Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

18 viewsSpecifications: The Red Jacket Submersible Turbine Pump

Specifications: The Red Jacket Submersible Turbine Pump

Uploaded by

Dario FloresThe document provides specifications for the Red Jacket Submersible Turbine Pump. It was designed for hazardous locations and has an adjustable operating range from 74.5 to 225 inches. It is compatible with diesel, gasoline, ethanol, and methanol fuels. Safety and ease of service were priorities in the design, which allows for simple electrical connections, easy installation and removal without tools, and spill-free operation. Discharge can be vertical or horizontal through the use of manifolds.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Reyrolle LMT Long Term CareDocument15 pagesReyrolle LMT Long Term Carecgoober100% (3)

- Bosch Rexroth Hydraulics CatalogDocument28 pagesBosch Rexroth Hydraulics CatalogSzilárd SzabóNo ratings yet

- Schneider EM RelaysDocument16 pagesSchneider EM RelaysMuneer MPNo ratings yet

- G3516 LeDocument4 pagesG3516 LeJOSE RICARDO DURAN100% (4)

- Astm D 823 - 95Document8 pagesAstm D 823 - 95Ennio Palumbo100% (2)

- Ecotechnics Car AC Service MachinesDocument2 pagesEcotechnics Car AC Service MachinesMagnus Mototech100% (1)

- POIRY STANDARD - Piping StandardDocument259 pagesPOIRY STANDARD - Piping StandardSutrisnoNo ratings yet

- Red JacketDocument3 pagesRed JacketDanilo MacenaNo ratings yet

- Brosur RED JACKET SUBMERSIBLE PDFDocument6 pagesBrosur RED JACKET SUBMERSIBLE PDFwarung1bensinNo ratings yet

- RJ STP BrochureDocument3 pagesRJ STP Brochurefrancisb65No ratings yet

- D1-170 LEWA Ecosmart en UsDocument20 pagesD1-170 LEWA Ecosmart en Uscandra trisilawatiNo ratings yet

- RH 120eDocument8 pagesRH 120eSawadogo Gustave NapinguebsonNo ratings yet

- Reciprocating Diaphragm Pumps PDFDocument16 pagesReciprocating Diaphragm Pumps PDFSushil GoswamiNo ratings yet

- Valve Automation BrochureDocument8 pagesValve Automation BrochuresalemNo ratings yet

- Rexroth D&C For Wind TurbinesDocument16 pagesRexroth D&C For Wind TurbinesxxshNo ratings yet

- Products and Solutions For A Smooth Power SupplyDocument11 pagesProducts and Solutions For A Smooth Power SupplyknsbNo ratings yet

- EPM Valve Automation TechnologiesDocument8 pagesEPM Valve Automation TechnologiesWahyu YuliadiNo ratings yet

- r999000228 - 2014-1 FIVA VV OHLDocument16 pagesr999000228 - 2014-1 FIVA VV OHLcryptforxvelNo ratings yet

- RC200 Range: Compact Scotch-Yoke ActuatorsDocument16 pagesRC200 Range: Compact Scotch-Yoke ActuatorsRosa PonceNo ratings yet

- Mas Overview 4p 0614Document4 pagesMas Overview 4p 0614Thein TunNo ratings yet

- Katalog Appolo EnglDocument24 pagesKatalog Appolo EnglTomhang No HangNo ratings yet

- Alma - Turbine-Adriane - Fc006en - HD (1) AdrianeDocument2 pagesAlma - Turbine-Adriane - Fc006en - HD (1) AdrianeMiguel AguirreNo ratings yet

- Accumulators and Coolers For Wind PowerDocument8 pagesAccumulators and Coolers For Wind PowerMiguel Angel LopezNo ratings yet

- Moog ServoValves 72series Catalog enDocument20 pagesMoog ServoValves 72series Catalog enChristopher YsitNo ratings yet

- Automax Actuators & Accessories English PDFDocument18 pagesAutomax Actuators & Accessories English PDFSt. Labuhan MaringgaiNo ratings yet

- Selwood Complete BrochureDocument8 pagesSelwood Complete BrochureRicky PradanaNo ratings yet

- Sumer Gib LeDocument44 pagesSumer Gib LeJan KerNo ratings yet

- DetentionDocument8 pagesDetentionLab RatNo ratings yet

- Schneider DIA5ED2170101EN v7 WebDocument82 pagesSchneider DIA5ED2170101EN v7 WebDenis RodriguezNo ratings yet

- Severe Service SolutionsDocument22 pagesSevere Service SolutionsAnonymous HGZfO4IQNo ratings yet

- Injection Moulding: Dedicated Products and Solutions ForDocument4 pagesInjection Moulding: Dedicated Products and Solutions ForArun NatoNo ratings yet

- 1600reozm 0720Document3 pages1600reozm 0720paksongchoiNo ratings yet

- Turbinas Bulb VoithDocument12 pagesTurbinas Bulb VoithGuilherme RosaNo ratings yet

- Heavy Equipment - Spek RH120EDocument12 pagesHeavy Equipment - Spek RH120EDavid HalomoanNo ratings yet

- Moog ServoValves 72series Catalog enDocument20 pagesMoog ServoValves 72series Catalog enbhekistoNo ratings yet

- AFT ImpulseDocument2 pagesAFT Impulseersin83aydinNo ratings yet

- C130 Brief - 2019Document30 pagesC130 Brief - 2019Jacob Jack YoshaNo ratings yet

- PT - AtT - Egatrol Gas Turbine Solutions - E - Rev1Document4 pagesPT - AtT - Egatrol Gas Turbine Solutions - E - Rev1rafik1995No ratings yet

- Rotary Power C Range 1221705 02 1021Document16 pagesRotary Power C Range 1221705 02 1021MIGUEL ÂNGELO DUTRA BUENONo ratings yet

- CompressorDocument8 pagesCompressorzahid_497No ratings yet

- Catalog Pompe CentrifugeDocument130 pagesCatalog Pompe CentrifugeAngelescu GeorgeNo ratings yet

- 576047-191 Bomba Red Yacket 3 PDFDocument2 pages576047-191 Bomba Red Yacket 3 PDFEstacion AvenidaNo ratings yet

- D1-170 Ecosmart en PDFDocument8 pagesD1-170 Ecosmart en PDFrakacyuNo ratings yet

- ANDRITZ PumpsDocument2 pagesANDRITZ Pumpsventaseh 2019100% (1)

- Severe Service Valve SolutionsDocument22 pagesSevere Service Valve SolutionsHector Flores Marcos100% (1)

- 1584543837d2gym Katalog MasoneilanDocument24 pages1584543837d2gym Katalog MasoneilanLPG Equipment Consulting and ServicesNo ratings yet

- 2200 SERIES: Gear Pumps and MotorsDocument16 pages2200 SERIES: Gear Pumps and MotorsGora FedotovNo ratings yet

- Rotork AWT PDFDocument12 pagesRotork AWT PDFTj Bro BroNo ratings yet

- Marine Generator Sets: C6.6 AcertDocument4 pagesMarine Generator Sets: C6.6 AcertNiza VidalNo ratings yet

- Seco-DC-Drives Catalog en-US Rev2005Document40 pagesSeco-DC-Drives Catalog en-US Rev2005milacronNo ratings yet

- Generator and BoilerDocument6 pagesGenerator and BoilerKaye GuceNo ratings yet

- ERP BrochureDocument4 pagesERP BrochureSandy ZhangNo ratings yet

- 1250reozm 0720Document3 pages1250reozm 0720paksongchoiNo ratings yet

- Howden BrochureDocument12 pagesHowden Brochurecarolina PortocarreroNo ratings yet

- s140w-vDocument16 pagess140w-vbinhvinavicoNo ratings yet

- Valves - Essential WorkhorsesDocument2 pagesValves - Essential WorkhorsesBramJanssen76No ratings yet

- DatasheetDocument6 pagesDatasheetjesus MartinezNo ratings yet

- Complete Pump Solutions Fire Protection BrochureDocument4 pagesComplete Pump Solutions Fire Protection BrochureOsmar AraujoNo ratings yet

- Moog Servo Valves CatalogueDocument20 pagesMoog Servo Valves Cataloguemt.sasongkoNo ratings yet

- Valve Automation Brochure USDocument8 pagesValve Automation Brochure USprufino2No ratings yet

- Operator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowFrom EverandOperator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowRating: 2 out of 5 stars2/5 (1)

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- Handbook of Microwave Component Measurements: with Advanced VNA TechniquesFrom EverandHandbook of Microwave Component Measurements: with Advanced VNA TechniquesRating: 4 out of 5 stars4/5 (1)

- Fruitland PDFDocument21 pagesFruitland PDFALEXNo ratings yet

- Process Improvement Study of Preparation of Medicinal Oil From NirgundiDocument8 pagesProcess Improvement Study of Preparation of Medicinal Oil From Nirgundidr_saketram6146100% (2)

- Cee Dee Transformer Oil Filtration Plant ManualDocument146 pagesCee Dee Transformer Oil Filtration Plant ManualApurba RoyNo ratings yet

- Oil Pump Type Aj Gear Sizes 4-6: ApplicationsDocument2 pagesOil Pump Type Aj Gear Sizes 4-6: Applicationsr_cristiNo ratings yet

- 18 Mas4000tecDocument12 pages18 Mas4000tecSimamora Samuel HansenNo ratings yet

- Price 1998Document11 pagesPrice 1998LỢI NGUYỄN CÔNGNo ratings yet

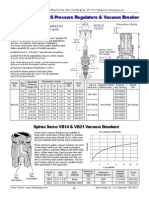

- SSC Cat Spirax Sarco Vacuum BreakersDocument1 pageSSC Cat Spirax Sarco Vacuum BreakersEb RahimNo ratings yet

- RandomDocument1,919 pagesRandomNajmul Puda Pappadam50% (2)

- Pitot-Static/Air Data Tester: Operation and Maintenance ManualDocument29 pagesPitot-Static/Air Data Tester: Operation and Maintenance ManualVitaliy FedchenkoNo ratings yet

- Principles of Centrifugal Pump Construction PDFDocument38 pagesPrinciples of Centrifugal Pump Construction PDFAjit KumarNo ratings yet

- Vacuum Pumps - CatalogDocument8 pagesVacuum Pumps - Catalogdéborah_rosalesNo ratings yet

- Job Procedure For Vacuum Test of Tanks: 10 of Ramadan City, Industrial Area A1, EgyptDocument5 pagesJob Procedure For Vacuum Test of Tanks: 10 of Ramadan City, Industrial Area A1, EgyptShubham ShuklaNo ratings yet

- Khan AbdulQudoosDocument418 pagesKhan AbdulQudoosrajubansalNo ratings yet

- MMB125PN35Document3 pagesMMB125PN35fixedxray.ionicsNo ratings yet

- Hurricane 828: Operation/Maintenance ManualDocument32 pagesHurricane 828: Operation/Maintenance ManualMatias Contreras KöbrichNo ratings yet

- D500MX Manual enDocument10 pagesD500MX Manual enمحمدعبدالخالق العلوانيNo ratings yet

- Relay PumpDocument61 pagesRelay PumpBerty TilarsoNo ratings yet

- LG GC 181 ManualDocument15 pagesLG GC 181 ManualadijayptNo ratings yet

- User Manual: Vacuklav 24 B+ Vacuklav 30 B+Document64 pagesUser Manual: Vacuklav 24 B+ Vacuklav 30 B+Petar ĐurkovićNo ratings yet

- Uniaxial Testing in Rock Mechanics LaboratoriesDocument107 pagesUniaxial Testing in Rock Mechanics LaboratoriesYongliang LiuNo ratings yet

- CAD Modeling and Simulation of A Semi-Automatic Machine For Olive Oil PackagingDocument11 pagesCAD Modeling and Simulation of A Semi-Automatic Machine For Olive Oil PackagingEbrahim Abd El HadyNo ratings yet

- Properties Changes of MaterialsDocument28 pagesProperties Changes of Materialsapi-273214847No ratings yet

- II. 8 .2 Alat Laboratorium 2Document290 pagesII. 8 .2 Alat Laboratorium 2085270710307No ratings yet

- Vitrectomy Machine:: Nadia Artha DewiDocument21 pagesVitrectomy Machine:: Nadia Artha DewiŘŷØoo TЯyNo ratings yet

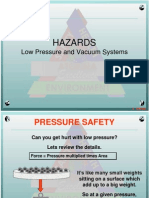

- Hazards: Low Pressure and Vacuum SystemsDocument12 pagesHazards: Low Pressure and Vacuum Systemstonytayic100% (1)

- Militair - I177 Tube TesterDocument243 pagesMilitair - I177 Tube TesterErik Van SoestNo ratings yet

Specifications: The Red Jacket Submersible Turbine Pump

Specifications: The Red Jacket Submersible Turbine Pump

Uploaded by

Dario Flores0 ratings0% found this document useful (0 votes)

18 views2 pagesThe document provides specifications for the Red Jacket Submersible Turbine Pump. It was designed for hazardous locations and has an adjustable operating range from 74.5 to 225 inches. It is compatible with diesel, gasoline, ethanol, and methanol fuels. Safety and ease of service were priorities in the design, which allows for simple electrical connections, easy installation and removal without tools, and spill-free operation. Discharge can be vertical or horizontal through the use of manifolds.

Original Description:

Original Title

specifications-the-red-jacket-submersible-turbine

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides specifications for the Red Jacket Submersible Turbine Pump. It was designed for hazardous locations and has an adjustable operating range from 74.5 to 225 inches. It is compatible with diesel, gasoline, ethanol, and methanol fuels. Safety and ease of service were priorities in the design, which allows for simple electrical connections, easy installation and removal without tools, and spill-free operation. Discharge can be vertical or horizontal through the use of manifolds.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

18 views2 pagesSpecifications: The Red Jacket Submersible Turbine Pump

Specifications: The Red Jacket Submersible Turbine Pump

Uploaded by

Dario FloresThe document provides specifications for the Red Jacket Submersible Turbine Pump. It was designed for hazardous locations and has an adjustable operating range from 74.5 to 225 inches. It is compatible with diesel, gasoline, ethanol, and methanol fuels. Safety and ease of service were priorities in the design, which allows for simple electrical connections, easy installation and removal without tools, and spill-free operation. Discharge can be vertical or horizontal through the use of manifolds.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

Specifications The Red Jacket

Submersible Turbine Pump

Designed for Hazardous Location: Siphon Ports:

Class 1, Group D atmospheres 2 available, 1/4" NPT. Vacuums

generated up to 25 in Hg.

Quick-Set Adjustment Range:

RJ 1 = 74.5" - 105"* Fuel Compatibility: Advanced environmental protection,

RJ 2 = 104.4" - 165"

RJ 3 = 164" - 225"

*Assumes 1.5 HP

Diesel

100% Gasoline

80% Gasoline with 20% TAME, ETBE,

serviceability, safety and flow

Just part of the solutions

or MTBE

Agency Listing: offered by the Flow Resource

0-100% Ethanol

UL at Red Jacket

0-100% Methanol

cUL We offer a range of solutions, including

ATEX Certified Line Pressure Port: leading pump technologies for both new

1 Available. 1/4" NPT installations and upgrades, manifolded

4" Horsepowers Available: pumping systems for increased uptime

3/4 HP, 60 HZ, 1-phase Vent Port: and product availability, and the

3/4 HP, 50 HZ, 1-phase or 3-phase 1 Available. 1/4" NPT industry’s leading tank monitoring and

1 1/2 HP, 60 HZ, 1-phase leak detection systems.

1 1/2 HP, 50 HZ, 1-phase or 3-phase All with the desired purpose of deliv-

X3, 60 HZ, 1-phase ering greater profitability and reliability

X4, 50 HZ, 1-phase or 3-phase to our customers.

2 HP, 60 HZ, 1-phase We are a valuable source of expertise

and information to both site owners and

our business partners. Consider us your

Flow Resource.

Call the Flow Resource today for more

information on systems design and

complete product specifications.

800-921-2228

For inside sales call

1-888-921-2228

P/N 0576047-083 Rev.B VRRS 2/2004 Printed in USA

Innovative technology delivers the

easiest and safest pump to install and service

The Red Jacket Submersible Turbine Pump incorporates a range of innovative new

features that keep the safety of service technicians and service related costs in mind.

If you’re concerned about rising labor costs and the safety of your workforce, you

need to take a look at The Red Jacket Submersible Turbine Pump.

Environmentally friendly features

The Red Jacket Submersible Turbine Pump has been specifically designed to eliminate Yoke assembly: quick, simple and Extractable: easy to install Manifold allows for vertical or

spills that can occur during service, and to integrate with Veeder-Root industry safe electrical connections and service horizontal discharge

leading leak detection systems. Current safety practice when servicing The Red Jacket Submersible Turbine The Red Jacket Submersible Turbine

existing submersible pumps requires Pump’s design incorporates industrial die Pump has been designed for vertical

turning off the circuit breaker, backing springs that break loose the o-ring seals product discharge, but with adequate

off the bolts by up to one inch, and then when the nuts holding the extractable swinging radius to allow for the

Service spill elimination Vacuum monitoring applications manually pulling the electrical yoke in place are removed. No physical effort addition of an elbow to accommodate a

Innovative Check Valve design Red Jacket Vacuum Sensor connection apart. When service is or special equipment is required to break side discharge. In fact, the discharge is

The Check Valve on the Red Jacket Siphon System complete, the technician has to force the seal, unlike competitive systems now located higher on the manifold so

Submersible Turbine Pump has been The Red Jacket Vacuum Sensor Siphon the connection back in place. that can require considerable force. that a side discharge is on the same

designed so that it can be raised, System is a monitoring-grade siphon With The Red Jacket Submersible In addition, all connected parts have plane as the rest of the pump.

providing a larger path to depressurize system. It is designed specifically for use Turbine Pump you turn off the circuit been moved to the manifold; so there is

the line and return fuel to the tank. in vacuum monitoring applications, breaker, then simply back off the two no need to remove parts, leak detectors Built-in contractor’s box

This feature eliminates the potential for and to integrate with Veeder-Root nuts holding the extractable in place and or siphons when service or upgrades The electrical connection housing

fuel spills. vacuum sensors. The pump offers two the yoke electrical connection is broken. require removing the extractable. (Contractor’s Box) is built into the

siphon system ports. The Red Jacket After service is complete, the electrical manifold of The Red Jacket Submersible

Spill-free extractable Vacuum Sensor Siphon System incor- circuit reconnects when the two nuts are Turbine Pump, and is completely isolated

When the two nuts holding the porates a redesigned one-piece rubber retightened. Safe, simple and easy. from the fuel path. Unlike existing

extractable in place are backed off, the Check Valve with an in-line filter screen systems, there is no adjustment required

o-ring seals are automatically broken, that reduces the clogs and failures that to fit the yoke, making this pump the

releasing pressure in the pump and the can cause false alarms and downtime in Check Valve pressure release

easiest to install.

non-isolated line, draining fuel back vacuum monitoring applications.

into the tank. This simple feature helps

eliminate potential human error that Line leak detection

could cause service spills, protecting the

environment from fuel contamination,

Veeder-Root/Red Jacket industry leading

pressurized line leak detection (PLLD)

Save time, lower service costs

and site owners from related liability. provides environmental compliance Service technicians will appreciate how the pump saves time and effort. They’ll also

without the fuel flow restrictions of appreciate how the electrical connections on the yoke assembly make installation

mechanical (MLLD) or electronic and service a much safer process. Site owners will appreciate the savings in service

(ELLD) systems. and upgrade costs.

Pre-installed capacitor and simple

electrical connections

The best performance

The Red Jacket Submersible Turbine Flow fuels profits

Red Jacket Vacuum Sensor Siphon System

Pump delivers the flow performance and The Red Jacket Submersible Turbine

reliability you’ve come to expect from Pump has the lowest pressure drop across

the industry leader. the packer manifold, optimizing flow

with any sized motor that meets the site

requirements. This results in more flow at

discharge so site owners can maximize

flow and profits.

Protect the environment. Protect your workforce and budget.

You might also like

- Reyrolle LMT Long Term CareDocument15 pagesReyrolle LMT Long Term Carecgoober100% (3)

- Bosch Rexroth Hydraulics CatalogDocument28 pagesBosch Rexroth Hydraulics CatalogSzilárd SzabóNo ratings yet

- Schneider EM RelaysDocument16 pagesSchneider EM RelaysMuneer MPNo ratings yet

- G3516 LeDocument4 pagesG3516 LeJOSE RICARDO DURAN100% (4)

- Astm D 823 - 95Document8 pagesAstm D 823 - 95Ennio Palumbo100% (2)

- Ecotechnics Car AC Service MachinesDocument2 pagesEcotechnics Car AC Service MachinesMagnus Mototech100% (1)

- POIRY STANDARD - Piping StandardDocument259 pagesPOIRY STANDARD - Piping StandardSutrisnoNo ratings yet

- Red JacketDocument3 pagesRed JacketDanilo MacenaNo ratings yet

- Brosur RED JACKET SUBMERSIBLE PDFDocument6 pagesBrosur RED JACKET SUBMERSIBLE PDFwarung1bensinNo ratings yet

- RJ STP BrochureDocument3 pagesRJ STP Brochurefrancisb65No ratings yet

- D1-170 LEWA Ecosmart en UsDocument20 pagesD1-170 LEWA Ecosmart en Uscandra trisilawatiNo ratings yet

- RH 120eDocument8 pagesRH 120eSawadogo Gustave NapinguebsonNo ratings yet

- Reciprocating Diaphragm Pumps PDFDocument16 pagesReciprocating Diaphragm Pumps PDFSushil GoswamiNo ratings yet

- Valve Automation BrochureDocument8 pagesValve Automation BrochuresalemNo ratings yet

- Rexroth D&C For Wind TurbinesDocument16 pagesRexroth D&C For Wind TurbinesxxshNo ratings yet

- Products and Solutions For A Smooth Power SupplyDocument11 pagesProducts and Solutions For A Smooth Power SupplyknsbNo ratings yet

- EPM Valve Automation TechnologiesDocument8 pagesEPM Valve Automation TechnologiesWahyu YuliadiNo ratings yet

- r999000228 - 2014-1 FIVA VV OHLDocument16 pagesr999000228 - 2014-1 FIVA VV OHLcryptforxvelNo ratings yet

- RC200 Range: Compact Scotch-Yoke ActuatorsDocument16 pagesRC200 Range: Compact Scotch-Yoke ActuatorsRosa PonceNo ratings yet

- Mas Overview 4p 0614Document4 pagesMas Overview 4p 0614Thein TunNo ratings yet

- Katalog Appolo EnglDocument24 pagesKatalog Appolo EnglTomhang No HangNo ratings yet

- Alma - Turbine-Adriane - Fc006en - HD (1) AdrianeDocument2 pagesAlma - Turbine-Adriane - Fc006en - HD (1) AdrianeMiguel AguirreNo ratings yet

- Accumulators and Coolers For Wind PowerDocument8 pagesAccumulators and Coolers For Wind PowerMiguel Angel LopezNo ratings yet

- Moog ServoValves 72series Catalog enDocument20 pagesMoog ServoValves 72series Catalog enChristopher YsitNo ratings yet

- Automax Actuators & Accessories English PDFDocument18 pagesAutomax Actuators & Accessories English PDFSt. Labuhan MaringgaiNo ratings yet

- Selwood Complete BrochureDocument8 pagesSelwood Complete BrochureRicky PradanaNo ratings yet

- Sumer Gib LeDocument44 pagesSumer Gib LeJan KerNo ratings yet

- DetentionDocument8 pagesDetentionLab RatNo ratings yet

- Schneider DIA5ED2170101EN v7 WebDocument82 pagesSchneider DIA5ED2170101EN v7 WebDenis RodriguezNo ratings yet

- Severe Service SolutionsDocument22 pagesSevere Service SolutionsAnonymous HGZfO4IQNo ratings yet

- Injection Moulding: Dedicated Products and Solutions ForDocument4 pagesInjection Moulding: Dedicated Products and Solutions ForArun NatoNo ratings yet

- 1600reozm 0720Document3 pages1600reozm 0720paksongchoiNo ratings yet

- Turbinas Bulb VoithDocument12 pagesTurbinas Bulb VoithGuilherme RosaNo ratings yet

- Heavy Equipment - Spek RH120EDocument12 pagesHeavy Equipment - Spek RH120EDavid HalomoanNo ratings yet

- Moog ServoValves 72series Catalog enDocument20 pagesMoog ServoValves 72series Catalog enbhekistoNo ratings yet

- AFT ImpulseDocument2 pagesAFT Impulseersin83aydinNo ratings yet

- C130 Brief - 2019Document30 pagesC130 Brief - 2019Jacob Jack YoshaNo ratings yet

- PT - AtT - Egatrol Gas Turbine Solutions - E - Rev1Document4 pagesPT - AtT - Egatrol Gas Turbine Solutions - E - Rev1rafik1995No ratings yet

- Rotary Power C Range 1221705 02 1021Document16 pagesRotary Power C Range 1221705 02 1021MIGUEL ÂNGELO DUTRA BUENONo ratings yet

- CompressorDocument8 pagesCompressorzahid_497No ratings yet

- Catalog Pompe CentrifugeDocument130 pagesCatalog Pompe CentrifugeAngelescu GeorgeNo ratings yet

- 576047-191 Bomba Red Yacket 3 PDFDocument2 pages576047-191 Bomba Red Yacket 3 PDFEstacion AvenidaNo ratings yet

- D1-170 Ecosmart en PDFDocument8 pagesD1-170 Ecosmart en PDFrakacyuNo ratings yet

- ANDRITZ PumpsDocument2 pagesANDRITZ Pumpsventaseh 2019100% (1)

- Severe Service Valve SolutionsDocument22 pagesSevere Service Valve SolutionsHector Flores Marcos100% (1)

- 1584543837d2gym Katalog MasoneilanDocument24 pages1584543837d2gym Katalog MasoneilanLPG Equipment Consulting and ServicesNo ratings yet

- 2200 SERIES: Gear Pumps and MotorsDocument16 pages2200 SERIES: Gear Pumps and MotorsGora FedotovNo ratings yet

- Rotork AWT PDFDocument12 pagesRotork AWT PDFTj Bro BroNo ratings yet

- Marine Generator Sets: C6.6 AcertDocument4 pagesMarine Generator Sets: C6.6 AcertNiza VidalNo ratings yet

- Seco-DC-Drives Catalog en-US Rev2005Document40 pagesSeco-DC-Drives Catalog en-US Rev2005milacronNo ratings yet

- Generator and BoilerDocument6 pagesGenerator and BoilerKaye GuceNo ratings yet

- ERP BrochureDocument4 pagesERP BrochureSandy ZhangNo ratings yet

- 1250reozm 0720Document3 pages1250reozm 0720paksongchoiNo ratings yet

- Howden BrochureDocument12 pagesHowden Brochurecarolina PortocarreroNo ratings yet

- s140w-vDocument16 pagess140w-vbinhvinavicoNo ratings yet

- Valves - Essential WorkhorsesDocument2 pagesValves - Essential WorkhorsesBramJanssen76No ratings yet

- DatasheetDocument6 pagesDatasheetjesus MartinezNo ratings yet

- Complete Pump Solutions Fire Protection BrochureDocument4 pagesComplete Pump Solutions Fire Protection BrochureOsmar AraujoNo ratings yet

- Moog Servo Valves CatalogueDocument20 pagesMoog Servo Valves Cataloguemt.sasongkoNo ratings yet

- Valve Automation Brochure USDocument8 pagesValve Automation Brochure USprufino2No ratings yet

- Operator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowFrom EverandOperator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowRating: 2 out of 5 stars2/5 (1)

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- Handbook of Microwave Component Measurements: with Advanced VNA TechniquesFrom EverandHandbook of Microwave Component Measurements: with Advanced VNA TechniquesRating: 4 out of 5 stars4/5 (1)

- Fruitland PDFDocument21 pagesFruitland PDFALEXNo ratings yet

- Process Improvement Study of Preparation of Medicinal Oil From NirgundiDocument8 pagesProcess Improvement Study of Preparation of Medicinal Oil From Nirgundidr_saketram6146100% (2)

- Cee Dee Transformer Oil Filtration Plant ManualDocument146 pagesCee Dee Transformer Oil Filtration Plant ManualApurba RoyNo ratings yet

- Oil Pump Type Aj Gear Sizes 4-6: ApplicationsDocument2 pagesOil Pump Type Aj Gear Sizes 4-6: Applicationsr_cristiNo ratings yet

- 18 Mas4000tecDocument12 pages18 Mas4000tecSimamora Samuel HansenNo ratings yet

- Price 1998Document11 pagesPrice 1998LỢI NGUYỄN CÔNGNo ratings yet

- SSC Cat Spirax Sarco Vacuum BreakersDocument1 pageSSC Cat Spirax Sarco Vacuum BreakersEb RahimNo ratings yet

- RandomDocument1,919 pagesRandomNajmul Puda Pappadam50% (2)

- Pitot-Static/Air Data Tester: Operation and Maintenance ManualDocument29 pagesPitot-Static/Air Data Tester: Operation and Maintenance ManualVitaliy FedchenkoNo ratings yet

- Principles of Centrifugal Pump Construction PDFDocument38 pagesPrinciples of Centrifugal Pump Construction PDFAjit KumarNo ratings yet

- Vacuum Pumps - CatalogDocument8 pagesVacuum Pumps - Catalogdéborah_rosalesNo ratings yet

- Job Procedure For Vacuum Test of Tanks: 10 of Ramadan City, Industrial Area A1, EgyptDocument5 pagesJob Procedure For Vacuum Test of Tanks: 10 of Ramadan City, Industrial Area A1, EgyptShubham ShuklaNo ratings yet

- Khan AbdulQudoosDocument418 pagesKhan AbdulQudoosrajubansalNo ratings yet

- MMB125PN35Document3 pagesMMB125PN35fixedxray.ionicsNo ratings yet

- Hurricane 828: Operation/Maintenance ManualDocument32 pagesHurricane 828: Operation/Maintenance ManualMatias Contreras KöbrichNo ratings yet

- D500MX Manual enDocument10 pagesD500MX Manual enمحمدعبدالخالق العلوانيNo ratings yet

- Relay PumpDocument61 pagesRelay PumpBerty TilarsoNo ratings yet

- LG GC 181 ManualDocument15 pagesLG GC 181 ManualadijayptNo ratings yet

- User Manual: Vacuklav 24 B+ Vacuklav 30 B+Document64 pagesUser Manual: Vacuklav 24 B+ Vacuklav 30 B+Petar ĐurkovićNo ratings yet

- Uniaxial Testing in Rock Mechanics LaboratoriesDocument107 pagesUniaxial Testing in Rock Mechanics LaboratoriesYongliang LiuNo ratings yet

- CAD Modeling and Simulation of A Semi-Automatic Machine For Olive Oil PackagingDocument11 pagesCAD Modeling and Simulation of A Semi-Automatic Machine For Olive Oil PackagingEbrahim Abd El HadyNo ratings yet

- Properties Changes of MaterialsDocument28 pagesProperties Changes of Materialsapi-273214847No ratings yet

- II. 8 .2 Alat Laboratorium 2Document290 pagesII. 8 .2 Alat Laboratorium 2085270710307No ratings yet

- Vitrectomy Machine:: Nadia Artha DewiDocument21 pagesVitrectomy Machine:: Nadia Artha DewiŘŷØoo TЯyNo ratings yet

- Hazards: Low Pressure and Vacuum SystemsDocument12 pagesHazards: Low Pressure and Vacuum Systemstonytayic100% (1)

- Militair - I177 Tube TesterDocument243 pagesMilitair - I177 Tube TesterErik Van SoestNo ratings yet