Professional Documents

Culture Documents

Prefabrication in India

Prefabrication in India

Uploaded by

apoorva jayaswalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Prefabrication in India

Prefabrication in India

Uploaded by

apoorva jayaswalCopyright:

Available Formats

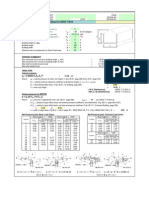

prefabrication equipments

prefabrication is the practice of assembling components of a structure in a factory or other cranes :

mobile crane

manufacturing site, and transporting the complete assemblies or sub- assemblies to the

tower crane (above 3stories)

construction site where the structure is to be located. lifting tools:

spreader beams

advantages : disadvantages: wire rope slings

High quality product Careful handling of prefabricated components such rigging tools:

Labor related savings as concrete panels or steel and glass panels is eye bolt

Savings in time required. shakles

Overall efficiency is greatly increased. Attention has to be paid to the strength and hooks 17

Overall efficiency is greatly increased corrosion-resistance of the joining of prefabricated

Mass production is easier and quick sections . MATERIALs USED IN Prefabrication

SYSTEM

Protected and controlled production leaks can form at joints in prefabricated components. Concrete, Steel, Treated wood, Aluminum, Cellular concrete, Light weight

environmentProtected and controlled production Transportation costs may be higher for voluminous concrete elements, Ceramic products, etcp

environment prefabricated sections .

Potential for lower production costs and other Large prefabricated sections require heavy-duty

cost savings cranes and precision measurements.

COMPONENTS OF PREFAB

Flooring and Roofing Scheme ,Beams Columns Walls ,Staircase Lintels

Sunshade/Chajja

design consderations:

final position and loads

transportation requirements

self load and position during transportation –

self load and position during storing –

lifting loads – distribution of lifting points – optimal way of lifting

types of pre cast system

large panel system frame systems lift slab systems prefabrication

box-like structure.

both vertical and horizontal

Components are usually linear

elements.

partially precast in plant (pillars) / partially

precast on- site (slabs)

in india

elements are load-bearing. The beams are seated on corbels of the .one or more storey high pillars (max 5).

one-story high wall panels (cross- pillars usually with hinged- joints (rigid up to 30 storey high constructions. apoorva jayaswal

wall system / longitudinal wall connection is also an option). special designed joints and temporary joints. 1bq18at012

system / two way system). Joints are filled with concrete at the slabs are casted on the ground (one on top of the

one-way or two way slabs. site. other) – then lifted with crane or special elevators. vii a

bmssa

You might also like

- Part Catelogue 750 Kva - KTA 38 G2 I - 5276656Document133 pagesPart Catelogue 750 Kva - KTA 38 G2 I - 5276656sblnt2008100% (4)

- Long Span Structure Portal FrameDocument25 pagesLong Span Structure Portal Frameharish gupta100% (1)

- Frame & Subframe Analysis For Vertical and Lateral LoadDocument39 pagesFrame & Subframe Analysis For Vertical and Lateral Loaddixn__100% (6)

- Wind Asce7 10Document5 pagesWind Asce7 10saravanan4286100% (1)

- National Productivity and Quality Specifications (NPQS) : C4-30 Pile TestingDocument36 pagesNational Productivity and Quality Specifications (NPQS) : C4-30 Pile TestingJacky TiongNo ratings yet

- Set, By, Fahad A Set, By, Fahad A: Pre-CastDocument3 pagesSet, By, Fahad A Set, By, Fahad A: Pre-CastFãhâd Õró ÂhmédNo ratings yet

- BC 3Document17 pagesBC 3chitrakshiNo ratings yet

- Criteria For Suspended Pipelines 5Document1 pageCriteria For Suspended Pipelines 5hamza laribiNo ratings yet

- Structural Systems For High Rise BuildingsDocument7 pagesStructural Systems For High Rise BuildingsSuncica Zurkovic100% (1)

- Chapter 2Document21 pagesChapter 2shamilnasir55No ratings yet

- Basics of Precast ConstructionDocument27 pagesBasics of Precast Constructionsatheesh kumarNo ratings yet

- Tos PDFDocument212 pagesTos PDFNikita MadaanNo ratings yet

- OrbitorDocument6 pagesOrbitorHairul NurbaityNo ratings yet

- Circulating Vertical ConveyorsDocument6 pagesCirculating Vertical Conveyors18118135No ratings yet

- Precast ConcreteDocument3 pagesPrecast ConcreteSage UniversityNo ratings yet

- Stability of Thin-Walled Composite StructuresDocument2 pagesStability of Thin-Walled Composite StructuresTarik Hassan ElsonniNo ratings yet

- Climbing Formworks: Reported By: Jol Marie L. LlantoDocument10 pagesClimbing Formworks: Reported By: Jol Marie L. LlantoJet JavierNo ratings yet

- "Prefabricated Technique in Construction Industry": M.E. Construction Engineering & ManagementDocument33 pages"Prefabricated Technique in Construction Industry": M.E. Construction Engineering & ManagementRishabh sharmaNo ratings yet

- L12 FormworkDocument242 pagesL12 FormworkErnst VenterNo ratings yet

- K.nischit 1RW20AT045 Assignment 8 FormworkDocument3 pagesK.nischit 1RW20AT045 Assignment 8 Formworkpavan.t.1rw20at069No ratings yet

- Prefabricated StructuresDocument25 pagesPrefabricated StructuresBK GoswamiNo ratings yet

- Recommended Frame Shoring Erection ProceduresDocument2 pagesRecommended Frame Shoring Erection ProceduresDak KaizNo ratings yet

- Pre Fabricated Modular StructuresDocument30 pagesPre Fabricated Modular Structuressanjai_rahulNo ratings yet

- 1 Prefabricated StructuresDocument42 pages1 Prefabricated Structurespooja apteNo ratings yet

- Prefabricated Structures - Exam, Viva, Interview Questions With Solution For Civil EngineeringDocument15 pagesPrefabricated Structures - Exam, Viva, Interview Questions With Solution For Civil Engineeringनोलराज पौडेल100% (1)

- Fdocuments - in Design Gantry Crane CalculationsDocument6 pagesFdocuments - in Design Gantry Crane CalculationstotoNo ratings yet

- 2-Production Technology of Prefabricated ComponentsDocument70 pages2-Production Technology of Prefabricated Componentspooja apteNo ratings yet

- Pre-Fabricated Structures: BY Priyaranjan Behera 8 Sem, Civil Engg PMEC, BerhampurDocument29 pagesPre-Fabricated Structures: BY Priyaranjan Behera 8 Sem, Civil Engg PMEC, BerhampurrajeshNo ratings yet

- Prefab StructuresDocument30 pagesPrefab StructuresJaiNo ratings yet

- Bracing DesignDocument1 pageBracing DesignAvijit Kar100% (1)

- PFS Full 5Document125 pagesPFS Full 5Itsme PrabhaNo ratings yet

- Irjet Design Analyasis and OptimizationDocument5 pagesIrjet Design Analyasis and OptimizationMustafa MazinNo ratings yet

- Hsbei 1412Document2 pagesHsbei 1412Heru WibowoNo ratings yet

- VSL Bridge ConstructionDocument28 pagesVSL Bridge ConstructionTran Nguyen Khiem100% (1)

- CxWa Workplace Systems Product Overview 23-09-10 KAT0401-0002-EDocument16 pagesCxWa Workplace Systems Product Overview 23-09-10 KAT0401-0002-Ecao van daiNo ratings yet

- Sustainability 12 00974 v2 PDFDocument16 pagesSustainability 12 00974 v2 PDFTAHIR TINWALANo ratings yet

- Checklist of Hazards in Tower CraneDocument11 pagesChecklist of Hazards in Tower CraneBruceHowardNo ratings yet

- 07 PRAMIN 1 Diaphragm Design 201611071Document45 pages07 PRAMIN 1 Diaphragm Design 201611071João Paulo MendesNo ratings yet

- Pre Fabricated Modular Structures: B.M.C.T - ViiDocument25 pagesPre Fabricated Modular Structures: B.M.C.T - ViiKanika SinghNo ratings yet

- Prefabrication Techniques: Precast Concrete Beams and GirdersDocument1 pagePrefabrication Techniques: Precast Concrete Beams and GirdersJAI SURYA TAMIZHANo ratings yet

- Max Meyer - BDET Presentation - 5th JuneDocument62 pagesMax Meyer - BDET Presentation - 5th JuneSailaja VempatiNo ratings yet

- Building Layout Plot Plan Most If Not All Communities Require The Builder or Owner To Furnish A Plot Plan BeforeDocument14 pagesBuilding Layout Plot Plan Most If Not All Communities Require The Builder or Owner To Furnish A Plot Plan BeforeMahad Ahmed HilowleNo ratings yet

- نظام انشاءاتDocument10 pagesنظام انشاءاتAziz SaedNo ratings yet

- IJRPR3495Document10 pagesIJRPR3495TEII03Yogesh JangidNo ratings yet

- CFR 2011 Title29 Vol8 Sec1926 704Document1 pageCFR 2011 Title29 Vol8 Sec1926 704Arnold GarciaNo ratings yet

- Our Ref:: We Shape A,, and Built EnvironmentDocument7 pagesOur Ref:: We Shape A,, and Built EnvironmentThaungMyintNo ratings yet

- KBK BR PDFDocument36 pagesKBK BR PDFselva.uae8207No ratings yet

- Building Technology: Pre-CastDocument12 pagesBuilding Technology: Pre-Castvalerie samarNo ratings yet

- Construction Planning, Equipment, Arid Methods Cranes: Bridge ProjectDocument3 pagesConstruction Planning, Equipment, Arid Methods Cranes: Bridge ProjectYusril HadiNo ratings yet

- CRUSINGDocument1 pageCRUSINGTomas Ttica GasparNo ratings yet

- Artisanal Manufactured HousesDocument14 pagesArtisanal Manufactured HousesSathish Moses RathinaswamyNo ratings yet

- 1.650 ATP 2023-24 GR 8 Techn FinalDocument7 pages1.650 ATP 2023-24 GR 8 Techn FinalKgotsofalangNo ratings yet

- Dr. Songkiat-Handout Precast Segmental Construction TechnologyDocument25 pagesDr. Songkiat-Handout Precast Segmental Construction TechnologymitnathNo ratings yet

- Non-Conventional Crane RunwayDocument5 pagesNon-Conventional Crane RunwaycharanNo ratings yet

- SAFETY in Form Work ProgramDocument73 pagesSAFETY in Form Work ProgramBharath CjNo ratings yet

- Precast and Prefab PDFDocument49 pagesPrecast and Prefab PDFAshish BhoirNo ratings yet

- Seismic Design of Cast-in-Place Concrete Diaphragms, Chords and CollectorsDocument71 pagesSeismic Design of Cast-in-Place Concrete Diaphragms, Chords and CollectorsMd Abdur RasidNo ratings yet

- MS Connecting Bridge Erection ACPLDocument16 pagesMS Connecting Bridge Erection ACPLRaju BiswasNo ratings yet

- Jibcranes 2012 05 23 eDocument5 pagesJibcranes 2012 05 23 ehimanshuNo ratings yet

- Self-Launching Erection Machines For Precast Concrete Bridges PDFDocument22 pagesSelf-Launching Erection Machines For Precast Concrete Bridges PDFMahmood MuftiNo ratings yet

- AISC - Design Guide 10 - Errata - Erection Bracing of Low - Rise Structural Steel Buildings PDFDocument2 pagesAISC - Design Guide 10 - Errata - Erection Bracing of Low - Rise Structural Steel Buildings PDFapuhapuh_153349No ratings yet

- Jobs For NICMAR Alumni (Responses)Document6 pagesJobs For NICMAR Alumni (Responses)Tushar DoshiNo ratings yet

- Agitatorhe On-Demand System: Technical SpecificationDocument1 pageAgitatorhe On-Demand System: Technical SpecificationJuanSebastianAlonsoNo ratings yet

- Diamond Chain StandardDocument3 pagesDiamond Chain StandardfaridyeniNo ratings yet

- Double Pipe & Multitube HEDocument4 pagesDouble Pipe & Multitube HEjagadish2012100% (1)

- CONCRETE IN BIAXIAL CYCLIC COMPRESSION - BuyukozturkDocument16 pagesCONCRETE IN BIAXIAL CYCLIC COMPRESSION - Buyukozturkdmep25No ratings yet

- Welmec 2Document71 pagesWelmec 2jaruna bNo ratings yet

- 07 Pulleys and DriveDocument6 pages07 Pulleys and DriveJerry HukyNo ratings yet

- Sure 4x100W at 4 Ohm TK2050 Class-D Audio Amplifier BoardDocument5 pagesSure 4x100W at 4 Ohm TK2050 Class-D Audio Amplifier BoardyodifoyorNo ratings yet

- 12 W20-Engine PDFDocument64 pages12 W20-Engine PDFСаша НемешNo ratings yet

- Terms in StaircaseDocument84 pagesTerms in StaircasesoumyasonawaneNo ratings yet

- Paola SassiDocument21 pagesPaola Sassisehgal91No ratings yet

- JK Transmission Cat.Document20 pagesJK Transmission Cat.Alexander López VillavicencioNo ratings yet

- Hewitt Hose Identify IDDocument2 pagesHewitt Hose Identify IDEdisonCorderoNo ratings yet

- 23-02-10 Design Problem-2 Storey Residence-R1 - RaniDocument4 pages23-02-10 Design Problem-2 Storey Residence-R1 - RaniROSS JOSEPH FAMARINNo ratings yet

- F1 11437SDocument8 pagesF1 11437ScolinyNo ratings yet

- ArcGIS Lab 1 - IntroductionDocument24 pagesArcGIS Lab 1 - IntroductionnayabNo ratings yet

- Phase 1 Event Entertainment Private Limi..Document18 pagesPhase 1 Event Entertainment Private Limi..Sana KhanNo ratings yet

- RIPE Whois Database Queries Reference CardDocument2 pagesRIPE Whois Database Queries Reference Cardapi-3744861100% (4)

- 2N2222 C118536Document3 pages2N2222 C118536Javier PuenteNo ratings yet

- 5054 w05 QP 1Document20 pages5054 w05 QP 1mstudy123456No ratings yet

- Earth / Clamp Instruction Manual: Version 1.0, Code No. 20 751 282Document8 pagesEarth / Clamp Instruction Manual: Version 1.0, Code No. 20 751 282Bruno DušićNo ratings yet

- Design of Fluid Power Systems: - Stuart J. WilliamsDocument37 pagesDesign of Fluid Power Systems: - Stuart J. WilliamsAnonymous Ms8nYcbxY2No ratings yet

- Everyday Ergonomics by Aura MatiasDocument10 pagesEveryday Ergonomics by Aura MatiasNicoelNo ratings yet

- HP SFP Support MatrixDocument9 pagesHP SFP Support MatrixtdashnikNo ratings yet

- Tamilnadu Road Sector Project: DATUM 260.000Document1 pageTamilnadu Road Sector Project: DATUM 260.000munisamyprabakaranNo ratings yet

- Abdul Rehman: Islamabad, PakistanDocument2 pagesAbdul Rehman: Islamabad, PakistanEngr Abdul RehmanNo ratings yet