x1.25 1x1.25 1x1.25 1x5.00 1x1.25 1x1.25 1x1.25 1x1.25

no tactile position.

You might also like

- Skills Test Unit 9 Test B PDFDocument5 pagesSkills Test Unit 9 Test B PDFmajaNo ratings yet

- Double Cut LP JRDocument55 pagesDouble Cut LP JRFoo100% (1)

- NCAB Design Guidelines FlexRigid 1 2 231221Document1 pageNCAB Design Guidelines FlexRigid 1 2 231221Adrián Avellán GarcíaNo ratings yet

- ODIN LT ManualDocument7 pagesODIN LT ManualK BitcoinNo ratings yet

- Transformer Testing Diagnostics ToolDocument1 pageTransformer Testing Diagnostics ToolOsi MalickNo ratings yet

- KENR3599KENR3599Document6 pagesKENR3599KENR3599Carlos Enrique Vega OrtegaNo ratings yet

- Pocket-GT Eng02 WDocument1 pagePocket-GT Eng02 WAntônio NetoNo ratings yet

- Series 320Document6 pagesSeries 320Prathamesh GangalNo ratings yet

- 036 CerberusPRO IP4 0-92314-EnDocument2 pages036 CerberusPRO IP4 0-92314-EnvagnerNo ratings yet

- DV422 DV426 DV626UserManualDocument2 pagesDV422 DV426 DV626UserManualSonaNo ratings yet

- Dis Coupling - Misumi 1Document1 pageDis Coupling - Misumi 1SenthilNo ratings yet

- Frenic-Mega g2 Instruction Manual Inr-Si47-2392b-EDocument2 pagesFrenic-Mega g2 Instruction Manual Inr-Si47-2392b-Ejunjun kurniaNo ratings yet

- CB434D Civiles Serie CNHDocument6 pagesCB434D Civiles Serie CNHJesusAntonioQuirinoCanoNo ratings yet

- Power Tools - Montly HSE Inspection ChecklistDocument3 pagesPower Tools - Montly HSE Inspection ChecklistphitoNo ratings yet

- Manual de Usuario Obulb ProDocument1 pageManual de Usuario Obulb ProPere Civit QuiterioNo ratings yet

- Played Loud, Played Heavy These Drums RespondDocument4 pagesPlayed Loud, Played Heavy These Drums RespondaeroglideNo ratings yet

- Tractor D6G - SIS PDFDocument2 pagesTractor D6G - SIS PDFEduardo TorresNo ratings yet

- GB ES FR NL: Quick Start GuideDocument2 pagesGB ES FR NL: Quick Start Guidemick_hussNo ratings yet

- Noblex: PLL Synthesizer Stereo Radio With Compact Disc Player DigitalDocument14 pagesNoblex: PLL Synthesizer Stereo Radio With Compact Disc Player DigitalHernánSchusterNo ratings yet

- Screenshot 2023-11-22 at 10.05.09 PMDocument4 pagesScreenshot 2023-11-22 at 10.05.09 PMMicheal RajeshNo ratings yet

- Reed Adjustment Guide One PageDocument1 pageReed Adjustment Guide One PageCamillo GrassoNo ratings yet

- Brother A3 Inkjet Printer 2022Document2 pagesBrother A3 Inkjet Printer 2022HuiChan LimNo ratings yet

- Benedetto17 3Document1 pageBenedetto17 3Thierry QuesimuNo ratings yet

- Noblex nxc939bt js-15002b Mmotion-Electronics rcd3227bt Car Audio SMDocument17 pagesNoblex nxc939bt js-15002b Mmotion-Electronics rcd3227bt Car Audio SMCiclo TucumanNo ratings yet

- FT Mini Sportster v1.0 Full-SizeDocument4 pagesFT Mini Sportster v1.0 Full-SizeUdhasu NayakNo ratings yet

- Tectonic Activity and HazardsDocument8 pagesTectonic Activity and Hazardstamarashort100% (1)

- 3203 - Changing W Sub Waiting Ambulant - Rls PDFDocument1 page3203 - Changing W Sub Waiting Ambulant - Rls PDFVinay PallivalppilNo ratings yet

- LSI Sunburst Series Spec Sheet 1985Document4 pagesLSI Sunburst Series Spec Sheet 1985Alan MastersNo ratings yet

- 22.5" & Above Wheel Diameter: 2021 Product Specification Guide - HEAVY DUTYDocument2 pages22.5" & Above Wheel Diameter: 2021 Product Specification Guide - HEAVY DUTYPSNo ratings yet

- Apxbrochureusv 3 DDocument9 pagesApxbrochureusv 3 DLeandro RosaNo ratings yet

- 2.2.02 Schedule of Components: L D SD S PIR DN L/P P Rtls Code Description TotalDocument1 page2.2.02 Schedule of Components: L D SD S PIR DN L/P P Rtls Code Description TotalVinay PallivalppilNo ratings yet

- ABBManobra A LineMidi2008Document82 pagesABBManobra A LineMidi2008Claudia MartinsNo ratings yet

- 1124 MurdersRueRevised Ebook PDFDocument104 pages1124 MurdersRueRevised Ebook PDFHimi SanNo ratings yet

- 2006 Trenier RW CustomDocument7 pages2006 Trenier RW CustomBetoguitar777No ratings yet

- Series 314Document8 pagesSeries 314Prathamesh GangalNo ratings yet

- Universal Heating Cross Reference ChartsDocument2 pagesUniversal Heating Cross Reference ChartsOsopanda PandaNo ratings yet

- Turner Group, Mechanical Engineering & Applied Mechanics, School of Engineering & Applied Sciences University of PennsylvaniaDocument1 pageTurner Group, Mechanical Engineering & Applied Mechanics, School of Engineering & Applied Sciences University of Pennsylvaniaapi-482373029No ratings yet

- MAGIC-NS 2 User ManualDocument2 pagesMAGIC-NS 2 User ManualIce BoyNo ratings yet

- CP-433E, CS-423E, and CS-433E Electrical System Vibratory CompactorDocument2 pagesCP-433E, CS-423E, and CS-433E Electrical System Vibratory CompactorHector VallesNo ratings yet

- 2Document10 pages2Abstruse RonNo ratings yet

- MRT M&E Drawing3Document1 pageMRT M&E Drawing3qinxuekunNo ratings yet

- Complete Guide Modern Javascript 4thDocument324 pagesComplete Guide Modern Javascript 4thEdgar Ricárdez PeraltaNo ratings yet

- 14M Motor Grader Electrical System: Harness and Wire Electrical Schematic SymbolsDocument6 pages14M Motor Grader Electrical System: Harness and Wire Electrical Schematic SymbolsTekooMohamedNo ratings yet

- Revisions By: Electrical LegendDocument1 pageRevisions By: Electrical Legendvinhson65-1No ratings yet

- Compressor: Design FeaturesDocument5 pagesCompressor: Design FeaturesGio GioNo ratings yet

- E200 - Electrical Panel SchedulesDocument1 pageE200 - Electrical Panel SchedulesDagmawi GashawNo ratings yet

- D11N PDFDocument2 pagesD11N PDFJhon Richard Chambi PacoNo ratings yet

- LG 320gDocument2 pagesLG 320gb52v9jbNo ratings yet

- 14M - R9J SchematicDocument6 pages14M - R9J SchematicDiki PurwandiNo ratings yet

- CoaxialConnectors 2019 WEB2Document4 pagesCoaxialConnectors 2019 WEB2Divanshu JainNo ratings yet

- CoaxialConnectors 2019 WEB2Document4 pagesCoaxialConnectors 2019 WEB2Divanshu JainNo ratings yet

- Owner's Manual: SetupDocument2 pagesOwner's Manual: SetuptatfutureNo ratings yet

- Project S-302: Inking, Length Measure, Area MeasureDocument2 pagesProject S-302: Inking, Length Measure, Area MeasureNoviantoNo ratings yet

- Sony Zs Pe60Document2 pagesSony Zs Pe60Lord VarioNo ratings yet

- Sony Zs Pe60Document2 pagesSony Zs Pe60Lord VarioNo ratings yet

- RZR PRO XP (Base Model)Document5 pagesRZR PRO XP (Base Model)Andrea CalandriNo ratings yet

- 14M Electric System B9J 1-UPDocument6 pages14M Electric System B9J 1-UPIndi100% (1)

- Solids & Semiconductors (Theory)Document25 pagesSolids & Semiconductors (Theory)Avi KedarrNo ratings yet

- 14M Motor Grader Electrical System: Harness and Wire Electrical Schematic SymbolsDocument6 pages14M Motor Grader Electrical System: Harness and Wire Electrical Schematic Symbolsmanu luvungaNo ratings yet

- The Genius of Fear: Unlocking Hitchcock's Cinematic SecretsFrom EverandThe Genius of Fear: Unlocking Hitchcock's Cinematic SecretsNo ratings yet

- Exercises For ERD: Material TypeDocument3 pagesExercises For ERD: Material TypeKi KiNo ratings yet

- White Program - Inline Back To Back High - 2.4m - Iphone, Ipad and Watch + MacDocument5 pagesWhite Program - Inline Back To Back High - 2.4m - Iphone, Ipad and Watch + MacRobert SilvaNo ratings yet

- Digital Signal Processing: - Introduction, MS (Computer Engineering) NUST, Pakistan Mtjahangir17@ce - Ceme.edu - PKDocument136 pagesDigital Signal Processing: - Introduction, MS (Computer Engineering) NUST, Pakistan Mtjahangir17@ce - Ceme.edu - PKHamza ShafiqNo ratings yet

- C# Books, .NET Books, ASP - NET Books, VB - NET BooksDocument5 pagesC# Books, .NET Books, ASP - NET Books, VB - NET BooksSlavica ZivkovicNo ratings yet

- Example of Connection To Machine Controller MP2¡¡¡Document8 pagesExample of Connection To Machine Controller MP2¡¡¡Đạt Trương TuấnNo ratings yet

- Simple CalculatorDocument3 pagesSimple CalculatoramaniNo ratings yet

- User Environment Manager Datasheet FAQDocument2 pagesUser Environment Manager Datasheet FAQOscarNo ratings yet

- 3 - QMT425-T3 Linear Programming (29-74)Document46 pages3 - QMT425-T3 Linear Programming (29-74)Ashraf RadzaliNo ratings yet

- Poster Presentation For BBA V GEUDocument1 pagePoster Presentation For BBA V GEUJayant JawlaNo ratings yet

- Hsdpa Ue CatDocument2 pagesHsdpa Ue CatJason BrathNo ratings yet

- Zynq Ultrascale+ Mpsoc Product Tables and Product Selection GuideDocument8 pagesZynq Ultrascale+ Mpsoc Product Tables and Product Selection GuidedavidparelloNo ratings yet

- Microsoft SQL Server Database AdministrationDocument6 pagesMicrosoft SQL Server Database AdministrationpeddareddyNo ratings yet

- Nopcommerce Auction & Multi-StoreDocument5 pagesNopcommerce Auction & Multi-StoreamgodhaniNo ratings yet

- Government Supporting Documents GuideDocument7 pagesGovernment Supporting Documents Guidemaricar buisanNo ratings yet

- Chapter 2: Part B: AcknowledgementDocument29 pagesChapter 2: Part B: AcknowledgementVioleta GjiniNo ratings yet

- Content PDFDocument3 pagesContent PDFrafita muñozNo ratings yet

- Gutranrelation: Error SheetDocument16 pagesGutranrelation: Error SheetAhmed BadrNo ratings yet

- A Systematic Review For Enabling of Develop A Blockchain Technology in Healthcare Application TaxonomyDocument35 pagesA Systematic Review For Enabling of Develop A Blockchain Technology in Healthcare Application TaxonomyAshraf AbdouNo ratings yet

- National University of Singapore School of Computing IS2102 Enterprise Systems Architecture and Design Tutorial 2 Discussion QuestionsDocument3 pagesNational University of Singapore School of Computing IS2102 Enterprise Systems Architecture and Design Tutorial 2 Discussion QuestionsDavid HardsonNo ratings yet

- Bruxo M15Document5 pagesBruxo M15Matheus GomesNo ratings yet

- Selection of Various Types of UPS (Part-1) - Electrical Notes & ArticlesDocument1 pageSelection of Various Types of UPS (Part-1) - Electrical Notes & ArticleskakagoNo ratings yet

- Journal of Purchasing and Supply Management: Christoph G. Schmidt, Stephan M. Wagner TDocument13 pagesJournal of Purchasing and Supply Management: Christoph G. Schmidt, Stephan M. Wagner TAbdo EłNo ratings yet

- Mastering Android Studio - A Beginner's GuideDocument263 pagesMastering Android Studio - A Beginner's GuidewebmasterNo ratings yet

- BS/BSC (B.tech Hons) Engineering Technology New Curriculum 2015-2016Document179 pagesBS/BSC (B.tech Hons) Engineering Technology New Curriculum 2015-2016EngrEjazURRehmanNo ratings yet

- Ai Master Class Series - Day 8: Emotion Recognition Using OpencvDocument11 pagesAi Master Class Series - Day 8: Emotion Recognition Using OpencvAdnanNo ratings yet

- Al Hisn Ul Haseen With Sharah by Shaykh Ashiq Ilahi Madni (R.a)Document265 pagesAl Hisn Ul Haseen With Sharah by Shaykh Ashiq Ilahi Madni (R.a)Musalman Bhai50% (2)

- Tugas Preprocessing DataDocument1,374 pagesTugas Preprocessing Data2210312006No ratings yet

- Day 1 AssignmentDocument15 pagesDay 1 AssignmentChaya MahadevNo ratings yet

- Thank You For Buying My G2A Method !: How It Works?Document8 pagesThank You For Buying My G2A Method !: How It Works?WayneNo ratings yet