Professional Documents

Culture Documents

Important Data Provided in This Chart Is For Informational Purposes Only. Always Consult Current API Publications To Verify Information and Trim Data

Important Data Provided in This Chart Is For Informational Purposes Only. Always Consult Current API Publications To Verify Information and Trim Data

Uploaded by

Leo0 ratings0% found this document useful (0 votes)

5 views1 pageThe document provides an API trim number chart that lists 18 different trim options for valves. Each trim number specifies the material used for the seat, disc, backseat, and stem. Trim options include various grades of stainless steel, alloy metals, and hardfaced materials suitable for different pressure and corrosion resistance requirements. The chart notes that the trim data should be verified in current API publications and is intended to provide general information only.

Original Description:

Original Title

Macomb Trim Chart

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides an API trim number chart that lists 18 different trim options for valves. Each trim number specifies the material used for the seat, disc, backseat, and stem. Trim options include various grades of stainless steel, alloy metals, and hardfaced materials suitable for different pressure and corrosion resistance requirements. The chart notes that the trim data should be verified in current API publications and is intended to provide general information only.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

5 views1 pageImportant Data Provided in This Chart Is For Informational Purposes Only. Always Consult Current API Publications To Verify Information and Trim Data

Important Data Provided in This Chart Is For Informational Purposes Only. Always Consult Current API Publications To Verify Information and Trim Data

Uploaded by

LeoThe document provides an API trim number chart that lists 18 different trim options for valves. Each trim number specifies the material used for the seat, disc, backseat, and stem. Trim options include various grades of stainless steel, alloy metals, and hardfaced materials suitable for different pressure and corrosion resistance requirements. The chart notes that the trim data should be verified in current API publications and is intended to provide general information only.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

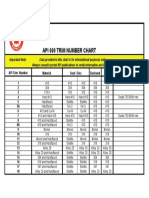

API VALVE TRIM NUMBER CHART

Important Data provided in this chart is for informational purposes only.

Note: Always consult current API publications to verify information and trim data.

API Trim Number Material Trim Code Seat / Disc Backseat Stem Notes

For oil and oil vapors and general services with heat treated seats and wedges/discs.

1 410 F6 410 410 410 410

General very low erosive or non-corrosive service.

2 304 304 304 304 304 304 For moderate pressure in corrosive, low erosive service.

3 F310 310 310 310 310 310 For moderate pressure in corrosive, low erosive service.

Same as trim 1 but seats and disc / wedge are 275 BHN min for medium pressure and more

4 Hard 410 F6H Hard 410 Hard 410 410 410

corrosive service

High pressure slightly erosive and corrosive service, premium trim service excellent for high

5 Hardfaced F6HF Stellite Stellite 410 410

pressure water and steam service

5a Hardfaced F6HF Ni-Cr Ni-Cr 410 410 Same as trim 5 where Co is not allowed

6 410 and Cu-Ni F6HFS Cu-Ni Cu-Ni 410 410 Same as trim 1 for more corrosive service

Same as trim 1 but seats and wedge / disc are 750 BHN min for higher pressure and more

7 410 and Hard 410 F6HF+ Hard 410 Hard 410 410 410

corrosive/erosive service

Universal trim for general service requiring long service life, for moderate pressure and

8 410 and Hardfaced F6HFS Stellite 410 410 410 more corrosive service. Steam, gas and general service "standard" trim. (Trim 5 is an

upgrade)

8a 410 and Hardfaced F6HFS Ni-Cr 410 410 410 Similar to trim 8 for moderate pressure and more corrosive service (Trim 5a is an upgrade)

For Corrosive service such as acids, alkalies, salt solutions, etc. for Very Corrosive fluids.

9 Monel Monel Monel Monel Monel Monel Erosive-corrosive service resistant to sea water, and has excellent corrosion resisting in

chlorine and alkylation services (Trim 11 is an upgrade)

For superior resistance to corrosion of media in liquid and gas states which are corrosive to

410 SS. Similar to trim 2 but a higher level of corrosive service. Provides excellent

10 316 316 316 316 316 316

resistance to corrosive media at high temperatures and toughness for service at low temps.

(Trim 12 is and upgrade)

11 Monel and Hardfaced MonelHFS Stellite Monel Monel Monel Hard seat trim 9 for medium pressure and more corrosive service

12 316 and Hardfaced 316HFS Stellite 316 316 316 Hard seat trim 10 for medium pressure and more corrosive service. (Trim 16 is an upgrade)

13 Alloy 20 Alloy 20 Alloy 20 Alloy 20 Alloy 20 Alloy 20 For very corrosive services (Trim 13 is an upgrade)

14 Alloy 20 and Hardfaced Alloy 20HFS Stellite Alloy 20 Alloy 20 Alloy 20 Hard seat trim 13 for moderate pressure and very corrosive service

15 304 and Hardfaced 304HS Stellite Stellite 304 304 Hard seat and wedge / disc trim 2 for more erosive service and higher pressures

16 316 and Hardfaced 316HFS Stellite Stellite 316 316 Hard seat and wedge / disc trim 10 for more erosive service and higher pressures

This trim is for higher pressures and temperatures than those in trim 13 with good

17 347 and Hardfaced 347HF Stellite Stellite 347 347

corrosion resistance.

18 Alloy 20 and Hardfaced Alloy 20 HF Stellite Stellite Alloy 20 Alloy 20 This trim is for more corrosive and higher pressures than trim 13 but not as high as trim 17

You might also like

- Packing Brochure SADocument20 pagesPacking Brochure SAfrederick alayonNo ratings yet

- Trim Material Valve PlugDocument4 pagesTrim Material Valve Plugalexmontell100% (1)

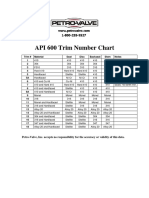

- API 600 Trim Number Chart API ValveDocument2 pagesAPI 600 Trim Number Chart API ValveCésar Oswaldo Aguilera OjedaNo ratings yet

- Powder MetallurgyDocument79 pagesPowder MetallurgyTrevor Menezes100% (1)

- Trim Number Chart API ValveDocument2 pagesTrim Number Chart API ValveVelu .cNo ratings yet

- Trim DetailsDocument15 pagesTrim DetailsDilip VaradharajanNo ratings yet

- Trim Numbers of Valves - API 600Document36 pagesTrim Numbers of Valves - API 600samsarizalNo ratings yet

- Valve TrimsDocument11 pagesValve TrimsAmarKumarNo ratings yet

- API 600 Trim Number Chart..Document1 pageAPI 600 Trim Number Chart..francisco abarcaNo ratings yet

- Stainless Steel DatasheetsDocument1 pageStainless Steel DatasheetsMunishTrichyNo ratings yet

- Gate Valve - Trim ChartDocument1 pageGate Valve - Trim Chartcrni rokoNo ratings yet

- Api Trime ChartDocument3 pagesApi Trime Charta.christopherNo ratings yet

- Fresia ESB 10Document2 pagesFresia ESB 10ranjanguptNo ratings yet

- MCHONE Stainless Grades Chart DownloadableDocument3 pagesMCHONE Stainless Grades Chart DownloadableSagar TikoneNo ratings yet

- Valve Soft Parts: Flanged End 3 Piece C ValvesDocument4 pagesValve Soft Parts: Flanged End 3 Piece C ValvesFLOW VALVE AUTOMATIONNo ratings yet

- Asiento Sello Valvula Trim Api CWP WOLSELEYDocument14 pagesAsiento Sello Valvula Trim Api CWP WOLSELEYRicNo ratings yet

- Section 13.2 - AT FluidsDocument40 pagesSection 13.2 - AT Fluidsban bekasNo ratings yet

- API 600 Trim No.Document19 pagesAPI 600 Trim No.SUBHASISH BHATTACHARYYANo ratings yet

- 05rotary Shaft Seals PDFDocument13 pages05rotary Shaft Seals PDFKhanh Pham DangNo ratings yet

- API 600 Trim Number Chart PDFDocument1 pageAPI 600 Trim Number Chart PDFBill GuNo ratings yet

- Invalved Valve Trim Materials Standard Trim ConfigurationsDocument1 pageInvalved Valve Trim Materials Standard Trim ConfigurationsmanishkapriNo ratings yet

- 02 Fers Resins For Abrasives Fsac05 To CD VersionDocument32 pages02 Fers Resins For Abrasives Fsac05 To CD VersionpmalexNo ratings yet

- Antico NJL Series PDFDocument7 pagesAntico NJL Series PDFraajc2No ratings yet

- Aalco Metals LTD - Stainless Steel 14016 430 Sheet and Plate - 95Document3 pagesAalco Metals LTD - Stainless Steel 14016 430 Sheet and Plate - 95bhushansalunkeNo ratings yet

- Aalco Metals LTD Stainless Steel 14301 Sheet and Plate Quarto Plate CPP Plate 343Document3 pagesAalco Metals LTD Stainless Steel 14301 Sheet and Plate Quarto Plate CPP Plate 343saravananNo ratings yet

- Catalog Wurth ChemicalsDocument258 pagesCatalog Wurth ChemicalsBillNo ratings yet

- SISCORBV030 Series Butterfly ValveDocument10 pagesSISCORBV030 Series Butterfly Valveloli2323No ratings yet

- 180 - 18 Seat Selection GuideDocument4 pages180 - 18 Seat Selection GuidemolinachNo ratings yet

- Aalco Metals LTD Stainless Steel 14301 Sheet and Plate 343Document3 pagesAalco Metals LTD Stainless Steel 14301 Sheet and Plate 343Manoj ManivasagamNo ratings yet

- TFM 1600Document1 pageTFM 1600Rendi MulyadiNo ratings yet

- E7112 7 11 16 - NF KatalogversionDocument10 pagesE7112 7 11 16 - NF KatalogversionmarcuswsantosNo ratings yet

- Carbon and Alloy Steel Compressible-Washer-Type Direct Tension Indicators For Use With Cap Screws, Bolts, Anchors, and StudsDocument6 pagesCarbon and Alloy Steel Compressible-Washer-Type Direct Tension Indicators For Use With Cap Screws, Bolts, Anchors, and StudsDarwin DarmawanNo ratings yet

- Cat NFPA-6 WebDocument16 pagesCat NFPA-6 WebnajimtecNo ratings yet

- TFM 1600 Ptfe Seats: Properties Benefi TsDocument2 pagesTFM 1600 Ptfe Seats: Properties Benefi TsagrovadoNo ratings yet

- Material Cross Reference List 1Document3 pagesMaterial Cross Reference List 1vinothcdmNo ratings yet

- SISCORBV020 Series Butterfly ValveDocument10 pagesSISCORBV020 Series Butterfly Valveloli2323No ratings yet

- LF310 Datasheet: Low-Flow Pressure RegulatorDocument4 pagesLF310 Datasheet: Low-Flow Pressure RegulatorIdehen KelvinNo ratings yet

- Ac 800 Series BrochureDocument12 pagesAc 800 Series BrochureAnung PriyantoNo ratings yet

- Loctite Caterpillar PDFDocument47 pagesLoctite Caterpillar PDFdanielzepeda_235851100% (1)

- 001 Steel BarsDocument24 pages001 Steel BarstohaphsianturiNo ratings yet

- Bestolife® 3010® NM SpecialDocument2 pagesBestolife® 3010® NM SpecialJorge ForeroNo ratings yet

- ABS Dry Installed Sewage Pump FR: ApplicationsDocument2 pagesABS Dry Installed Sewage Pump FR: ApplicationsIR MA Al AzharNo ratings yet

- Mini Cataloq AM 1 - UTDocument11 pagesMini Cataloq AM 1 - UTDipta HaryonoNo ratings yet

- PTFE Seated enDocument20 pagesPTFE Seated enrubenNo ratings yet

- EN V6000 S740 KnifeGate Web 20220202Document8 pagesEN V6000 S740 KnifeGate Web 20220202Julian David RodriguezNo ratings yet

- Swivel Joint SRL825: Ptfe-LinedDocument1 pageSwivel Joint SRL825: Ptfe-Linedady vNo ratings yet

- Chemical Pump Data EbaraDocument8 pagesChemical Pump Data EbaraGea Mandiri ciptaNo ratings yet

- Berulub FR - 16 - MS-001-20Document1 pageBerulub FR - 16 - MS-001-20avinashchauhan2695No ratings yet

- FLOWTEK - Ficha Tecnica-ComprimidoDocument8 pagesFLOWTEK - Ficha Tecnica-ComprimidoJosé BrionesNo ratings yet

- Alfa Laval Alfa Laval Diabon Product Leaflet enDocument4 pagesAlfa Laval Alfa Laval Diabon Product Leaflet enAyelen VillarinoNo ratings yet

- Spira-Trol DN15 To DN100 LE, LF and LL Two-Port Control ValvesDocument10 pagesSpira-Trol DN15 To DN100 LE, LF and LL Two-Port Control ValvesVincenzo SenatoreNo ratings yet

- Shashi Fluoroplastiks E-BrochureDocument6 pagesShashi Fluoroplastiks E-BrochureYogesh LadolaNo ratings yet

- Hoja Tecnica Urethano LiquidoDocument4 pagesHoja Tecnica Urethano LiquidoInsein ECNo ratings yet

- Datasheet CPM S110Vv12010 PDFDocument3 pagesDatasheet CPM S110Vv12010 PDFMaximiliano GarciaNo ratings yet

- Keystone f990 920 CatalogoDocument4 pagesKeystone f990 920 CatalogoGino Chavez ValenciaNo ratings yet

- SKF Filament Wound BushingsDocument8 pagesSKF Filament Wound BushingsWes VendrigNo ratings yet

- Corrosion Resistant Bearing and Housing SolutionsDocument1 pageCorrosion Resistant Bearing and Housing Solutionsjoshua surbaktiNo ratings yet

- Revision Unit 4Document74 pagesRevision Unit 4minalhasan2No ratings yet

- Fluid Mechanics Lecture 101820Document1 pageFluid Mechanics Lecture 101820John Dalton ValenciaNo ratings yet

- Huagong Xuebao/Journal of Chemical Industry and Engineering (China) November 2020Document10 pagesHuagong Xuebao/Journal of Chemical Industry and Engineering (China) November 2020valery akhmNo ratings yet

- Structure Factor PDFDocument28 pagesStructure Factor PDFAndrea EspinosaNo ratings yet

- Nanoscale Transistors: Device Physics, Modeling and SimulationDocument27 pagesNanoscale Transistors: Device Physics, Modeling and SimulationBhaskar KNo ratings yet

- VITEEE 2024 Information BrochureDocument20 pagesVITEEE 2024 Information BrochureIgnatius IgnatiusNo ratings yet

- GHS Vs MSDS FormatsDocument5 pagesGHS Vs MSDS Formatse1717y8653No ratings yet

- Physics C Tables and Equations List PDFDocument3 pagesPhysics C Tables and Equations List PDFFrancesNo ratings yet

- How A Water Rocket WorksDocument8 pagesHow A Water Rocket WorksAd ComelNo ratings yet

- Carcinogenicidad Y Toxicidad para La ReproducciónDocument17 pagesCarcinogenicidad Y Toxicidad para La ReproducciónAngela MazónNo ratings yet

- Science: First Quarter - Module 4B Saturated SolutionsDocument26 pagesScience: First Quarter - Module 4B Saturated Solutionsdibose8563No ratings yet

- Rivera-Centrifugation - Gas CentrifugeDocument5 pagesRivera-Centrifugation - Gas CentrifugeMarjorie Luares RiveraNo ratings yet

- Handout Force and Motion S2Document13 pagesHandout Force and Motion S2rozy kjsNo ratings yet

- Physics 9 O Level TestDocument4 pagesPhysics 9 O Level TestAllam S/o Mumtaz Ali TunioNo ratings yet

- Materials Letters 62 - 2008Document3 pagesMaterials Letters 62 - 2008Hong Nguyen 눈 꽃No ratings yet

- Bio Lab: Reducing and Non-Reducing SugarsDocument3 pagesBio Lab: Reducing and Non-Reducing SugarschistanaNo ratings yet

- Dual Nature of Radiation and MatterDocument22 pagesDual Nature of Radiation and MatterAvinashGowdNo ratings yet

- Mid M1500 Ba 02 0193Document44 pagesMid M1500 Ba 02 0193cuno florinNo ratings yet

- BIOL1408 Introductory Biology Name Lab Unit 6/7: Diffusion & Osmosis Date Dr. Flo OxleyDocument10 pagesBIOL1408 Introductory Biology Name Lab Unit 6/7: Diffusion & Osmosis Date Dr. Flo OxleyJavier E. Dubon0% (1)

- Van de Graaff GeneratorDocument5 pagesVan de Graaff GeneratorOm PatelNo ratings yet

- 55NO3LTADocument14 pages55NO3LTASantiago DiosdadoNo ratings yet

- Acid Rain: Heinz Rennenberg, Arthur GesslerDocument2 pagesAcid Rain: Heinz Rennenberg, Arthur GesslerFrancisco BecerraNo ratings yet

- Geiger Muller CounterDocument8 pagesGeiger Muller CounterPriyanshu Sisodia100% (1)

- Swirl FluidizerDocument4 pagesSwirl FluidizerantiquekNo ratings yet

- Product Elastakote Oct18Document1 pageProduct Elastakote Oct18DWI RAHMASARI FATMAWATINo ratings yet

- NSS Public School PerunthanniDocument18 pagesNSS Public School PerunthanniparthipparameshNo ratings yet

- Chapter 17 - CorrosionDocument11 pagesChapter 17 - CorrosionmuthuhcuNo ratings yet

- Certificado Copla 6000 1Document1 pageCertificado Copla 6000 1juan aguilarNo ratings yet

- Irjet Laterite Soil Stabilisation by UsiDocument7 pagesIrjet Laterite Soil Stabilisation by UsijaciseNo ratings yet