Professional Documents

Culture Documents

Cadcam and 3d Printing

Cadcam and 3d Printing

Uploaded by

apoorva jayaswalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cadcam and 3d Printing

Cadcam and 3d Printing

Uploaded by

apoorva jayaswalCopyright:

Available Formats

cad/cam

introduction cad/cam process

cad/cam generally stands for Computer aided design and Computer aided manufacturing design is created in cad.

numerical control respectively. design is then imported into cam software.

Designing usually starts with CAD software where the actual drawing of the part to be then the imported data is used to generate a g-code.

machined is made which is followed by generating tool paths on CAM software machine then creates a physical product.

advantages disadvantages

Increased productivity.

Lower overhead costs. Expensive software.

Error free drafting.

Designs can be altered with minimal effort Special Skills required.

Repeatability.

It gives us a “zoom” feature Expensive machines required.

Improved Collaboration.

similar to a camera lens. High maintenance cost.

Nature of material of the object.

3-d printing

introduction

3-d printing is the computer controlled sequential layering of materials to create 3-d shapes.

it is particularly useful for prototyping and for the manufacturing of geometriclly complex components.

the process is slow, but it enables almost any shape to be created.

depending on the technique adopted, printing can produce multiple components simulatneously , can use multiple materials and can ise multiple colours,

construction in 3d printing may allow, faster and more accurate construction of complex or bespoke items as well as lowering labour costsand producing less waste.

3-d process 3-d printing materials

stereolithography plastics

digital light processing metals

extrusion ceramics

inkjet- binder jetting and material jetting paper

selective deposition lamination biomaterials

electron beam melting food

cad/cam and

advantages disadvantages 3-d printing

reduced material costs: a considerable reduction of fabric waste , 3-d printers. use the errors that can occur in digital model can result in uncertain situation during the

precise amount of concrete needed for the wall, floor. construction phase.

apoorva jayaswal

quicker construction: this is the place solid 3-d printers , set themselves apart from

conventional techniques. 3-d printers finish a project within hours.

restricted build size: 3-d printers currently have small print chambers which 1bq18at012

restrict the size of parts that can be printed.

ease of access: 3-d printers are becoming more and more accessible with more local service. reduction in manufacturing jobs. vii a

environmental friendly: technology reduces the amount of material wastage used in the

process. bmssa

You might also like

- Module-1 Additive Manufacturing 18 SchemeDocument47 pagesModule-1 Additive Manufacturing 18 SchemeSANTOSH100% (1)

- 3D PRINTING OF BUILDING PresentationDocument19 pages3D PRINTING OF BUILDING PresentationMd Fayazuddin50% (2)

- Concept ModellersDocument39 pagesConcept ModellersParth Modi83% (6)

- 3D Printing: By: Bhumika MaroliaDocument23 pages3D Printing: By: Bhumika MarolianavaneethNo ratings yet

- Seminar Presentation On: 3D PrintingDocument20 pagesSeminar Presentation On: 3D Printingapple chickenNo ratings yet

- Notion 3D Version 01 - N.Jet PrinterDocument5 pagesNotion 3D Version 01 - N.Jet PrinterDihNo ratings yet

- Impact and Application of 3D Printing Technology: Key Words: AM, FDM, PLA, ABS, and CADDocument6 pagesImpact and Application of 3D Printing Technology: Key Words: AM, FDM, PLA, ABS, and CADpradeep rocksNo ratings yet

- Design and Fabrication of 3d PrintingDocument23 pagesDesign and Fabrication of 3d PrintingManikanta Venkata100% (1)

- Module - 1: Regulation - 2015 (CBCS Scheme) Additive Manufacturing - 15me82Document37 pagesModule - 1: Regulation - 2015 (CBCS Scheme) Additive Manufacturing - 15me82swaroop kenganalNo ratings yet

- 3D Printing: Slicing: From 3D Model To 3D PrinterDocument10 pages3D Printing: Slicing: From 3D Model To 3D PrinterAadil KakarNo ratings yet

- AM Applications 25 DecDocument74 pagesAM Applications 25 DecuddhavNo ratings yet

- Best Engineering JournalsDocument10 pagesBest Engineering JournalsSaritaNo ratings yet

- Avances TecnologicosDocument13 pagesAvances TecnologicosSALAZAR VILLEGAS ESTEBAN DAMIANNo ratings yet

- Berman, 2012 - 3-D Printing - The New Industrial Revolution PDFDocument8 pagesBerman, 2012 - 3-D Printing - The New Industrial Revolution PDFLara JucanNo ratings yet

- Tutorial On Digital ManufacturingDocument80 pagesTutorial On Digital ManufacturingasdfghjklNo ratings yet

- 3d Printing For Manufacture A Basic Design Guide Download OriginalDocument26 pages3d Printing For Manufacture A Basic Design Guide Download OriginalritamendesNo ratings yet

- 3d PrinterDocument25 pages3d PrinterabdullahNo ratings yet

- A New Emerging TechnologyDocument16 pagesA New Emerging TechnologyHumanityNo ratings yet

- Coatings: Review On Development and Application of 3D-Printing Technology in Textile and Fashion DesignDocument13 pagesCoatings: Review On Development and Application of 3D-Printing Technology in Textile and Fashion Designmartina torresNo ratings yet

- AM Presentation Group 2Document12 pagesAM Presentation Group 2gudducelloNo ratings yet

- 3de PrintingDocument17 pages3de PrintingNaveen AnanthNo ratings yet

- ATOA 3D Priniting PromoDocument7 pagesATOA 3D Priniting PromoRaj C ThiagarajanNo ratings yet

- 3D PrintingDocument12 pages3D Printingriddhima.thankiNo ratings yet

- A New Emerging TechnologyDocument16 pagesA New Emerging TechnologyAmey MairalNo ratings yet

- CSE 3D Printing ReportDocument18 pagesCSE 3D Printing ReportAksh RawalNo ratings yet

- Stamping Journal 3D Die Design ArticleDocument4 pagesStamping Journal 3D Die Design ArticlekavinkumarNo ratings yet

- Baran Tunç Department of Metallurgical and Materials Engineering, METU, 06800 Ankara, TurkeyDocument4 pagesBaran Tunç Department of Metallurgical and Materials Engineering, METU, 06800 Ankara, Turkeyadi tamrinNo ratings yet

- CNC Fabrication Final Ca 3 Arc 488Document13 pagesCNC Fabrication Final Ca 3 Arc 488Apoorva SinghNo ratings yet

- Design & 3D Printing of 180cc EngineDocument4 pagesDesign & 3D Printing of 180cc EngineS.V.S.K DEEPAK KUMARNo ratings yet

- Module 1Document37 pagesModule 1Lokesh Lokesh D SNo ratings yet

- Using 3D Printing Technology in Prototype ProductionDocument9 pagesUsing 3D Printing Technology in Prototype Productionxuyan yinNo ratings yet

- mgtCADCAM TAMAYODocument3 pagesmgtCADCAM TAMAYONath ReyesNo ratings yet

- 3-D PrintingDocument26 pages3-D PrintingOmkar ShivajiNo ratings yet

- APM Additive Manufacturing FinalDocument4 pagesAPM Additive Manufacturing FinalAnish KumarNo ratings yet

- Presented By: Kalpesh Shah M.E. (Design)Document40 pagesPresented By: Kalpesh Shah M.E. (Design)Terminator941988No ratings yet

- SeminarDocument19 pagesSeminarSharath Kumar100% (1)

- Unit - 1 IntroductionDocument26 pagesUnit - 1 IntroductionAbinaya VarmaNo ratings yet

- Buyers Guide 3DPDocument18 pagesBuyers Guide 3DPBjarne jakobsenNo ratings yet

- 3 D Printing TechnologyDocument17 pages3 D Printing TechnologyClassic PrintersNo ratings yet

- Printer 4Document1 pagePrinter 4msania654No ratings yet

- WP FDM JigsAndFixtures 0316a WebDocument8 pagesWP FDM JigsAndFixtures 0316a WebAnish RayNo ratings yet

- Optimization of Production Process Parameters of DLP Type 3D Printer Design For Product Roughness ValueDocument5 pagesOptimization of Production Process Parameters of DLP Type 3D Printer Design For Product Roughness ValueJyothendra Pavan DamarlaNo ratings yet

- Digital Modeling and Rapid PrototypingDocument28 pagesDigital Modeling and Rapid PrototypingAnonymous mzF3JvyTJsNo ratings yet

- Cad, Cam, 3d PrintingDocument20 pagesCad, Cam, 3d Printingvanikv40No ratings yet

- 3D Print of The Housing Used in The Agricultural Vehicle: GoalsDocument4 pages3D Print of The Housing Used in The Agricultural Vehicle: GoalsLaksarNo ratings yet

- Jjmie: A Comprehensive Review On 3D Printing Technology: Current Applications and ChallengesDocument14 pagesJjmie: A Comprehensive Review On 3D Printing Technology: Current Applications and Challengesahmedessam2004No ratings yet

- Freeform Fabrication Using Three Dimensional Printing (3Dp) : Designing Objects - Any Material Any Design Any GeometryDocument22 pagesFreeform Fabrication Using Three Dimensional Printing (3Dp) : Designing Objects - Any Material Any Design Any Geometryurvish_soniNo ratings yet

- Design For 3D Printing EbookDocument20 pagesDesign For 3D Printing Ebookshambala100% (2)

- Rapid Prototyping: Introduction To RPDocument72 pagesRapid Prototyping: Introduction To RPHari HaranNo ratings yet

- 3d Systems Jigs+fixtures Brief 2019 12 05 WebDocument4 pages3d Systems Jigs+fixtures Brief 2019 12 05 WebMFNo ratings yet

- FDM 3D PrinterDocument23 pagesFDM 3D PrinterYuvraj MarneNo ratings yet

- 3D Printing: Applications in ConstructionDocument13 pages3D Printing: Applications in ConstructionKeshav JasoriyaNo ratings yet

- Seven Secrets Of: 3D Printing For AerospaceDocument4 pagesSeven Secrets Of: 3D Printing For Aerospaceitsme5616No ratings yet

- Pros and Cons of Additive ManufactuDocument2 pagesPros and Cons of Additive ManufactuPallabi JaiswalNo ratings yet

- Enhancing Precision Investment Casting Via 3D PrintingDocument16 pagesEnhancing Precision Investment Casting Via 3D Printingantracite.worktestNo ratings yet

- InternshipDocument16 pagesInternshipĀbd DùttNo ratings yet

- 3D Printing: A SeminarDocument17 pages3D Printing: A SeminarRajesh SahuNo ratings yet

- Desktop Manufacturing Use Machine Above This To Make ProductsFrom EverandDesktop Manufacturing Use Machine Above This To Make ProductsNo ratings yet

- Pre-Stressed Concrete Methods of Producing Pre Stressed ConcreteDocument1 pagePre-Stressed Concrete Methods of Producing Pre Stressed Concreteapoorva jayaswalNo ratings yet

- Earth Retaining StructuresDocument1 pageEarth Retaining Structuresapoorva jayaswalNo ratings yet

- Prefabrication in IndiaDocument1 pagePrefabrication in Indiaapoorva jayaswalNo ratings yet

- Advanced Foundation TechniquesDocument1 pageAdvanced Foundation Techniquesapoorva jayaswalNo ratings yet

- Idioms 2Document4 pagesIdioms 222Alyss22No ratings yet

- UAD Plug-Ins ManualDocument917 pagesUAD Plug-Ins ManualhighlanderoneNo ratings yet

- HW1 PtelcoDocument3 pagesHW1 Ptelcobrian mohinogNo ratings yet

- Athenahealth Announces Patient Communication Program, Releases FinancialsDocument16 pagesAthenahealth Announces Patient Communication Program, Releases FinancialsjustdoyourNo ratings yet

- 6 CurriculumDocument1 page6 Curriculumapi-237183310No ratings yet

- 2021 Airs Lms-Cover-Page-Shs Empowerment Technologies FinalDocument23 pages2021 Airs Lms-Cover-Page-Shs Empowerment Technologies FinalGlenda AstodilloNo ratings yet

- 20TL / 33TL: Three-Phase TL Inverters With The Maximum Efficiency at The Best PriceDocument4 pages20TL / 33TL: Three-Phase TL Inverters With The Maximum Efficiency at The Best PriceMarcelo SilvaNo ratings yet

- Machine Learning Applications Used in Accounting and AuditsDocument6 pagesMachine Learning Applications Used in Accounting and AuditsVIVA-TECH IJRI100% (1)

- AUTOCADDocument192 pagesAUTOCADThe Informative Corner हिंदीNo ratings yet

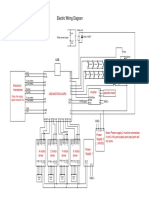

- Electric Wiring DiagramDocument1 pageElectric Wiring DiagramJoe Pañol RmzNo ratings yet

- Viken Detection Product Catalog v3 Apr 2024 UAEDocument46 pagesViken Detection Product Catalog v3 Apr 2024 UAEethanplays2020123100% (1)

- SCI Job Application - CleanerDocument3 pagesSCI Job Application - CleanerShujauddin SultaniNo ratings yet

- Thuật toán brenhamDocument10 pagesThuật toán brenhamThanh MinhNo ratings yet

- String Inbuilt MethodsDocument54 pagesString Inbuilt MethodsJhagan A. MNo ratings yet

- EE1101: Signals and Systems Tutorial 3 SolutionsDocument19 pagesEE1101: Signals and Systems Tutorial 3 SolutionsRohan Kumar ee21b113No ratings yet

- BRKNMS 3043Document56 pagesBRKNMS 3043cool dude911No ratings yet

- Customer Inquiry Report-9Document7 pagesCustomer Inquiry Report-9notarisppat mustopaNo ratings yet

- SAP BPM With SAPUI5 Integration R1.0Document33 pagesSAP BPM With SAPUI5 Integration R1.0abapthNo ratings yet

- 6AV66440AA012AX0 Datasheet enDocument6 pages6AV66440AA012AX0 Datasheet enJoseph MagonduNo ratings yet

- TESTO-6651-6600 VOL2-1-20.en - EsDocument20 pagesTESTO-6651-6600 VOL2-1-20.en - EsEliana Guzman PachecoNo ratings yet

- Сервис Мануал На Английском Samsung Ua32eh500r Шасси u73aDocument173 pagesСервис Мануал На Английском Samsung Ua32eh500r Шасси u73aiuri63No ratings yet

- 1preventive Maintenance Belts PDFDocument6 pages1preventive Maintenance Belts PDFrezeiba_74No ratings yet

- Agras t10 Spraying Drone ManualDocument25 pagesAgras t10 Spraying Drone ManualThiago FrankNo ratings yet

- Health ManagementDocument2 pagesHealth Managementcabansag cnikjay35No ratings yet

- Assignment 4Document5 pagesAssignment 4Ashish KabiNo ratings yet

- Materials 3ds Max Week 3Document32 pagesMaterials 3ds Max Week 3moturidesignsNo ratings yet

- PinAAcle 500 Flame AA SpecificationsDocument3 pagesPinAAcle 500 Flame AA SpecificationsUswatul HasanahNo ratings yet

- Report On Hand Gesture Controlled WheelchairDocument4 pagesReport On Hand Gesture Controlled WheelchairPRERNA SONINo ratings yet

- Schmatics Dell 7548 7547 Quanta AM6 MB - DA0AM6MB8E0 REV E PDFDocument58 pagesSchmatics Dell 7548 7547 Quanta AM6 MB - DA0AM6MB8E0 REV E PDFacsacrNo ratings yet

- PY090Document10 pagesPY090dharmesh patelNo ratings yet