Professional Documents

Culture Documents

ABC Risk Classification

ABC Risk Classification

Uploaded by

docsenOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ABC Risk Classification

ABC Risk Classification

Uploaded by

docsenCopyright:

Available Formats

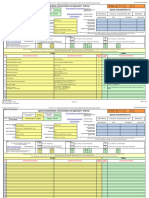

RfQ description

Part number family

(e.g. A212 690 XX 20):

Supplier

Location

Project:

RfQ-No.:

(e.g. X156)

Risk classification : A, B or C Assessment

1. Product- 1.1 Complexity (type and number of functions, level of system integration, number of variants, number of departments involved)

related high = 2, average = 1, low = 0

criteria 1.2 Product innovation (concept; design; material; function; appearance; feel)

(Product) Basically new = 2, part-criteria new = 1, known = 0

1.3 Critical problems in the past (field rejects; in-house problems)

No. of incidents : very frequent = 2, frequent = 1, low = 0

1.4 Launch problems in the past

high = 2, average = 1, low = 0

1.5 Development effort (expertise; different development areas involved)

critical = 2, fairly critical = 1, not critical = 0

2. Production 2.1 Process innovation

process- New technology for the supplier = 2, for the location = 1, none = 0

related 2.2 Predicted process stability (level of automation; manual production; production system; scrap levels)

criteria critical = 2, fairly critical = 1, not critical = 0

(Process) 2.3 Production facility / machinery technology

New technology for the supplier = 2, for the location = 1, none = 0

2.4 Infrastructure (re number and complexity of sub-suppliers, location, logistics)

critical = 2, fairly critical = 1, not critical = 0

2.5 Delivery / call-off times (combination of long transport distances, range of variants, JIT- / JIS deliveries, several delivery locations)

critical = 2, fairly critical = 1, not critical = 0

3. Time-related 3.1 Procurement times for production facility and machines, if appropiate, related to the date for placing the order

criteria critical = 2, fairly critical = 1, not critical = 0

3.2 Procurement times for tools, if appropiate, related to the date for placing the order

critical = 2, fairly critical = 1, not critical = 0

3.3 Procurement times for parts and basic materials

critical = 2, fairly critical = 1, not critical = 0

3.4 Critical timing issues in the past

critical = 2, fairly critical = 1, not critical = 0

3.5 Frequency of changes (effects on / by other delivered products / dependency on design and system)

high = 2, average = 1, low = 0

4. Supplier- 4.1 Supplier assessment (new supplier, reliability of deliveries, overall reliability, sub-supplier management)

related critical = 2, fairly critical = 1, not critical = 0

criteria 4.2 New product for the supplier

new = 2, new for the location = 1, known to the supplier = 0

4.3 New supplier production location

new, no experience = 2, new, with experience = 1, a previous or known location = 0

4.4 Supplier project management (complexity of the supply chain, contact personnel, availability, general readiness, capacity, structure)

critical = 2, fairly critical = 1, not critical = 0

4.5 Problems with earlier (other) deliveries (launch; field and in-house problems)

very frequent = 2, frequent = 1, low = 0

Total points

0

Overall risk classification

C

Classification

Verification done by:

(Name, Department)

Date:

Comments:

Dokumentennummer: 12.04.2005-XNCC-33ZT

Papierform unterliegt nicht dem Änderungsdienst

You might also like

- VW - 10131 - enDocument64 pagesVW - 10131 - enKinga EnNo ratings yet

- QRS Rev.7 enDocument162 pagesQRS Rev.7 enKarolina QuirozNo ratings yet

- Vda 63 Potenzialanalyse Version r3 EnglDocument18 pagesVda 63 Potenzialanalyse Version r3 EnglSudhagarNo ratings yet

- Template Q-Offer v1 2Document25 pagesTemplate Q-Offer v1 2Krishna Mohan T.R100% (1)

- Formel Q Capability Appendix 4.0 2022 12 ONE-KBPDocument9 pagesFormel Q Capability Appendix 4.0 2022 12 ONE-KBPHenrique LeocádioNo ratings yet

- GORE Automotive Vents Exterior Lighting Datasheet ENDocument4 pagesGORE Automotive Vents Exterior Lighting Datasheet ENAaron HuangNo ratings yet

- VW 60564 enDocument5 pagesVW 60564 enRicardo VitorianoNo ratings yet

- ABC Risk ClassificationDocument1 pageABC Risk ClassificationcinconconNo ratings yet

- Din 929 PDFDocument1 pageDin 929 PDFprathmesh238No ratings yet

- Anexo 03 - VW - 10130Document36 pagesAnexo 03 - VW - 10130José María MorenoNo ratings yet

- SREA TrainingDocument59 pagesSREA TrainingYoohyun LeeNo ratings yet

- GMs Drill Deep and Wide Example MatrixDocument3 pagesGMs Drill Deep and Wide Example MatrixDavid MorenoNo ratings yet

- General Rules and Guidelines For IMDS Material DatasheetsDocument22 pagesGeneral Rules and Guidelines For IMDS Material DatasheetsVanessa Alves MoreiraNo ratings yet

- Functional Requirements Document User Management DashboardDocument13 pagesFunctional Requirements Document User Management DashboardBabar ZafarNo ratings yet

- Protean Electric Presentation For PAESDocument36 pagesProtean Electric Presentation For PAESGeorge CălinNo ratings yet

- Embedded Generation Connection Guide PDFDocument43 pagesEmbedded Generation Connection Guide PDFSunrider2014No ratings yet

- CMRT Candidate Guide For Certification and Recertification 2-17 PDFDocument26 pagesCMRT Candidate Guide For Certification and Recertification 2-17 PDFÂñçhūlä SrïkâñthNo ratings yet

- VDA - Band - 05 - 3. Auflage - Juli 2021 - EnglischDocument234 pagesVDA - Band - 05 - 3. Auflage - Juli 2021 - EnglischManuel NevarezNo ratings yet

- Formel Q Capability 9.0 2022 12 ONE-KBPDocument36 pagesFormel Q Capability 9.0 2022 12 ONE-KBPNedra DebbechNo ratings yet

- 03 Ppap-3 PDFDocument91 pages03 Ppap-3 PDFMalla Reddy AVNo ratings yet

- en 32 - HCPPDocument9 pagesen 32 - HCPPsoniya RNo ratings yet

- VDADocument20 pagesVDASting GonsalisNo ratings yet

- 112 0003Document41 pages112 0003judithvelasquezNo ratings yet

- Copper Sheet, Strip, Plate, and Rolled Bar: Standard Specification ForDocument7 pagesCopper Sheet, Strip, Plate, and Rolled Bar: Standard Specification ForgoggerNo ratings yet

- Volkswagen Group Customer Specific Requirements March 2022 1Document6 pagesVolkswagen Group Customer Specific Requirements March 2022 1Tania HernandezNo ratings yet

- VDA 6.3-Analysis Tool: User ManualDocument23 pagesVDA 6.3-Analysis Tool: User ManualIstvan KisNo ratings yet

- MX551200Zincatura Passivata StandardDocument7 pagesMX551200Zincatura Passivata StandardpopoNo ratings yet

- FAF03-111-2-Externally Supplied ContentDocument6 pagesFAF03-111-2-Externally Supplied ContentKinga EnNo ratings yet

- Supplier Quality Requirements: Key Elements Procedures # 2Document14 pagesSupplier Quality Requirements: Key Elements Procedures # 2Juan DavidNo ratings yet

- Mno2604 - Study Guide Final 03122020Document349 pagesMno2604 - Study Guide Final 03122020T-ROLL--No ratings yet

- DBL 9440 - 201912 - Englisch - Fasteners With Metric Thread Surface ProtectionDocument18 pagesDBL 9440 - 201912 - Englisch - Fasteners With Metric Thread Surface ProtectionEmir AkçayNo ratings yet

- VDA 6.3 2010 - enDocument45 pagesVDA 6.3 2010 - enMahender KumarNo ratings yet

- Sae J121M-2013Document5 pagesSae J121M-2013phan hoai nam PhanNo ratings yet

- VW 99000-4 Build Sample Approval Issue 12 2015Document2 pagesVW 99000-4 Build Sample Approval Issue 12 2015sevilmisu100% (1)

- Productivity ExercisesDocument3 pagesProductivity ExercisesKeira TanNo ratings yet

- Groupe Renault - CSR V2020Document7 pagesGroupe Renault - CSR V2020OBSC PerfectionNo ratings yet

- Vision: VDA Infosolutions Private LimitedDocument18 pagesVision: VDA Infosolutions Private LimitedsudhakaremcNo ratings yet

- GM Customer Specifics - Rev 05-07-15Document34 pagesGM Customer Specifics - Rev 05-07-15hugocronyNo ratings yet

- VDA - Band - 16 - 3. Ausgabe 2016 - EnglischDocument83 pagesVDA - Band - 16 - 3. Ausgabe 2016 - EnglischManuel NevarezNo ratings yet

- Benutzerhandbuch QTR Online Englische Version PDFDocument34 pagesBenutzerhandbuch QTR Online Englische Version PDFBrian BoruNo ratings yet

- Autoliv Material Specification: Flat Hot Rolled Steel For Safety Products - E116088Document4 pagesAutoliv Material Specification: Flat Hot Rolled Steel For Safety Products - E116088krishnamartial8269No ratings yet

- Gila Quality ManualDocument60 pagesGila Quality ManualABU ELBANATNo ratings yet

- IPC-SpecTree - IPC SpecTree 2014-09Document1 pageIPC-SpecTree - IPC SpecTree 2014-09edubrunno100% (1)

- System-Based, Customer-Centered Quality Plan For ManufacturersDocument9 pagesSystem-Based, Customer-Centered Quality Plan For ManufacturersmsbarretosNo ratings yet

- Mvss206 Door LockDocument51 pagesMvss206 Door LockPratik_rush2905No ratings yet

- VW QualityDocument16 pagesVW Qualityjohnoo7No ratings yet

- Iso and Iatf 16949.2016 ManualDocument48 pagesIso and Iatf 16949.2016 Manualsanjay sharma100% (1)

- Supplier Charge Back PDFDocument4 pagesSupplier Charge Back PDFKhtb AshrafNo ratings yet

- Msa 4th Edition PDFDocument2 pagesMsa 4th Edition PDFSenthil KumarNo ratings yet

- VDA 2020 - en - A Process Description Covering Special Characteristics (SC)Document13 pagesVDA 2020 - en - A Process Description Covering Special Characteristics (SC)cdming0% (1)

- 2019 - KIA US Supplier Quality Manual KR GA PD SQD S 0001 - 02!19!2019Document32 pages2019 - KIA US Supplier Quality Manual KR GA PD SQD S 0001 - 02!19!2019rekik99266No ratings yet

- VDA 6 - 3 Questionnaire Summary of Changes PDFDocument6 pagesVDA 6 - 3 Questionnaire Summary of Changes PDFAnonymous CW8L9FkuNo ratings yet

- SQMS Manual For Suppliers: 1. General InformationDocument87 pagesSQMS Manual For Suppliers: 1. General Informationlennad1No ratings yet

- Part Inspection Standard (May 2013)Document9 pagesPart Inspection Standard (May 2013)san moedano100% (1)

- Quality Management in The Automotive Industry: Documentation and ArchivingDocument37 pagesQuality Management in The Automotive Industry: Documentation and ArchivingdavidNo ratings yet

- Beon - Bemusterung Online: Release Letter Version 3.1.00 - Sampling PlanDocument11 pagesBeon - Bemusterung Online: Release Letter Version 3.1.00 - Sampling PlanRamón G. Pacheco100% (1)

- IATF 16949 2016 Gap ToolDocument232 pagesIATF 16949 2016 Gap Toolvaibhavmalhotra14No ratings yet

- GRR MSA-4 Anova MethodDocument6 pagesGRR MSA-4 Anova MethodSead ZejnilovicNo ratings yet

- Part Submission Warrant - PSWDocument2 pagesPart Submission Warrant - PSWPuneet Sharma100% (1)

- INGFRT-11 Run at RateDocument3 pagesINGFRT-11 Run at RateMarisol RubioNo ratings yet

- Bmw Spqm 供应商管理Document30 pagesBmw Spqm 供应商管理isolong100% (1)

- EG-M36+Assignment 2024Document5 pagesEG-M36+Assignment 2024Raghuraam GunasegaranNo ratings yet

- QSP-001633 - Rev 04 - Luminus Testing Laboratory Quality Manual207Document34 pagesQSP-001633 - Rev 04 - Luminus Testing Laboratory Quality Manual207SureshNo ratings yet

- Uptime 8 - Total Productive MaintenanceDocument38 pagesUptime 8 - Total Productive Maintenancetoyota952No ratings yet

- SWOT AnalysisDocument8 pagesSWOT AnalysisEdmundo DíazNo ratings yet

- Digitisation of University Administration in A Post-Covid Era by PROF. MARSHALL A. AZEKEDocument109 pagesDigitisation of University Administration in A Post-Covid Era by PROF. MARSHALL A. AZEKEAlegbe AnthonyNo ratings yet

- ME404-QP - Ktu QbankDocument2 pagesME404-QP - Ktu QbankVishu SomgadeNo ratings yet

- Catalogo Leviton PDFDocument13 pagesCatalogo Leviton PDFAntonio Hernandez Leonides100% (1)

- EN13849 Revised 080908Document120 pagesEN13849 Revised 080908sujal_aminNo ratings yet

- Mis Srs Doc Iit Bom PDFDocument18 pagesMis Srs Doc Iit Bom PDFKoutilya PathakNo ratings yet

- SE10 Is Chapter4Document37 pagesSE10 Is Chapter4Katori Taku OfficialNo ratings yet

- 1-Proposal For Asset Management of Transformer Power & Distribution Tf-LADocument21 pages1-Proposal For Asset Management of Transformer Power & Distribution Tf-LAAradhana RayNo ratings yet

- Technical Handbook Parker HosesDocument620 pagesTechnical Handbook Parker HosesjoebrazNo ratings yet

- Unit - Iii TQM Tools and Techniques: The Seven Traditioal Tools of Quality or Statistical Process ControlDocument19 pagesUnit - Iii TQM Tools and Techniques: The Seven Traditioal Tools of Quality or Statistical Process Controlsafina rahmanNo ratings yet

- Line Differential Protection Red670Document8 pagesLine Differential Protection Red670igorsfaceNo ratings yet

- BY Alehegn Gashu Submitted To: Yibeltal Tarekegn (Asst - Professor)Document7 pagesBY Alehegn Gashu Submitted To: Yibeltal Tarekegn (Asst - Professor)ayanaNo ratings yet

- Identifying Electric Motor BearingsDocument1 pageIdentifying Electric Motor BearingsEmad Elsaid100% (1)

- Epri Instrumentation and Control Program - Complete Product ListDocument20 pagesEpri Instrumentation and Control Program - Complete Product ListkaicyemNo ratings yet

- Books 2008Document4 pagesBooks 2008Arvind KumarNo ratings yet

- Aashto-Lrfr 2005Document445 pagesAashto-Lrfr 2005alpyilmaz87100% (2)

- Mi 2 2014Document106 pagesMi 2 2014Natalia IonelNo ratings yet

- Lifetime Estimation Method For The Power Semiconductors Considering Mission ProfilesDocument10 pagesLifetime Estimation Method For The Power Semiconductors Considering Mission ProfilesLionildo LucyNo ratings yet

- Brunel Dissertation ResultsDocument7 pagesBrunel Dissertation ResultsWriteMyPaperForMeFastUK100% (2)

- Technical System Maintenance - Delay-Time-Based Modelling PDFDocument361 pagesTechnical System Maintenance - Delay-Time-Based Modelling PDFDario DorkoNo ratings yet

- Fiabilité ATR - Ed.1 Rev.1Document36 pagesFiabilité ATR - Ed.1 Rev.1Fred SagreraNo ratings yet

- IRIS Guideline 3: Maintenance: EnglishDocument46 pagesIRIS Guideline 3: Maintenance: EnglishAli FilizNo ratings yet

- b10 Valdoc Irv Irvn-Sm00004Document3 pagesb10 Valdoc Irv Irvn-Sm00004최재호No ratings yet