Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

21 viewscsp-020 I0r0

csp-020 I0r0

Uploaded by

romixrayzenMD500

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Flight Controls ReviewDocument8 pagesFlight Controls ReviewromixrayzenNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- MC 10230573 0001Document27 pagesMC 10230573 0001romixrayzenNo ratings yet

- MC 10214482 0001Document8 pagesMC 10214482 0001romixrayzenNo ratings yet

- Link2000 DecisionTree 2012 12bDocument1 pageLink2000 DecisionTree 2012 12bromixrayzenNo ratings yet

- Data Link Services Workshop Brussels 17june2014Document47 pagesData Link Services Workshop Brussels 17june2014romixrayzenNo ratings yet

- SA3644SWDocument2 pagesSA3644SWromixrayzenNo ratings yet

- 05 Диагностика неисправностейDocument12 pages05 Диагностика неисправностейromixrayzenNo ratings yet

- Active Service Bulletins With Instructions For Continued AirworthinessDocument1 pageActive Service Bulletins With Instructions For Continued AirworthinessromixrayzenNo ratings yet

- csp-023 I0r0Document18 pagescsp-023 I0r0romixrayzenNo ratings yet

- AW600 23 2387 - Rev4Document7 pagesAW600 23 2387 - Rev4romixrayzenNo ratings yet

- 02 Техническое описаниеDocument20 pages02 Техническое описаниеromixrayzenNo ratings yet

- csp-015 I0r0Document20 pagescsp-015 I0r0romixrayzenNo ratings yet

- Flight Instruments Review: Pitot-Static SystemDocument5 pagesFlight Instruments Review: Pitot-Static SystemromixrayzenNo ratings yet

- csp-019 I0r0Document16 pagescsp-019 I0r0romixrayzenNo ratings yet

- csp-089 I0r0Document24 pagescsp-089 I0r0romixrayzenNo ratings yet

- Fire Protection Review: Fire Detection and ExtinguishingDocument7 pagesFire Protection Review: Fire Detection and ExtinguishingromixrayzenNo ratings yet

- Landing Gear and Brakes ReviewDocument8 pagesLanding Gear and Brakes ReviewromixrayzenNo ratings yet

- Auxiliary Power Unit (Apu) Systems ReviewDocument5 pagesAuxiliary Power Unit (Apu) Systems Reviewromixrayzen100% (1)

csp-020 I0r0

csp-020 I0r0

Uploaded by

romixrayzen0 ratings0% found this document useful (0 votes)

21 views20 pagesMD500

Original Title

csp-020_i0r0

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMD500

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

21 views20 pagescsp-020 I0r0

csp-020 I0r0

Uploaded by

romixrayzenMD500

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 20

Publication No. CSP-020

Illustrated Paris List

and

Maintenance Insiructions

FOR

RADIO INSTALLATION (ASB-125/60)

Part No, 369H90144-501,

369H90144-503 and 369H90144-505

USED ON HUGHES 500D (MODEL 369D) HELICOPTERS

6 Hughes Helicopters arisin or summa comoraton /euver cy cata

cope71310 Issued 1 March 1977

csP-020

Section

1 ILLUSTRATED PARTS LIST .

- Organization of Contents»

Literature Changes and

Opt Eqpt Manual

Table of Contents

TABLE OF CONTENTS

Page

Purpose and Content

of this Manual........., F-1

Applicability... < .

Compatibility of Combined

Optional Equipment . .

Use of this Manual... . .

Related Publications

Revisions... 2.0.2.4

Scope and Contents....... 1-1

Group Assembly Parts

List»...

Mlustrations .-. 2...

2 MAINTENANCE INSTRUCTIONS. . 2-1

Bel,

2-2.

2-3.

General Information ...... 2-1

Description of RE-1200/600

Receiver/Exciter .... Bel

Description of PA-1010B,

Power Amplifier/Power

Supply ae at

Section

2

Page

MAINTENANCE INSTRUCTIONS

(cont)

2-4. Description of AC31-1

Antenna . at

2-5. Description

Control Head . 2-2

2-6, Description of AC3i-3

ASW Sensor ......

1. Reference Data

8, Troubleshooting

9. Operational Check . :

1

1

=i

0. Alignment .

1. Inspection

2. Replacement of A

Control Head... 2.2... 2-3

2-18, Replacement of ASB-125/60

Receiver/Exciter. .

2-14. Replacement of ASB-125/60

Power Amplifier/Power

Supply .- ++...

2-15, Replacement of AC31-3

SWR Sensor. . wees BB

2-17. Adjustment: :

2-18. Repair .

2-19. Wiring Diagram | |)

csP-020

Opt Eapt Manual

Foreword

FOREWORD

F-1, PURPOSE AND CONTENT OF THIS

MANUAL. This manual supplements information

‘contained in HMI - Vol 1 and 369D - IPC, and

contains instructions for maintenance of the

ASB-125/60 radio installation, This manual also

contains parts lists for procuring replacement

parts for the radio installation.

F-2, APPLICABILITY, The ASB-125/60 radio

is applicable for use on any Hughes 500D (Model

369D) helicopter.

F-3. COMPATIBILITY OF COMBINED

OPTIONAL EQUIPMENT. For compatibility

information on which optional equipment may or

‘may not be used in combination at the same time,

refer to Section 21, HMI - Vol 1.

F-4, ORGANIZATION OF CONTENTS. The

conterits of this manual are grouped into sections

as outlined in the Table of Contents. Each sec-

tion is organized to provide comprehensive

coverage of entire systems, major equipment

groupings, and major components that are

similar of associated. Procedures for each of

these are presented in sequence as defined in

Section 1, HMI - Vol 1.

F-5, USE OF THIS MANUAL, This manual is

for use by operators of the Model 369D helicopter

equipped with ASB-125/60 radio. Although this

manual is a separate publication, it should be

kept with HMI - Vol 1, HMI - Vol 2, 369D - IPC

and other handbooks listed in Section 1, HMI -

Vol 1 that form the primary information file for

the helicopter.

F-6, RELATED PUBLICATIONS. Reference is

made fo applicable portions of HMI - Vol 1 and

369D - IPC as required to accomplish instructions

contained herein,

F-1, LITERATURE CHANGES AND REVISIONS.

Changes and revisions to contents of this manual

are made as defined in Section 1, HMI - Vol 1.

P-I/F-2

csP-020

Opt Eqpt Manual

Section 1

SECTION 1

ILLUSTRATED PARTS LIST

1-1. SCOPE AND CONTENTS. This illustrated

parts list provides, by means of text (parts lists)

and companion illustrations, a complete parts

definition of the 369H9014¢ Radio (ASB-125/60)

installation, manufactured by Hughes Helicopters,

Culver City, California.

NOTE: The illustrated parts list is organized

and presented in the same manner as the 369D

Series Illustrated Parts List (369D~ IPC). (For

information on use, refer to the 369D - IPC.)

1-2. GROUP ASSEMBLY PARTS LIST. The

parts lists furnish information for procuring

replacement parts for the ASB-125/60 radio

installation and shall not be used for any

other purpose.

1-8, ILLUSTRATIONS. An isometric illustration

is provided for the group assembly parts list. The

illustration is exploded to the extent necessary to

show parts relationship for the complete

ASB-125/60 radio installation,

14

Section 1 Opt Egpt Manual csP-020

Figure 1-1, ASB-125/60 radio installation

csP-020

(SUPPLIED WITH AC3iC)

Opt Egpt Manual Section 1

FIG. & units:

INDEX PaRT DESCRIPTION PER

No. No. ASSY

i | s60H90144-501 RADIO INSTL (ASB-125/60).... « ee 1

369H90144-503 RADIO INSTL (ASB-125/60) (PROVISIONS FOR INSTI) 1

369H90144-505 RADIO INSTL (ASB-128/0) (PROVISIONS FOR INSTL) 1

<1 | 2cT13-15 CIRCUIT BREAKER . . Goceoonens 1

-2 | MS90311-231 2 SWITCH .. 7

-3. | SFSW6C8D-LOIBK| - SCREW 2

-4 | 369H90144-13 @ COVER @:tstee seereeeccrn s: 1

‘AC3IC + ANTENNA SET (NHA 369H90144-501 AND 1

-5 | NONUMBER + SCREW (NHAAC31-2).....eceeeeseeeereeeees | 4

-6 | Aca1-2 : CONTROL HEAD (NHA'ACS1C) ¢ eeeeee cree 1

-7 | NAS173884-2 . RIVET 2

8 | NASIT3884-1 + RIVET 4

-9 | 369H90144-11 {BRACKET .. 1

10 | 369H90144-12 1 BRACKET |: 1

-11 | Msz0426aD3 6 aja Wenoo be ngee cuogsenooreed 6

-12 | PRG 3-1/2 {RECEPTACLE s. 2.0.02) 4

13 | Ms21059-06 1 NUTPLATE . ee 2

-14 | MS21266-1N GROMMET +00. t 1

ASB-125/60 1 COMMUNICATIONS TRANSCEIVER SET

(NHA 369H90144-501) «+--+ esses eves eee 1

15 | 99681/99718 RECEIVER/EXCITER (RE~1200 28V/RE-60 28V)

(NHA ASB-125/60) « sees 1

-16 | Nas517-2-0 p SOREWiteesanetn ec ce eeeet eee: | a

-17 | Ms20143-08 : NUT. es 1

-18 | AN960PDeL @ WASHER eee e ee tee seen eee s ce se se 1

-19 | NAS517-2-0 qTSCREWE Stet sec ences te cess s ee 1

-20 | 10121 + DUST COVER (NHA ASB-125/60). +. + 1

-21 | NAS623-3-2 {SCREW . . Senenenecn dst 2

-22 | NASIT3a84-2 1D RIVET (ALTERNATE PART) veeseee 2

-23 | ANS60PDI0L : WASHER ....... ee 2

-24 | 369H90144-9 {BRACKET oe eee 1

NO NUMBER 2 POWER AMPLIFIER /POWER SUPPLY INSTL

(SEE FIG, 1-2 FOR BRKDN) « benpoogoooc (

NO NUMBER . SWR SENSOR AND ANTENNA INSTL

(SBE FIG. 1-3 FOR BRKDN) «... 0.200. e000 1

369H90144-25, . WIRE HARNESS (RECEIVER POWER) - - 1

uG-88/U ts CONNECTOR seseeseseeeseeeee 2

3691190144-27 + WIRE HARNESS (EXCITER POWER) - +. 1

UG-28/U t+ CONNECTOR «eee eeeeeeeeeenee 1

UG-536/U S CONNECTOR cee cueces ces scne ccs uat 1

369H90144-29 + WIRE HARNESS (SWR SENSOR POWER) eee 1

UG-88/U CONNECTOR @eee ene et crc tee 1

UG-203/U @ CONNECTOR sc guceccaeeeusennaa aces. 1

369H90144-31 + WIRE HARNESS (RECEIVER/EXCITER TO POWER

AMPLIFIER/POWER SUPPLY INTERCONNECTION) - 1

T4996 - . CONNECTOR (SUPPLIED WITH ASB-125/60)... - 1

74726 + + QONNECTOR (SUPPLIED WITH ASB-125/60) -- 1

MPCM20M-1-12 |: . HYTIP .... eee 5

MS25181-1 1) TERMINAL - : : : 2

D121 {| SOLDER SLEEVE «+++. 0- Bho a cen 7

MS25036-153 IL TERMINAL. «+... +s 7 : 2

MS25036-108 +. TERMINAL 2

‘MS25036-103 {1 TERMINAL... eee see ee eee : 2

MS25036-101 11 TERMINAL. «22. c ss esses 1

NO NUMBER ) WIRE HARNESS (CONTROL HEAD To TBio2) *

1-3

Section 1 Opt Bapt Manual cSP-020

Figure 1-2, Power amplifier/power supply installation

csP-020

Opt Eqpt Manual Section 1

Fic. & units

INDEX PART DESCRIPTION PER

NO. NO. assy

1-2- | NONUMBER POWER AMPLIFIER/POWER SUPPLY INSTL

(SEE FIG. 1-1 FORNHA) .... +. -. | REF

<1 | Hseai-7 | COVER oo: ee 1

-2 | MS21043-06 : : ae 5 ||

-3 | ANS6OPDEL : : oe ||

-4 | Ms21043-04 , : ce el 2

5 | Ms24693-3 : : eee | a

6 | Ms27212-1-7 : : |

-7 | Naséo1-8 : 5 | a

-3 | Ms95333-37 : 3 pees | a

-9_ | NAss00-4 ; oe

=10 | Ms35333-36 ; =| 3

-11 | 99683 ) POWER AMPLIFIER /POWER SUPPLY (PAi010B 28V)

(NHA ASB-125/60, FIG. I-1)...... +006 1

-12 | Ms20¢70AD5-3 1/2]. RIVET . Bein eo af 4

-13 | 101798 + SIDE MOUNT PLATE (NHIA’ASB-125/60,” Fic. oo

-14 | NO NUMBER + BUST COVER (SHA ASB-125/60, FIG. 1-1) v.....+. | 2

=15 | Ms21043-08 : | hl

=16 | AN96OPDEL_ : : ee 32

-17 | NAS623-2-4 E SCREW ieee mnt ssc enee | 6

718 | 99916 2 SHOCK MOUNT’ (NitA’ASB-125/60, FIG. | a

369192052 | AMPLIFIER BRACKET INSTL . . ees |

-19 | NAS6O3-7 BS eCREW 4

-20 | AN96oPD10L, [1 WASHER’ 10022007 Bapes ain

“21 | 369H92052-9 DBASE PLATE SITIIIIIIIT 1

-22 | Ms20470AD3 Ge RIVED eee eee 2

-23 | s6oH92052-8 : 1 cup. teers 1

=24 | 369H92052-7 1 cur: eee 1

=25 | 369H92052-15 1 CUP Tee a

-26 | 369H92052-13 oe ae 1

-27 | 369H92052-12 |] Cues iz

+28 | 369H92052-11 oe ae 1

-29 | MS20470AD3 + RIVET.......006 AR

-30 | MS20426aD3, eRVED 8

“31 | MS21059L9K DL NUPPLATE 111011 4

-32 | 369H92052-5 eS BRACKET eee 1

~33 | 969H92052-3 DI OBRACKET 20 1

15

Section 1 ‘Opt Eqpt Manual csP-020

Figure 1-3. SWR sensor and antenna installations

csP-020

Opt Eqpt Manual Section 1

FIG. & UNITS.

INDEX PART DESCRIPTION PER

NO, No. ASSY

1-3- | NO NUMBER ‘SWR SENSOR AND ANTENNA INSTL

(SEE FIG. 1-1 FORNHA)........ee00eeeeeee++ | REF

<1 | Nasoo1-6 | SOREWs eee e ee Been eobapaoocann 4

2 | AN96oD6 + WASHER 22222001 : ‘5 8

-3 | AN96OPDsL. @ WASHERS eee sce es 4

-4 | acsi-3 + SWR SENSOR (NHA AC3iG, Fic. “1-1) | : 1

-5 | MS20470AD3 : RIVET ... oe : | 5

-6 | 369H90144-15 ‘ DOUBLER | 7 ’ 1

-7 | Ms95490-11 + GROMMET) : : 1

-8 | ms20470AD3 : RIVET ... : : 6

-9 | 36919014417 + DOUBLER eee eee 1

-10 | NO NUMBER + SETSCREW (NHA AC3I-I) oe ee 1

-i1 | NASi105~4 ; BOM eset Ress 2

12 | ANS6OPDS16L. : WASHER |: baad 2

-13 | NO NUMBER + BOLT (NHA AC31-1) 21... nao 4

-14 | Msssssa-104 @ WASHERIsca scence cues se 4

369H90144-33 {ANTENNA ASSY (VHA 369H90144"501 AND ~503) | 1

UG-88/U ‘+ CONNECTOR . eens q

‘MS25036-101 7

15 | AC3I-1 1

-16 | MS20470aD3 30

-11 | 369H92051 :

1/18

csP-020

Opt Eqpt Manual

Section 2

SECTION 2

MAINTENANCE

2-1, GENERAL INFORMATION, The ASB-125

and ASB-60 radio installations are 10-channel

(ASB-125) and 6-channel (ASB-60) single side-

band (SSB) and compatible amplitude modulated

(AM) transceiver systems. The radio installa

tion is used for long range voice communications

in the 2 to 18 MHz frequency range. The radio

installation receives +28 vde, at 7.5 amperes

‘maximum, operating power irom the main power

bus through the 15-ampere SSB (RADIO HF) eir-

cuit breaker (CB122) on the instrument panel.

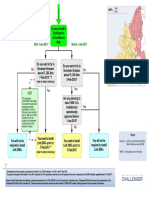

Figure 2-1 shows the wiring diagram for radio

system. Radio installation equipment is supplied

in three configurations: part number 3691190144~

501, the equipment as installed at the factory and

3694190144-503 and -505, the provisions (com-

ponents, wire harness, cables, and hardware)

required for field installation, ‘but without the

radio set (-803, -505) or the antenna set (-505).

‘The major components supplied with each of the

three configurations are listed in table 2-1 and

described in following paragraphs.

NOTE: Refer to the manufacturer's publica

‘ion (table 2-1, HMI - Vol 1) and to Federal

Communications Commission (FCC) regula

tions for information on legal requirements

and limitations applicable to transmitting

SSB and AM signals, Also, note that an inte

grated interphone communication system

(CS) must be installed in the helicopter for

use with the radio installation. The ICS

audio equipment (headset, microphone,

switch and jack assembly, and control unit)

are required for reception and transmission

of voice communications. The electrical

interface of the radio and ICS is shown in

figure 2-1, and the ICS electrical circuitry

is described in the ICS Opt Eqpt Manual

(table 21-1, HMI - Vol 1).

2-2, DESCRIPTION OF RE-1200/600

RECEIVER/EXCITER, The receiver of the

‘RE-1200/600 receiver/exciter (15, fig. 1-1),

part number 99681/99718, receives and demodu-

lates either SSB or AM radio-frequency inputs

and presents the audio to two MIKE RF jacks

and two PHONE RF jacks (369190144) or to the

ICS audio cireuitry (369H90144-501-503, and

-505). ‘The exciter converts voice inputs to

INSTRUCTIONS

low-level SSB or AM outputs which are supplied

to the power amplifier for amplification to broad-

cast power. The receiver/exciter is contained

ina Single unit which is enclosed in a dust cover

and mounted on the instrument panel. The front

panel of the unit contains controls and indicators

for operation of the radio system. Refer to the

manufacturer's publication (table 2-2, HMI -

Vol 1) for a detailed description of the unit.

2-8, DESCRIPTION OF PA-1010B POWER

AMPLIFIER/POWER ‘The power amp-

Iifier of the PA-I010B power amplifier/power

supply (11, fig. 1-2), part number 99683, ampli-

fies the low level signal from the exciter to a

power level of 125 watts peak envelope power

(PEP) for SSB operation, or 30 waits average for

AM operation, and supplies the amplified signal

to the 50-ohm antenna for transmitting. The

power supply converts the 28 vde input to voltages

required for operation of the radio system. The

power amplifier/power supply is contained in a

Single unit which is shock-mounted in the avionics

compartment beneath the pilot's compartment

floor. Refer to the manufacturer's publication

(table 2-2, HMI - Vol 1) for a detailed descrip-

tion of the unit.

2-4, DESCRIPTION OF AC31-1 ANTENNA. The

AC31=1 antenna (15, fig. 1-3) Isa center-loaded

rf whip antenna which may be remotely tuned to

resonance at any operating frequency within its

two-octave tuning range. ‘The antenna consists

of three main sections: the whip, the body, and

the base. The body consists of an outside’fiber-

glass tube and a thin-walled inner tube on which

the tuning coil is wound. A core, composed of

powdered iron and copper tuning’slugs, is moved

within the coil by a de motor and gear drive in

the base tube. The motor drive consists of a

permanent magnet de motor and two nylon reduc~

tion gears turning a threaded rod. A block riding

on the threaded rod is coupled to the tuning slug

by an insulated pushrod. Travel of the block is

limited to seven inches by limit switches which

break the power to relays in the control unit,

and thereby interrupt the power to the motor.

A loop of nichrome wire is mounted so that as

the block moves on the threaded rod 2 shorting

contact. changes the resistance of the circuit.

aa

Section 2 Opt Eqpt Manual csP-020

Table 2-1, Major components of radio installations

Configuration Part No, 369190144

Equipment -501 503 505

Receiver/Exciter* 99681 or 99718

Microphone None

Power Amplifier/Power Supply* 99683

Antenna** AC31-1 ACBIA-L

Control Head** Ac31-2 Ac1-2

SWR Sensor** Ac31-3 AC31-3

*Part of ASB-125/60 Radio Set.

‘**Part of AC31C Antenna Set.

‘The motor drive and coil assembly slides into the

base tube and body of the antenna and is sealed and

anchored by tightening three screws which expand

a rubber gland at the bottom of the base tube.

‘The antenna is tuned by using controls and indica

tors on AC31-2 control head (6, fig. 1-1) to oper-

ate the de motor and position the core. The

antenna is mounted on the right forward underside

of the helicopter beneath the pilot's compartment,

with the whip extending forward. Refer to the

manufacturer's publication (table 2-2, HMI -

Vol 1) for a detailed description of the antenna.

2-5. DESCRIPTION OF AC 31-2 CONTROL,

HEAD, The AC3I-2 control head (6, ig. 1-1)

contains controls, indicators, and circuitry which

enable the operator to accurately tune the antenna

to the frequency of the receiver/exciter. The

control head has a meter which has a FREQ

(érequency) scale for approximate tuning and a

SWR scale for fine tuning. The variable resist-

ance in the antenna forms one arm of a bridge

circuit in the control head. The circuit provides

a reading related to the tuning slug position, so

the meter can be calibrated directly in frequency.

Fine tuning is accomplished by switching to a

‘SWR scale on the same meter. The meter is then

operated by an external SWR sensor placed in the

coax line to the antenna. This sensor has con-

stant sensitivity over the antenna's frequency

range and, once set up for an installation, re~

quires no further adjustments. The FREQ/ANT

switch is set to the frequency of the channel se-

lected for radio receive or transmit operation.

Then, the switch is set to SWR and while operat

ing the radio to transmit a carrier or tone, the

ANT TUNE control is rotated to obtain the lowest

22

level dip of the meter needle, This indicates that

the antenna is tuned to the receiver/exciter fre-

quency. The control head is secured to upper and

lower brackets inside a thermo-plastic cover that

is mounted on the leit side fairing of the instru-

ment panel, Refer to the manufacturer's publica-

tion (table 2-2, HMI ~ Vol 1) for a detailed descrip

tion of the control head,

2-8, DESCRIPTION OF AC31-3 ASW SENSOR.

‘The ACSI-3 ASW sensor (, fig. 1-3) is connected

in series with the antenna cable to measure the

ratio of transmitter power output to reflected

power. ‘The sensor delivers a voltage propor-

tional to this ratio to the SWR meter in the control

head for visual display for use in fine tuning the

antenna. The SWR sensor is mounted with a

doubler to the lower support structure for the

instrument console in the avionics compartment

beneath the pilot's compartment floor. Refer to

‘the manufacturer's publication (table 2-2, HMI -

Vol 1) for detailed description of the SWR sensor.

2-1, REFERENCE DATA. Information on heli-

copier components that interface with the radio

system is in HMI - Vol 1 and 369D - IPC. For

information on associated optional avionics equip-

ment used with the radio system, refer to the

applicable Opt Eqpt Manual for that specific equip-

‘ment (Section 21, HMI - Vol 1).

2-8, TROUBLESHOOTING. If the radio system

does siot operate properly during operational

check or normal use, refer to table 2-2 for aid

in locating the probable trouble and for corrective

action, Refer to the wiring diagram (fg. 2-1)

for aid in troubleshooting. The troubleshooting

csP-020

procedures are based on the assumption that the

radio set is being operated properly, and that all

electrical connectors are connected securely.

If troubleshooting indicates that the trouble is in

the radio set or the antenna set, refer to the

applicable manufacturer's publication (table 2-2,

HMI - Vol 1) for unit troubleshooting and correc

tive action.

NOTE: The radio audio is reproduced by

‘components of the integrated interphone

‘communication system (ICS) which, in itself,

may be the source of audio trouble. When

audio malfunction is encountered, refer to

the ICS Opt Eqpt Manual (table 2-21, HMI -

Vol 1) for troubleshooting procedures for

that portion of audio cireuitry.

2-9, OPERATIONAL CHECK, An operational

check should be periormed any time a malfunction

is suspected and prior to normal operation follow

ing repair. Refer to the manufacturer's publica-

ton (fable 2-2, HMI - Vol 1) for the antenna set

and the radio Set for procedures and perform the

following operational checks:

‘a, Antenna Set

(1) Frequency Scale Adjustment

@) Tuning Motor Speed

Radio Set

(1) Channeling

@) Transmitter Output - AM

(3) ‘Transmitter Output - SSB

() Sidetone Volume

(6) Squeleh

(6) Audio Volume

(1) Clarifier

(@) Interference

2-10, ALIGNMENT. Refer to the manufacturer's

publication (table 2-2, HMI - Vol 1) for align-

ment procedures for the radio set.

2-11, INSPECTION. To aid in determining the

extent of repair and replacement required, in-

spect the components of the radio system in

accordance with FAA AC 43.19-1A, standard

avionies maintenance practices, and the following:

"a. Inspect all components for corrosion and

obvious physical damage.

'b, Inspect the receiver/exciter, power ampli-

ir/power supply, control head, antenna base,

and wire harness for evidence of electrical over-

heating.

‘¢. Inspect the receiver/exciter and control

head for loose or missing control knobs, damaged

or obscured markings, and damaged indicator

glass,

‘d._ Inspect for loose or damaged connectors,

loose or missing mounting hardware, and worn

or frayed wiring insulation,

Opt Eqpt Manual

Section 2

2-12, REPLACEMENT OF AC31-2 CONTROL

HEAD.

CAUTION: Check that all electrical power

is OFF.

a. Remove screws (3, fig. 1-1) and cover (4).

5, Disconnect SWR eable plug from control

head (6).

‘e. Disconnect wires from terminal board TBL

oni control head (6).

d. Remove screws (5) and control head (6).

©. Install replacement control head in reverse

oxtier of removal.

2-13, REPLACEMENT OF ASB-125/60

RECEI TER.

CAUTION: Check that all electrical power

Is OFF.

a, Disconnect three electrical connectors from

réar of receiver/exciter (15, tig. 1-1).

>, Withdraw receiver/exeiter from dust

cover (20).

‘¢. Install replacement receiver/exeiter in

reverse order of removal. See figure 2-1 for

wiring and cable connections.

2-14. REPLACEMENT OF ASB-125/60 POWER

AMPLIFIER/POWER SUPPLY.

CAUTION: Check that all electrical power

isOFF.

a, Gain access to avionics compartment be-

neath pilots compartment floor.

b, Disconnect four electrical connectors from

rear of power amplifier/power supply (11, fig. 1-2).

‘¢. Remove wing nut and plate from shock

mount (18), and remove power amplifier/power

supply (11) along with attached dust cover (14) and

side mount plate (13).

d. Remove screws (7, 9) and washers (8, 10),

and remove dust cover (14).

‘e._ Install replacement power amplitier/power

supply in reverse order of removal. See figure

2-1 for wiring and cable connections.

2-15, REPLACEMENT OF AC31-3 SWR

SENSOR ree

CAUTION: Check that all electrical power

Is OFF.

a. Gain access to the avionics compartment

beneath the pilot's compartment floor.

'b, Disconnect two electrical connectors from

SWR sensor (4, fig. 1-3).

2-3

Section 2

‘Symptom

SSB circuit breaker trips.

SSB circuit breaker trips

following reset.

Control head frequency

meter pointer does not

move during coarse

tuning.

Control head frequency

meter pointer has exces-

sive overshoot during

fine tuning,

Control head SWR meter

does not dip during fine

tuning.

Radio transmission weak

Audio weak at full volume,

ICS 0.k.

Radio transmitter and

receiver in-operative,

ICS 0.k.

Opt Eapt Manual

Table 2-2, Troubleshooting

Probable Trouble

Momentary overload.

Overload or short in power

amplifier/power supply or

receiver/exciter.

Short in wire hamess.

Defective antenna tuning

mechanism.

Defective meter.

No 26 vde present at

antenna,

‘Antenna fuse open.

Antenna motor speed

excessive.

Radio not transmitting AM

signal.

Defective antenna tuning

mechanism.

Defective SWR sensor of

meter.

Exciter or power amplifier

out of adjustment.

Defective exciter or power

amplifier.

Receiver out of adjustment.

Detective power supply.

Defective wire harness.

csP-020

Corrective Action

Reset breaker to ON.

Repair or replace faulty

unit,

Repair or replace wire

harness.

Repair or replace antenna,

Repair or replace control

head.

‘Trace power cireuit and

repair or replace as

required.

Replace fuse.

Adjust antenna motor speed.

Switch radio to AM mode.

Repair or replace antenna,

Repair or replace SWR

sensor or control head.

Align or adjust as

required.

Repair or replace defec-

tive unit.

Align or adjust receiver.

Repaif or replace power

supply.

Repair or replace wire

harness.

csP-020

Disconnect two wires from terminal board

on SWR sensor (4).

d, Remove screws (1) and washers (2, 3), and

remove SWR sensor (4).

‘e. Install replacement SWR sensor in reverse

order of removal, See figure 2-1 for wiring and

cable connections.

2-16, REPLACEMENT OF AC31-1 ANTENN.

CAUTION: Check that all electrical power

is OFF.

a, Gain access to the avionics compartment

beneath the pilot's compartment floor.

'B. Remove cover (1, fig. 1-2) from terminal

board TB102,

¢. Disconnect seven wires of antenna cable

from TB102.

d. Disconnect antenna cable connector from

SWR sensor (4, fig. 1-2).

e. Remove grommet (7) and pall antenna

cables through hole in doubler (8).

{, Remove bolts (13), eashers (14), clamp

halves, and antenna (15).

'g. Install replacement antenna in reverse

order of removal. See figure 2-1 for wiring

and cable connections.

Opt Bapt Manual

Section 2

NOTE: Add washers (14) as required to

‘HIT gap between clamp halves before

tightening bolts (13). Tighten setscrew (10)

to ensure electrical contact between clamp

and antenna.

2-17. ADJUSTMENT. Refer to the manufac

turer's publication (lable 2-2, HMI - Vol 1) for

the radio set and the antenna set for adjustment

procedures.

2-18, REPAIR, Refer to the manufacturer's

publication (table 2-2, HMI - Vol 1) for the

radio set and the antenna set for periodic main-

tenance and repair procedures. Replace defec-

tive cables, wiring, and attaching and mounting

parts with new parts.

2-19, WIRING DIAGRAM. See figure 2-1 for

the radio system interconnecting diagram.

Refer to the manufacturer's publication

(table 2-2, HMI ~ Vol 1) for the radio set

and the antenna set for interval schematics

and wiring diagrams for components of the

sets.

2-5/2-6

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Flight Controls ReviewDocument8 pagesFlight Controls ReviewromixrayzenNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- MC 10230573 0001Document27 pagesMC 10230573 0001romixrayzenNo ratings yet

- MC 10214482 0001Document8 pagesMC 10214482 0001romixrayzenNo ratings yet

- Link2000 DecisionTree 2012 12bDocument1 pageLink2000 DecisionTree 2012 12bromixrayzenNo ratings yet

- Data Link Services Workshop Brussels 17june2014Document47 pagesData Link Services Workshop Brussels 17june2014romixrayzenNo ratings yet

- SA3644SWDocument2 pagesSA3644SWromixrayzenNo ratings yet

- 05 Диагностика неисправностейDocument12 pages05 Диагностика неисправностейromixrayzenNo ratings yet

- Active Service Bulletins With Instructions For Continued AirworthinessDocument1 pageActive Service Bulletins With Instructions For Continued AirworthinessromixrayzenNo ratings yet

- csp-023 I0r0Document18 pagescsp-023 I0r0romixrayzenNo ratings yet

- AW600 23 2387 - Rev4Document7 pagesAW600 23 2387 - Rev4romixrayzenNo ratings yet

- 02 Техническое описаниеDocument20 pages02 Техническое описаниеromixrayzenNo ratings yet

- csp-015 I0r0Document20 pagescsp-015 I0r0romixrayzenNo ratings yet

- Flight Instruments Review: Pitot-Static SystemDocument5 pagesFlight Instruments Review: Pitot-Static SystemromixrayzenNo ratings yet

- csp-019 I0r0Document16 pagescsp-019 I0r0romixrayzenNo ratings yet

- csp-089 I0r0Document24 pagescsp-089 I0r0romixrayzenNo ratings yet

- Fire Protection Review: Fire Detection and ExtinguishingDocument7 pagesFire Protection Review: Fire Detection and ExtinguishingromixrayzenNo ratings yet

- Landing Gear and Brakes ReviewDocument8 pagesLanding Gear and Brakes ReviewromixrayzenNo ratings yet

- Auxiliary Power Unit (Apu) Systems ReviewDocument5 pagesAuxiliary Power Unit (Apu) Systems Reviewromixrayzen100% (1)