Professional Documents

Culture Documents

190-196 Alqassar

190-196 Alqassar

Uploaded by

Sumartono SaribOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

190-196 Alqassar

190-196 Alqassar

Uploaded by

Sumartono SaribCopyright:

Available Formats

Journal of Engineering Science and Technology

Vol. 3, No. 2 (2008) 190 - 196

School of Engineering, Taylors University College

190

EXPERIMENTAL DETERMINATION OF ELECTRICAL

AND MECHANICAL PARAMETERS OF DC MOTOR USING

GENETIC ELMAN NEURAL NETWORK

ARIF A. AL-QASSAR

1

*,

MAZIN Z. OTHMAN

2

1

University of Technology, Baghdad, Iraq

2

Technical College, Mosul, Iraq

*Corresponding Author: arifqassar@yahoo.com

Abstract

The most suitable and generalized neural network that represents the control

system dynamics is the Elman Neural Network (ENN). This is due to its ability to

memorize and emulate the system states. Moreover, ENNs learned by Genetic

algorithms are found to be more representative to system order in terms of its

structural complexity in comparison to those learned by back propagation

algorithm. This facility is utilized efficiently to find the minimum ENN structure

that represents the discrete-time state space model of the DC motor. Then by

comparing the ENN weights with the well-known discrete-time state space

equation in terms of the motor physical parameters (moment of inertia, torque

constant, armature inductance, etc.), these parameters can be obtained.

Keywords: Elman Neural Networks, DC motor modelling, Genetic Algorithms,

Parameters system identification.

1. Introduction

The neural networks can be used effectively in identification and control of linear

and nonlinear systems [1-3]. Many neural network structures are suggested to

map the input/output system dynamics such as feed-forward, recurrent and

partially recurrent networks [3]. ENNs, as partially recurrent networks, attract

many researchers due to their ability to memorize the system states and can be

trained using the standard back propagation algorithm. However, it is found that

the Genetic Algorithms (GAs) is more efficient in finding the minimum ENN

structure that emulates suitably the unknown system dynamics [3].

Experimental Determination of Electrical and Mechanical of DC Motor 191

Journal of Engineering Science and Technology AUGUST 2008, Vol. 3(2)

Nomenclatures

A Continuous-time state matrix

B Viscous Friction, N.m/rad.s

b Continuous-time input matrix

C Continuous-time (or discrete time) output matrix

F Discrete time state matrix

G Discrete time input matrix

i

m

Armature current, A

J

Moment of inertia, kg.m

2

K

b

Back e.m.f constant, V/rad.s

K

T

Torque constant, N.m/A

L

m

Armature inductance, H

R

m

Armature resistance,

T Sampling time, s

U System Input (armature voltage), V

W

xc

Hidden-context weights

W

xu

Hidden-input weights

W

yx

Hidden-output weights

X(k) State vector of k

th

sampling instant

X

c

(k) Context layer state vector

Y System output

Greek Symbols

m

Angular speed, rad/s

Furthermore, physical parameters system identification is also an attractive branch

in system modelling which is sometime called the Gray-box system identification.

This branch deals with finding the physical system parameters rather than finding its

input/output mapping as transfer function or state-space representation.

Isermann [4] suggested an estimation procedure for obtaining the physical

parameters of a 6-axis industrial robot DC motor from nonlinear algebraic

relations known from the theoretical modelling. Sandareswaran [5] used neural

networks for computing the real time adaptive speed information of the induction

motor without priori knowledge of the drive.

In this work, the weights of the genetic based ENN with minimum state

realizable DC motor representation are used to find its physical unknowns such as

moment of inertial, torque constant, armature inductance, etc. The learning

procedure is accomplished using input (armature voltage) and output (angular

velocity) data.

2. Utilizing GAs for ENN learning

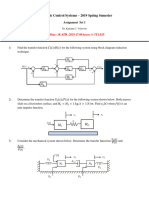

The main structure of the ENN is given in Fig. 1, where it consists of modifiable

feed-forward connections. The ENNs are able to approximate to any arbitrary

precision a discrete time-state- space description [3].

In addition to input and output units, the Elman network has a hidden unit x

k

and

a context unit x

c

. When linear hidden units are adopted and the biases of the hidden

and output units are zero then the dynamic equations of the Elman Network are:

192 A. A. Al-Qassar and M. Z. Othman

Journal of Engineering Science and Technology AUGUST 2008, Vol. 3(2)

) 1 ( ) ( ) ( + = k U W k X W k X

xu c xc

(1a)

) 1 ( ) ( = k X k X

c

(1b)

) ( ) ( k X W k Y

yx

= (1c)

where the matrices W

xc

, W

xu

, and W

yx

define the interconnection for the context-hidden

layer , the input-hidden layer, and the hidden-output layer, respectively. Eq. (1) is the

standard state space description of dynamic systems where the order of the model

depends on the number of states, which is also the number of hidden units.

In order to update the weight matrices W

xc

, W

xu

, and W

yx

, the GAs is used as an

optimization procedure to minimize the square of error between the Neural

Network output and the actual output data (supervised learning). The standard GAs

operations as selection, crossover and mutation are used.

3. Physical Parameter Evaluation of a DC Motor

The armature controlled DC motor with fixed excitation can be described by the

following state space equations [8];

GU FX X + =

&

(2a)

CX Y = (2b)

where

=

m

m

m

b

T

L

R

L

K

J

K

J

B

F

(3)

=

m

L

G

1

0

(4)

| | 0 1 = C (5)

Fig. 1. The Modified Elman Network.

U(k)

X(k)

Context

unit

Ouput

unit

Y(k)

Hidden

unit

Input

unit

X

c

(k)

Experimental Determination of Electrical and Mechanical of DC Motor 193

Journal of Engineering Science and Technology AUGUST 2008, Vol. 3(2)

are the state, input and output matrices.

In Eq. (3), B is viscous friction constant, J is the moment of inertia, K

T

is the

torque constant, K

b

is the back e.m.f constant, R

m

is the armature resistance

,

L

m

is

the armature inductance,

m

m

m

i

X

=

is the angular motor speed, i

m

is the

armature current, and U is the armature voltage.

The equivalent discrete-time state space equation is [7]

k k k

bU AX X + =

+1

(6a)

k k

CX Y =

(6b)

where the state and input matrices (A and b) are evaluated by:

i

i

F

i

T T

F FT I A

!

.........

! 2

2

2

+ + + + =

(7)

1

2

!

........

! 2

+ + + =

i

i

F

i

T

FG

T

TG b

(8)

Usually T (the sampling time) is chosen to be less than one, therefore Eqs. (7)

and (8) can be truncated up to T, then

=

m

m

m

b

T

L

T R

L

T K

J

T K

J

BT

A

1

1

(9)

=

m

L

T

B

0

(10)

and C as in Eq. (3).

Therefore, comparing Eqs. (1a) and (1c) with Eqs. (6a) and (6b), one can find that:

= =

=

m

m

m

b

T

xc xc

xc xc

xc

L

T R

L

T K

J

T K

J

BT

A

w w

w w

W

1

1

22 21

12 11 (11)

= =

=

m

xu

xu

xu

L

T

b

w

w

W

0

21

11 (12)

| | | | 0 1

12 11

= = = C w w W

yx yx yx

(13)

Indeed, a special ENN was suggested to match the state space equation of DC

motor. The weights of this ENN are used in Eqs. (11) and (12) in order to obtain

directly, using GAs, the unknown physical parameters. Notice that some ENN weights

are forced to have constant values ( 0 , 1 , 0

12 11 11

= = =

yx yx xu

w w w ). However, in order to

have consistency in solving Eqs. (11) and (12) by the GAs, it is assumed that the

194 A. A. Al-Qassar and M. Z. Othman

Journal of Engineering Science and Technology AUGUST 2008, Vol. 3(2)

armature resistance is known as it can be directly measured using Volt-Ampere method

while the other physical parameters (J, K

T

, K

b

, B, and L

m

) can be suitably evaluated.

4. Experimental Results

The parameters of the separately excited DC motor under consideration are:

Rated armature voltage = 220 V, Rated current = 3.3 A,

Rated horse power = 0.75 hp, Moment of inertia, J = 0.052 kg.m

2

,

Torque constant, K

T

= 0.66 N.m/A, Back e.m.f constant, K

b

= 0.64 V/rad.s

Armature resistance, R

m

= 2.3 , Armature inductance, L

m

= 34.5x10

-3

H,

Viscous friction control, B = 0.002 N.m/rad.s,

These parameters are obtained from the nameplate and the data sheet of the

motor. In order to have a priori knowledge about the motor dynamic, a step

armature voltage is applied and a motor speed is recorded. From this test it was

found that the motor time constant is nearly equal to 0.4 s, therefore having 0.01 s

as a sampling time is adequate.

An interface card was built to record 4000 samples of input-output where the

learning input data are taken as follows:

<

<

<

<

=

s 40 28 V 9

s 28 16 V 7

s 16 3 V 8 . 3

s 3 0 V 0

) (

t

t

t

t

k U

(14)

The genetic algorithm of 20 population size with crossover probability (P

c

= 0.75)

and mutation probability (P

m

= 0.04) is used to find the physical parameters of the DC

motor using the ENN of Fig. 2.

The variations of each unknown parameter during 160 generations are shown

in Figs. 3 (a) through (e). The actual and the mean values of the physical

parameters during the last 60 generations are shown in Table 1.

Moreover, it is clearly illustrated from Fig. 4 that the responses of the motor

and the trained ENN are comparable.

U(k)

Y(k)

Fig. 2. The ENN for the DC Motor.

Experimental Determination of Electrical and Mechanical of DC Motor 195

Journal of Engineering Science and Technology AUGUST 2008, Vol. 3(2)

Table 1. The Actual and Estimated DC Motor Physical Parameters.

Physical

parameters

The actual

parameters

The estimated

parameters

J (kg.m

2

) 0.045 0.052

L

m

(mH) 0.03 0.036

K

b

(V/rad.s) 0.64 0.58

K

t

(N.m/A) 0.62 0.65

B (N.m/rad/s) 710

-3

5.610

-3

(c) Back e.m.f Constant.

Number of Generations

0 20 40 60 80 100 120 140 160

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

B

a

c

k

e

.

m

.

f

.

c

o

n

s

t

a

n

t

,

K

b

(

V

/

r

a

d

.

s

)

T

o

r

q

u

e

c

o

n

s

t

a

n

t

,

K

T

(

N

.

m

/

A

)

0 20 40 60 80 100 120 140 160

0.4

0.45

0.5

0.55

0.6

0.65

0.7

0.75

Number of Generations

(d) Torque Constant.

0 20 40 60 80 100 120 140 160

0

0.01

0.02

0.03

0.04

0.05

0.06

Number of Generations

M

o

m

e

n

t

o

f

i

n

e

r

t

i

a

,

J

2

(a) Moment of Inertia.

0 20 40 60 80 100 120 140 160

0.015

0.02

0.025

0.03

0.035

0.04

0.045

A

r

m

a

t

u

r

e

i

n

d

u

c

t

a

n

c

e

,

L

m

(

m

H

)

(b) Armature Inductance.

0 20 40 60 80 100 120 140 160

0

1

2

3

4

5

6

7

x 10

-3

Number of Generations

V

i

s

c

o

u

s

f

r

i

c

t

i

o

n

c

o

e

f

f

i

c

i

e

n

t

,

B

(

N

.

m

/

r

a

d

.

s

)

(e) Viscous Friction Coefficient.

Fig. 3. Variation of Physical

Parameters against Number

of Generations.

Number of Generations

196 A. A. Al-Qassar and M. Z. Othman

Journal of Engineering Science and Technology AUGUST 2008, Vol. 3(2)

5. Conclusions

Linear ENN based Genetic algorithm is not only used to find the exact state-space

order of the linear system, but also to identify its unknown physical parameters.

Comparing the Elman neural network weights with discrete-time state space

model representative does this by its physical parameters. As illustrates in the

case of DC motor, the unknown parameters such as torque constant, armature

inductance, viscous friction and the reflected moment of inertia on the motor shaft

are very useful parameters for control engineers in servomechanism applications.

In contrast to the physical parameters identification by comparing the ENN with

the symbolic representation of system state space, it is required during learning

procedure that some weights should be fixed to certain values and update those

which are symbolically related to the unknown physical parameters. This learning

paradigm can cause problem of falling into local minimum if back propagation

technique is used, while GA's can easily cooperate with such situation.

References

1. Chen, S. and Billings, S. A. (1992). Neural Networks for non-linear dynamic

system modelling and identification. Int. J. Control, Vol.56, No.2, 319-346.

2. Narendra, K. and Parthasarathy, K. (1990). Identification and control of

dynamic system using neural networks. IEEE transaction on Neural

Networks.Vol.1, No.1, 1054-9227.

3. Pham, D. T., Truong and Liu Xing. (1997). Neural Networks for identification,

prediction and control. Springer-Verlag.

4. Isermann, R. (1992). Estimation of physical parameters for dynamic

processes with application to an industrial robot. Int. J. Control, Vol.55,

No.6, 1287-1298.

5. Sundareswaran, K., Palani, S. (1997). Speed Identification of voltage controlled

induction motor drive using neural networks. International Conference on

Computer Application in Electrical Engineering Recent Advances. India.

6. Franklin, G. F., Powell, J. D. and Workman, M. L. (1998). Digital control of

dynamic systems. Addison-Wesley.

7. D'AZZO, J. J. (1988). Linear Control system analysis and design, Conventional

and Modern, McGraw-Hill Book Company.

0 500 1000 1500 2000 2500 3000 3500 4000

- 100

0

100

200

300

400

500

600

700

Time (samples)

M

o

t

o

r

a

n

d

E

N

N

s

p

e

e

d

s

(

r

.

p

.

m

)

DC Motor

Trained ENN

Fig. 4. The ENN and the DC Motor Speed Responses.

You might also like

- Task 1 - Model AnswerDocument4 pagesTask 1 - Model AnswerShauryaNo ratings yet

- Note: No Additional Answer Sheets Will Be Provided.: (An Autonomous Institution)Document3 pagesNote: No Additional Answer Sheets Will Be Provided.: (An Autonomous Institution)Rajesh AnugulaNo ratings yet

- Post-Outage State Estimations For Outage ManagementDocument5 pagesPost-Outage State Estimations For Outage ManagementSlimane SouagNo ratings yet

- Analysis of Electromagnetic Characteristics of Asynchronous Induction MachineDocument4 pagesAnalysis of Electromagnetic Characteristics of Asynchronous Induction MachineИгор СтерјовскиNo ratings yet

- Adaptive Microcomputer: Controller ImplementationDocument11 pagesAdaptive Microcomputer: Controller ImplementationToe Zune MayNo ratings yet

- Modelling Phtsical SystemsDocument9 pagesModelling Phtsical SystemsHüseyin Murat PolaterNo ratings yet

- Modeling Induction Motors: Abstract: in This Paper, A Novel Technique For On-Line Estimation of MostDocument10 pagesModeling Induction Motors: Abstract: in This Paper, A Novel Technique For On-Line Estimation of Mostseshubabu_999No ratings yet

- Optimal State Space Control DC MotorDocument6 pagesOptimal State Space Control DC MotoraurivalNo ratings yet

- State Space Analysis of Power System Stability EnhDocument6 pagesState Space Analysis of Power System Stability EnhAmmar MyhoubNo ratings yet

- EE531 Lab 3Document11 pagesEE531 Lab 3ahmed113525No ratings yet

- A, B C j ∈ m τ ∈ (0 ≤ τ ≤ τ ≤ ≤ τ j ∈Document3 pagesA, B C j ∈ m τ ∈ (0 ≤ τ ≤ τ ≤ ≤ τ j ∈Originall LozanoNo ratings yet

- On-Line Modal Monitoring of Aircraft Structures Under Unknown Excitation SDocument15 pagesOn-Line Modal Monitoring of Aircraft Structures Under Unknown Excitation SLida H CaballeroNo ratings yet

- Prediction of Stability and Performance of An Active Mechanical Structure Under Uncertainty Conditions Using Finite Element and Neural ComputationDocument8 pagesPrediction of Stability and Performance of An Active Mechanical Structure Under Uncertainty Conditions Using Finite Element and Neural ComputationHadhoud MécaniqueNo ratings yet

- Effect of Compensation Factor On The Subsynchronous Resonance in Single Machine Infinite Bus SystemDocument6 pagesEffect of Compensation Factor On The Subsynchronous Resonance in Single Machine Infinite Bus SystemLong LeoNo ratings yet

- Unesco - Eolss Sample Chapters: Fundamentals of Electrical Drive ControlsDocument10 pagesUnesco - Eolss Sample Chapters: Fundamentals of Electrical Drive ControlsMsc MaiaNo ratings yet

- Induction Motor Modelling and Interfacing Technique For Fasta Transiet Stability SimulationDocument4 pagesInduction Motor Modelling and Interfacing Technique For Fasta Transiet Stability Simulationjaroldane1000No ratings yet

- AEE 68 1 2019 - Art - 8Document14 pagesAEE 68 1 2019 - Art - 8Ali ErNo ratings yet

- Acs 2019s1 Assn1Document5 pagesAcs 2019s1 Assn1MiraelNo ratings yet

- Calculation of Lightning-Induced Voltages in MODELS Including Lossy Ground EffectsDocument6 pagesCalculation of Lightning-Induced Voltages in MODELS Including Lossy Ground EffectsTante HannyNo ratings yet

- Electromagnetic Levitation System: An Experimental ApproachDocument7 pagesElectromagnetic Levitation System: An Experimental Approachsh1n00b1No ratings yet

- Scattering by A Truncated Periodic Array: II IIDocument8 pagesScattering by A Truncated Periodic Array: II IIKalyan SinghNo ratings yet

- RBF BP JieeecDocument5 pagesRBF BP JieeecEyad A. FeilatNo ratings yet

- Online Control of SVC Using ANN Based Pole Placement ApproachDocument5 pagesOnline Control of SVC Using ANN Based Pole Placement ApproachAbdo AliNo ratings yet

- Comparison Between Full Order and Minimum Order Observer Controller For DC MotorDocument6 pagesComparison Between Full Order and Minimum Order Observer Controller For DC MotorInternational Journal of Research and DiscoveryNo ratings yet

- Estimation of Unbalance Parameters Using Finite Element Method and Joint Input-State Estimation TechniqueDocument8 pagesEstimation of Unbalance Parameters Using Finite Element Method and Joint Input-State Estimation TechniqueakashNo ratings yet

- Dfig Book PDFDocument29 pagesDfig Book PDFSrinivasan PurushothamanNo ratings yet

- Mathematical Modeling of Open Loop PMDC Motor Using Matlab/SimulinkDocument6 pagesMathematical Modeling of Open Loop PMDC Motor Using Matlab/SimulinkSharath KumarNo ratings yet

- Simulation of Electric Machine and Drive Systems Using Matlab and SimulinkDocument17 pagesSimulation of Electric Machine and Drive Systems Using Matlab and SimulinkSamuel Alves de SouzaNo ratings yet

- Fast Transients Analysis of Non-Uniform Multiconductor Transmission Lines Excited by Incident FieldDocument6 pagesFast Transients Analysis of Non-Uniform Multiconductor Transmission Lines Excited by Incident FieldItalo ChiarellaNo ratings yet

- Simulation of Piezoelectric Devices by Two - and Three-Dimensional Finite ElementsDocument15 pagesSimulation of Piezoelectric Devices by Two - and Three-Dimensional Finite Elementszhangcwy1225No ratings yet

- Robust Position Control of A DC Motor by Sliding ModeDocument10 pagesRobust Position Control of A DC Motor by Sliding ModeDuy TrươngNo ratings yet

- Jpe 8-4-8Document9 pagesJpe 8-4-8Hieu LENo ratings yet

- Mini Problem s2 2023Document5 pagesMini Problem s2 2023Annette TageufoueNo ratings yet

- Trzyna 1999Document7 pagesTrzyna 1999Laiba GulNo ratings yet

- 10 - Overvoltage Calculation by Monte Carlo Method With Accurate Substation Components Modeling PDFDocument5 pages10 - Overvoltage Calculation by Monte Carlo Method With Accurate Substation Components Modeling PDFAnonymous IjLgxu9fXPNo ratings yet

- Experiment No.03: Mathematical Modeling of Physical System: ObjectiveDocument5 pagesExperiment No.03: Mathematical Modeling of Physical System: ObjectiveSao SavathNo ratings yet

- Exploring The Problems and Remedies: Lech M. Grzesiak and Marian P. KazmierkowskiDocument12 pagesExploring The Problems and Remedies: Lech M. Grzesiak and Marian P. KazmierkowskiSathishraj SaraajNo ratings yet

- Acs 2018s2 Assn1Document4 pagesAcs 2018s2 Assn1MiraelNo ratings yet

- Modeling of A Three-Axes MEMS Gyroscope With Feedforward PI Quadrature CompensationDocument10 pagesModeling of A Three-Axes MEMS Gyroscope With Feedforward PI Quadrature CompensationDavide MaranoNo ratings yet

- Design of PID CONTROLLERDocument6 pagesDesign of PID CONTROLLERRAJ KUMAR SHIHINo ratings yet

- Application Of..... (ICEE2010) PDFDocument6 pagesApplication Of..... (ICEE2010) PDFdennypolariszNo ratings yet

- Internal ModelDocument15 pagesInternal ModelDiego RamirezNo ratings yet

- Output Feedback Stabilization of Wireless Networked Control System With Packet DropoutDocument6 pagesOutput Feedback Stabilization of Wireless Networked Control System With Packet DropoutMicuko OšinokoNo ratings yet

- International Conference NeruDocument10 pagesInternational Conference NeruNeeru SinghNo ratings yet

- Simulation and Analysis Calculation of PMBLDCM Based On Time-Stepping Finite Element and Matlab MethodsDocument4 pagesSimulation and Analysis Calculation of PMBLDCM Based On Time-Stepping Finite Element and Matlab Methodsபொன்னியின் செல்வன்No ratings yet

- Control System Lab Manual by AMIT KUMARDocument35 pagesControl System Lab Manual by AMIT KUMARamit kumar83% (6)

- Smart Materials and Structures: International WorkshopDocument10 pagesSmart Materials and Structures: International WorkshopPartha SarathiiNo ratings yet

- Design of A Distributed Power System Stabiliser: Infinite BusbarDocument6 pagesDesign of A Distributed Power System Stabiliser: Infinite BusbarRudanekNo ratings yet

- Modeling and Analysis of Self Excited Slip Ring Induction Generator Using Newton Raphson MethodDocument10 pagesModeling and Analysis of Self Excited Slip Ring Induction Generator Using Newton Raphson MethodIJERD100% (1)

- Optimal Location of SVC and TCSC For Voltage Stability EnhancementDocument6 pagesOptimal Location of SVC and TCSC For Voltage Stability EnhancementnikhileshwarNo ratings yet

- Constrained Predictive Control of A Servo-Driven Tracking TurretDocument6 pagesConstrained Predictive Control of A Servo-Driven Tracking TurretVu Duc TruongNo ratings yet

- Chang 2020Document14 pagesChang 2020René Mboyo KouayepNo ratings yet

- Advances in Natural and Applied Sciences, 8 (21) Special 2014, Pages: 7-14Document8 pagesAdvances in Natural and Applied Sciences, 8 (21) Special 2014, Pages: 7-14Gajalakshmi SaravananNo ratings yet

- JESV5SI0109Document5 pagesJESV5SI0109Kiran YaddanapudiNo ratings yet

- 11 2017jamdsm0080Document12 pages11 2017jamdsm0080Traore k.B.ClenaNo ratings yet

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetRating: 2 out of 5 stars2/5 (1)

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNo ratings yet

- NOTH Menu Aug 22Document10 pagesNOTH Menu Aug 22Devin SwanepoelNo ratings yet

- Immunomodulators: By: Payal Suthar Department of PharmacognosyDocument26 pagesImmunomodulators: By: Payal Suthar Department of PharmacognosyHely Patel100% (1)

- PM265 ch2Document47 pagesPM265 ch2M. AhmedNo ratings yet

- Final Health EducDocument139 pagesFinal Health EducsprrwgoldenNo ratings yet

- Analyzing The Value of Vehicle Maintenance Activities: Selin Dönmez Mahasin ZemmouriDocument71 pagesAnalyzing The Value of Vehicle Maintenance Activities: Selin Dönmez Mahasin ZemmouriAgnys Gomes - DR UNITECNo ratings yet

- 20130401Document15 pages20130401SebNo ratings yet

- SGP TR 012Document276 pagesSGP TR 012Kevin Devalentino Versi IINo ratings yet

- Ero / Bheemadevarapally Ero / Bheemadevarapally Ero / Bheemadevarapally Sub Ero Gudur & Ero MahabubabadDocument59 pagesEro / Bheemadevarapally Ero / Bheemadevarapally Ero / Bheemadevarapally Sub Ero Gudur & Ero MahabubabadHARSHAVARDHAN REDDY MYADADHANo ratings yet

- THE LAW PERTAINING TO PRIVATE PERSONAL & COMML RELATIONS - AdDU Bar NotesDocument54 pagesTHE LAW PERTAINING TO PRIVATE PERSONAL & COMML RELATIONS - AdDU Bar NotesDevilleres Eliza DenNo ratings yet

- Geophysics & Remote SensingDocument5 pagesGeophysics & Remote SensingHaris Eko SetyawanNo ratings yet

- Kerala University of Health Sciences Thrissur - 680 596: Application For Duplicate Mark Lists / CertificatesDocument2 pagesKerala University of Health Sciences Thrissur - 680 596: Application For Duplicate Mark Lists / CertificatesDevassy KVNo ratings yet

- 01 DTMDocument2 pages01 DTMMauro BorgesNo ratings yet

- HXGP 116 Detailed Course OutlineDocument2 pagesHXGP 116 Detailed Course OutlinePARDON MATARENo ratings yet

- APA102-2020 LED DatasheetDocument16 pagesAPA102-2020 LED DatasheetDaisyNo ratings yet

- Bird HDC High Density CleanerDocument2 pagesBird HDC High Density CleanerFaridUZamaNo ratings yet

- A Brief Note On Plants of Medicinal Importance To LivestockDocument84 pagesA Brief Note On Plants of Medicinal Importance To LivestockSunil100% (1)

- Climate Variability and Climate Change 2016Document91 pagesClimate Variability and Climate Change 2016Laila Guarin100% (1)

- 1953-File Utama Naskah-6037-2-10-20200429Document20 pages1953-File Utama Naskah-6037-2-10-20200429taufik hidayatNo ratings yet

- Cost Effective Housing PDFDocument16 pagesCost Effective Housing PDFSaurav ShresthaNo ratings yet

- LEFORT, Claude. Thinking With and Against Hannah ArendtDocument14 pagesLEFORT, Claude. Thinking With and Against Hannah ArendtGabriel VecchiettiNo ratings yet

- BD BBL, Crystal Identification SystemsDocument40 pagesBD BBL, Crystal Identification SystemsAnabell Sanchez PuertinezNo ratings yet

- The Unstoppable Human Species The Emergence of Homo Sapiens in Prehistory John J Shea 2 All ChapterDocument52 pagesThe Unstoppable Human Species The Emergence of Homo Sapiens in Prehistory John J Shea 2 All Chapterfrieda.jaimes821100% (9)

- A Critical Literature Review of World-Class Universities Characteristics, Enablers, and StrategiesDocument9 pagesA Critical Literature Review of World-Class Universities Characteristics, Enablers, and StrategiesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Hitting LogsDocument3 pagesHitting LogsSTRESSEDD -No ratings yet

- Savage: Science Fiction Roleplaying For Savage WorldsDocument45 pagesSavage: Science Fiction Roleplaying For Savage WorldsJohn Churchill0% (1)

- Catalogo Biomédico 2016 PDFDocument36 pagesCatalogo Biomédico 2016 PDFMartinNo ratings yet

- A Brief History of Jazz DrummingDocument8 pagesA Brief History of Jazz DrummingManoloPantalonNo ratings yet

- Production Planning - 095252Document13 pagesProduction Planning - 095252Jocidelle LubricoNo ratings yet

- BEM3060 Managing EntrepreneuriallyDocument13 pagesBEM3060 Managing Entrepreneuriallyngolodedan2No ratings yet