Professional Documents

Culture Documents

Agricultural Machinery and Mechanization: Definitions

Agricultural Machinery and Mechanization: Definitions

Uploaded by

Jireh LoquinarioOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Agricultural Machinery and Mechanization: Definitions

Agricultural Machinery and Mechanization: Definitions

Uploaded by

Jireh LoquinarioCopyright:

Available Formats

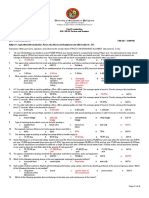

PSAE Region IV - Agricultural Engineering Board Review Materials I-1

Agricultural Machinery and Mechanization

Dr. Arsenio N. Resurreccion

Director

Agricultural Machinery Testing Center

College of Engineering and Agro-Industrial Technology

University of the Philippines Los Baños

College, Laguna

Definitions:

FAO (1979): Embracing the manufacture, distribution, utilization and provision of

after-sales service of tools, implements and machines for land

development, agricultural production and primary post-production

processes. It includes the use of three main sources of power: human,

animal and mechanical.

STOUT AND DOWNING (1974): Use of hand and animal-operated tools and implements

as well as motorized equipment to reduce human effort, improve quality,

perform operations that cannot be done by other means, and improve

the timeliness of various operations, thereby increasing yield, quality of

product and overall efficiency.

The first definition emphasized the scope of services and the different levels of

mechanization (scope: manufacture to after-sales service; levels: the use of

tools, implements and machines; the use of human, animal and mechanical

sources of power).

However, a particular mechanization program can be a combination of the

different levels for the different farm operations. Consider the mechanization of

a rice farm shown below:

OPERATION LEVEL OF MECHANIZATION

Land preparation Tractor-drawn disc plow

Planting Hand Jabber

Spraying Lever-operated knapsack sprayer

Weeding/cultivating Animal-drawn moldboard plow

Harvesting Sickle

Threshing Mechanical thresher

Drying Sun drying

Milling Mechanical rice mill

The second definition dealt with the objectives and benefits from mechanization:

OBJECTIVES BENEFITS

1. Reduce human effort 1. increase yields

2. Improve quality 2. increase quality of product

3. perform operations that cannot be 3. increase overall efficiency

done by other means

4. improve timeliness of operation of

various operations

Agricultural Machinery and Mechanization

PSAE Region IV - Agricultural Engineering Board Review Materials I-2

The two definitions combined give us a more complete picture of mechanization

and its complexities.

Models of mechanization:

1. High land area to farmer ratio: (example: USA)

Motivated into increasing the level of mechanization in order to cultivate large

agricultural lands with limited available manpower and take advantage of

favorable agricultural commodity prices.

Thailand, Malaysia and Indonesia follow the USA model

2. Low land area to farmer ratio: (example: Japan)

Motivated into increasing the level of mechanization in order to increase yields

and cropping intensities to meet the growing demands for food and agricultural

raw materials.

South Korea, China, Taiwan, Sri Lanka and the Philippines follow the Japanese

model.

Potential benefits from mechanization:

1. Increased cropping intensity and production

Tractors, power tillers, irrigation pumps, harvesters and threshers

increased cropping intensities

Irrigation pumps increased yields

Harvester and threshers reduced losses which effectively increased yields

2. Increased productivity of labor

Tractors in land preparation reduced 50% of the labor inputs

However, labor for land preparation in the Philippines comprised mainly

family labor

Freed family labor can look for alternative work opportunities; children

can go to school

3. Full utilization of farm products and by products

Availability of machines allow the processing of farm products and by-

products

Take the case of pineapple and coconut. Rather than just selling the

fruit and nut, they can be processed into different products

4. Reduction of losses

Development of harvesting, threshing and processing machines reduced

harvest and postharvest losses

Losses: Rice: 10 – 37%

Corn: 30%

5. Increased value added of farm products

Secondary and tertiary processing open up market potentials and lead to

higher retail prices

Shelled peanut retailers earn P0.50/kg or more

Agricultural Machinery and Mechanization

PSAE Region IV - Agricultural Engineering Board Review Materials I-3

Dried corn can extend the selling period and need not be forced to sell at

a low price

6. Employment and livelihood generation

Machines designed to increase cropping intensities and production will

correspondingly increase labor requirements for production and

postharvest operations

Machines designed to diversify farm products and by products open up

various livelihood opportunities

Use of machines will require the putting up of repair shops in the village

areas

7. Import substitution

Local agricultural machinery manufacturing will minimize the importation

of agricultural machinery

8. Export possibilities

Locally manufactured agricultural machinery can be exported to

countries with similar farming conditions such as the Philippines

Conceptions and misconceptions on mechanization

1. Mechanization is synonymous to tractorization

2. High level mechanization is equated to modernization and therefore, is an

indicator and requirement for development

3. Mechanization displaces farm labor and causes unemployment in agriculture; any

substitution of capital for labor is socially undesirable

4. Mechanization is a western or developed country system of farming that is not

suited for developing countries

5. Mechanization is a costly input in farming especially the rising costs of fossil fuel

6. Mechanization is not feasible where farm holdings are fragmented and

inaccessible

7. Only the large farms can afford the cost of mechanization

It is the responsibility of all those involved in agricultural mechanization not to

advocate indiscriminate high level mechanization and those against

mechanization not to come up with sweeping statements that mechanization is

undesirable.

There exist combinations of levels of mechanization that will render

mechanization in a specific area desirable.

Agencies involved in agricultural mechanization:

Agricultural Machinery and Mechanization

PSAE Region IV - Agricultural Engineering Board Review Materials I-4

GOVERNMENT SECTOR

1. Department of Agriculture (DA):

a.) Agriculture and Fisheries Mechanization Committee (AFMeC) – inter-

agency committee which serves as advisory to the Secretary on

mechanization concerns

b.) Bureau of Postharvest Research and Extension (BPRE) – in-charge of

post harvest mechanization and corn mechanization

c.) Philippine Rice Research Institute (PhilRice) – In-charge of rice

mechanization

d.) Bureau of Soils and Water Management (BSWM) – In-charge of

developing small-scale irrigation projects

e.) National Irrigation Administration (NIA) – In-charge of developing large-

scale irrigation projects

f.) Bureau of Plant Industry (BPI) – In-charge of vegetable mechanization

g.) National Food Authority (NFA) – In-charge of grain storage and

marketing

h.) Bureau of Agricultural Research (BAR) – Base of the Agricultural Eng’g

RDE Network

i.) Regional Agricultural Engineering Group (RAEG) – In-charge of

agricultural mechanization concerns in the different regions

2. University of the Philippines Los Baňos (UPLB):

a) Agricultural Mechanization Development Program (AMDP) – Research

and extension on agricultural mechanization; Philippine counterpart of

the Regional Network for Agricultural Machinery (RNAM)

b) Agricultural Machinery Testing and Evaluation Center(AMTEC) – Testing

and evaluation of agricultural machinery; Development of agricultural

machinery standards

3. Central Luzon State University (CLSU):

a.) Philippine-Sino Center for Agricultural Technology (PhilSCAT) –

adaption and promotion of Chinese agricultural machinery for local

conditions

4. Department of Science and Technology (DOST):

a) Philippine Council for Agriculture, Forestry and Natural Resources Research

and Development (PCARRD) – base of the Agricultural Engineering R&D

Team which provides policy direction for agricultural mechanization

Agricultural Machinery and Mechanization

PSAE Region IV - Agricultural Engineering Board Review Materials I-5

5. Professional Regulation Commission (PRC) – base of the Board of Agricultural

Engineering (BOAE) which regulates and promotes the agricultural engineering

profession

PRIVATE SECTOR

6. Philippine Society of Agricultural Engineers (PSAE) – national and regional

professional organization of agricultural engineers with similar functions as BOAE

7. Agricultural Machinery Manufacturers, Dealers and Distributors Association

(AMMDA) – Heart of the agricultural machinery manufacturing, marketing and

after-sales service

Selection of agricultural machinery:

Proper selection of agricultural machinery is important because it is considered a

major investment

A variety of farm machinery (different types, models and brands) are now

commercially available. Data on actual performance of the various types, models

and brands are needed for a wise selection.

Point or features of machines that may help select the right machine:

1. Trade mark – stands for the reputation of the manufacturer and a

guarantee of what lies beneath the paint

2. Materials – take note of the quality of materials used and the

manufacturing technology employed in the manufacture of the machine

as this will have a direct bearing on performance and durability

3. Ease of operation – pay attention to placement of controls. Ensure that

controls are accessible and soft to operate. Look for adjustments of

handle bars and seats

4. Ease of maintenance – a machine requires daily and periodic

maintenance and adjustments. Ensure that points of maintenance and

adjustment are easy to perform. The machine should have an operator’s

manual explaining the procedures.

5. Safety – check for safety provisions for both machine and operator. All

rotating parts should be provided with shields. Snap clutches or similar

devices should be installed to protect the machine and prime mover in

case of overload.

6. Source of repair – make sure that spare parts and service are available

nearby. Ask for local dealers and for the machine.

7. Power source – decide if you will need an engine or electric motor.

If an engine, decide if you want a diesel or gasoline engine.

With the gasoline engine, first cost is lower but operating cost is

high. With the diesel engine, first cost is high but operating cost

is low.

Agricultural Machinery and Mechanization

PSAE Region IV - Agricultural Engineering Board Review Materials I-6

If an electric motor, decide if you need single-phase or three-

phase electric motor. Acquisition cost and current requirement

of three-phase electric motor is lower but is three-phase supply

line available in your area?

Optimum capacity of machines:

Smallest capacity that will get the job done on time. However, there should be

some excess capacity on the machine to cover unexpected delays due to

weather and/or machine breakdown

Often, it is an option to have several small capacity machines rather than just

one big machine. If a big machine breaks down, there is 100% stoppage of

work. In the case of two smaller machines, if one machine breaks down, there is

only 50% stoppage of work. Further, it allows for a 50% lowering of production

output.

Economics of farm machinery:

The economic goal of mechanization is to maximize profits by getting the

maximum output from machines at a minimum cost.

A mechanization scheme does not mean mechanizing all farm operations but

only those that will contribute to increased output and reduction of operating

cost.

The use of machinery does not only imply ownership; renting of machines or

custom-hire operation are very sound options especially for small farms. This is

common in land preparation, high capacity shelling and threshing, and milling

operations.

Joint ownership of machines by two or more farms to justify the purchase of a

machine is also another viable option.

And for cooperatives, acquisition of machines and renting out to members is also

another viable option.

Measures of machinery investment appraisal:

1. Undiscounted measures – does not take into consideration the change in

value of money over time. These are usually crude methods of

comparing several investment alternatives.

a. Payback period (PBP) – length of time it takes to recover the

investment or until the net benefits equal the investment cost.

The decision rule is to select the alternative with the shortest

PBP.

b. Break-even point (BEP) – level of operation where the

investment neither produces a profit nor incurs a loss. The

decision rule is to accept the alternative with the lowest BEP.

2. Discounted measure – the time value of money is taken into

consideration through the process called discounting.

Agricultural Machinery and Mechanization

PSAE Region IV - Agricultural Engineering Board Review Materials I-7

Discounting is the process of translating future values in present worth

by applying a set of discount factors that reflects the diminishing value

of the same amount of money as one moves further into the future.

a. Benefit-Cost Ratio (BCR) – ratio of the present worth of the

benefit stream over the present worth of cost stream extending

over a period of time usually the life of the machine. Decision

rule is to accept projects with BCR ≥ 1.

b. Net Present Value (NPV) – the difference of the present value of

the benefit stream and the present value of the cost stream

extending over a period of time usually the life of the machine.

The decision rule is to accept projects with NPV ≥ 0

c. Internal Rate of Return (IRR) – the maximum interest rate the

project can pay for the use of money if the project is to break-

even. At this point, the NPV = O and BCR = 1. The decision

rule is that the IRR of the project should be higher than the

prevailing interest rate of the bank.

PHILIPPINE AGRICULTURAL ENGINEERING STANDARDS

(PAES)

Development of agricultural engineering standards has not been given due attention.

The practice of agricultural engineering has always been based on standards from the US

and other countries.

Locally, there existing Philippine standards for selected machines. Standards for

irrigation, structures and alternative energy are non-existent. Standards for rural

electrification, domestic water supply, farm roads and bridges are lodged in other

engineering fields and not with agricultural engineering.

There is a need to develop our own agricultural engineering standards.

In the late 70s, the Bureau of Product Standards (BPS) established the Technical

Committee on Machinery for Agriculture and Forestry (TC 56). TC 56 came out with six

standards

Later, TC 56 was replaced by TC 19. TC 19 came out with five standards

In 1992, the Consumer Act of the Philippines (RA 7394) was enacted identifying

standards development to three agencies:

Department of Agriculture: agricultural products including machinery

Department of Health: drugs, cosmetics, devices and substances

Department of Trade and Industry: others not covered by the two agencies

In 2001, the Department of Agriculture issued AO 11 on Implementation of the National

Agriculture and Fisheries Mechanization Program which stated, among others:

AMTEC, in partnership with PSAE and other concerned agencies, shall be charged with

the formulation and development of the official agriculture and fisheries machinery

standards.

AMTEC implemented a series of projects on the development of the Philippine

Agricultural Engineering Standards (PAES).

Agricultural Machinery and Mechanization

PSAE Region IV - Agricultural Engineering Board Review Materials I-8

Breakdown of standards developed:

PRODUCTION POSTHARVEST ENGINEERING AGRICULTURAL

TOTAL

MACHINERY MACHINERY MATERIALS STRUCTURES

PAES I 15 11 6 3 35

PAES

8 - 7 10 25

II

PAES

7 - 7 8 22

III

PAES

10 11 - - 21

IV

PAES V 6 8 - - 14

TOTAL 46 30 20 21 117

Agricultural Machinery and Mechanization

PSAE Region IV - Agricultural Engineering Board Review Materials I-9

Flowchart of standards development:

Preparation of Draft Standards

(Secretariat)

Review & Modification of Draft Standards

(Technical Committee)

Circulation & Public Hearing of Draft Standards

(Secretariat and NAFC)

Finalization of Draft Standards

(Secretariat)

Recommend adoption of Draft Standards Recommend adoption of Draft Standards

(NAFC) (PSAE)

Adoption of PAES Adoption of PAES

(DA) (BOAE-PRC)

Publication

(Secretariat)

Public hearing conducted on standards developed:

No. of

STANDARDS DATE (S) VENUE (S)

Participants

Apacible Hall, NAFC,

PAES I August 27, 2001 Quezon City 70

PhilRice, Muñoz, Nueva

October I, 2002 Ecija 38

Felis Resort, Matina, Davao

PAES II October 8, 2002 26

City

DA-Region VII,

October I0, 2002 Cebu City 33

Agricultural Machinery and Mechanization

PSAE Region IV - Agricultural Engineering Board Review Materials I-10

Apacible Hall, NAFC,

PAES III March 12, 2003 Quezon City 70

Apacible Hall, NAFC,

PAES IV October 15, 2004 Quezon City 60

Adoption of standards:

STANDARDS DA BOAE-PRC

PAES I AO 10 Series of 2002 BR 05 Series of 2002

PAES II AO 06 Series of 2003 BR 01 Series of 2003

PAES III AO 11 Series of 2003 BR 02 Series of 2003

PAES IV AO 05 Series of 2005 -

DA adoption of standards:

Require all offices of the DA to adopt and comply with the standards as Philippine

Agricultural Engineering Standards.

PRC adoption of standards:

Adopt PAES as a Code of Technical Standards of Agricultural Engineering, and shall

serve as technical reference by all agricultural engineers in the signing and sealing of

plans, designs and specifications, and other related works in the practice of their

profession.

Agricultural Machinery and Mechanization

PSAE Region IV - Agricultural Engineering Board Review Materials I-11

Publication of standards:

PAES Volume I PAES Volume II

PAES Volume III PAES Volume IV

st nd

PAES CD 1 Edition PAES CD 2 Edition

Agricultural Machinery and Mechanization

You might also like

- Research ProposalDocument5 pagesResearch ProposalBea Maica Gavino75% (4)

- Republic Airways Pilots Final Contract OfferDocument217 pagesRepublic Airways Pilots Final Contract OfferBrianSumers100% (2)

- Hydro MeteorologyDocument258 pagesHydro MeteorologyChessmyssNo ratings yet

- PART 2 PrintDocument6 pagesPART 2 PrintMisheru Misaki AyuzawaNo ratings yet

- Part 1 Pre Board 2019 FinalDocument16 pagesPart 1 Pre Board 2019 FinalMenard SoniNo ratings yet

- 2 - Review Notes - PAESDocument14 pages2 - Review Notes - PAESJOE JoJoNo ratings yet

- PAES Definition of TermsDocument114 pagesPAES Definition of TermsU-one Frago0% (1)

- I-1c FarmMech 20-60Document41 pagesI-1c FarmMech 20-60SannyBombeoJomoc50% (2)

- LWUA SpecificationsDocument274 pagesLWUA SpecificationsSannyBombeoJomocNo ratings yet

- III-9 Eng'g Laws 1-40Document43 pagesIII-9 Eng'g Laws 1-40SannyBombeoJomoc100% (2)

- 3 - Review Notes - AGRICULTURAL MECHANIZATIONDocument12 pages3 - Review Notes - AGRICULTURAL MECHANIZATIONJoey camalitaNo ratings yet

- Preboards Exam Part I Answer Key 2Document9 pagesPreboards Exam Part I Answer Key 2Peter ian AutenticoNo ratings yet

- 2017-MSU-Agricultural Power and Energy Sources-BlackDocument47 pages2017-MSU-Agricultural Power and Energy Sources-BlackJordan YapNo ratings yet

- 7 - Review Notes - TILLAGE EQUIPMENTDocument20 pages7 - Review Notes - TILLAGE EQUIPMENTJoey camalitaNo ratings yet

- 2011 Msu-Gsc Preboard Part 1Document7 pages2011 Msu-Gsc Preboard Part 1Mark Kevin AlletoNo ratings yet

- First Part Questions 1-751Document75 pagesFirst Part Questions 1-751Ken Lloyd F. PabilanNo ratings yet

- AME-Chap05-Power Transmission DriveDocument11 pagesAME-Chap05-Power Transmission DriveJordan Yap50% (2)

- 4 - Review Notes - HUMAN and ANIMAL POWERDocument10 pages4 - Review Notes - HUMAN and ANIMAL POWERJoey camalitaNo ratings yet

- Dr. Tambong Part 1Document18 pagesDr. Tambong Part 1Raymarck PatricioNo ratings yet

- Agricultural Waste CharacteristicDocument40 pagesAgricultural Waste CharacteristicAfrizal Muhamad NurNo ratings yet

- CLSU ABE Review 2022 APE Chap 03 Draft Animal PowerDocument29 pagesCLSU ABE Review 2022 APE Chap 03 Draft Animal PowerBilly AgustinNo ratings yet

- AE Reviewer Volume IIvvvvDocument90 pagesAE Reviewer Volume IIvvvvFaith YilmazNo ratings yet

- Area-2 - Cpu (Exam 8-12)Document26 pagesArea-2 - Cpu (Exam 8-12)Jake Balila100% (1)

- Eloisa Mae S. Semilla - ABE 131 Lecture (Chapter 4) Problem SetDocument3 pagesEloisa Mae S. Semilla - ABE 131 Lecture (Chapter 4) Problem SetEloisa Mae Sotelo Semilla100% (1)

- Sample ProblemsDocument53 pagesSample ProblemsMay AnnNo ratings yet

- Board Exam Questions 2016Document6 pagesBoard Exam Questions 2016JC Yabis100% (1)

- Review 2 Farm Mach. & Mech.Document25 pagesReview 2 Farm Mach. & Mech.dongzkie60% (5)

- AE Reviewer VolumeDocument94 pagesAE Reviewer VolumeGladys Ruth PaypaNo ratings yet

- Agricultural Electrifiction and InstrumentationDocument15 pagesAgricultural Electrifiction and InstrumentationEdgen Mae Banluta AsnaNo ratings yet

- Abe Quiz Season XviiDocument7 pagesAbe Quiz Season XviiMeljun GementizaNo ratings yet

- Problem SetDocument12 pagesProblem SetRenato OcinarNo ratings yet

- Board Reviewin Soil and Water Conservation EngineeringDocument13 pagesBoard Reviewin Soil and Water Conservation EngineeringKevin V LampaanNo ratings yet

- AE Reviewer Volume IIcDocument86 pagesAE Reviewer Volume IIcRegan Roldan RolaNo ratings yet

- Pre Board Part IDocument6 pagesPre Board Part IMeljun GementizaNo ratings yet

- 2 ReviewNotes PAESDocument14 pages2 ReviewNotes PAESJan14No ratings yet

- Abe Tos 2023Document28 pagesAbe Tos 2023DelenayNo ratings yet

- Soil - Plant - Water Relationship: Practice Exercise No. 4bDocument3 pagesSoil - Plant - Water Relationship: Practice Exercise No. 4bAlexis LopezNo ratings yet

- Review 13 Rural ElectrificationDocument17 pagesReview 13 Rural Electrificationdongzkie100% (1)

- I 2 Power&Energy 1 20Document21 pagesI 2 Power&Energy 1 20ChessmyssNo ratings yet

- AMTEC Presentation July 2019-PSABE ReviewDocument99 pagesAMTEC Presentation July 2019-PSABE ReviewRachele Janice Capuchino Ramirez100% (1)

- Mechanization Power Machinery Equipment AlliedDocument244 pagesMechanization Power Machinery Equipment Alliedjo-an gido100% (1)

- Subject: Agricultural Engineering LAW: Engr. Roland J. Macana Xavier University - Agricultural Engineering DepartmentDocument63 pagesSubject: Agricultural Engineering LAW: Engr. Roland J. Macana Xavier University - Agricultural Engineering DepartmentJC YabisNo ratings yet

- Area-1 2Document256 pagesArea-1 2Wil AlgonesNo ratings yet

- Excercises Ae17Document12 pagesExcercises Ae17Honie Liane Tagose VillamorNo ratings yet

- Agricultural Engineering Reviewer 1Document89 pagesAgricultural Engineering Reviewer 1Jehad KangoNo ratings yet

- Exam View ProDocument112 pagesExam View ProRico Esponilla100% (1)

- EXERCISE 1 - SolDocument19 pagesEXERCISE 1 - SolmaeNo ratings yet

- Chapter 14 Crop DryingDocument74 pagesChapter 14 Crop DryingaudreyshanemarinoNo ratings yet

- Tillage and Tillage EquipmentDocument82 pagesTillage and Tillage EquipmentArnel SisonNo ratings yet

- 02June282018Power EnergyADocument7 pages02June282018Power EnergyAAlejandrino PascuaNo ratings yet

- ABE Quiz Bee Week 2 SolutionsDocument6 pagesABE Quiz Bee Week 2 SolutionsSita HousNo ratings yet

- Rural Electrification, Agricultural Processing, Agricultural Structures Allied SubjectsDocument29 pagesRural Electrification, Agricultural Processing, Agricultural Structures Allied SubjectsJewellord CabatitNo ratings yet

- Area 1 PROBLEM SET #2Document10 pagesArea 1 PROBLEM SET #2JC YabisNo ratings yet

- Part 1 Mock Questions-YeahDocument4 pagesPart 1 Mock Questions-YeahMisheru Misaki AyuzawaNo ratings yet

- Iv. Irrigation Water RequirementsDocument21 pagesIv. Irrigation Water RequirementsJose Carlo DizonNo ratings yet

- PAEStigan Vol. I-XI (Review Lay-Out)Document12 pagesPAEStigan Vol. I-XI (Review Lay-Out)John Vincent Nate100% (1)

- Reviewer 2Document66 pagesReviewer 2Hermie Cabarubias AkiatanNo ratings yet

- Ag. Power, Machinery, and Allied Subject - Part 3Document102 pagesAg. Power, Machinery, and Allied Subject - Part 3Vonne Bryan IhalasNo ratings yet

- Farm To Market Question UpdatedDocument10 pagesFarm To Market Question UpdatedKen Lloyd F. PabilanNo ratings yet

- Module 1 Agricultural Mechanics and MechanizationDocument16 pagesModule 1 Agricultural Mechanics and MechanizationDavie Martinez100% (2)

- 1) IntroDocument95 pages1) IntroHaziq AmdanNo ratings yet

- BS Agricultural Mechanization in The Philippines - Beta - 361500Document117 pagesBS Agricultural Mechanization in The Philippines - Beta - 361500Jason GuiruelaNo ratings yet

- BAH 1 Module 1 in AB Machinery and MechanizationDocument15 pagesBAH 1 Module 1 in AB Machinery and MechanizationDistor, Jane F.No ratings yet

- Algebra Solve Problem-3Document128 pagesAlgebra Solve Problem-3SannyBombeoJomocNo ratings yet

- Package 3 V.ODocument96 pagesPackage 3 V.OSannyBombeoJomocNo ratings yet

- Derivation of Formulas in Spherical Trigonometry BDocument6 pagesDerivation of Formulas in Spherical Trigonometry BSannyBombeoJomocNo ratings yet

- Modified Penman Method TablesDocument9 pagesModified Penman Method TablesSannyBombeoJomocNo ratings yet

- Estimates & BarschemeDocument62 pagesEstimates & BarschemeSannyBombeoJomocNo ratings yet

- MBS Water Supply EPANETDocument232 pagesMBS Water Supply EPANETSannyBombeoJomocNo ratings yet

- Conference Building Contract OVER ALL POWDocument120 pagesConference Building Contract OVER ALL POWSannyBombeoJomocNo ratings yet

- Conference Building Contract POW (FINAL)Document76 pagesConference Building Contract POW (FINAL)SannyBombeoJomocNo ratings yet

- Vertical GatesDocument243 pagesVertical GatesSannyBombeoJomocNo ratings yet

- ProblemsDocument112 pagesProblemsSannyBombeoJomocNo ratings yet

- 3.3 Bridge DesignDocument24 pages3.3 Bridge DesignSannyBombeoJomoc100% (1)

- K-060 General InstallationDocument11 pagesK-060 General InstallationSannyBombeoJomocNo ratings yet

- General Notes: Beginning of Project (End of Diaphragm) End of Project (End of Diaphragm)Document8 pagesGeneral Notes: Beginning of Project (End of Diaphragm) End of Project (End of Diaphragm)SannyBombeoJomocNo ratings yet

- II 1 Irri&Drainage1 17Document18 pagesII 1 Irri&Drainage1 17SannyBombeoJomoc100% (1)

- II-6 Agronomy 1-23Document24 pagesII-6 Agronomy 1-23SannyBombeoJomocNo ratings yet

- L&D Trends 2024Document35 pagesL&D Trends 2024Ahmad Masantum Pca100% (1)

- DEWI LESTARI HASWINDIAHWURY WIDAGDO, S.PD., MM - English For Special Purpose I - AB6.19.01 - UTS-dikonversiDocument3 pagesDEWI LESTARI HASWINDIAHWURY WIDAGDO, S.PD., MM - English For Special Purpose I - AB6.19.01 - UTS-dikonversiYeni SetiyowatiNo ratings yet

- Employee TurnoverDocument18 pagesEmployee Turnovervj4249No ratings yet

- TEVTA FinalDocument32 pagesTEVTA Finallahore0022No ratings yet

- FAQ On Statutory BonusDocument3 pagesFAQ On Statutory BonusSathesh KumarNo ratings yet

- CH 07 Interviewing CandidatesDocument30 pagesCH 07 Interviewing CandidatesKashif Ullah KhanNo ratings yet

- Code of ConductDocument14 pagesCode of ConductsakthivelbalakrishnanNo ratings yet

- Bicycle Thieves A Re-ReadingDocument13 pagesBicycle Thieves A Re-ReadingDaniel Avila ZarateNo ratings yet

- ApparentshipDocument18 pagesApparentshippaulos.tesfaw92No ratings yet

- Conbook Below35 2011Document28 pagesConbook Below35 2011Lawson Chung Jenn HaurNo ratings yet

- Strategic TrainingDocument39 pagesStrategic TrainingFarhan HaseebNo ratings yet

- 2010 Coast Guard Diversity Action PlanDocument7 pages2010 Coast Guard Diversity Action PlancgreportNo ratings yet

- Are You Ready For Grad School? Take The Quiz.Document2 pagesAre You Ready For Grad School? Take The Quiz.DePaul CareerCtrNo ratings yet

- ACFrOgAXHgtW7HNg2vN RLE MVyhRh8psIHSYSfj5ztdXGpXG1fbRpt0-yZy5OBA0Lyq0fWmOZGFVpFa5o3ujw3px-HcE7tN5iI vIi8kw8azO6R9j6n00Vdwq9zJffWPQlFwLkdDJp4bkXg7lqDocument14 pagesACFrOgAXHgtW7HNg2vN RLE MVyhRh8psIHSYSfj5ztdXGpXG1fbRpt0-yZy5OBA0Lyq0fWmOZGFVpFa5o3ujw3px-HcE7tN5iI vIi8kw8azO6R9j6n00Vdwq9zJffWPQlFwLkdDJp4bkXg7lqleah r. polancosNo ratings yet

- HM3&2Document484 pagesHM3&2mchl13100% (1)

- Gamillo v. MariñoDocument10 pagesGamillo v. MariñoJoanna RosemaryNo ratings yet

- Cases Touching On Non-Diminution of BenefitsDocument36 pagesCases Touching On Non-Diminution of BenefitsCliffordNo ratings yet

- Sales Management - Final Report - Group 2Document22 pagesSales Management - Final Report - Group 2Duy Nguyễn Lê NhậtNo ratings yet

- OIT (2021) World Employment and Social OutlookDocument283 pagesOIT (2021) World Employment and Social OutlookMario Morales SotoNo ratings yet

- 6 Basic Employee Benefits in The Philippine LABOR CODEDocument1 page6 Basic Employee Benefits in The Philippine LABOR CODERoli Sitjar Arangote100% (1)

- Venue ScannerDocument28 pagesVenue ScannerBretton PutterNo ratings yet

- Submitted By:: Kirt Raj Phagna (B.B.A III Year)Document13 pagesSubmitted By:: Kirt Raj Phagna (B.B.A III Year)sangeetar28129No ratings yet

- Employment After Lockdown"Document3 pagesEmployment After Lockdown"20ECF042 VIGNESH SNo ratings yet

- MacEachern - Enough Is Enough - The Hellraiser's Guide To Community Activism (1994)Document412 pagesMacEachern - Enough Is Enough - The Hellraiser's Guide To Community Activism (1994)mutzunache2001No ratings yet

- Wip of ProjectDocument47 pagesWip of ProjectAvilash PattnaikNo ratings yet

- Cambridge O Level: Business Studies 7115/11 May/June 2021Document21 pagesCambridge O Level: Business Studies 7115/11 May/June 2021nayna sharminNo ratings yet

- Johnson & Johnson Leadership ProgramDocument2 pagesJohnson & Johnson Leadership ProgramchilloutbrahNo ratings yet

- DTR January 1-15, 2024Document2 pagesDTR January 1-15, 2024julietoNo ratings yet

- UST v. BitonioDocument174 pagesUST v. BitonioNhaz PasandalanNo ratings yet