Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

11 viewsCondensation and Boiling PK Nag Solved Examples

Condensation and Boiling PK Nag Solved Examples

Uploaded by

Thoran BruceleeCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5824)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Curved Beam Data Hand BookDocument6 pagesCurved Beam Data Hand BookThoran BruceleeNo ratings yet

- Dme Y18Document6 pagesDme Y18Thoran BruceleeNo ratings yet

- FEM NotesDocument84 pagesFEM NotesThoran BruceleeNo ratings yet

- Linked ListDocument15 pagesLinked ListThoran BruceleeNo ratings yet

- Creation of A Binary Search TreeDocument3 pagesCreation of A Binary Search TreeThoran BruceleeNo ratings yet

- Syuabuo: Desican of Machtne Flements - 2Document11 pagesSyuabuo: Desican of Machtne Flements - 2Thoran BruceleeNo ratings yet

- Dme Cie PapersDocument5 pagesDme Cie PapersThoran BruceleeNo ratings yet

- Cbse R: User ManualDocument4 pagesCbse R: User ManualThoran BruceleeNo ratings yet

Condensation and Boiling PK Nag Solved Examples

Condensation and Boiling PK Nag Solved Examples

Uploaded by

Thoran Brucelee0 ratings0% found this document useful (0 votes)

11 views14 pagesOriginal Title

Condensation and Boiling Pk Nag Solved Examples

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

11 views14 pagesCondensation and Boiling PK Nag Solved Examples

Condensation and Boiling PK Nag Solved Examples

Uploaded by

Thoran BruceleeCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 14

[498 Heat and Mass Transfer

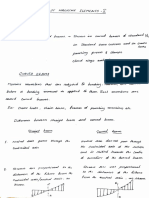

from the correlations in Chapter 4. However, once boiling is initateg

appear atthe surface and are carried into the mainstream of the fgg; by

known as bubbly flow. There i a sharp increase in the convection fe Tht

coefficient associated with this bubbly flow regime. As the volung'st "tty

bubbles increases individual bubbles coalesce to form larger bubbles to

vapour. The volume occupied by bubbles Keeps on increasing gi) 7 that

fraction of about 0.1 isreached. The slug flow regime is followed by 4,

flow regime in which liquid forms a film. This moves along the inng Mr

while vapour moves ata larger velocity trough the core ofthe tube pt

transfer coefficient continues to increase through the bubbly flow ang"

the annular flow regimes. However, dry spots eventually appear on co

surface, at which point h begins to decrease. The transition reget

characterised by the growth of dry spots, until the surface is completely

all remaining liguid is inthe form of droplets appearing inthe vapour got?

canvection coefficient continues to decrease through this regime, There gt

change in this coefficient through the mistflow regime which peri units

the droplets are converted to vapour. The vapour is then superheated by forced

convection from the surface [20, 21].

SOLVED EXAMPLES.

Example 6.1

Saturated steam at 54.5°C condenses on the outside surface of a 25.4 mm our

diameter 3.66 m long vertical tube maintained at a uniform temperature of

43.3°C. Because of the occurrence of ripples on the surface of the condensate

film the actual heat transfer coefficient is about 20% higher than that obtained

by Nusselt’s equation. Determine the average condensation heat transfer

coefficient over the entire length of the tube and the rate of condensate flow at

the bottom of the tube. Check that the flow is laminar. The Properties of

condensate at 48.9°C are hy, = 2372.4 kJ/kg, k = 0.642 W/mK, p= 988.4 kgin’

and #1 = 0.558 x 10° kg/ms.

Solution:

By using Nusselt’s equation with 20% excess and neglecting density of vaout,

: Aan

ho ao (tistem

MOL

a [° 642)" x (988.4)? x9.81x(2372.4x10)]

(0.558 10->) (54.5— 43.3) x 3.66

= 4559 Wim? K Ans.

Condensate flow rate,

= EDL by (T,-Ty)

Ig

“4

Scanned with CamScanner

r Condensation and Bolling 499 |

2X 25.4 x10"

66 x 4559 (54.5 ~ 43.3

59 (34,5 ~ 43,3)

4x10 :

26.24% 10" kg/s Ans,

ids number,

Reyne are 4%6.24x1073

“"p (0.558%10") rx 25.4107

= 560.2

since Re < 2000, the flow is laminar and the above calculations are valid,

6.2

im lowing at a rate of 10,000 kg/h and at 120°C is con

\densed using coolin;

water at an average temperature of 20°C. The condenser contains 800 tubes

jchhave an outer diameter of 18 mm. Estimate the heat transfer coefficient

whetcondenser i vertical and (b) ifthe condenser is horizontal with tubes on

iim pd condensation takes place outside the tubes,

Solution: From Eq. (6.34),

2 \l3 13

(Hi } - (*)

he} AB-| =1.47) 4b

o(Z pig A, o

Atthe average temperature of (120 + 20)/2 or 70°C, for condensate film p=

g718kg/m’, k = 0.66 W/m K and 41 = 404.7 x 10° ke/ms.

T= mass rate of flow of condensate per unit length of perimeter

_ _10,000/3600

~ 800 x x 0.018

= 6.14 x 10°? kg/s per metre of perimeter.

Re

2

Reynolds number, Re = a = 4614x107 _ Go

404.7 10°

Flow in the film is thus laminar and the equation (1) above is valid

3

404.7 107°)" r

Im Sa = 1.47 (607)"*

(0.66)° (977.8)" x9.81

Ig (3.931 X 10°) = 1.47 x 0.116

= ONT4 2 4426 Wim? K Ans. (a)

™ 3931x107

(b) Horizontal tubes

2 Ww ya

tn( gr] 1si(4")

A pig My

here T

Nee” is defined as the mass rate of flow per unit length of tube

nN

Scanned with CamScanner

500 Heat and Mass Transfer

$$

10,000/3600

3x 800

47’ _ 4x1.15x1073

“p 404.7x10

The flow is laminar and the equation is valid.

Ir, X 3.931 x 10° = 1.51 x (11.44

_ 0.670

™ 3.931x107

This illustrates the advantage of using horizontal rath

condensers.

Example 6.3

Saturated steam at 110°C condenses on the outside of a bank Of 64 hori,

tubes of 25 mm outer diameter, 1 m long arranged in a 8 x 8 square ary,

Calculate the rate of condensation if the tube surface is maintained at 100°C. Th,

Properties of saturated water at 105°C are p= 954.7 kg/m’, k = 0.684 Win? K,

H= 271 x 10° kg/ms and hy, = 2243.7 ki/kg.

Had the condenser been vertical, what would have been the rate of

condensation?

Solution:

Using Nusselt’s equation for condensation on a bank of horizontal tubes,

Bi pt aly \!*

(hy) = 0.725 [Sabet

re = 1.15 x 10” kg/s per metre

=114

= 17,048 Wim? K Ans. (by

ler than Verticay

.684)? (954.7)? x9, .7x10°) ]

-ons{ * )° (954.7)? x 9.81% (2243.7 x 10 T

8x271x10"6 x 25x10™ x10

.725 (10.432 x 10°) = 7563.5 Wim? K

Rate of condensation, @

= 7563.5 xx 25x103 x 1x 10x64

. 2243.7 10°

= 0.1694 kg/s Ans.

Fora vertical condenser,

a v4

hady = 0.943 (aise

MOL

4

= 0.943 | (0-684)? (954.7)? x9.81x2243,7x 2)

21x10" x10x1

= 0.943 (69.77 x 10) = 6579 Wm? K

Scanned with CamScanner

-— |

Condensation and Bolling 501 |

ofondensation fora vertical condenser,

pate’ 6579 x 64 xm x0.025x1x10

= S5T9XOAXHX0.025x1x10.

2243.7 x 1000

= 0.147 kg/s Ans,

ple 6.4

surface of a vertical cylindrical drum of 350 mm diameter i

‘qe ca steam at 2.0 bar for condensation. If the surfece temperame’ of ae

sai ig maintained at 80°C, calculate (i) the length of the drum and Gi) the

dieanes of the condensate layer to condense 70 kg/h of steam.

‘Solu ition:

Given: D = 0.35 m, T,, = 80°C, rt = 70 kg/h

Comesponding to 2 bar, from steam tables,

Trae = 120.2°C, py =

hiyg = 2201.6 kJ/kg.

‘The properties of saturated water at the mean film temperature,

Te 120.2 +80 7

2

P= 956.4 kg/m’, k = 68.23 x 10? WimK,

H= 283 x 10% ke/m-s

Assuming film condensation and laminar flow, the film thickness at the bottom.

14

4k Ox

& =| ————$_

Pr (Pr~ Pe )Bhg |

2 6 v4

§, = | 4%68:23 x10 x283 x 10° 4120.2 80) xL

958.4(958.4 — 1.13) x 9.81 x 2201.6 x 10°

= 1.988 x 107 x (L)4

Average heat transfer coefficient is given by

4 ky 4 68.23x107

36, 31.988x10*L"

Heat = 3432.09 (Ly*

Transfer rate, Q (using McAdam’ correction of 20% excess of h)

100°C

he

‘ =H A, (Ts —T,y) = mh

l s (Tat fg

2 3432.09 x 14x wx 0.35 x Lx (120.2 ~ 80)

~~

Scanned with CamScanner

[502 Heat and Mass Transfer

5 30 x 2201.6 x 10°

182046.8(L)** = 42808.88

L= 0.1452 m= 145.2 mm Ans. (i)

1,988 x 107 x (0,1452)"

= 1.227 x 104 m= 0.1227 mm Ans. (ii)

Let us now check whether the condensate flow is laminar or not,

= Ani 4 x (70/3600)

~ BRD ~ 283x10% x 7x 0.35

AsR, < 1800, the assumption of laminar flow is correct.

Example 6.5

A vertical plate 300 mm wide and 1.2 m high is maintained at 79°¢ and

exposed to saturated steam at 1 atm pressure. Calculate the heat trang

coefficient and the total mass of steam condensed per hour. What Would be the

heat transfer coefficient if the plate is inclined at 30° to the vertical?

Solution:

Re 50

The mean film temperature of the condensate = 70100 . gsc,

Properties of saturated water at 85°C are:

Pr= 968 mi/kg, U; = 3.37 x 104 Pa-s,

k, = 0.674 WimK, he, = 2255 kI/kg.

3q4

ease Pr (Pe ~ Py )8 hig Ke

Lug (Tey - Ty)

Ke pt aly

Titi Tux =Te)

ws

= 0.943 ] » Since DP, >> py.

Poss [om X (968)? x 9.81 x 2255 x10? |"

1.2x337x10~* x30

= 4.51 x 10° W/m’K Ans.

For checking

_ Ain

Re= Fp.

Also, A (Ty - Ty) = hey

= MAGx - Ty)

Ing

th

4

Scanned with CamScanner

Condensation and Boling __503 |

the plate width and L its length,

ing. iW is

sos AhA (Tex ~ Tw)

Rea) PH 7 , A=WL,P=w

_ 4xX451X10? x1.2x 30

= 2055 x 10° x 3.37 x10-*

ge < 1800, the flow is laminar and the equation used is valid.

= 856.6

R

so ose tough the plate,

= hA AT =4.51 x 10° x (1.2 x 0.3) x 30

= 48.7 kW

Mass flow rate of condensate, rit

_ 487

= Olle, = F555 X 3600

= 71.16 kg/h Ans.

Ifthe plate is inclined at 30° to the vertical, @= 60°,

4

r kf pi gh sin®

= 0.943 | 4" —

h [ LuaT

= 0.943 | (0.574? (968)? x 9.81% 2255 x 10? x sin60°]

nee: 1.2x337x10* x30

= 43510? Wim°K Ans.

Example 6.6

Atube of 15 mm outside diameter and

0 KPa, Calculate the average heat

horizontal, (b) vertical and its surface temperature

Solution:

Saturation temperature at 40 kPa or 0.4 bar is 7

jg 047

: ee = 63°C and the properties of saturated water are:

1.5 mong is used for condensing steam at

transfer coefficient when the tube is (a)

is maintained at 50°C.

16°C. The mean film temperature

p, = 980 ke/m?, 41, = 0.432 x 10° Pa-s,

k, = 0.66 WimK, hg, = 2320 keg, P1? Pur

(@) Horizontal tube

Scanned with CamScanner

504 Heat and Mass Transfer

—

——

= 0.725 | (0-66)? x (980)? x 9.81 x 2320x1939!

— 0.432 x 107 x1.5x 26 ]

= 10,000 W/m7K Ans,

(b) Vertical tube :

Equation (6.13) shouldbe used fora vertical tube ifthe film thickng

small in comparison with the tube diameter. 8 iy,

4

4uKLAT

Film thickness, , = | —“———

° . [ hg Pi ]

4 [sagazzate® |

© | 981x2320x10° x (980)

= 0.3413 x 107 m= 0.3413 mm

Since 5, << 150 mm, the tube diameter, Eq. (6.26) is used,

Coda - 0.77 (5)"

On)v

_ 10,000

Cav = 0.77150/15)°

= 7303 Wim?’K Ans,

‘Thus, the performance of horizontal tubes for filmwise laminar condensation

better than vertical tubes, thus horizontal tubes are preferred,

Example 6.7

A square array of 400 tubes 15 mm outer diameter is used to condense steam

atmospheric pressure. The tube walls are maintained at 88°C by a coo

flowing through the tubes. Calculate the amount of seam condensed per hou pt

unit length of the tubes.

Solution:

Properties of condensate at mean film temperature of 884100 - s4-c a:

c= 963 kg/m”, 1, = 3.06 x 10 kg/m-s,

ky = 0.678 WimK, hg, = 2255 x 10° Jikg.

A square array of 400 tubes will have N = 20.

4

“ h =0.725 Hotehg

NU, Doo

4

(0.678)? x (963)? x 9,81 x 2255 x 7)

20 x 3.06 x 10°4 x 0.015 x12

= 6.328 x 10° Wim?K

= 0.725 [

4

Scanned with CamScanner

_— _________Condensation and Bolling __505 |

100 tubes, Ap = 400 x 3.1416 x 0.015 x 1

rea of 4

ye = 18.852 m? per metre length of tube

8

Q=h Ap AT = 6.328 x 18.852 x 12 = 1431.56 kW

1431.56

7255 * 3600

Condensation rate,

= 2285.4 kg/h per metre length Ans.

ple 6.8 .

the power required to boil water in a copper pan, 0.35 m in diameter.

js maintained at 120°C by an electric heater. What is the, evaporation

a xia the critical heat flux. :

soliton:

Table A.6, for saturated water at 100°C: p, = 1/v, = 957.9 kg/m’, p, = I/

70.5955 kg/m”, Cp = 4.217 KI/kg K, 4, = 279 x 10°* No/m?, Pry = 1.76, hy

Th ys7 kiikg and = 8.9 x 10-3 N/m. .

*‘pycess temperature AT, = 120 ~ 100 = 20°C. According to the boiling curve

affig. 6.14, nucleate pool boiling will occur and the recommended correlation is

given in Eq. 6.52.

an [e5e]"| “nat ]

" . o Cog Igy Pry

‘The values of C,, and n corresponding to the polished copper surface water

combination are taken from Table 6.1, where Cy = 0.013 and n = 1.0.

Substituting numerical values, the boiling heat flux is

Gy = 279 X 10° N s/m? x 2257 x 10° Ike

9.8 m/s? (957.9 - 0.5955) kg/m? |

58.9 x10"? N/m

tite

%

4 (_4:217 x10? Ikgk x20°C

0.013 x 2257 x 10° J/kg x 1.76

= 630 Jims x 39.1 + x 4.36

m

= 1096.25 k Wim? = 1.096 MW/m?

Boiling heat transfer rate

Q = gy A= 1096.25 kWim? x a x (0.35) m?

B =105.5kW Ans.

‘Yaporation rate of water,

3

= 105.5x10° W__ 9.9467 kg/s = 168.3 kg/h Ans.

225710? J/kg

Scanned with CamScanner

506 Heat and Mass Transfer _

‘The critical heat flux for nucleate boiling can be estimated from 24.6,

ia aaa

naz = 0-149 hg Py [poz]

= 0.149 x 2257 x 10° J/kg x 0.5955 kg/m?

54,

-3 N/m x 9.8 m/s? x (957.9-

| $8:2102 Nim x3.8 m/s? X(857.9- 0.5955 igi

(0.5955)? (kg/m?)

= 1.26 MW/m*

Operation of the heater at qy = 1.096 MW/m? is below the critical hea fn,

Example 6.9

{A metal-clad heating element of mm diameter and emissivity 0.9ishoionaty

immersed in a water bath. The surface temperature of the metal is 260°C unig

steady-state boiling conditions. Estimate the power dissipation per unit length

heater. \

Solution:

Properties of water at 100°C are p; = 957.9 kg/m’ and hi, = 2257 kifkg.

2

Properties of water vapour at (260 + 100)/2 or 180°C are , = 4.808 kp,

qv 2.56 kITkg K, ky = 0.0331 Wim K and 1, = 14.85 x 10° N sh’,

Excess temperature = 260 - 100 = 160°C.

‘According to the boiling curve of Fig. 6.14, film pool boiling conditions

prevail.

Using Bromley’s correlation, Eq. (6.55)

8(01~Px)Py Kili +0.68¢p, AT) |"

Dy AT.

i = 0.62

9.8 m/s? (957.9 - 4.808) kg/m? x 4.808 kg/m?

= oe

1

Wt

. (0.0331)? (W/m K)°(2257 x 10°? + 0.68 x 2.56 x 10° J/kg K x160°C)

14.85 x 10°® Ns/m? x 8 x 10°* m x 160°C

. 1.629 (2535.5x 10°) ]*

= 0.62 [ee = 423 Wim? K

£0 (Ty - Ti)

Ty ~ Toa

0.9 5.67 10-* W/m? K* x (5334 — 373*) K*

(633 -373)K j

}

Scanned with CamScanner

;

©

_ wdensation and Boiling 507

p19 (807.066 ~ 193.569) = 19.87 Win? K

20!

Reh 2 h, = 423 +0.75 x 19.57

= 437.68 W/m? K

per unit length

= WA (Ty ~ Toa) = 437.68 X x8 x 1073 160

=1,76kW/m Ans,

est transfer rate

mple 6.10

is desired £0 generate 100 kg/h of saturated steam at 100°C using a heating

Iris dene copper of surface area 5 m”. Calculate the convective heat transfer

riient, the temperature of the heating surface and the critical heat flux.

solution:

Mass of steam (0 be evaporated is 100 kg/h. Enthalpy of vaporization at 100°C,

Iigg = 2255 Ki/kg.

Q = 2255 x 10° x 100/3600 = 62,639 W

OIA = Gu = pg = 12,528 Wim?

Properties of ‘saturated water at 100°C are

7, = 958.4 kg/m?, py = 0.598 kg/m’,

= 0.283 x 10°? Pa-s, Cy = 4217 IkgK, Pr =1.75, C= 0.013,

= 58.8X 10° N/m.

From Eq. (6.52),

oe 0.33,

ar,= £4 Mig Pol Ow o

Cu Hate 8(P1- Pv)

033,

0013x2255 x 10? x 1.75 12528 4c [588x107

4217 0.283 x 107 x 2255 x 10° 9.81x 9578

=45°C

Ty = 104,5°C Ans.

y= AT, = 12528 Wim?

12528

45

h= = 2784 Wim?K Ans.

Citcal heat flux is obtained from Eq. (6.54)

4

op) - |

Pp

max = 0.149 hig a

N

Scanned with CamScanner

[508 Heat and Mass Transfer X

588x107 x9 91

= 0.149 x 2255 x 100596 7

(O5ogp

= 1259.7 x 10° W/m? Ans.

UMMARY

Phase change heat transfer processes such as boiling and co, .

easier indice a Condensation yy

have wide applications in industry are introduced. Vapour can egos.” Mtg

cooled surface intwo ways, i. dropwise and filmwise. Atentionhas eet

mainly to film condensation. The classical Nusselt analysis of laminae

condensation on a vertical plate has been presented and the exten,

analysis to account for subcooling of condensate, and superheating of

been discussed. Nusselt’s approach to the analysis of laminar film conden

on a single horizontal tube as well as a vertical tier of N horizontal test

explained.

In boiling heat transfer the fundamentals of pool boiling, Nukiany

experiment, typical saturated boiling curve for water at atmospheric Pressure ang

various boiling regimes are explained in detail. Nucleate boiling reine

elaborated, Rohsenow’s correlation and Zuber’s critical heat flux coreatones

Presented. Flow regimes for forced convection boiling and two phase fow a

explained.

IEW QUESTIONS

6.1 Why are heat transfer rates high for a phase change process?

6.2. What are the five significant dimensionless numbers in boiling and cor

densation?

6.3 Explain the physical significance of Jakob number and Bond number.

6.4 What are the two modes in which condensation can take place on a cooling

surface? What is film condensation?

6.5 Explain the conditions under which dropwise condensation can take plac.

Why is the rate of heat transfer in dropwise condensation many tines

larger than in filmwise condensation?

6.6 Whatis a promoter? Why does its effectiveness decay with time?

6.7 State the assumptions made in deriving Nusselt’s equation for film

densation,

68 Explain how the condensate film thickness on a vertical plates ifluen

by different parameters. and

ee hatis bulk temperature of the condensate? Show that itis subeooled

1s less than the saturation temperature b 30/8, where 0=7,-To |

6.10 Whatis the effect of inclination of the teee plate on the average conde

Sation heat transfer coefficient?

zontal tbe

6:11 How does the Nusselt’s equation for condensation on a horizon!

differ from that on a vertical tube?

~

Scanned with CamScanner

_ ———-— ...Condensation and Boiling __ 509 |

in why the condenser tubes are usually horiz

si splat the mean hent transfer coefficient ina eee decrease if the

4! wymber of horizontal tubes in a vertical tier (N) increases?

rr ati condensation number? How is it related with Reynolds number for

614 condensation on (a) a vertical tube and (b) a horizontal tube?

what is the effect of turbulence on condensation heat transfer coefficient?

Why is turbulent flow of condensate hardly ever reached on a horizontal

on the effect of high vapour velocity on the rate of condensati

i i y isthe Cia of superheat not significant on condensation heat tinasfer

coefficient? ;

g Discuss the Gis ofa noncondensable gas like air on the rate of condensa-

ton of steam How is air removed continuously from the condenser shell in

power plant? ;

9 What do you mean by subcooled boiling? What is saturated boiling?

20 What is pool boiling? How is forced convection boiling different from

1 boiling?

621 State the regimes of pool boiling.

6) Draw and explain the Farber-Scorah boiling curve.

#5 What is nucleate boiling? Why is it important?

624 What is excess temperature? What do you mean by ONB and DNB?

6.25 What is critical heat flux? What is its importance?

£26 Explain partial or unstable film boiling.

627 What is Leidenfrost point? What is its significance?

698 Explain film boiling. Why is it avoided? What is boiling crisis?

6.29 What are the two separate,processes of nucleate boiling?

630 State the two conditions which are required to be fulfilled for bubbles to

form.

631 Why do bubbles form on the heating surface?

632 When does a bubble grow or collapse as it moves up through the liquid?

633 What are nucleation sites? What are active cavities?

634 Why is less liquid superheat required for bubble formation when a

noncondensable gas is present in the bubble?

635 What is Rohsenow’s correlation in nucleate boiling? On what does the

coefficient Cy-depend?

636 Explain the flow regimes in two phase flow through a tube. What is the

difference between slug-flow regime and annular flow regime.

637 What are dry spots? What is mist flow regime?

as

PROBLEMS FOR PRACTICE

6.1 Saturated steam at 1.46 bar and 110°C condenses ona 25 mm outer diam-

tter vertical tube which is 50 cm long. The tube wall is maintained at

100°C. Calculate ‘the average heat transfer coefficient and the rate of

condensation, Check that the condensate flow is laminar. The properties of

~~

Scanned with CamScanner

510 "Heat and Mass Transfer

the condensate at 150°C are k = 0.68 Wim K, p = 954.7 kpjm}

= 0.271 x 10”? ke/ms and hy, = 2243.7 kJ/kg. :

ns. 7789.33 Wim? K, 1.36 x 10° kpjs)

6.2 Air-free saturated steam at 65°C condenses on the outer surface of a

25 mm outer diameter 3 m long vertical tube maintained at a uniform tem,

perature of 35°C by flow of cooling water through the tube. Assuming film

condensation and 20% in excess of Nusselt’s value calculate the average

heat transfer coefficient over the entire length of the tube and the rate of

condensate flow at the bottom of the tube. Confirm that the flow is lami.

nar.

(Ans. 3729 Wim? K, 11.23 x 10™* kg/s, Re = 1018)

6.3 Determine the average heat transfer coefficient and the total condensation

rate for problem 6.2 when the tube is horizontal.

(Ans. 7918 Wim? K, 23.86 x 10° kg/s)

Saturated air-free steam at 75°C condenses on a 0.5 m x 0.5 m vertical

plate maintained at a uniform temperature of 45°C. Calculate (a) the aver-

age heat transfer coefficient over the entire length of the plate, (b) the total

rate of condensation and (c) the thickness of the condensate at the bottom

of the plate.

Be

6.

(Ans. (a) 6142 Wim? K, (b) 1.953 x 107 kg/s, (c) 17 mm)

6.5 Saturated air-free steam at 85°C condenses on the outer surface of 225

horizontal tubes of 12.7 mm outer diameter arranged in a 15x 15 array

Tube surfaces are maintained at 75°C. Calculate the total condensation

rate per metre length of the tube bundle.

(Ans. hp, = 7150 Wim? K, O/L = 697.84 kW/m, W/L = 0.3 kg/sm)

6.6 Saturated steam at atmospheric pressure,condenses on a horizontal copper

tube of 25 mm inner diameter and 29 mm outer diameter through which

water flows at the rate of 25 kg/min entering at 30°C and leaving at 70°C.

Making necessary assumptions, calculate (a) the condensing heat transfer

coefficient, (b) the inside heat transfer coefficient and (c) the length of the

tube.

(Ans. (a) 11,489.0 W/m? K, (b) 4618.2 W/m? K, (c) 5.47 m)

6.7 Saturated water at 100°C is boiled with a copper heating element having a

heating surface of area 0.04 m? which is maintained at 15°C. Calculate the

surface heat flux and the rate of evaporation.

(Ans. 484 kW/m, 30.9 kg/h)

6.8 In the above problem, if the heating element were made of brass instead of

copper, what would be the heat flux at the surface of the heater?

(Ans. 4930 kW/m’)

6.9 Water at atmospheric pressure is boiling on a mechanically polished stait-

less steel surface that is heated electrically from below. Determine the

heat flux from the surface to the water when the surface temperature is

106°C, and compare it with the critical heat flux for nucleate boiling. Re-

peat for the case of water boiling on a Teflon-coated stainless steel UI"

(Ans. 29.29 kWim?, dag = 1.107 MW/m?, 345.3 kW/at?)

uo ——s

Scanned with CamScanner

> we

ae Condensation and Boiling 511

sag the boiling of saturated water at 100°C wi ic heati

a busing a ogc of S00 KW? with an electric heating

, is achieved with a temperature differ- .

ce of 9.3°C. What is the value of the coefficient Cy for the heater sur-

face?

‘ (Ans. 0.008)

1 Repeat Problem 6.9 using a surface temperature of 400°C for the mechani-

6.11 Bify polished stainless stee! surface,

. (Ans. 44.74 kW/m?)

ia Water at saturation temperature and atmospheric pressure is boiled with

6:12 electrically heated, horizontal platinum wire of 1.27 mm diameter. De-

mine the boiling heat transfer coefficient and the heat flux f -

perature difference AT, = 650°C. ux for a tem

(Ans. 368.2 Wim? K, 239.33 kW/m?)

413 Anelectrically heated copper kettle with aflat bottom of diameter 25 emis

to boil water at atmospheric pressure at a rate of 2.5 kg/h. What is the

temperature of the bottom surface of the kettle?

(Ans. 106.1°C)

6:14 An electrically heated, copper, spherical heating element of diameter

10 cm is immersed in water at atmospheric pressure and saturation tem-

ture. The surface of the element is maintained at a uniform tempera-

ture at 115°C. Calculate (a) the surface heat flux, (b) the rate of evapora-

tion and (c) the peak heat flux.

(Ans. 484 kW/m?, (b) 24.3 kg/h, (c) 0.933 MW/m?)

6.15 Water at saturation temperature and atmospheric pressure is boiled in the

stable film boiling regime with an electrically heated, horizontal platinum

wire of diameter 1.27 mm. Calculate the surface temperature necessary to

produce a heat flux of 150 kW/m’.

6.16 Calculate the heat transfer coefficient during stable film boiling of water

from 9 mm diameter horizontal carbon tube. The water is saturated at

100°C and the tube surface is at 1000°C. Assume the emissivity of carbon

surface to be 0.8. Properties of steam are p, = 0.266 kg/m’, fly = 28.7 x

10° kg/ms and k, = 0.0616 W/mk.

(Ans, 283.8 Wim? K)

6.17 Saturated water at 100°C flows through a 20 mm diameter copper tube

with an average velocity of 2 m/s. The tube well is maintained at 111°C.

Calculate the heat flux, assuming nucleate boiling. Take p, = 0.6 kg/m

(Ans. 326 kW/m?)

—__—————

REFERENCES :

pod W Nusselt, "Die Oberflachenkondensation des Wasserdampfes”,

e ler. Deut. Ing.; Vol. 60, p. 541, 1916.

be me Meddatte’ Heat Transmission, 3rd Ea, MeGraw-Hil, New

ork 1954. pags ie ee

: 30WAM! Rohsenow, “Heat Transfer and Temperature, Distribution in

lame ane Heat Tees ie Ye 7,149, 1986,

Scanned with CamScanner

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5824)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Curved Beam Data Hand BookDocument6 pagesCurved Beam Data Hand BookThoran BruceleeNo ratings yet

- Dme Y18Document6 pagesDme Y18Thoran BruceleeNo ratings yet

- FEM NotesDocument84 pagesFEM NotesThoran BruceleeNo ratings yet

- Linked ListDocument15 pagesLinked ListThoran BruceleeNo ratings yet

- Creation of A Binary Search TreeDocument3 pagesCreation of A Binary Search TreeThoran BruceleeNo ratings yet

- Syuabuo: Desican of Machtne Flements - 2Document11 pagesSyuabuo: Desican of Machtne Flements - 2Thoran BruceleeNo ratings yet

- Dme Cie PapersDocument5 pagesDme Cie PapersThoran BruceleeNo ratings yet

- Cbse R: User ManualDocument4 pagesCbse R: User ManualThoran BruceleeNo ratings yet