Professional Documents

Culture Documents

Angle Grinder Sop

Angle Grinder Sop

Uploaded by

kylealamangoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Angle Grinder Sop

Angle Grinder Sop

Uploaded by

kylealamangoCopyright:

Available Formats

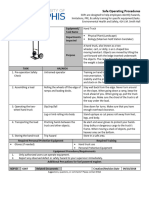

Safe Operating Procedures

SOPs are designed to help employees identify hazards,

limitations, PPE, & safety training for specific equipment/tasks.

Environmental Health and Safety, 414 J.M. Smith Hall

Equipment/ Angle Grinder

Task Name

Departments Art & Architecture Department

Impacted

An angle grinder, also known as a side grinder or disc

grinder, is a handheld power tool used for grinding

(abrasive cutting) and polishing. Angle grinders can be

powered by an electric motor, petrol

Purpose engine or compressed air. The motor drives a geared

head at a right-angle on which is mounted

an abrasive disc or a thinner cut-off disc, either of

which can be replaced when worn.

TASK HAZARDS CONTROLS

1. Inspect work area. Slip, trip, and fall hazard. Check workspace, walkways and machine

surrounds to ensure no slip/trip hazards are

present.

2. Inspect angle grinder. Electric shock hazard. Visually inspect the cord to make sure it is in

good condition.

Hand laceration and abrasion. • Unplug grinder to check the condition and

tightness off the grinding wheel and guard.

• Ensure appropriate guarding is in place on

grinder.

3. Install and tighten Accidental starting and hand • Visually check to see if the drill is unplugged.

grinding disc (if injury hazards.

necessary). Foot injury hazard. • Rest the tool on a flat surface to prevent it

from dropping.

• Wear closed toed or safety shoes.

4. Prior to grinding items. Projectile hazards. • Make sure the materials being ground are

adequately secured and positioned

correctly.

• Verify the work is adequately secured by

trying to dislodge it with a gloved hand.

• Check the trigger switch to insure it is off

prior to plugging in the grinder.

5. Hold grinder above Loss of control and injury. • Never start grinder while resting on

material and turn on. material.

• Always firmly hold grinder.

6. Begin grinding. Projectile and eye injury hazards. • Wear safety glasses/goggles and/or a face

shield to minimize hazards associated with

flying objects and sparks.

Entanglement, abrasion, and • Keep fingers, hands, and cords away from

laceration hazards. grinding disc.

Safe Operating Procedures

SOPs are designed to help employees identify hazards,

limitations, PPE, & safety training for specific equipment/tasks.

Environmental Health and Safety, 414 J.M. Smith Hall

• Wear leather gloves to protect the hands.

• Tie back hair and do not wear loose clothing

or jewelry.

Loss of control and bodily injury • Maintain a firm grip on the grinder.

hazards. • Allow grinding wheel to reach working

speed before applying to work piece.

Increase working loads gradually. Never

abruptly. Use smooth fluid motions.

• Always keep the grinder moving across the

material, never holding it in one place.

Hearing loss hazard. Wear ear plugs.

Inhalation of toxic, irritant fume, Wear N95 or appropriate respirator.

or particulate hazard.

Fire hazard. Be aware of flying sparks and particulate. Aim

debris away from self and other people as well

as flammable materials.

7. Turn off grinder. Entanglement, loss of control, • Keep clear of grinder until it has stopped

and bodily injury hazard. completely.

• Do not set grinder on table until it has

completely stopped.

8. Clean grinder. Accidental starting and hand Ensure machines have been isolated from power

injury hazards. sources before being cleaned, adjusted,

maintained or repaired.

9. Store grinder in Equipment damage hazard. • Ensure disk is still in good condition before

appropriate location. putting away.

• Store cord in such a way that it is not in

contact with the grinding disc.

• Never carry any power tool by its cord.

10. Clean work area. Slip, trip, and fall hazard. • Make sure the floor of the work area is free

of cords, equipment, and debris.

• Clean up any spills or dust.

• Place equipment back in the storage area.

Required Training: Required Personal Protective Equipment (PPE)

1. Angle grinder training. 1. Safety glasses or face shield

2. Dust mask

3. Appropriate footwear (no open toed footwear)

4. Hearing protection

5. Leather gloves

SOP ID A011 Related Documents Art Shop Manual Creation/Revision Date 11/2018

Suggestions, questions, or comments? Please contact EH&S

You might also like

- Tb175w Electric DiagramDocument851 pagesTb175w Electric DiagramPIKO MOB83% (6)

- Telsmith 52s Catalogo de Partes GyrasphereDocument68 pagesTelsmith 52s Catalogo de Partes GyrasphereАлександрNo ratings yet

- PFClean5 0Document224 pagesPFClean5 0naving100% (1)

- Process Description DmeDocument3 pagesProcess Description DmeFirdaus YahyaNo ratings yet

- Solved Problems in SEC by Mark Guimba PDFDocument138 pagesSolved Problems in SEC by Mark Guimba PDFRayyanNo ratings yet

- Philakone's Cryptocurrency Superstar Trading GuideDocument8 pagesPhilakone's Cryptocurrency Superstar Trading GuideJhol AnthonyNo ratings yet

- Metal Chop Saw SopDocument2 pagesMetal Chop Saw SopkylealamangoNo ratings yet

- Working at Maintenance Shop-Sheet metal-JOB PROCEDURE - 2Document2 pagesWorking at Maintenance Shop-Sheet metal-JOB PROCEDURE - 2ananthu.uNo ratings yet

- Safe Work Procedure in Cold SawDocument1 pageSafe Work Procedure in Cold SawCyril AngkiNo ratings yet

- Record Power Sabre 450 Manual - 1607084931Document44 pagesRecord Power Sabre 450 Manual - 1607084931markNo ratings yet

- Tem FacilDocument1 pageTem FacilVin AyusteNo ratings yet

- Safety InductionDocument63 pagesSafety Inductionereniacamilo09No ratings yet

- Safe Working Procedure (SWP) General Office Equipment: Safe Work Procedures and Basic DescriptionDocument4 pagesSafe Working Procedure (SWP) General Office Equipment: Safe Work Procedures and Basic DescriptionArnulfoCruzNo ratings yet

- Reducing Brush & Trees With Wood Chipper: Job Safety AnalysisDocument3 pagesReducing Brush & Trees With Wood Chipper: Job Safety AnalysisRetselisitsoeNo ratings yet

- Band Saw JSADocument3 pagesBand Saw JSADian Rahma Putra0% (1)

- 43 Rodwork: Tools of The TradeDocument17 pages43 Rodwork: Tools of The TradeKevin L KermodeNo ratings yet

- Grinder SafetyDocument1 pageGrinder SafetyWaqas SaeedNo ratings yet

- Rsde1, Rsde2, Rsde2/A DX4000 & DX5000: High Filtration Dust ExtractorsDocument20 pagesRsde1, Rsde2, Rsde2/A DX4000 & DX5000: High Filtration Dust ExtractorsedwardmbartonNo ratings yet

- Sears Scroll SawDocument6 pagesSears Scroll Sawamauri bittencourtNo ratings yet

- Black and Decker CMM1200 Mower ManualDocument32 pagesBlack and Decker CMM1200 Mower ManualWilliam WoolleyNo ratings yet

- PlannerDocument32 pagesPlannerzhexoNo ratings yet

- Guillotine Blade Change: Take Exceptional Care When Handling The Blade. If You Are Unsure Stop & AskDocument2 pagesGuillotine Blade Change: Take Exceptional Care When Handling The Blade. If You Are Unsure Stop & AskRiddhi SarvaiyaNo ratings yet

- Playing It Safe - Chain Saw SafetyDocument1 pagePlaying It Safe - Chain Saw Safetybraulio.correaNo ratings yet

- Additional Specific Safety Instructions For Jig Saws: 1-800-4-D WALT (1-800-433-9258)Document6 pagesAdditional Specific Safety Instructions For Jig Saws: 1-800-4-D WALT (1-800-433-9258)Igor EnriqueNo ratings yet

- Lijadora Craftsman 351Document28 pagesLijadora Craftsman 351Sonia Castillo RodriguezNo ratings yet

- Jsa Ut Thickness PV PDF FreeDocument3 pagesJsa Ut Thickness PV PDF FreeSKH CultureNo ratings yet

- Injury & Illness Prevention ProgramDocument2 pagesInjury & Illness Prevention ProgramsampathdtNo ratings yet

- Zelios: Saw and Reciprocating Saw Hand Power Tools - Including: Drills, CircularDocument3 pagesZelios: Saw and Reciprocating Saw Hand Power Tools - Including: Drills, CircularLuke CornettNo ratings yet

- Hydraulic Breaker Guide PDFDocument13 pagesHydraulic Breaker Guide PDFFahri100% (1)

- Bs-245h Manual 2020Document16 pagesBs-245h Manual 2020richard nyeNo ratings yet

- Sears Craftsman 10 Inch Band Saw - L0901656Document20 pagesSears Craftsman 10 Inch Band Saw - L0901656MIKNo ratings yet

- OB Afety Nalysis: Perating A Rill RessDocument3 pagesOB Afety Nalysis: Perating A Rill RessKarl Makoy100% (1)

- nrcs144p2 042421Document3 pagesnrcs144p2 042421Mohd AleemNo ratings yet

- Breaking Out The MastDocument1 pageBreaking Out The MastDQE040 HSSENo ratings yet

- 手动工具的安全使用 en.Document35 pages手动工具的安全使用 en.queNo ratings yet

- 403UK ManualDocument40 pages403UK ManualantonyNo ratings yet

- ' - : - Airs/ CRRFT$ Ivlrn: Owner'SDocument33 pages' - : - Airs/ CRRFT$ Ivlrn: Owner'SsNo ratings yet

- DML305 Cast Iron 6 Speed Midi Lathe: Original Instruction ManualDocument28 pagesDML305 Cast Iron 6 Speed Midi Lathe: Original Instruction ManualwiiiNo ratings yet

- DP16B Bench Drill PressDocument20 pagesDP16B Bench Drill Pressalfri7370% (1)

- Centrifuge JSADocument2 pagesCentrifuge JSAandriNo ratings yet

- Takeuchi Compact Excavator Tb23rcd5e000 Workshop ManualDocument20 pagesTakeuchi Compact Excavator Tb23rcd5e000 Workshop Manualann98% (54)

- Credit 1 Mill-2003Document49 pagesCredit 1 Mill-2003Gokul Prasad ChettiNo ratings yet

- Binder2 6Document1 pageBinder2 6Shahid BhattiNo ratings yet

- Takeuchi Excavator TB153FR CJ2E000 WM 06860Document686 pagesTakeuchi Excavator TB153FR CJ2E000 WM 06860rok.feleNo ratings yet

- JSA GrinderAngleDocument2 pagesJSA GrinderAngleslamet_rNo ratings yet

- OB Afety Nalysis: D M E O W JDocument2 pagesOB Afety Nalysis: D M E O W JdonniNo ratings yet

- Grinding Operation JSA HSE ProfessionalsDocument4 pagesGrinding Operation JSA HSE ProfessionalsYogisopian HadiNo ratings yet

- Lathe ManualDocument32 pagesLathe ManualRowena EamesNo ratings yet

- Lathe ManualDocument32 pagesLathe ManualRowena EamesNo ratings yet

- 750X User Manual HighlightedDocument17 pages750X User Manual HighlightedThomas BetressNo ratings yet

- Grinding Operation JSA HSE ProfessionalsDocument1 pageGrinding Operation JSA HSE ProfessionalsSamadov 13No ratings yet

- SOP Material InstructionsDocument1 pageSOP Material Instructionspankajbhatt376100% (1)

- Concrete Placement - FootingsDocument2 pagesConcrete Placement - Footingsadelin TinIndoNo ratings yet

- RT3422 Tapping Tool ManualDocument48 pagesRT3422 Tapping Tool ManualJesus amésquitaNo ratings yet

- Swj802e Manual Eng Mr9 08112020 FinalDocument20 pagesSwj802e Manual Eng Mr9 08112020 FinalRose CosenStudioNo ratings yet

- Plinth Shuttering JSA HSE ProfessionalsDocument1 pagePlinth Shuttering JSA HSE ProfessionalsSamadov 13No ratings yet

- Builder Hoist Erection JSA HSE ProfessionalsDocument2 pagesBuilder Hoist Erection JSA HSE ProfessionalsMAM ENERGINDONo ratings yet

- Fy15 Sh-27664-Sh5 Toolbox Angle GrinderDocument2 pagesFy15 Sh-27664-Sh5 Toolbox Angle GrinderZakirhasNo ratings yet

- Instruction Manual: 1-800-54-HOW-TODocument5 pagesInstruction Manual: 1-800-54-HOW-TOrianrureNo ratings yet

- JHA Power ToolsDocument3 pagesJHA Power ToolsJulzNo ratings yet

- Cordless Drills User Manual - KC9045-KC9049 - UkDocument12 pagesCordless Drills User Manual - KC9045-KC9049 - UkAntonio ArduinoNo ratings yet

- Owners ManualDocument19 pagesOwners Manuallmiclub9089No ratings yet

- IOM Pneumatic ActuatorsDocument15 pagesIOM Pneumatic Actuatorskylealamango100% (1)

- Hand Truck Sop - CleanedDocument1 pageHand Truck Sop - CleanedkylealamangoNo ratings yet

- Tangit ProcedureDocument5 pagesTangit ProcedurekylealamangoNo ratings yet

- Metal Chop Saw SopDocument2 pagesMetal Chop Saw SopkylealamangoNo ratings yet

- Socket Welding: InstructionsDocument3 pagesSocket Welding: InstructionskylealamangoNo ratings yet

- Hammerita Paint - 2021Document15 pagesHammerita Paint - 2021kylealamangoNo ratings yet

- Tunnel Fire SafetyDocument13 pagesTunnel Fire SafetykylealamangoNo ratings yet

- TM National Cycling StrategyDocument106 pagesTM National Cycling StrategykylealamangoNo ratings yet

- Study On The Heat Load Characteristics of Underground StructuresDocument9 pagesStudy On The Heat Load Characteristics of Underground StructureskylealamangoNo ratings yet

- Design of Modern Subway Ventilation SystemDocument5 pagesDesign of Modern Subway Ventilation SystemkylealamangoNo ratings yet

- Converting Railway Tunnels Into Walking and Cycling RoutesDocument60 pagesConverting Railway Tunnels Into Walking and Cycling RouteskylealamangoNo ratings yet

- Performance Analysis of Earth-Air Tunnel System Used For Air-Conditioning of The College ClassroomDocument9 pagesPerformance Analysis of Earth-Air Tunnel System Used For Air-Conditioning of The College ClassroomkylealamangoNo ratings yet

- Systems Approach To Underground Safety: SciencedirectDocument9 pagesSystems Approach To Underground Safety: SciencedirectkylealamangoNo ratings yet

- E3sconf Clima2019 01039Document5 pagesE3sconf Clima2019 01039kylealamangoNo ratings yet

- 5 - Zhou Xu Wang and Sheng Estimating Capacity of Bicycle Path On Urban Roads in Hangzhou China - 2014Document18 pages5 - Zhou Xu Wang and Sheng Estimating Capacity of Bicycle Path On Urban Roads in Hangzhou China - 2014kylealamangoNo ratings yet

- Assessment of The Type of Cycling Infrastructure Required To Attract New Cyclists October 2011Document154 pagesAssessment of The Type of Cycling Infrastructure Required To Attract New Cyclists October 2011kylealamangoNo ratings yet

- Correspondence Between My Friend, The Late Gordon T. "Gordy" Pratt, and Chicago Tribune Reporter Lisa Black and Editor Peter Hernon (Sept/Oct 2009)Document8 pagesCorrespondence Between My Friend, The Late Gordon T. "Gordy" Pratt, and Chicago Tribune Reporter Lisa Black and Editor Peter Hernon (Sept/Oct 2009)Peter M. HeimlichNo ratings yet

- Introduction To Modelling PDFDocument329 pagesIntroduction To Modelling PDFclaudiuteodorNo ratings yet

- Track and Trace Your Delivery STDocument1 pageTrack and Trace Your Delivery STRufaizaNo ratings yet

- Determination of Total Phenolic Content Using The Folin-C Assay: Single-Laboratory Validation, First Action 2017.13Document7 pagesDetermination of Total Phenolic Content Using The Folin-C Assay: Single-Laboratory Validation, First Action 2017.13Naye VillalónNo ratings yet

- Form Emsd Ee Ct2B: Fresh Water Cooling Towers Scheme Notification of Completion of Cooling Tower InstallationDocument3 pagesForm Emsd Ee Ct2B: Fresh Water Cooling Towers Scheme Notification of Completion of Cooling Tower InstallationSimoncarter LawNo ratings yet

- Mixed CV Motion and UA Motion Review-1Document4 pagesMixed CV Motion and UA Motion Review-1juliannlevine445No ratings yet

- Internet SlangDocument95 pagesInternet SlangDanang WibisanaNo ratings yet

- Case Study 2Document10 pagesCase Study 2Mary Joy AquinoNo ratings yet

- COORD EN 00 Optical Pendulum ReadoutDocument4 pagesCOORD EN 00 Optical Pendulum ReadoutOswaldo EscuderoNo ratings yet

- Specifications For Lightning & Earthing Protection SystemDocument9 pagesSpecifications For Lightning & Earthing Protection SystemMuhammad Ibad Alam100% (1)

- Control Towers: What Every Executive Needs To Know AboutDocument8 pagesControl Towers: What Every Executive Needs To Know AboutAlberto VasquezNo ratings yet

- Module17 Question OnlyDocument50 pagesModule17 Question OnlysyahirazaihadNo ratings yet

- Extra HOTS: Chapter 9: Probability of Combined EventDocument2 pagesExtra HOTS: Chapter 9: Probability of Combined EventSnow TownNo ratings yet

- Sage Book Proposal Form (BPF)Document4 pagesSage Book Proposal Form (BPF)brammaballNo ratings yet

- English: Quarter 4 - Module 4: Relative Clause in Making DefinitionsDocument25 pagesEnglish: Quarter 4 - Module 4: Relative Clause in Making DefinitionsDorothy Yen Escalaña0% (1)

- Gopal ProjectDocument31 pagesGopal Projectjayesh.gaming9212No ratings yet

- External PTT Pedal Circuit (RS232)Document2 pagesExternal PTT Pedal Circuit (RS232)SmartPTT100% (1)

- ChipperDocument75 pagesChipperJerônimo RafaelNo ratings yet

- Varnashrama DharmaDocument18 pagesVarnashrama DharmaMillindar Segar100% (1)

- Career Development ProjectDocument12 pagesCareer Development Projectapi-281199790No ratings yet

- Changes-7 0 1Document5 pagesChanges-7 0 1karthik12317175No ratings yet

- The Politics of Ethnicity in PakistanDocument3 pagesThe Politics of Ethnicity in PakistansidraNo ratings yet

- Safety Data Sheet: Musol SolventDocument15 pagesSafety Data Sheet: Musol SolventHưng Lê TrungNo ratings yet

- Fault Detection in Three-Phase Transmission Line by Using IoTDocument5 pagesFault Detection in Three-Phase Transmission Line by Using IoTIJRASETPublicationsNo ratings yet

- Rajasekaran S-ResumeDocument3 pagesRajasekaran S-ResumeRees JohnsonNo ratings yet

- School Quality Assessment and Assurance Framework: Central Board of Secondary EducationDocument300 pagesSchool Quality Assessment and Assurance Framework: Central Board of Secondary EducationPolice DAV Public SchoolNo ratings yet