Professional Documents

Culture Documents

Spe-0713-0094-Jpt - Measured Plunger Fall Velocity Used To Calibrate New Fall Vel Model

Spe-0713-0094-Jpt - Measured Plunger Fall Velocity Used To Calibrate New Fall Vel Model

Uploaded by

ArsalanCopyright:

Available Formats

You might also like

- 2024 BSTD Grade 12 ScopeDocument7 pages2024 BSTD Grade 12 ScopeAquanero SA100% (1)

- Surge Analysis ReportDocument22 pagesSurge Analysis ReportAh Leng LauNo ratings yet

- 1965, Foss e Gaul PDFDocument17 pages1965, Foss e Gaul PDFJoão GadelhaNo ratings yet

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- TRG Module PPT - Flow MeasurementsDocument30 pagesTRG Module PPT - Flow Measurementspawan deepNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Trico J P PDFDocument207 pagesTrico J P PDFsoomro99100% (2)

- Bollard PullDocument10 pagesBollard PullKarem Lastarria Monardes100% (1)

- Wellhead and Christmas Tree Components, Types, Functions and MoreDocument143 pagesWellhead and Christmas Tree Components, Types, Functions and MoreMohamed Abozeima98% (42)

- 05 - Andersen - Choke Collapse SimulationsDocument13 pages05 - Andersen - Choke Collapse Simulations903352No ratings yet

- InfoClim & Climate Risk Management, Crop Calendar, Far North Region of CameroonDocument3 pagesInfoClim & Climate Risk Management, Crop Calendar, Far North Region of CameroonabdoulayNo ratings yet

- Cobbett 1982Document8 pagesCobbett 1982GERARDO TORRES RUIZNo ratings yet

- 29!541 Transient Aspects of Unloading Oil and Gas Wells With Coiled TubingDocument6 pages29!541 Transient Aspects of Unloading Oil and Gas Wells With Coiled TubingWaode GabriellaNo ratings yet

- WC Shallow GasDocument26 pagesWC Shallow GasRicardo Hurtado HernándezNo ratings yet

- Spe 29541 MsDocument6 pagesSpe 29541 MssariNo ratings yet

- 8.1 Hole CleaningDocument45 pages8.1 Hole CleaningJesús Leyva100% (1)

- !3..sub SeaDocument44 pages!3..sub Seaanugrah.setiaoneNo ratings yet

- Spe 29541 MsDocument6 pagesSpe 29541 Msmetta804No ratings yet

- Ss 03009Document4 pagesSs 03009hesam asgariNo ratings yet

- DF9 - Tubing Performance EvaluationDocument7 pagesDF9 - Tubing Performance Evaluationadnan0307No ratings yet

- Artificial Lift Systems: Matthew AmaoDocument56 pagesArtificial Lift Systems: Matthew AmaoYusrohDarmantoroNo ratings yet

- Model 210 Digital Electro-Hydraulic Set StopDocument4 pagesModel 210 Digital Electro-Hydraulic Set StopykozeNo ratings yet

- WellheadsDocument134 pagesWellheadsdana mohammedNo ratings yet

- M Cavitation1Document8 pagesM Cavitation1Ade RizkiNo ratings yet

- Pages From Centrifugal Pumps HandbookDocument4 pagesPages From Centrifugal Pumps HandbookSHINo ratings yet

- 210 Control Valve NewDocument4 pages210 Control Valve Newabdulhayee199811No ratings yet

- 01-Wellhead - Rev-01 (FD)Document174 pages01-Wellhead - Rev-01 (FD)Verda Yunita100% (1)

- Flooding, Dewatering and VentingDocument5 pagesFlooding, Dewatering and VentingAngel NgoNo ratings yet

- The New Generation of Roto Drum Oil Skimmer 1995Document3 pagesThe New Generation of Roto Drum Oil Skimmer 1995arondaniel ocampoNo ratings yet

- Crystallization In: Four With Usually Into The If by in VacuumDocument1 pageCrystallization In: Four With Usually Into The If by in VacuumMegatantri Sekar HapsariNo ratings yet

- ASME Paper 82-PET-12Document4 pagesASME Paper 82-PET-12Hadi VeyseNo ratings yet

- Solución 5 - Carga de LiquidosDocument7 pagesSolución 5 - Carga de Liquidosmanuel cabarcasNo ratings yet

- Bombas de Desagüe Sumergibles SJ 150-400Document2 pagesBombas de Desagüe Sumergibles SJ 150-400Dennis MedinaNo ratings yet

- 022 MDT Sampling Training PDFDocument6 pages022 MDT Sampling Training PDFミス・ ナディアNo ratings yet

- Day 2.3-ESPDocument221 pagesDay 2.3-ESPAhmed ElgharbawyNo ratings yet

- Hidrolika Saluran TerbukaDocument58 pagesHidrolika Saluran TerbukaArif Husain SidikNo ratings yet

- Content Report Open ChannelDocument22 pagesContent Report Open ChannelAmirul HusniNo ratings yet

- FCC Catalyst Fluidization: Theory & PracticeDocument22 pagesFCC Catalyst Fluidization: Theory & Practiceccnew3000100% (1)

- CR 0701 CH 10Document13 pagesCR 0701 CH 10Rıfat BingülNo ratings yet

- Underbalanced Drilling and Workover Rev 2-5Document225 pagesUnderbalanced Drilling and Workover Rev 2-5Nassim NassimNo ratings yet

- Spe 2104 PaDocument7 pagesSpe 2104 Paomkar6142No ratings yet

- High Volume Pumping With Sucker Rods (1968) PDFDocument7 pagesHigh Volume Pumping With Sucker Rods (1968) PDFMuhammad Yunaldi PrayogaNo ratings yet

- Prince Hydraulics Wolverine Adjustable Flow Control Valve Offered by PRC Industrial SupplyDocument1 pagePrince Hydraulics Wolverine Adjustable Flow Control Valve Offered by PRC Industrial SupplyPRC Industrial SupplyNo ratings yet

- V001t01a071 91 GT 194Document10 pagesV001t01a071 91 GT 194Uzair BukhariNo ratings yet

- Crude Unit Startup Consequences of High Liquid LevelDocument4 pagesCrude Unit Startup Consequences of High Liquid LevelAlessio ScarabelliNo ratings yet

- Lecture-5 Drilling EngineeringDocument23 pagesLecture-5 Drilling Engineeringحيدر بادي - Haider BadiNo ratings yet

- Classification of Water Turbines: Impulse vs. Reaction TurbineDocument2 pagesClassification of Water Turbines: Impulse vs. Reaction TurbineRohit DiwakarNo ratings yet

- Equivalent Length - Rules of Thumb For Chemical EngineersDocument4 pagesEquivalent Length - Rules of Thumb For Chemical EngineersMohammad ahsan mirNo ratings yet

- Steam Turbine Water WashingDocument1 pageSteam Turbine Water WashingsoumitrabanNo ratings yet

- Mueller - Mixing BasicsDocument4 pagesMueller - Mixing BasicsVasilis PolykarpidisNo ratings yet

- Logan 120-Ton Power Swivel - Logan Oil ToolsDocument2 pagesLogan 120-Ton Power Swivel - Logan Oil Toolsanyaa426No ratings yet

- Pertemuan12 ESP 04042016 13042016Document192 pagesPertemuan12 ESP 04042016 13042016Priozky Pratama Purba100% (1)

- Pages From Design of Fluid Systems-Hook-Ups, Spirax Sarco 2Document1 pagePages From Design of Fluid Systems-Hook-Ups, Spirax Sarco 2Ujwal KhandokarNo ratings yet

- Fluid Pipe InstallationDocument1 pageFluid Pipe InstallationKrishna PATELNo ratings yet

- Carrying Capacity of Drilling MudsDocument10 pagesCarrying Capacity of Drilling MudsHai LinhNo ratings yet

- Artificial LiftDocument29 pagesArtificial LiftDivyanshu DkNo ratings yet

- Chapter 4-DDocument14 pagesChapter 4-DMahrouz MadoNo ratings yet

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- A Collaborative Study On DFIT InterpretationDocument39 pagesA Collaborative Study On DFIT InterpretationArsalanNo ratings yet

- 2002 Deliq Forum V1 3.5 PlungersDocument21 pages2002 Deliq Forum V1 3.5 PlungersArsalanNo ratings yet

- US6634426 - 2003 - Plunger Lift AnalysisDocument54 pagesUS6634426 - 2003 - Plunger Lift AnalysisArsalanNo ratings yet

- Spe-84215-Ms - Frac FluidDocument8 pagesSpe-84215-Ms - Frac FluidArsalanNo ratings yet

- Health Education, Advocacy and Community MobilisationDocument162 pagesHealth Education, Advocacy and Community Mobilisationأحمد خيري التميميNo ratings yet

- En DVC 2018 35Document18 pagesEn DVC 2018 35Lina María CañónNo ratings yet

- 21TH PRO Invitation For Schools - DepEd BataanDocument2 pages21TH PRO Invitation For Schools - DepEd BataanFranz Lorenz FuentesNo ratings yet

- Space Law Seminar BharatDocument26 pagesSpace Law Seminar BharatBharat JoshiNo ratings yet

- Types of Communication Session 7Document4 pagesTypes of Communication Session 7supratimloveNo ratings yet

- 4.2penjaminan Mutu Sediaan Farmasi - Oky YudiswaraDocument29 pages4.2penjaminan Mutu Sediaan Farmasi - Oky YudiswaraMUNIFRIZALNo ratings yet

- Cambridge Checkpoint Science English Language Skills Teachers SupportDocument14 pagesCambridge Checkpoint Science English Language Skills Teachers SupportDanilo Pereira GonçalvesNo ratings yet

- SodapdfDocument47 pagesSodapdfYolanda LegaspiNo ratings yet

- CH 08Document21 pagesCH 08Juan PepeNo ratings yet

- Mechanism and Compensation of Measurement Error Induced by Thermal Deformation of Digital Camera in Photo MechanicsDocument21 pagesMechanism and Compensation of Measurement Error Induced by Thermal Deformation of Digital Camera in Photo MechanicsTestingAccNo ratings yet

- Unit 4-From Recusrsive EstimationDocument17 pagesUnit 4-From Recusrsive EstimationTufail DarNo ratings yet

- SpaceLogic Glass Touch Panels - LSSMTH07NSDocument2 pagesSpaceLogic Glass Touch Panels - LSSMTH07NSrohan modkeNo ratings yet

- Review Session5 Hoop Tension (4 Slides)Document5 pagesReview Session5 Hoop Tension (4 Slides)Benjie MorenoNo ratings yet

- The Chi-Square Test: Statistics and Research DesignDocument2 pagesThe Chi-Square Test: Statistics and Research DesignTommy Winahyu PuriNo ratings yet

- Reineck (1980) Fluvial EnvironmentDocument58 pagesReineck (1980) Fluvial EnvironmentJuan JoseNo ratings yet

- Sip Math DeptDocument4 pagesSip Math DeptJERRYCO GARCIANo ratings yet

- 1 Place ValueDocument4 pages1 Place ValueKNAH TutoringNo ratings yet

- Problem Set in Fluid MechanicsDocument8 pagesProblem Set in Fluid Mechanicschristine Jade AtilanoNo ratings yet

- Calibration of Measuring Network of Leakage Current Tester by High Frequency Current SourceDocument2 pagesCalibration of Measuring Network of Leakage Current Tester by High Frequency Current SourceSAKKARIN TURATHAMNo ratings yet

- Cu THHNDocument2 pagesCu THHNdekadimahendra03No ratings yet

- Format For A Research PaperDocument2 pagesFormat For A Research PaperVishnu VenugopalNo ratings yet

- Department of Mahtematics and Statistics University of Jaffna LEVEL 1S (2018/2019) Statistics For Computing I - CSC105S3 Tutorial - 02Document2 pagesDepartment of Mahtematics and Statistics University of Jaffna LEVEL 1S (2018/2019) Statistics For Computing I - CSC105S3 Tutorial - 02Michael JhonshonNo ratings yet

- Hydrins: Navigation-Grade INS For Hydrographic SurveyDocument2 pagesHydrins: Navigation-Grade INS For Hydrographic SurveyGonzalo OpazoNo ratings yet

- Use Common and Socially Acceptable Expressions (E.g., Greetings, Leave-Taking)Document5 pagesUse Common and Socially Acceptable Expressions (E.g., Greetings, Leave-Taking)Mary Grace De QuirozNo ratings yet

- Syed Asad AbbasDocument1 pageSyed Asad AbbasAsad AbbasNo ratings yet

- Y4 Module 2 Performing Duties and Functions of An Enterprise OwnerDocument19 pagesY4 Module 2 Performing Duties and Functions of An Enterprise Owneranecita rodriguezNo ratings yet

- 701P50924 FF Accxes Drivers Client Tools EN PDFDocument28 pages701P50924 FF Accxes Drivers Client Tools EN PDFМихаил ВалерьевичNo ratings yet

- Math A Module18Document18 pagesMath A Module18Zen Zhyree CorpuzNo ratings yet

Spe-0713-0094-Jpt - Measured Plunger Fall Velocity Used To Calibrate New Fall Vel Model

Spe-0713-0094-Jpt - Measured Plunger Fall Velocity Used To Calibrate New Fall Vel Model

Uploaded by

ArsalanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Spe-0713-0094-Jpt - Measured Plunger Fall Velocity Used To Calibrate New Fall Vel Model

Spe-0713-0094-Jpt - Measured Plunger Fall Velocity Used To Calibrate New Fall Vel Model

Uploaded by

ArsalanCopyright:

Available Formats

Measured Plunger-Fall Velocity Used

To Calibrate New Fall-Velocity Model

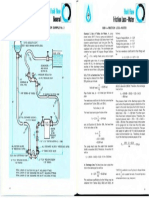

F all velocities for various plungers

have been measured under

many different field and simulator Slower 120

100

Falling Through Gas

Gradually Slows From

0

conditions. A new theoretical 240 to 135 ft/min −1,600

Plunger Fall Velocity, ft/min

140

plunger-fall-velocity model uses a

Downloaded from http://onepetro.org/JPT/article-pdf/65/07/94/2211156/spe-0713-0094-jpt.pdf/1 by United Energy Pakistan Ltd, Qaiser Hafeez on 30 June 2022

Depth to Plunger, ft

specific pressure and temperature for 160

−3,200

calibration. The model can then be

180

used to calculate fall velocity at other

conditions for the same plunger or can 200

−4,800

be used to show how changing a feature Falling

Normal Fall-Velocity Profile

such as plunger weight can affect fall 220 Through −6,400

(1) Tubing Is OK

velocity. (2) Liquid in Bottom Liquid

Faster 240

260 Bottom of Tubing−7773.00 ft Plunger Hits Liquid−7313.59 ft −8,000

0.000 8.691 17.361 26.042 34.722 43.403 52.083 60.764

Introduction

Conventional plunger lift is a low-cost Fig. 1—Plunger depth and plunger fall velocity for a typical plunger well.

method for lifting liquids (water, con-

densate, or oil) from gas and oil wells. line, and the high-pressure gas in the gaseous liquid column at the bottom of

Lifting liquids from the well is achieved casing begins to decrease by expanding the well. Processing this acoustic signal

by closing a surface valve to store ener- to fill the tubing, displacing the plunger allows the depth and fall velocity of the

gy in the well during a shut-in time pe- and most of the liquid above the plunger falling plunger to be determined.

riod, which is followed by opening the to the surface. This plunger-operation Fig. 1 shows the plunger-fall veloc-

surface valve for a time period so liq- cycle is repeated continually to produce ity decreasing smoothly as a function of

uids are unloaded as gas flows to the the well. time. Although there seems to be some

surface. During shut-in, the gas flow An operator can produce from the scatter of velocities on the plunger-

is stopped when the controller clos- well efficiently if the plunger’s fall rate velocity trace, note that the left ver-

es the surface motor valve. The plung- and location and the time taken to fall tical scale is amplified and that the

er leaves the lubricator to begin its fall to the liquid and bottom of the tubing general trend of the velocity is to con-

from the surface because of a tubing- are known accurately. The distance to sistently decrease as time (plunger

pressure increase that is caused by clos- the plunger and the rate of fall can be depth) increases.

ing the motor valve or begun when the determined by examining the acoustic

plunger is released from a catcher. The signal created by a falling plunger. The Theoretical General Plunger-

plunger falls through gas until entering acoustic pulse generated at the tubing- Fall-Velocity Model

the accumulated liquid at the bottom of collar recess travels through the gas to A new theoretical general plunger-fall

the tubing. Once the plunger is on bot- the surface to be detected by a micro- velocity model has been developed that

tom and sufficient unloading energy is phone, and the change in pressure can can be used to predict plunger-fall ve-

stored, the controller opens the surface be detected by a tubing pressure trans- locity in a well at any pressure and tem-

valve into the lower-pressure flowline. ducer. These acoustic pulses are normal- perature condition. If the fall velocity

High-pressure gas in the tubing above ly detected as a plunger falls down the for a particular plunger is measured in

the liquid column flows down the flow- relatively dry tubing interior above the a well at a specific pressure and tem-

perature, then the general model is

used to determine the calibration con-

This article, written by JPT Technology Editor Chris Carpenter, contains highlights

stant C. Using a measured fall velocity

of paper SPE 164495, “Measured Plunger-Fall Velocity Used To Calibrate New at a known pressure and temperature

Fall-Velocity Model,” by O.L. Rowlan and J. McCoy, Echometer Company; J. Lea, to calibrate the general model enables

PLTech; and R. Nadkrynechny and C. Cepuch, T-RAM Canada, prepared for the the general plunger-fall-velocity model

2013 SPE Production and Operations Symposium, Oklahoma City, Oklahoma, USA, to calculate the plunger fall velocity at

23–26 March. The paper has not been peer reviewed. other pressures and temperatures.

For a limited time, the complete paper is free to SPE members at www.spe.org/jpt.

94 JPT • JULY 2013

Elapsed Time, minutes stick the plunger is a fluid level shot

0 25 50 75 100 125 150 down the tubing. The pressure wave

0 240 from the gas gun discharged at the sur-

Fall Velocity for Each Cycle

face travels down the tubing and often

255.8 ft/min 163.0 Tbg-psig

will exert sufficient force to free a stuck

–100 319.8 ft/min 130.7 Tbg-psig 200

355.9 ft/min 102.0 Tbg-psig

plunger. When the plunger gets stuck

394.8 ft/min 73.3 Tbg-psig and does not fall to the bottom, dam-

Tubing Presure, psig

–200 478.1 ft/min 41.6 Tbg-psig 160 age to the surface equipment is possible.

Fall Velocity, ft/min

Tubing Pressure-psig Dangerous conditions can be avoided

–300 120

when such problems are identified.

Fall Velocity of Different

–400 80 Types of Plungers

Downloaded from http://onepetro.org/JPT/article-pdf/65/07/94/2211156/spe-0713-0094-jpt.pdf/1 by United Energy Pakistan Ltd, Qaiser Hafeez on 30 June 2022

As the diameter of the plunger increas-

–500 40 es, the fall velocity of the same type

of plunger decreases. As the diameter

Dual-Pad Plunger Fail Velocity Faster 1.75 ft/min

of a plunger increases, the weight of

–600 With Each 1-psi Decrease in Pressure 0

the plunger increases. Friction between

Fig. 2—Plunger-fall velocity increases as tubing pressure decreases. the plunger and the tubing increases as

the diameter increases, because the in-

Two equations were considered to severely restricted, so for each cycle, crease in diameter causes a larger sur-

be representative of the conditions that the well pressure decreased because the face area of the plunger to contact the

control the plunger fall through the gas gas inflow did not replace the gas used tubing. The cross-sectional area of the

in the tubing. For the first, the “drag to unload the well. The average tub- plunger increases by the square of the

model,” the plunger weight is set equal ing pressure for the five different tests diameter, and less differential pressure

to the drag force acting on the plung- continually decreased. For this padded is required to resist the fall of the plung-

er. At a certain pressure, temperature, plunger, there is an almost linear 1.75-ft/ er. The larger-diameter plunger increas-

and gas gravity, the density of the gas min increase in the fall velocity per each es the friction, and the larger area in-

is determined. In the “orifice model,” 1-psi drop in tubing pressure. When the creases the force from the differential

the plunger/tubing seal acts as a choke, pressure is low, the p lunger-fall velocity pressure applied to the plunger cross-

allowing a specific amount of gas to be is much faster than is considered nor- sectional area, which results in slower

pushed past the plunger as the plunger mal, but when the pressure is higher, fall speed. The presence of pads on a

falls through the tubing. the plunger-fall velocity is measured at plunger results in slower fall velocities

From field measurements, it has a rate that is considered normal. when compared with solid plungers of

been observed that all plungers fall Slow fall velocities caused by high the same diameter. The slower fall ve-

slower at higher pressure and faster at pressure also have an effect on plungers locity of the pad plunger is caused by

lower pressure. Field observations dur- that are considered to fall fast, such as the better seal and the additional fric-

ing shut-in confirm the general-model the dual-pad bypass type of plunger. In tion between the tubing and plunger

predictions of plunger-fall-velocity general, the fall velocity through gassy caused by the springs behind the pads.

slowing that is inversely proportional fluid is approximately 40 ft/min. But If rubber or neoprene is placed between

to the square root of the density of the when a well is treated with surfactant, a set of pads and the plunger body, the

gas through which the plunger is falling. the gassy fluid is less dense, and the improved seal results in a much slower

plunger-fall velocity is near 80 ft/min. plunger fall.

Plunger-Fall-Velocity Function When a plunger-lifted well is treated The bypass type of plunger has a

of Gas or Fluid Density with surfactant, the gaseous liquid col- valve that opens to reduce restriction

The data from field testing usually show umn may stand three times taller than of gas flow past the plunger. The by-

that the plunger fall velocity decreases a normal untreated gaseous liquid col- pass creates a large opening through the

as the plunger gets closer to the bottom umn for the same differential tubing and plunger, and this large opening allows

of the tubing. This behavior agrees with casing pressure. The plunger falls ap- fluids to flow with less restriction past

the general plunger-fall model because proximately twice as fast, and the height the plunger. The ability to bypass fluids

the increasing pressure increases the of the surfactant-treated gaseous liquid through the plunger results in higher

gas density inside the tubing. column is approximately three times fall velocity.

Fig. 2 shows the measured fall ve- higher. When a plunger-lifted well is Brush plungers have the largest

locity for the same dual-pad plunger in treated with surfactant, additional shut- range of fall velocities for any type of

the same 2.375-in. tubing string in the in time may be required to allow time for plunger. A new brush with soft bristles

same gas well for five consecutive shut- the plunger to fall to the bottom. that fill the area between the plung-

in time periods. Gas flow into the well- If the plunger becomes stuck in the er and tubing will exhibit a very slow

bore from the damaged formation was tubing, all that may be required to un- fall velocity (and therefore an efficient

96 JPT • JULY 2013

plunger). Other brush plungers have stiff nylon bristles that Conclusions

do not contact the tubing wall; this type of brush plunger falls Knowing the plunger-fall velocity for specific well conditions

much faster, having a poorer seal. A worn-out brush that ap- will ensure that the plunger will reach the bottom of the tubing

pears to be smooth and shiny because of paraffin clogging the by the end of the shut-in period. Use of an acoustic instrument

bristles, or that has worn bristles that do not contact the tub- is an effective method to determine the fall velocity during the

ing, can fall very fast. If a worn plunger is replaced, then the shut-in time period and provides a calibration point to enter

resulting increase in gas production can quickly pay off the into the general fall-velocity model. Maximum production

cost of the new plunger. from the plunger-lift installation will be obtained by having

Solid types of plungers that have spiral grooves at the the shortest possible shut-in time equal to the time required

top and bottom of the plunger spin as they fall during shut- for the plunger to reach bottom, as long as sufficient casing

in. This spinning motion of the plunger results in slower pressure exists to return the plunger and accumulated liquid

fall velocities. to the surface. JPT

Downloaded from http://onepetro.org/JPT/article-pdf/65/07/94/2211156/spe-0713-0094-jpt.pdf/1 by United Energy Pakistan Ltd, Qaiser Hafeez on 30 June 2022

JPT • JULY 2013

You might also like

- 2024 BSTD Grade 12 ScopeDocument7 pages2024 BSTD Grade 12 ScopeAquanero SA100% (1)

- Surge Analysis ReportDocument22 pagesSurge Analysis ReportAh Leng LauNo ratings yet

- 1965, Foss e Gaul PDFDocument17 pages1965, Foss e Gaul PDFJoão GadelhaNo ratings yet

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- TRG Module PPT - Flow MeasurementsDocument30 pagesTRG Module PPT - Flow Measurementspawan deepNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Trico J P PDFDocument207 pagesTrico J P PDFsoomro99100% (2)

- Bollard PullDocument10 pagesBollard PullKarem Lastarria Monardes100% (1)

- Wellhead and Christmas Tree Components, Types, Functions and MoreDocument143 pagesWellhead and Christmas Tree Components, Types, Functions and MoreMohamed Abozeima98% (42)

- 05 - Andersen - Choke Collapse SimulationsDocument13 pages05 - Andersen - Choke Collapse Simulations903352No ratings yet

- InfoClim & Climate Risk Management, Crop Calendar, Far North Region of CameroonDocument3 pagesInfoClim & Climate Risk Management, Crop Calendar, Far North Region of CameroonabdoulayNo ratings yet

- Cobbett 1982Document8 pagesCobbett 1982GERARDO TORRES RUIZNo ratings yet

- 29!541 Transient Aspects of Unloading Oil and Gas Wells With Coiled TubingDocument6 pages29!541 Transient Aspects of Unloading Oil and Gas Wells With Coiled TubingWaode GabriellaNo ratings yet

- WC Shallow GasDocument26 pagesWC Shallow GasRicardo Hurtado HernándezNo ratings yet

- Spe 29541 MsDocument6 pagesSpe 29541 MssariNo ratings yet

- 8.1 Hole CleaningDocument45 pages8.1 Hole CleaningJesús Leyva100% (1)

- !3..sub SeaDocument44 pages!3..sub Seaanugrah.setiaoneNo ratings yet

- Spe 29541 MsDocument6 pagesSpe 29541 Msmetta804No ratings yet

- Ss 03009Document4 pagesSs 03009hesam asgariNo ratings yet

- DF9 - Tubing Performance EvaluationDocument7 pagesDF9 - Tubing Performance Evaluationadnan0307No ratings yet

- Artificial Lift Systems: Matthew AmaoDocument56 pagesArtificial Lift Systems: Matthew AmaoYusrohDarmantoroNo ratings yet

- Model 210 Digital Electro-Hydraulic Set StopDocument4 pagesModel 210 Digital Electro-Hydraulic Set StopykozeNo ratings yet

- WellheadsDocument134 pagesWellheadsdana mohammedNo ratings yet

- M Cavitation1Document8 pagesM Cavitation1Ade RizkiNo ratings yet

- Pages From Centrifugal Pumps HandbookDocument4 pagesPages From Centrifugal Pumps HandbookSHINo ratings yet

- 210 Control Valve NewDocument4 pages210 Control Valve Newabdulhayee199811No ratings yet

- 01-Wellhead - Rev-01 (FD)Document174 pages01-Wellhead - Rev-01 (FD)Verda Yunita100% (1)

- Flooding, Dewatering and VentingDocument5 pagesFlooding, Dewatering and VentingAngel NgoNo ratings yet

- The New Generation of Roto Drum Oil Skimmer 1995Document3 pagesThe New Generation of Roto Drum Oil Skimmer 1995arondaniel ocampoNo ratings yet

- Crystallization In: Four With Usually Into The If by in VacuumDocument1 pageCrystallization In: Four With Usually Into The If by in VacuumMegatantri Sekar HapsariNo ratings yet

- ASME Paper 82-PET-12Document4 pagesASME Paper 82-PET-12Hadi VeyseNo ratings yet

- Solución 5 - Carga de LiquidosDocument7 pagesSolución 5 - Carga de Liquidosmanuel cabarcasNo ratings yet

- Bombas de Desagüe Sumergibles SJ 150-400Document2 pagesBombas de Desagüe Sumergibles SJ 150-400Dennis MedinaNo ratings yet

- 022 MDT Sampling Training PDFDocument6 pages022 MDT Sampling Training PDFミス・ ナディアNo ratings yet

- Day 2.3-ESPDocument221 pagesDay 2.3-ESPAhmed ElgharbawyNo ratings yet

- Hidrolika Saluran TerbukaDocument58 pagesHidrolika Saluran TerbukaArif Husain SidikNo ratings yet

- Content Report Open ChannelDocument22 pagesContent Report Open ChannelAmirul HusniNo ratings yet

- FCC Catalyst Fluidization: Theory & PracticeDocument22 pagesFCC Catalyst Fluidization: Theory & Practiceccnew3000100% (1)

- CR 0701 CH 10Document13 pagesCR 0701 CH 10Rıfat BingülNo ratings yet

- Underbalanced Drilling and Workover Rev 2-5Document225 pagesUnderbalanced Drilling and Workover Rev 2-5Nassim NassimNo ratings yet

- Spe 2104 PaDocument7 pagesSpe 2104 Paomkar6142No ratings yet

- High Volume Pumping With Sucker Rods (1968) PDFDocument7 pagesHigh Volume Pumping With Sucker Rods (1968) PDFMuhammad Yunaldi PrayogaNo ratings yet

- Prince Hydraulics Wolverine Adjustable Flow Control Valve Offered by PRC Industrial SupplyDocument1 pagePrince Hydraulics Wolverine Adjustable Flow Control Valve Offered by PRC Industrial SupplyPRC Industrial SupplyNo ratings yet

- V001t01a071 91 GT 194Document10 pagesV001t01a071 91 GT 194Uzair BukhariNo ratings yet

- Crude Unit Startup Consequences of High Liquid LevelDocument4 pagesCrude Unit Startup Consequences of High Liquid LevelAlessio ScarabelliNo ratings yet

- Lecture-5 Drilling EngineeringDocument23 pagesLecture-5 Drilling Engineeringحيدر بادي - Haider BadiNo ratings yet

- Classification of Water Turbines: Impulse vs. Reaction TurbineDocument2 pagesClassification of Water Turbines: Impulse vs. Reaction TurbineRohit DiwakarNo ratings yet

- Equivalent Length - Rules of Thumb For Chemical EngineersDocument4 pagesEquivalent Length - Rules of Thumb For Chemical EngineersMohammad ahsan mirNo ratings yet

- Steam Turbine Water WashingDocument1 pageSteam Turbine Water WashingsoumitrabanNo ratings yet

- Mueller - Mixing BasicsDocument4 pagesMueller - Mixing BasicsVasilis PolykarpidisNo ratings yet

- Logan 120-Ton Power Swivel - Logan Oil ToolsDocument2 pagesLogan 120-Ton Power Swivel - Logan Oil Toolsanyaa426No ratings yet

- Pertemuan12 ESP 04042016 13042016Document192 pagesPertemuan12 ESP 04042016 13042016Priozky Pratama Purba100% (1)

- Pages From Design of Fluid Systems-Hook-Ups, Spirax Sarco 2Document1 pagePages From Design of Fluid Systems-Hook-Ups, Spirax Sarco 2Ujwal KhandokarNo ratings yet

- Fluid Pipe InstallationDocument1 pageFluid Pipe InstallationKrishna PATELNo ratings yet

- Carrying Capacity of Drilling MudsDocument10 pagesCarrying Capacity of Drilling MudsHai LinhNo ratings yet

- Artificial LiftDocument29 pagesArtificial LiftDivyanshu DkNo ratings yet

- Chapter 4-DDocument14 pagesChapter 4-DMahrouz MadoNo ratings yet

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- A Collaborative Study On DFIT InterpretationDocument39 pagesA Collaborative Study On DFIT InterpretationArsalanNo ratings yet

- 2002 Deliq Forum V1 3.5 PlungersDocument21 pages2002 Deliq Forum V1 3.5 PlungersArsalanNo ratings yet

- US6634426 - 2003 - Plunger Lift AnalysisDocument54 pagesUS6634426 - 2003 - Plunger Lift AnalysisArsalanNo ratings yet

- Spe-84215-Ms - Frac FluidDocument8 pagesSpe-84215-Ms - Frac FluidArsalanNo ratings yet

- Health Education, Advocacy and Community MobilisationDocument162 pagesHealth Education, Advocacy and Community Mobilisationأحمد خيري التميميNo ratings yet

- En DVC 2018 35Document18 pagesEn DVC 2018 35Lina María CañónNo ratings yet

- 21TH PRO Invitation For Schools - DepEd BataanDocument2 pages21TH PRO Invitation For Schools - DepEd BataanFranz Lorenz FuentesNo ratings yet

- Space Law Seminar BharatDocument26 pagesSpace Law Seminar BharatBharat JoshiNo ratings yet

- Types of Communication Session 7Document4 pagesTypes of Communication Session 7supratimloveNo ratings yet

- 4.2penjaminan Mutu Sediaan Farmasi - Oky YudiswaraDocument29 pages4.2penjaminan Mutu Sediaan Farmasi - Oky YudiswaraMUNIFRIZALNo ratings yet

- Cambridge Checkpoint Science English Language Skills Teachers SupportDocument14 pagesCambridge Checkpoint Science English Language Skills Teachers SupportDanilo Pereira GonçalvesNo ratings yet

- SodapdfDocument47 pagesSodapdfYolanda LegaspiNo ratings yet

- CH 08Document21 pagesCH 08Juan PepeNo ratings yet

- Mechanism and Compensation of Measurement Error Induced by Thermal Deformation of Digital Camera in Photo MechanicsDocument21 pagesMechanism and Compensation of Measurement Error Induced by Thermal Deformation of Digital Camera in Photo MechanicsTestingAccNo ratings yet

- Unit 4-From Recusrsive EstimationDocument17 pagesUnit 4-From Recusrsive EstimationTufail DarNo ratings yet

- SpaceLogic Glass Touch Panels - LSSMTH07NSDocument2 pagesSpaceLogic Glass Touch Panels - LSSMTH07NSrohan modkeNo ratings yet

- Review Session5 Hoop Tension (4 Slides)Document5 pagesReview Session5 Hoop Tension (4 Slides)Benjie MorenoNo ratings yet

- The Chi-Square Test: Statistics and Research DesignDocument2 pagesThe Chi-Square Test: Statistics and Research DesignTommy Winahyu PuriNo ratings yet

- Reineck (1980) Fluvial EnvironmentDocument58 pagesReineck (1980) Fluvial EnvironmentJuan JoseNo ratings yet

- Sip Math DeptDocument4 pagesSip Math DeptJERRYCO GARCIANo ratings yet

- 1 Place ValueDocument4 pages1 Place ValueKNAH TutoringNo ratings yet

- Problem Set in Fluid MechanicsDocument8 pagesProblem Set in Fluid Mechanicschristine Jade AtilanoNo ratings yet

- Calibration of Measuring Network of Leakage Current Tester by High Frequency Current SourceDocument2 pagesCalibration of Measuring Network of Leakage Current Tester by High Frequency Current SourceSAKKARIN TURATHAMNo ratings yet

- Cu THHNDocument2 pagesCu THHNdekadimahendra03No ratings yet

- Format For A Research PaperDocument2 pagesFormat For A Research PaperVishnu VenugopalNo ratings yet

- Department of Mahtematics and Statistics University of Jaffna LEVEL 1S (2018/2019) Statistics For Computing I - CSC105S3 Tutorial - 02Document2 pagesDepartment of Mahtematics and Statistics University of Jaffna LEVEL 1S (2018/2019) Statistics For Computing I - CSC105S3 Tutorial - 02Michael JhonshonNo ratings yet

- Hydrins: Navigation-Grade INS For Hydrographic SurveyDocument2 pagesHydrins: Navigation-Grade INS For Hydrographic SurveyGonzalo OpazoNo ratings yet

- Use Common and Socially Acceptable Expressions (E.g., Greetings, Leave-Taking)Document5 pagesUse Common and Socially Acceptable Expressions (E.g., Greetings, Leave-Taking)Mary Grace De QuirozNo ratings yet

- Syed Asad AbbasDocument1 pageSyed Asad AbbasAsad AbbasNo ratings yet

- Y4 Module 2 Performing Duties and Functions of An Enterprise OwnerDocument19 pagesY4 Module 2 Performing Duties and Functions of An Enterprise Owneranecita rodriguezNo ratings yet

- 701P50924 FF Accxes Drivers Client Tools EN PDFDocument28 pages701P50924 FF Accxes Drivers Client Tools EN PDFМихаил ВалерьевичNo ratings yet

- Math A Module18Document18 pagesMath A Module18Zen Zhyree CorpuzNo ratings yet