Professional Documents

Culture Documents

HexPly F155 Us DataSheet3

HexPly F155 Us DataSheet3

Uploaded by

ajazCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HexPly F155 Us DataSheet3

HexPly F155 Us DataSheet3

Uploaded by

ajazCopyright:

Available Formats

HexPly® F155

resin systems for advanced composites

Product Data Sheet

Description

HexPly® F155 is an advanced modified epoxy formulation designed for autoclave curing to offer very high

laminate strengths, coupled with increased fracture toughness and adhesive properties. HexPly® F155 is

a controlled flow epoxy resin for lamination and co-curing at 250°F (121°C) cure. HexPly® F155 will pass

MIL-R-9300, co-cure as a honeycomb facing, and bond metal to metal.

Features

Uncured Cured

¥ Controlled flow in the basic formulation to offer ¥ High laminate strengths

balanced tool and bagside sandwich peels ¥ Good sandwich panel and metal-to-metal bonding

¥ Good tack and drape properties for layup and ¥ Self-extinguishing properties

assembly purposes

¥ Can be adapted for use on various weaves and

fiber reinforcements

¥ Long out time

Neat Resin Properties

Specific gravity 1.335

Tg dry 250°F (121°C)

Equilibrium moisture absorption 9.4%

Linear coefficient of thermal expansion 2.93 x 10–5 in/in/°F (5.27 x 10–5 cm/cm/°C)

Tensile strength 11.6 ksi (80 MPa)

Tensile modulus 0.47 msi (3.24 GPa)

Tensile strain 5.2%

Fracture toughness, K1C 1.50 ksi in (1.65 MPa m )

Strain energy release rate, G1C 4.18 in-lb/in2 (0.73 kJ/m2)

Gel time @ 250°F (121°C) 4–10 min

Rheometrics Curve of F155 Resin

4°F (2°C)/min, 10 rad/sec,

Gel Time vs Temperature RDS-7700, 50 mm Plates

103 108

107

102 106

Viscosity, CPS

Gel Time (min)

105

101 104

103

100 102

101

300 275 250 225 200 150 230 310 390

(149) (135) (121) (107) (93) (66) (110) (154) (199)

Temperature — °F (°C) Temperature — °F (°C)

Copyright © 2020 – Hexcel Corporation – All Rights Reserved. 1

HexPly® F155

resin systems for advanced composites

Product Data Sheet

Availability

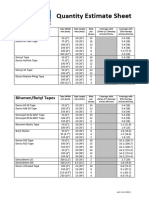

Fiber Areal Count Widths Available

Form Hexcel Designation Fiber Weave

Wt. g/m2 Warp x Fill Standard Width, in (cm)

W3T282-42”–F155 T300 42”, 60”

194 Plain 12.5 x 12.5

Carbon W3C282-42”–F155 Toho® (106.7, 152.4)

Fabrics F3T584-42”–F155 T300 42”, 60”

370 8 Harness Satin 24 x 24

F3C584-42”–F155 Toho® (106.7, 152.4)

Crowfoot

38”, 50”, 60”

120-38”–F155 450-1/2 115 MIL-C-9084 60 x 58

(96.5, 127, 152.4)

TYIII

8 Harness Satin 38”, 50”, 60”, 72”

Glass Fabrics 1581-38”–F155 150-1/2 303 MIL-C-9084 57 x 54 (96.5, 127, 152.4,

TYVIIIA 182.9)

8 Harness Satin 38”, 50”, 60”, 72”

7781-38”–F155 75-1/0 303 MIL-C-9084 57 x 54 (96.5, 127, 152.4,

TYVIIIB 182.9)

Kev. 49 38”, 50”, 60”

K120-38”–F155 61 Plain 34 x 34

195 (96.5, 127, 152.4)

Kevlar ®

Kev. 49 38”, 50”, 60”

K285-38”–F155 170 Crowfoot 17 x 17

Fabrics 1140 (96.5, 127, 152.4)

Kev. 49 38”, 50”, 60”

K281-38”–F155 170 Plain 17 x 17

1140 (96.5, 127, 152.4)

TXX095-12”–F155 Various 95

Carbon Tapes TXX145-12”–F155 Various 145

TXX190-12”–F155 Various 190

12”, 3”–24”

E-Glass n/a n/a

Glass Tape T2E285-12”–F155 285 (30.5, 7.6–61)

1062

Kev. 49

Kevlar® Tape T7D150-12”–F155 150

7100

Note: Alternate carbon, glass, and Kevlar weaves may be used with the HexPly® F155 Resin System. Also, HexPly® F155 carbon tapes may be produced with

various carbon fiber types and tow sizes. In designating carbon tape, the second digit represents tow size and the third digit represents fiber source. Contact the

nearest Hexcel Sales Office for additional information.

Copyright © 2020 – Hexcel Corporation – All Rights Reserved. 2

HexPly® F155

resin systems for advanced composites

Product Data Sheet

Physical Properties

Property Kevlar Fabrics Glass Fabrics Carbon Tapes Carbon Fabrics

W3T282 F3T584

Material

K120 K285 120 1581 95 g/m2 145 g/m2 190 g/m2 or or

description

W3C282 F3C584

% Flow @

250°F

Prepreg 50 psi 14–26 14–26 8–20 8–20 4–16 4–16 4–16 4–16 4–16

(121°C

345 kPa)

% Resin

content 54–60 49–55 42–48 36–40 38–40 38–40 38–40 40–44 40–44

(dry)

Cured

thickness 0.0045 0.0100 0.0047 0.0104 0.0037 0.0056 0.0074 0.0086 0.0150

per ply, (0.011) (0.0250) (0.012) (0.026) (0.0094) (0.014) (0.019) (0.022) (0.038)

Laminate

in (cm)

% Fiber

42 46 38 45 57 57 57 50 51

volume

Mechanical Properties

Temp. Kevlar® 49 Carbon

Glass Fabrics Carbon Tapes

Property °F Fabrics Fabric

(°C) 120 285 120 220 181 T3T095 T2C145 T2C190 W3T282

Tensile strength, ksi 62 82.8 57.0 60.3 70 225 266 225 123

75 (24)

(MPa) (427) (571) (393) (416) (483) (1552) (1834) (1518) (848)

Tensile modulus, msi 3.9 4.4 3.0 3.0 3.4 18.3 18.3 18.1 8.4

75 (24)

(GPa) (26.7) (30.3) (20.7) (20.7) (23.4) (126.2) (126.2) (124.8) (58)

Tensile strain 75 (24) 15,900 – – – – 10,180 10,370 10,470 10,490

Tensile strength, ksi 58 79.3 52.7 62 248 226

160 (71) – – –

(MPa) (400) (547) (363) (427) (1710) (1558)

Tensile modulus, msi 3.7 3.9 2.7 3.1 17.2 17.0

160 (71) – – –

(GPa) (25) (26.9) (18.6) (21.4) (119) (117)

Tensile strain 160 (71) – – – – – – – – –

Tensile strength, ksi 46.3 47.9 57

200 (93) – – – – – –

(MPa) (319) (330) (393)

Tensile modulus, msi 2.6 2.6 2.9

200 (93) – – – – – –

(GPa) (17.9) (17.9) (20)

Tensile strain 200 (93) – – – – – – – – –

Compression strength, 75 32.0 37.9 64.4 71.9 75 168 193 170 131

ksi (MPa) (24) (221) (261) (444) (496) (517) (1158) (1331) (1172) (904)

Copyright © 2020 – Hexcel Corporation – All Rights Reserved. 3

HexPly® F155

resin systems for advanced composites

Product Data Sheet

Temp. Kevlar® 49 Carbon

Glass Fabrics Carbon Tapes

Property °F Fabrics Fabric

(°C) 120 285 120 220 181 T3T095 T2C145 T2C190 W3T282

Compression modulus, 75 3.9 3.4 3.0 3.2 3.7 15.9 8.3

– –

msi (GPa) (24) (26.9) (23.4) (20.7) (22.1) (25.5) (109.6) (57.2)

Compression strength, 160 24 28.3 57.4 58 134 170 140 72.0

–

ksi (MPa) (71) (165) (195) (376) (400) (924) (1172) (965) (496)

Compression modulus, 160 3.0 3.4 3.0 3.4 16.5

– – – –

msi (GPa) (71) (21) (23.4) (20.7) (23.4) (117)

Compression strength, 200 43.8 49.5 48

– – – – – –

ksi (MPa) (93) (302) (341) (331)

Compression modulus, 200 2.8 2.7 3.2

– – – – – –

msi (GPa) (93) (19.3) (18.6) (22.1)

Compression

9.5 9.8 10 13.0

interlaminar shear RT – – – – –

(61) (63) (68.9) (89.6)

strength, ksi (MPa)

Compression

160 7.7 7 10.4

interlaminar shear – – – – – –

(71) (53) (48) (71.7)

strength, ksi (MPa)

Compression

200 6.8 6.2 5.4

interlaminar shear – – – – – –

(93) (47) (43) (37)

strength, ksi (MPa)

Flatwise tensile 75 800 749 846 874 780 670 940

– –

strength, psi (kPa) (24) (5516) (5164) (5833) (6026) (5378) (4620) (6481)

Flatwise tensile 160 600 640 799 700

– – – – –

strength, psi (kPa) (71) (4137) (4413) (5509) (4826)

Flatwise tensile 200 657 659 610

– – – – – –

strength, psi (kPa) (93) (4523) (4544) (4206)

Long beam flexure, 75 65 129 122 112 216

– – – –

lb (kg) (24) (29.5) (58.6) (55.5) (50.9) (98.2)

Long beam flexure, 160 5.5 107 104 177

– – – – –

lb (kg) (71) (25) (48.6) (47.3) (80.4)

Long beam flexure, lb 200 93 85 165

– – – – – –

(kg) (93) (42.3) (38.7) (75.1)

Drum peel, in-lb/3” 75 8 29 11 14 14

– – – –

width (cm-kg/7.6 cm) (24) (9.2) (33) (13) (16) (16)

All mechanical property values are based on the calculated fiber volume found on the previous table.

Reported property values are averages to which no statistical assurance should be associated. While Hexcel believes that the data contained herein are factual,

the data are not to be taken as a warranty or representation for which Hexcel assumes legal responsibility. They are offered solely for your consideration,

investigation, and verification.

Copyright © 2020 – Hexcel Corporation – All Rights Reserved. 4

HexPly® F155

resin systems for advanced composites

Product Data Sheet

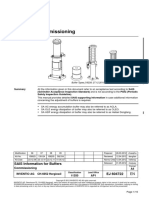

Cure Cycle

+ 15 min

Hold 90 – 0 min

@ 260 ± 10°F

(127 ± 6°C) Cool-down

5°F/min (3°C/min)

250

maximum

(121)

Temperature – °F (°C)

190

(88)

Heat-up

2–8°F (1–4°C)/min

130

(54)

70

(21)

Time

Cure Procedure

A. Apply vacuum of 22 inches (74 kPa) Hg minimum.

B. Apply 85 + 15 – 0 psig (586 + 103 – 0 kPa) pressure for laminates.

C. Apply 45 + 15 – 0 psig (310 + 103 – 0 kPa) pressure for sandwich.*

D. Vent vacuum bag to atmosphere when pressure reaches 20 psi (138 kPa).

E. During cool-down when the part temperature falls below 140°F (60°C), pressure can be released

and the test panel removed from the autoclave and debagged.

* * Typical for Hexcel HRH® 10 – 1/8 – 3.0 honeycomb.

Storage

HexPly® F155 has a storage life of 180 days from date of receipt when stored at 10°F (-12°C), plus a handling

life of 200 hours at 75°F (24°C) and mechanical life of 200 hours at 75°F (24°C) (maximum, from date of

manufacture).

Copyright © 2020 – Hexcel Corporation – All Rights Reserved. 5

HexPly® F155

resin systems for advanced composites

Product Data Sheet

Shipping

Prepreg fabric and tape are generally shipped in sealed polyethylene bags in insulated containers packed with dry ice.

Disposal of Scrap

Disposal of this material should be in a secure landfill in accordance with state and federal regulations.

Corrosion of Potential

A need for the management of corrosion potential is necessary when graphite composites are placed in contact

with metallic honeycomb, skins, or fasteners.

Handling and Safety Precautions

Hexcel recommends that customers observe established precautions for handling epoxy resins and fine fibrous

materials. Operators working with this product should wear clean, impervious gloves to reduce the possibility of

skin contact and to prevent contamination of the material.

Airborne graphite as a result of sawing, grinding, etc., can present electrical shorting hazards; refer to NASA

Technical Memorandum 78652. Safety Data Sheets (SDS) have been prepared for all Hexcel products and are

available to company safety officers on request from your nearest Hexcel Sales Office.

For more information

Hexcel is a leading worldwide supplier of composite materials to aerospace and industrial markets.

Our comprehensive range includes:

¥ HexTow® carbon fibers ¥ HexFlow® RTM resins ¥ Engineered core

¥ HexForce reinforcements

® ¥ HexBond adhesives

™ ¥ Engineered products

¥ HiMax® multiaxial ¥ HexTool® tooling materials ¥ Polyspeed® laminates

reinforcements ¥ HexWeb honeycombs

®

& pultruded profiles

¥ HexPly® prepregs ¥ Acousti-Cap® sound ¥ HexAM® additive manufacturing

¥ HexMC®-i molding compounds attenuating honeycomb

FTU 338 AG17

For U.S. quotes, orders and product information call toll-free 1-800-688-7734. For other worldwide sales office

telephone numbers and a full address list, please go to:

https://www.hexcel.com/contact

©2020 Hexcel Corporation – All rights reserved. Hexcel Corporation and its subsidiaries (“Hexcel”) believe that the technical data and other information

provided herein was materially accurate as of the date this document was issued. Hexcel reserves the right to update, revise or modify such technical data and

information at any time. Any performance values provided are considered representative but do not and should not constitute a substitute for your own testing

of the suitability of our products for your particular purpose. Hexcel makes no warranty or representation, express or implied, including but not limited to the

implied warranties of merchantability and fitness for a particular purpose, and disclaims any liability arising out of or related to, the use of or reliance upon any of

the technical data or information contained in this document.

6

You might also like

- Standard Quality Assurance Plan For Ac MotorDocument6 pagesStandard Quality Assurance Plan For Ac MotorSonti Mani kumar100% (1)

- Voltage Drop CalculationDocument9 pagesVoltage Drop CalculationparasNo ratings yet

- HexPly F155Document6 pagesHexPly F155DaniloNo ratings yet

- LR Magna Comp BPDocument2 pagesLR Magna Comp BPherbster28No ratings yet

- 3900 Prepreg SystemDocument5 pages3900 Prepreg SystemLiran KatzNo ratings yet

- HexPly 8552 Eu DataSheetDocument6 pagesHexPly 8552 Eu DataSheetpablo.vila2000No ratings yet

- 2000 CWP - Full Port - Threaded Ends: Materials of ConstructionDocument1 page2000 CWP - Full Port - Threaded Ends: Materials of ConstructionAxel BernabeNo ratings yet

- Insulating Structures: 31501 Solon RD., Solon, OH 44139 Tel: (440) 248-0500 Fax: (440) 248-8864Document2 pagesInsulating Structures: 31501 Solon RD., Solon, OH 44139 Tel: (440) 248-0500 Fax: (440) 248-8864Juan David Perez CaicedoNo ratings yet

- HTL-MKT - 200275-1 (S1-8004) - Old Rose (R&D Sample Test Report)Document1 pageHTL-MKT - 200275-1 (S1-8004) - Old Rose (R&D Sample Test Report)Niaz IslamNo ratings yet

- 4114A042 TestingDocument10 pages4114A042 TestingmuratNo ratings yet

- All Dimensions in Inches and (MM)Document1 pageAll Dimensions in Inches and (MM)Sudarshan GopalNo ratings yet

- 3900 Prepreg System: Mechanically Stable Readily AvailableDocument7 pages3900 Prepreg System: Mechanically Stable Readily AvailableChiranthanRameshNo ratings yet

- Denso Quantity Estimate SheetDocument3 pagesDenso Quantity Estimate SheetJames DickinsonNo ratings yet

- Kumho KHS: HSR (High Styrene Resin Masterbatch)Document2 pagesKumho KHS: HSR (High Styrene Resin Masterbatch)Greg PanganNo ratings yet

- 3M Nextel Woven Ceramic FabricsDocument3 pages3M Nextel Woven Ceramic FabricsninatenaNo ratings yet

- Adhesive TapeDocument1 pageAdhesive TapeMuthuswamyNo ratings yet

- Cam Switches CA SeriesDocument26 pagesCam Switches CA SeriesAndreas StathatosNo ratings yet

- Understanding Laminate Prepreg ManufacturingDocument34 pagesUnderstanding Laminate Prepreg ManufacturingSamora Tooling EngineerNo ratings yet

- BVSimplanUSkl18!05!05 enDocument2 pagesBVSimplanUSkl18!05!05 enpatatas_papadopoulosNo ratings yet

- FRP - Part I, FundamentalDocument58 pagesFRP - Part I, FundamentalbiondimiNo ratings yet

- Isotopes Selenium v10Document2 pagesIsotopes Selenium v10cindy anggrilitaNo ratings yet

- Timetal: Ti - 1 0 V-2 F e - 3 A LDocument2 pagesTimetal: Ti - 1 0 V-2 F e - 3 A LBüyüleyici GözlerNo ratings yet

- Features and Benefits: Technical Data SheetDocument6 pagesFeatures and Benefits: Technical Data SheetTaufiq SatrioNo ratings yet

- Am Braycote 601 EF Micronic US Eng 04 08 PdsDocument2 pagesAm Braycote 601 EF Micronic US Eng 04 08 PdsGrégory EcalleNo ratings yet

- Catálogo Sprinkler HD331 FOAM-WATERDocument1 pageCatálogo Sprinkler HD331 FOAM-WATERcarlosNo ratings yet

- MIRATAKDocument1 pageMIRATAKmiroslava mondragonNo ratings yet

- CTM Geosynthetics Uniaxial-UnlockedDocument1 pageCTM Geosynthetics Uniaxial-UnlockedGautam RaiNo ratings yet

- Suez ZeeWeed 500D Cassette Fact sheetDocument1 pageSuez ZeeWeed 500D Cassette Fact sheetJose A. SuarezNo ratings yet

- Technical Data HPDE GeomembraneDocument1 pageTechnical Data HPDE Geomembranemariodiogo75No ratings yet

- FerrulesDocument2 pagesFerrulesdavid.menendez77No ratings yet

- Guide Hand Book3Document37 pagesGuide Hand Book3Osman QaasimNo ratings yet

- NBR Catalogue Eng KKPCDocument2 pagesNBR Catalogue Eng KKPCChandrasekar KrishnamurthyNo ratings yet

- F3102 CeChPkgDocument5 pagesF3102 CeChPkgIrvin FrederickNo ratings yet

- Magnum Composite Plug Catalog 06-30-10Document21 pagesMagnum Composite Plug Catalog 06-30-10Emad JamshidiNo ratings yet

- Magnum Composite Plug Catalog 06-30-10 PDFDocument21 pagesMagnum Composite Plug Catalog 06-30-10 PDFEmad JamshidiNo ratings yet

- Victaulic Quick Vic Rigid CouplingsDocument7 pagesVictaulic Quick Vic Rigid Couplingsionut cerneaNo ratings yet

- Ficha Tecnica Mylard Tipo A DupontDocument2 pagesFicha Tecnica Mylard Tipo A DupontJuan Hilares AlejandroNo ratings yet

- Compressive PropertiesDocument3 pagesCompressive PropertiesSh.nasirpurNo ratings yet

- F Bushes To Suit 95mm To 120mm Dia Pins Pages 29 - 32Document4 pagesF Bushes To Suit 95mm To 120mm Dia Pins Pages 29 - 32sashaNo ratings yet

- Catalogo Junta VictaulicDocument7 pagesCatalogo Junta VictaulicandhucaosNo ratings yet

- 2tech Data - MF PET (300 601-td-0219)Document4 pages2tech Data - MF PET (300 601-td-0219)Ismacahyadi Mohamed JaisNo ratings yet

- 15 Mds FDM Nylon 12cf 0920aDocument9 pages15 Mds FDM Nylon 12cf 0920akaledioskoppNo ratings yet

- Rubber Extrusions CatalogueDocument111 pagesRubber Extrusions CatalogueS.KAMBANNo ratings yet

- Manufacturing SpecificationsDocument3 pagesManufacturing Specificationsaeroforce1007No ratings yet

- MDS - FDM - ULTEM 1010 Resin - 0920aDocument10 pagesMDS - FDM - ULTEM 1010 Resin - 0920aEzra FeildenNo ratings yet

- Microplan - Katalog 2008 ENDocument10 pagesMicroplan - Katalog 2008 END.T.No ratings yet

- M20Document1 pageM20FRANZ RICHARD SARDINAS MALLCO75% (4)

- AASHTO M20-70 Penetration Graded Asphalt CementDocument1 pageAASHTO M20-70 Penetration Graded Asphalt CementharihfclNo ratings yet

- m20 PDF FreeDocument1 pagem20 PDF FreeDede NurcahyadiNo ratings yet

- MDS - FDM - ULTEM 1010 Resin - 0520aDocument10 pagesMDS - FDM - ULTEM 1010 Resin - 0520aBill MurrayNo ratings yet

- 11 Mds FDM Ultem 1010 Resin 0520aDocument10 pages11 Mds FDM Ultem 1010 Resin 0520akaledioskoppNo ratings yet

- Stellite 6Document2 pagesStellite 6백승훈No ratings yet

- SGL Technical Info REFRASIL Slit and Woven Tapes enDocument2 pagesSGL Technical Info REFRASIL Slit and Woven Tapes enBentley BeckleyNo ratings yet

- ACFrOgDxwrC5H78oqC4GxnmanoGIr1JecM3BNphq6Z08oTu7fsfvHXh NU5 GPK MG R33wMfuaOr8Z2XmJoA8offSuIFr0W4BPx8aaoOooPZSyyqdFduA34Hv3gqwQIYi48qz2tWF9a6fJexkGoDocument1 pageACFrOgDxwrC5H78oqC4GxnmanoGIr1JecM3BNphq6Z08oTu7fsfvHXh NU5 GPK MG R33wMfuaOr8Z2XmJoA8offSuIFr0W4BPx8aaoOooPZSyyqdFduA34Hv3gqwQIYi48qz2tWF9a6fJexkGokhoochengmayNo ratings yet

- Chave de Fluxo - 024 12144 000 fs7-4wDocument2 pagesChave de Fluxo - 024 12144 000 fs7-4wFernando BarbosaNo ratings yet

- MacWeb 1033 PDFDocument1 pageMacWeb 1033 PDFศุภณัฐ ชื่นใจดีNo ratings yet

- Wellcare Oil Tools Private LimitedDocument4 pagesWellcare Oil Tools Private LimitedPedro Andrés GarzonNo ratings yet

- Stellite 6 DS01-21708 (S R0808)Document2 pagesStellite 6 DS01-21708 (S R0808)bwv1006No ratings yet

- Kenmore 385.15510200 Sewing Machine Instruction ManualDocument77 pagesKenmore 385.15510200 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Technical Manual: StandardsDocument35 pagesTechnical Manual: StandardsIlyasHasanNo ratings yet

- JaxfunDocument91 pagesJaxfunCasper ManNo ratings yet

- Ashley Nash Power Point TwoDocument18 pagesAshley Nash Power Point Twoashleynashley16No ratings yet

- Lecture 2 Notes: (A) Fixed Capital Requirements: in Order To Start Business, Funds Are Required To Purchase FixedDocument5 pagesLecture 2 Notes: (A) Fixed Capital Requirements: in Order To Start Business, Funds Are Required To Purchase FixedAmrit KaurNo ratings yet

- 2015 VN Single InverterDocument29 pages2015 VN Single InverterMinhvan LeNo ratings yet

- A Biomechanical Analysis of The Vertebral and RibDocument10 pagesA Biomechanical Analysis of The Vertebral and RibDorin DorinNo ratings yet

- Ch1 Intro To AnatomyDocument5 pagesCh1 Intro To AnatomyztolmanNo ratings yet

- Ruwais Refinery Expansion Project Project No. 5578 Epc Package - 6 (Non Process Building)Document32 pagesRuwais Refinery Expansion Project Project No. 5578 Epc Package - 6 (Non Process Building)Mohammed AzharNo ratings yet

- DPV EC Cert of ConformityDocument1 pageDPV EC Cert of ConformityFelipe Gamboa GálvezNo ratings yet

- PMR v26 I4 158 166 PDFDocument9 pagesPMR v26 I4 158 166 PDFemzzNo ratings yet

- 10 Types of Plants AlbumDocument11 pages10 Types of Plants AlbumMateo GarciaNo ratings yet

- Science and Technology Grade 7 ContentDocument1 pageScience and Technology Grade 7 ContentNorjana Otto Medal-Madale67% (3)

- Thin Paste-Grade Material For Rebuilding Shallow PittingDocument2 pagesThin Paste-Grade Material For Rebuilding Shallow PittingIrvansyah RazadinNo ratings yet

- Httpswww-Clinicalkey-Es Pbidi Unam Mx2443servicecontentpdfwatermarked3-S2 0-B9780323680134000195 Pdflocale Es - ES&searcDocument18 pagesHttpswww-Clinicalkey-Es Pbidi Unam Mx2443servicecontentpdfwatermarked3-S2 0-B9780323680134000195 Pdflocale Es - ES&searcDafne TeranNo ratings yet

- Prepare and Cook Meat: Cookery 10 School Year 2019 - 2020Document43 pagesPrepare and Cook Meat: Cookery 10 School Year 2019 - 2020Alodie Dela Raiz AsuncionNo ratings yet

- Strobilanthes CrispusDocument46 pagesStrobilanthes CrispusHilman AdzimNo ratings yet

- GLASSElder Cohousing 3 Case Studies 2012Document19 pagesGLASSElder Cohousing 3 Case Studies 2012Bernice GonzalezNo ratings yet

- Pre Commissioning Inspection Report (PIR QSM1 03)Document5 pagesPre Commissioning Inspection Report (PIR QSM1 03)Muhammad MudassirNo ratings yet

- Confined Space Hazards Assessment FormDocument3 pagesConfined Space Hazards Assessment FormAhmed El-sherpiniNo ratings yet

- Padampur ReportDocument16 pagesPadampur ReportSaudagar BiswalNo ratings yet

- PNLE NursingDocument631 pagesPNLE NursingLenaj Ebron50% (2)

- PolymerDocument2 pagesPolymermmmd.krmv.00No ratings yet

- January 2011 MS - Unit 5 Edexcel Biology A-LevelDocument19 pagesJanuary 2011 MS - Unit 5 Edexcel Biology A-LevelPatricia MorelNo ratings yet

- School-Based Report On Incidents of Bullying SY 2020-2021Document5 pagesSchool-Based Report On Incidents of Bullying SY 2020-2021Jeraldine MayolNo ratings yet

- 370 HRDocument3 pages370 HRMritunjay SrivastavaNo ratings yet

- Commissioning: SAIS Information For BuffersDocument16 pagesCommissioning: SAIS Information For BuffersAli DiabNo ratings yet

- Skin Staples HectingDocument5 pagesSkin Staples HectingdesyNo ratings yet