Professional Documents

Culture Documents

8738

8738

Uploaded by

Karim ElgammalOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

8738

8738

Uploaded by

Karim ElgammalCopyright:

Available Formats

Desalination 217 (2007) 260266

Desalination of sodium chloride solutions and seawater with hydrophobic ceramic membranes

L. Gazagnes, S. Cerneaux, M. Persin, E. Prouzet, A. Larbot*

Institut Europen des Membranes (UMR 5635CNRS, ENSCM, UM 2), 1919, route de Mende, 34293 Montpellier cedex 5, France Tel. +33 (0)4 67 61 33 88; Fax: +33 (0)4 67 04 28 20; email: gazagneslaetitia@yahoo.fr Received 25 March 2006; Accepted 12 January 2007

Abstract Desalination of seawater and NaCl solutions is of great interest as potable water sources are dramatically declining on earth. Most of the techniques used to decontaminate water involve polymeric membranes and expensive desalination processes. To improve thermal, chemical and physical resistance of these membranes, research is now focused on ceramic membranes and hydrophobic ones in particular. The technique used to desalinate water is the Air Gap Membrane Distillation (AGMD), which is more compact, less energy-consuming and required lower temperature than conventional distillation processes. Therefore, ceramic membranes of different nature, zirconia, alumina and alumino-silicate, with pore diameters of 50 nm, 200 and 400 nm, and 800 nm, respectively, were chemically modified using 1H, 1H, 2H, 2H-perfluorodecyltriethoxysilane and applied to desalination of NaCl solutions and seawater using AGMD. Highest rejection rate (>95%) and flux were measured for hydrophobic zirconia membrane (50 nm). Keywords: Desalination; Membrane distillation; Hydrophobic; Ceramic membranes

1. Introduction Even though water represents 70% of the planet, its repartition is very unequal, coming essentially from seawater and icebergs. Rarefaction of potable water has become a major concern in many countries and therefore new

*Corresponding author.

techniques are required to produce fresh water. To take advantage of natural resources, attention has been focused on desalination of seawater and brackish water, using effective however still expensive techniques. Desalination technology usually involves a phase change such as freezing and distillation in thermal processes but also membranes in reverse osmosis and electrodialysis experiments [1,2]. Salt solutions desalination by

0011-9164/07/$ See front matter 2007 Elsevier B.V. All rights reserved

L. Gazagnes et al. / Desalination 217 (2007) 260266

261

membrane distillation (MD) process is thus of interest as it combines advantages of conventional distillation and membrane-based systems, being more compact, less energy-consuming and requiring lower temperature appliance. Highly pure water can finally be collected without strong chemical interaction between the solution and the membrane, limiting therefore water contamination [1]. Several types of MD processes can be found, such as direct contact membrane distillation (DCMD), air gap membrane distillation (AGMD), sweeping gas membrane distillation (SGMD) and vacuum membrane distillation (VMD) [3]. We propose to perform filtration of NaCl solutions at a concentration of 1, 2 and 3 mol/L as well as water from the Mediterranean Sea (C = 0.5 M) using a pilot of AGMD. The principle of AGMD, described in Fig. 1, involves the appliance of a difference of temperature between (a) the feed side and (b) the permeate, that enables (c) vaporization of water at the surface of the membrane and transport of the gaseous phase through the membrane.

For that purpose, hydrophobic ceramic membranes were used in place of polymeric membranes since they are thermically, chemically and mechanically more resistant. The hydrophobic and tubular membranes, usually applied in ultrafiltration and microfiltration, were functionalised with 1H, 1H, 2H, 2H-perfluorodecyltriethoxysilane, following a procedure published earlier [4]. Different parameters influencing the efficiency of desalination were thus studied and performances compared with those obtained for polymeric membranes. 2. Experimental Ceramic membranes of 15 cm-long and a diameter of 1 cm were tested on the AGMD pilot and are represented in Fig. 2. A temperature of 95C was applied to the feed tank and the cooling system maintained at 5C, giving thus a temperature of the condensation wall of 25C. The solution circulation rate was fixed at 3.34 L/min. Permeate flux is expressed in L/day.m2 with a precision of 5 L/day.m2. Salt

Fig. 1. Principle of AGMD.

262

L. Gazagnes et al. / Desalination 217 (2007) 260266

Fig. 2. Schematic illustration of the AGMD pilot.

concentration was determined by ionic chromatography and the rejection rates, denoted R, were calculated using Eq. (1) with a precision of 6 %.

C C0

100

(1)

where C0 represents the initial concentration of the salted solution and C, the concentration of permeate. Zirconia (Zr50), alumina (Al200 and Al800) and aluminosilicate (AlSi400) membranes with pore diameter of 50, 200 and 800, and 400 nm, respectively, were grafted with 1H, 1H, 2H, 2Hperfluorodecyltriethoxysilane (Lancaster) in chloroform (Carlo Erba Reagenti). The following conditions were applied for the grafting procedure [4]: grafting time of 2 days, concentration of the grafting solution of 10 1 mol/L and ratio of grafting Rg of 7.8.10 3 mol/m2. Rg is representative of the number of fluoroalkylsilane molecules over the specific surface area of the ceramic membranes. Details on membrane preparation and characterization are given elsewhere [4]. 3. Results Performances of the hydrophobic ceramic membranes were evaluated in desalination of NaCl solutions (1, 2 and 3 mol/L) and water from the Mediterranean Sea at about 0.5 mol/L, using

Fig. 3. Evolution of permeate flux as a function of NaCl solution concentration using Zr50, Al200, Al800 and AlSi400 membranes.

AGMD technology. The influence of salt concentration, temperature and nature of the membrane on permeate flux and rejection rates will be discussed. 3.1. Influence of NaCl concentration The evolution of the permeate flux FP was followed by tangential filtration using Zr50, Al200, Al800 and AlSi400 membranes, at fixed feed temperature of 95C (Fig. 3). The highest FP of about 120 L/day.m2 is obtained for a NaCl concentration of 0.5 mol/L (seawater) and decreases drastically whilst increasing the concentration to 1, 2 and 3 mol/L. As a larger amount of salt is present in highly concentrated solutions,

L. Gazagnes et al. / Desalination 217 (2007) 260266 Table 1 Ebullioscopic elevation of temperature calculated from Eq. (2) for NaCl solutions tested and corresponding boiling point Bp [NaCl] (mol/L) T (C) Bp (C) 0.5 0.51 100.51 1 1.02 101.02 2 2.04 102.04 3 3.06 103.06

263

Fig. 4. Rejection rate as a function of NaCl concentration.

the vapour of fresh water is minimized and probably slowed down along the membrane, lowering therefore FP, which is consistent with previous results [57]. It should be noted that neither the nature of the membrane nor the pore diameter affects this behaviour. To corroborate this result, the ebullioscopic elevation T of NaCl solutions (Table 1) was determined using Raoults law [Eq. (2)].

K eb

i.CB

sol

(2)

where sol represents the density of pure water (1 kg/L) and i, the Vant Hoff coefficient of 2 for NaCl salt. CB corresponds to NaCl concentration and Keb, the ebullioscopic constant of water (0.51 K.kg/mol). The higher the concentration, the higher the boiling point of the NaCl solution. This shows that less vaporization of water occurs at the membrane surface, diminishing therefore the amount of steam going through the membrane. In addition, the rejection rates present no dependence with the NaCl concentration as observed in Fig. 4. They are ranging from 85% for Al800 to 100% for Zr50. Hydrophobic ceramic membranes are thus efficient towards the rejection of NaCl and, in particular, membranes presenting the lowest pore diameter values. 3.2. Influence of the feed temperature Measurements of FP and rejection rates were carried out by AGMD as a function of the system

Fig. 5. Variation of permeate flux with the feed permeate temperature using membranes Zr50, Al200, Al800 and AlSi400.

temperature. The feed side temperature was thus varied from 75 C to 85 C and 95 C, while keeping the cooling system temperature constant at 5 C. Fig. 5 illustrates the permeate flux variations of a 2 mol/L NaCl solution tested at different temperature of the feed side. Increasing the temperature of the source solution from 75C to 85C and 95C led to an increase of FP from 20 to 60 L/day.m2 for Al800 and AlSi400 but also from 40 to 100 L/day.m2 for membranes with smaller pores, Al200 and Zr50. Besides, rejection rates around 90100% were not influenced by the temperature changes, which is in accordance with

264

L. Gazagnes et al. / Desalination 217 (2007) 260266

Fig. 7. Variation of the permeate flux as a function of the pore diameter for Zr50, Al200, AlSi400 and Al800. The values reported on the graph correspond to the rejection rates calculated for the different membranes after filtration of a 1 mol/L NaCl solution. Fig. 6. Evolution of permeate flux as a function of the feed solution temperature for Zr50 membrane.

the literature [5,6,8,9]. In addition, the highest permeate fluxes were reached for Zr50, whatever the applied feed temperature. Therefore, this membrane was used to desalinate the different NaCl solutions (Fig. 6). As observed in Fig. 5, temperature increase of the feed source implies a permeate flux improvement. Hence, at 95C, 95, 110 and 125 L/day.m2 are obtained for filtration of NaCl solution of 2 and 3 mol/L, 1 mol/L and 0.5 mol/L, respectively. Nevertheless, no relationship can be established between rejection rates and temperature as they remained constant at around 95100%. This result is moreover in total agreement with the observations made earlier on Fig. 3. 3.3. Influence of the pore diameter of the membrane In order to study the influence of the pore diameters of each membrane on the distillation characteristic parameters, experiments were conducted with a feed side temperature fixed at 95C and a cooling tank thermostated at 5C. The permeate flux variations and corresponding rejection rates were reported as a function of the

different pore diameters when a 1 mol/L NaCl solution was filtered in Fig. 7. The highest flux is obtained for the membrane containing the smallest pores Zr50, decreasing though to stabilize at 95100 L/day.m2 for membranes containing larger pores. Pores superior than 200 nm did not give rise to flux enhancement, whereas rejection rates decreased with the pore diameter increase as observed in Fig. 7. 3.4. Comparison with results of the literature Maximum flux of 1265 L/day.m2 was obtained with Zr50 for desalination of seawater at 0.5 mol/L, whilst a temperature difference between the feed side and the cooling system of 70C was applied. Table 2 regroups data obtained for a polymeric PTFE membrane. In this study, maximum flux of 1265 L/day.m2 has been obtained with a zirconia tested in AGMD at a similar circulation speed of 3.34 L/min. A difference of temperature almost three times higher than in PTFE membrane case has to be applied on a hydrophobic ceramic membrane with pores of 200 nm to reach an equivalent flux. Fluoro-modified ceramic membranes give fluxes of permeate almost as high as those obtained ion reverse osmosis, while using a 60 times more concentrated salt solution. Moreover, 100% of

L. Gazagnes et al. / Desalination 217 (2007) 260266

265

Table 2 Comparison of permeate fluxes obtained in desalination of NaCl solutions of various concentration with polymeric, reverse osmosis and hydrophobic ceramic membranes AGMD process Hydrophobic ceramic membrane Membrane Zr50 Al200 Polymeric membrane PTFE RO Polymeric membrane TRISEP8040TS80-TSA (8") Pressure: 6.9 bars 8.510 3 149.5 [2]

70 Temp. difference ( C) 50 1 1 [NaCl] (mol/L) 38.4 110.2 FP (L/day.m2) Reference This study This study

70 0.5 126.0 This study

70 0.5 120.7 This study

70 1 99.9 This study

25 0.50.85 120.0 [1]

rejection is achieved with the grafted membrane compared to 90% for a reverse osmosis membrane. Therefore, the grafted ceramic membranes are more effective in AGMD than polymer membranes in reverse osmosis. 3.5. Membrane lifetime and desalination economical benefit Twenty desalination experiments were conducted on the grafted ceramic membranes for 10 h of treatment each time. No variation was encountered in time, which is due to a strong chemical bond between the oxide and the grafting agent. Moreover, membrane fouling often caused by the presence of microorganisms in seawater did not occur with the hydrophobic ceramic membranes. Even though this could happen after a long period of filtration, a simple ultrasonic treatment will be effective to clean the membrane without deterioration of the grafted layer. In Table 3 the energy consumption and maximum flux obtained using reverse osmosis are reported for VMD and AGMD technology. Four times less energy (1 kWh/m3) is required to reach a flux of 5 L.h.m 2 using an air gap membrane distillation process compared to reverse osmosis

Table 3 Comparison of performances of reverse osmosis and VMD technology with a commercial membrane in desalination Process Energy consumption (kWh/m3) 4 3.2 1.2 1 Flux (L.h.m 2) 510 0.7 0.50.7 5.2

Reverse osmosis with energy recovery Single pass VMD Discontinuous VMD AGMD

[7,10]. In addition, AGMD consumes as much energy as single pass or discontinuous VMD, which give rise to flux one tenth lower. Finally, using natural energy sources such as solar or geothermal energies allows a decrease of the desalination cost [11]. 4. Conclusion Hydrophobic ceramic membranes of different nature were chemically modified with 1H, 1H, 2H, 2H-perfluorodecyltriethoxysilane and tested

266

L. Gazagnes et al. / Desalination 217 (2007) 260266 [4] L. Gazagnes, Modification de la surface de membranes cramiques par greffage Applications au dessalement et la sparation dmulsions, Thse, Montpellier, 2005. [5] D. Wirth and C. Cabassud, Water desalination using membrane distillation: comparison between inside/ out and outside/in permeation, Desalination, 147 (2002) 139145. [6] M. Khayet, J.I. Mengual and T. Matsuura, Porous hydrophobic/hydrophilic composites membranes Application in desalination using direct contact membranes distillation, J. Membr. Sci., 252 (2005) 101113. [7] C. Cabassud and D. Wirth, Membrane distillation for water desalination: how to chose an appropriate membrane?, Desalination, 157 (2003) 307314. [8] T.Y. Cath, V.D. Adams and A.E. Childress, Experimental study of desalination using direct contact membrane distillation: a new approach to flux enhancement, J. Membr. Sci, 228 (2004) 516. [9] F. Banat, R. Jumah and M. Garaibeh, Exploitation of solar energy collected by solar stills for desalination by membrane distillation, Renewable Energy, 25 (2002) 293305. [10] A. El Amali, S. Bouguecha and M. Maalej, Experimental study of air gap and direct contact membrane distillation configurations: application to geothermal and seawater desalination, Desalination, 168 (2004) 357. [11] M.C. Garca-Payo, M.A. Izquierdo-Gil and C. Fernndez-Pineda, Air gap membrane distillation of aqueous alcohol solutions, J. Membr. Sci., 169 (2000) 6180. [12] L. Martinez, Comparison of membrane distillation performance using different feeds, Desalination, 168 (2004) 359365. [13] J.-M. Li, Z.-K. Xu, Z.-M. Liu, W.-F. Yuan, H. Xiang, S.-Y. Wang and Y.-Y. Xu, Microporous polypropylene and polyethylene hollow fiber membranes. Part 3. Experimental studies on membrane distillation for desalination, Desalination, 155 (2003) 153156.

in desalination of seawater and NaCl solutions of various concentrations (from 0.5 to 2 mol/L). Very good rejection rates of 95100% were obtained, which is characteristic of very effective membranes in this application. They were only influenced by the pore diameters of the membranes used, Zr50, with the smallest pores, giving the best rejection rates. The difference of temperature between the feed side and the cooling system, which is one main parameter of this membrane distillation process, give rise to permeate fluxes improvement. The FP increase is greater when membranes with small pore diameters, such as Zr50, but also with decreasing concentration of salt in the feed tank. Even though the permeate fluxes remain lower than fluxes obtained with hydrophobic polymer membranes, it would be possible to increase them by carrying out tests whilst increasing the circulation speed of the pilot [8,13,14]. These hydrophobic ceramic membranes can in addition be used in other applications and, in particular, in the treatment of polluted water for removal of heavy metal ions. References

[1] S.T. Hsu, K.T. Cheng and J.S. Chiou, Seawater desalination by direct contact membrane distillation, Desalination, 143 (2002) 279287. [2] E. Brauns, V. Van Hoof, C. Dotremont, H. De Wever, P. Lens, E. Van Hoof, G. Thomas, B. Molenberghs and D. Demey, The desalination of an Arthrospira platensis feed solution by electrodialysis and reverse osmosis, Desalination, 170 (2004) 123136. [3] G. Marek, Osmotic MD and other membrane distillation variants, J. Membr. Sci., 246 (2005) 145 156.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ASWP Manual - Section 2 - Steel Pipe Design (6-2013)Document21 pagesASWP Manual - Section 2 - Steel Pipe Design (6-2013)Shahril Izzuddin Or DinoNo ratings yet

- Abrasive Blast Media Quick Selection Guide: Single Use Surface Preparation MediaDocument1 pageAbrasive Blast Media Quick Selection Guide: Single Use Surface Preparation MediaskNo ratings yet

- 4 - Simple StrainDocument24 pages4 - Simple StrainLorene Ropeta.No ratings yet

- TRANSGENIC PLANTS - PhytoremediationDocument10 pagesTRANSGENIC PLANTS - PhytoremediationAnam nesarNo ratings yet

- FDA PPT of Definitions Emulsion SuspensionDocument15 pagesFDA PPT of Definitions Emulsion SuspensionvijayrnjnNo ratings yet

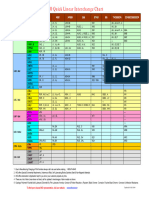

- IKO Linear Interchange ChartDocument1 pageIKO Linear Interchange ChartleviettienCTMNo ratings yet

- Energy Production in Human BodyDocument30 pagesEnergy Production in Human Bodymohitime100% (2)

- Eco CoulometerDocument110 pagesEco CoulometerThiago CardosoNo ratings yet

- Geology ReviewerDocument12 pagesGeology ReviewerGrace MagbooNo ratings yet

- Particles Fibres Pulp WhitepaperDocument11 pagesParticles Fibres Pulp WhitepaperGorack ShirsathNo ratings yet

- Water Problems Questions and Answers: 1. A Circular Well of 10 Meter Diameter With 15 Meter Depth of Water Is To BeDocument6 pagesWater Problems Questions and Answers: 1. A Circular Well of 10 Meter Diameter With 15 Meter Depth of Water Is To BeHarshitha LokeshNo ratings yet

- 1988, TwiltDocument7 pages1988, TwiltWaibhaw KumarNo ratings yet

- Cryogenic HardeningDocument17 pagesCryogenic HardeningchetanNo ratings yet

- ME 218 - Spring 2018 - Week02 HandoutDocument15 pagesME 218 - Spring 2018 - Week02 HandoutHassan KhalidNo ratings yet

- Definition of TermsDocument3 pagesDefinition of TermsSteph Phanie G. GomezNo ratings yet

- Coa - Hach DPD && Glycine PackDocument3 pagesCoa - Hach DPD && Glycine PackMechem EurofinsNo ratings yet

- Thermodynamics MCQDocument13 pagesThermodynamics MCQBhaskar jyoti BhuyanNo ratings yet

- Aniline From Nitrobenzene 1Document11 pagesAniline From Nitrobenzene 1Neha Miracle100% (1)

- Job MethodDocument3 pagesJob MethodSebastián MartinezNo ratings yet

- SDS CRC Coil CleanerDocument10 pagesSDS CRC Coil CleanerrudiNo ratings yet

- PSQCA Mineral WaterDocument15 pagesPSQCA Mineral WaterSulman_Rashid__2464No ratings yet

- Steady State Simulation of Continuous Stirred Tank Reactor (CSTR) System Using Aspen PlusDocument46 pagesSteady State Simulation of Continuous Stirred Tank Reactor (CSTR) System Using Aspen Plusqurat ul ainNo ratings yet

- MK GMB 07 Wettability Cap Pressure SaturationDocument28 pagesMK GMB 07 Wettability Cap Pressure SaturationRoni Hepson TambunNo ratings yet

- IOE Entrance Syllabus and Sample QuestionDocument6 pagesIOE Entrance Syllabus and Sample QuestionBishwash BhattaraiNo ratings yet

- Pharma Manual PDFDocument25 pagesPharma Manual PDFElena TrofinNo ratings yet

- Appendix B: Examples of Flexible Packaging Film StructuresDocument13 pagesAppendix B: Examples of Flexible Packaging Film Structuresbilly chrisNo ratings yet

- Carta Alir KimpalanDocument7 pagesCarta Alir KimpalanHisham Mat Salleh50% (2)

- GM Counter PDFDocument14 pagesGM Counter PDFabahyn100% (1)

- Biphasic Liquid Dosage FormDocument18 pagesBiphasic Liquid Dosage FormSai Nath NNo ratings yet

- Semiconductor PhysicsDocument15 pagesSemiconductor PhysicsjhonalejoNo ratings yet