Professional Documents

Culture Documents

Computer Engineering, Inc.: P WPS D1.1 - C - AWS 5.2.0 Form 2000 Rev. 0

Computer Engineering, Inc.: P WPS D1.1 - C - AWS 5.2.0 Form 2000 Rev. 0

Uploaded by

Erick GoyesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Computer Engineering, Inc.: P WPS D1.1 - C - AWS 5.2.0 Form 2000 Rev. 0

Computer Engineering, Inc.: P WPS D1.1 - C - AWS 5.2.0 Form 2000 Rev. 0

Uploaded by

Erick GoyesCopyright:

Available Formats

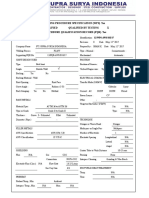

Computer Engineering, Inc.

509 NW 5th Street

Blue Springs, MO 64014

AWS D1.1 Welding Procedure Specification (WPS)

WPS No. WPS 231 Date 12/1/1987 Rev. No. 1 Date 1/18/1988 Page 1 of 1

Prepared By: Date Welding Engineer

Welding Process FCAW Welding Method Semiautomatic

Joint Design Used Joint Detail

Weld Type CJP Groove welds

Joint Type Butt, T- or corner joint

Groove Type Single-V groove

Double Welded No

Backing Yes Material ASTM A 131, Grade A

Root Opening 1/4 in. Root Face 0 in.

Groove Angle 52.5° Radius N/A

Back Gouging No Method N/A

Base Metals

Base Metal ASTM A 131, Grade A

Thickness: Groove 1 in.

Thickness: Fillet N/A

Pipe Diameter - Position

Weld Position: Groove Overhead only

Filler Metals

Weld Position: Fillet N/A

AWS Specification 5.20

Vertical Progression N/A

AWS Classification E71T-1

Electrical Characteristics

Shielding

Current / Polarity DCEP (reverse)

Gas 100% CO2 Flow Rate 45 - 55 CFH

Transfer Mode Globular arc

Gas Cup Size #4

Tungsten Electrode: Type N/A Size N/A

Electrode-Flux (Class) N/A

Heat Input 32000 J/in

Flux Trade Name N/A

Technique

Preheat

Stringer or Weave Bead String bead

Preheat Temperature, Min. 75°F

Multi-pass or Single Pass (per side) Multipass

Interpass Temperature, Min. 75°F Max. 350°F

Number of Electrodes 1

Electrode Spacing: Longitudinal N/A

Lateral N/A Angle N/A

Contact Tube to Work Distance 3/4 - 1"

Peening None

Interpass Cleaning Wire brush

Postweld Heat Treatment

Temperature None

Time (hr.) None

Welding Procedure

Pass Filler Metal Current Travel

or Weld AWS Size Type & Speed

Layer(s) Process Classification (in.) Polarity Amps Volts (in/min)

1 FCAW E71T-1 0.045 DCEP (reverse) 180 - 220 25 - 26 8 - 12

2 FCAW E71T-1 0.045 DCEP (reverse) 200 - 240 26 - 27 10 - 14

P WPS D1.1 - C - AWS 5.2.0

Form 2000 Rev. 0

You might also like

- Aws D1.6 - SS316 WPSDocument1 pageAws D1.6 - SS316 WPSBoby Thomas0% (1)

- AWS D1.1 - Example PQR & WPS DocumentsDocument4 pagesAWS D1.1 - Example PQR & WPS DocumentsPaul Cassells0% (1)

- Welding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin JasmirDocument3 pagesWelding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin Jasmirshahaljawaie87100% (3)

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- Wps Butt AWSDocument4 pagesWps Butt AWSMohd Ashraf75% (4)

- Wps Fillet AWSDocument4 pagesWps Fillet AWSMohd Ashraf100% (1)

- Perkins 804C-33 ManualDocument25 pagesPerkins 804C-33 ManualIbrahim Awad50% (2)

- Computer Engineering, Inc.: C PQR D1.1 - C - AWS 5.2.0 Form 2002 Rev. 0Document2 pagesComputer Engineering, Inc.: C PQR D1.1 - C - AWS 5.2.0 Form 2002 Rev. 0Erick GoyesNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Rejoy babyNo ratings yet

- QC E7018 CJP B-L1a OverheadDocument1 pageQC E7018 CJP B-L1a Overheadwmajordan13No ratings yet

- Draf WPSDocument2 pagesDraf WPSMj EdinNo ratings yet

- Procedure Qualification Record (PQR) : Filler Metals AWS Specification AWS ClassificationDocument3 pagesProcedure Qualification Record (PQR) : Filler Metals AWS Specification AWS ClassificationRejoy babyNo ratings yet

- Quinco Steel Inc.: Welding Procedure Specification (WPS)Document1 pageQuinco Steel Inc.: Welding Procedure Specification (WPS)wmajordan13No ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document3 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmack100% (1)

- Welding Procedure Specifications (WPS) : AWS D1.1Document2 pagesWelding Procedure Specifications (WPS) : AWS D1.1BS AhnNo ratings yet

- WPS NMB 001Document6 pagesWPS NMB 001mohamed nasserNo ratings yet

- Wps Emp 01-16 s275jr - s275jr BW P Smaw Awsd1 1Document2 pagesWps Emp 01-16 s275jr - s275jr BW P Smaw Awsd1 1Touil HoussemNo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document2 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmackNo ratings yet

- WPS Welding Performance SpecialistDocument2 pagesWPS Welding Performance SpecialistGobinath GovindarajNo ratings yet

- Arl-Al - WPS-001 PDFDocument2 pagesArl-Al - WPS-001 PDFrajuajiNo ratings yet

- WDI-WPS-072 Rev.00 SMAW 2Document4 pagesWDI-WPS-072 Rev.00 SMAW 2MohamedNo ratings yet

- Wps 7018 SmawDocument1 pageWps 7018 SmawErick VazquezNo ratings yet

- WPS - 600 MW ChampaDocument7 pagesWPS - 600 MW ChampaAmjad PathanNo ratings yet

- PQR WPSDocument2 pagesPQR WPSMiguel Alejandro SierraNo ratings yet

- Aramco Hot Tap Welding Procedure Rev 1Document3 pagesAramco Hot Tap Welding Procedure Rev 1BWQNo ratings yet

- Tz.O.R.C R.O. Project: Second and OtherDocument5 pagesTz.O.R.C R.O. Project: Second and Otherbehzad mohammadiNo ratings yet

- WPS NewDocument1 pageWPS NewErica SandersNo ratings yet

- Procedure Qualification SpecificationDocument4 pagesProcedure Qualification Specificationriyas.hvacworkNo ratings yet

- Draft WPSDocument3 pagesDraft WPSWale OyeludeNo ratings yet

- Prequalified Qualified by TestingDocument5 pagesPrequalified Qualified by Testingcarlosoliveros1967No ratings yet

- WPS & PQRDocument6 pagesWPS & PQRMuhammad AwaisNo ratings yet

- WPS-ASME SEC IX-for PSODocument3 pagesWPS-ASME SEC IX-for PSOSultan ZebNo ratings yet

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Document4 pagesPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNo ratings yet

- Welding Procedure Specification (WPS) Yes Prequalified X Qualified by Testing or Procedure Qualification Records (PQR) YesDocument2 pagesWelding Procedure Specification (WPS) Yes Prequalified X Qualified by Testing or Procedure Qualification Records (PQR) YessdgshhNo ratings yet

- Preliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Document2 pagesPreliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Vijaya Barani100% (1)

- Je C 006 WPSDocument4 pagesJe C 006 WPScameron toolseeNo ratings yet

- Annex M AWS D1.1/D1.1M:2015: Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)Document2 pagesAnnex M AWS D1.1/D1.1M:2015: Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)Daniel ZapataNo ratings yet

- Welding Procedure Specifications (Wps - 6G) : 2mm (Max)Document2 pagesWelding Procedure Specifications (Wps - 6G) : 2mm (Max)Gbenga Mobolade100% (1)

- PQR Format PDFDocument2 pagesPQR Format PDFHarshit Adwani100% (2)

- QW 482 WPSDocument2 pagesQW 482 WPSsmit patelNo ratings yet

- Preliminary - Welding Procedure Specification (WPS)Document1 pagePreliminary - Welding Procedure Specification (WPS)Rudi DaNo ratings yet

- PQR Saw ProcessDocument1 pagePQR Saw ProcessARUL ARON JOSENo ratings yet

- Afcons Infrastructure Limited: Procedure Qualification Record (PQR)Document21 pagesAfcons Infrastructure Limited: Procedure Qualification Record (PQR)GaapchuNo ratings yet

- WC9Document5 pagesWC9Suresh KrishnanNo ratings yet

- Procedure Qualification Record (PQR) : Annex N AWS D1.1/D1.1M:2010Document2 pagesProcedure Qualification Record (PQR) : Annex N AWS D1.1/D1.1M:2010Menad SalahNo ratings yet

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Document2 pagesASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- Welding Procedure Specification: ST NDDocument1 pageWelding Procedure Specification: ST NDMaung SleeperNo ratings yet

- Pre-Liminary WELDING PROCEDURE Specification (PWPS) : RDMP RU-V Balikpapan ProjectDocument2 pagesPre-Liminary WELDING PROCEDURE Specification (PWPS) : RDMP RU-V Balikpapan ProjectBagandi ManurungNo ratings yet

- Welding Procedure Specification (WPS) Yes Prequalified or Procedure Qualification Records (PQR) YesDocument2 pagesWelding Procedure Specification (WPS) Yes Prequalified or Procedure Qualification Records (PQR) YesRuben Purca0% (1)

- BGR Energy Systems Limited: Oil & Gas Equipment Division Welding Procedure Specification (WPS) - Aws D1.1Document1 pageBGR Energy Systems Limited: Oil & Gas Equipment Division Welding Procedure Specification (WPS) - Aws D1.1Eswar Enterprises QcNo ratings yet

- WCBDocument5 pagesWCBSuresh KrishnanNo ratings yet

- WPS-ASME-007-1 Rev0Document1 pageWPS-ASME-007-1 Rev0Ahmed LepdaNo ratings yet

- Main - Sample Welding Procedure Specification Wps FormDocument2 pagesMain - Sample Welding Procedure Specification Wps FormmuhammaddanishafandiNo ratings yet

- Welding Procedure Specification Pipe 6G PDFDocument3 pagesWelding Procedure Specification Pipe 6G PDFchepurthiNo ratings yet

- Aic Asf PQR 0120Document2 pagesAic Asf PQR 0120AHMED MEDANYNo ratings yet

- PWPS 005Document2 pagesPWPS 005Mehrdad RezaeiNo ratings yet

- Lampiran 3. WPS of Pile JointDocument3 pagesLampiran 3. WPS of Pile JointDoni TriatmojoNo ratings yet

- Welding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeDocument1 pageWelding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeKishan ChauhanNo ratings yet

- Piping WpsDocument37 pagesPiping WpsZulfokar FahdawiNo ratings yet

- GM TCL 1 2F - WebExampleDocument1 pageGM TCL 1 2F - WebExamplesuronocaturatmojoNo ratings yet

- Final IEM UG PG Thesis Template and GuidelinesDocument24 pagesFinal IEM UG PG Thesis Template and Guidelinessnh.2k19No ratings yet

- P Control Via Internal Pressure Sensor For The Control of Up To 48 Solenoid ValvesDocument4 pagesP Control Via Internal Pressure Sensor For The Control of Up To 48 Solenoid ValvesChangHuiChuanNo ratings yet

- Single Storey Industrial BuildingsDocument40 pagesSingle Storey Industrial BuildingsLahlou DahmaniNo ratings yet

- Major 317 AccidentsDocument13 pagesMajor 317 AccidentsBamaNo ratings yet

- Earth-to-Mars Mission Design (Fortran)Document50 pagesEarth-to-Mars Mission Design (Fortran)Anonymous REw1YIq4q7No ratings yet

- Block Diagram of Electromechanical SystemDocument20 pagesBlock Diagram of Electromechanical SystemSandeep ReddyNo ratings yet

- Cummins GGPA GGPB GGPC Installation ManualDocument106 pagesCummins GGPA GGPB GGPC Installation ManualRajan Lakshmanan100% (2)

- AS Level Physics Revision NotesDocument39 pagesAS Level Physics Revision NotesjoshuaNo ratings yet

- KUKA Datenblatt FlexFELLOW enDocument2 pagesKUKA Datenblatt FlexFELLOW enMarincean MihaiNo ratings yet

- Basic Piping PrintDocument22 pagesBasic Piping PrintDeepak KumarNo ratings yet

- Chemistry Lesson 3Document11 pagesChemistry Lesson 3Vinod Varadan SNo ratings yet

- Direct Drive Blade 1 25 18 2Document8 pagesDirect Drive Blade 1 25 18 2KM KarthikNo ratings yet

- Upf PWM ConverterDocument5 pagesUpf PWM ConverterDeepak GehlotNo ratings yet

- A TEC Rocket Mill v11.1Document26 pagesA TEC Rocket Mill v11.1Dilnesa EjiguNo ratings yet

- Myers The Ranger SeriesDocument4 pagesMyers The Ranger SeriesjkangwsNo ratings yet

- CV Saed DababnehDocument12 pagesCV Saed DababnehSaed DababnehNo ratings yet

- GEA18574 Hydro Generator Test and InspectDocument4 pagesGEA18574 Hydro Generator Test and InspecteciceranNo ratings yet

- Wong K.V. Thermodynamics For Engineers (2ed., CRC, 2012) (ISBN 9781439897027) (O) (440s) PTDocument440 pagesWong K.V. Thermodynamics For Engineers (2ed., CRC, 2012) (ISBN 9781439897027) (O) (440s) PTWilliam WilliamNo ratings yet

- Physgen Unit 5Document13 pagesPhysgen Unit 5emji miraNo ratings yet

- 100 IC CircuitsDocument60 pages100 IC CircuitsGicu CapatinaNo ratings yet

- ACM0002 Version 13.0.0Document20 pagesACM0002 Version 13.0.0Sandip KeswaniNo ratings yet

- 07 Pegasus Ibms v5.2Document4 pages07 Pegasus Ibms v5.2h2odavidNo ratings yet

- Whitco Pressure WasherDocument2 pagesWhitco Pressure WasherDaniel “D” GrayNo ratings yet

- Smoke - Ventilation CalculationsDocument8 pagesSmoke - Ventilation CalculationsdasmechNo ratings yet

- 049 - CRT With OLTC - 2500 KVA - 33-0.433 KV - GODAVARI PROJECTS PRIVATE LIMITED - Dt. 25.05.2021Document5 pages049 - CRT With OLTC - 2500 KVA - 33-0.433 KV - GODAVARI PROJECTS PRIVATE LIMITED - Dt. 25.05.2021Ajay MedikondaNo ratings yet

- Practical Guide: Signal and Data Lines Surge Protection of Low Current SystemsDocument52 pagesPractical Guide: Signal and Data Lines Surge Protection of Low Current SystemsSujith KarayilNo ratings yet

- Waste Minimization in Fertilizer IndustryDocument23 pagesWaste Minimization in Fertilizer IndustryRavi Bhaisare100% (5)

- Gallus Net - Residential Smart Gas MeterDocument2 pagesGallus Net - Residential Smart Gas MeterFilip SerafimovNo ratings yet

- 17.5 Propeller Ice Protection.Document4 pages17.5 Propeller Ice Protection.Anuruddha Rukmal67% (3)