Professional Documents

Culture Documents

MH-22 Rebuild (Shooting Bridle) V1.7

MH-22 Rebuild (Shooting Bridle) V1.7

Uploaded by

Jose Antonio AcostaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MH-22 Rebuild (Shooting Bridle) V1.7

MH-22 Rebuild (Shooting Bridle) V1.7

Uploaded by

Jose Antonio AcostaCopyright:

Available Formats

MH-22 Rebuild (shooting bridle) V1.

7

The MH-22 is obsolete and should not be used in the field, it has been replaced by the PEH-EFA(101043054).

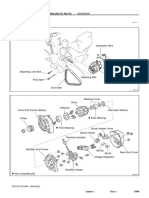

1. Choose sub assembly (includes fishing head and rope socket) according to the cable size used as 2. Assemble parts onto cable and position the rope socket as shown.

per Table 1.

Fishing Head Clamp Nut Thrust Ring Wrap the cable with tape about 10.5" to establish the position

(H035970) (H230460) Rope Socket

of the rope socket.

5. Unwrap an outer armor from the core and fastened to the rope socket as shown. Repeat the

procedure using the proper number of strands of outer armor wires evenly spaced around the rope

3. Hold the rope socket socket. All strands should be pulled snug so that slack has been removed.

by the split jig

(H122090) on a vise in Unwrapping and looping Bend and cut remaining outer armors.

order to get proper outer armors.

torque. Do not bend wire ends

with a punch String tie

Bend and

6. Unlay and install three inner armors in the

4. Based on the selected weakpoint strength

rope socket for torque control (as per Table 2).

determine quantity of inner and outer armors as

Two inner armors are to be left for ground.

well as torque value to be used to tighten the

Remaining inner armors are left ~2” long as

clamp nut as per Table 2.

shown above.

7. Clamp Nut must be properly torqued as indicated on Table 2 (torque 9. Lower head assembly: Position the lock ring. Install o-ring and position feed thru. Connect ground wire from spider rope

values units: in-lbf). socket to lower head. Install set screw.

End terminal Set screw

1-3/8 in monocable head

Torque wrench (B034859) on H036486 B013811

Feed-thru H030464

clamp nut (H035970) connector

Wires must be flat in their grooves as

shown. Centering ring (H701896) goes

Thrust ring over the rope socket and thrust ring.

(H230460)

O-rings Bevelled insulator

8. Prepare the conductor assembly. Refer to BCC SWI 6658523 for details B013113 Lock ring O-ring B011968

H125979 Set screws

on BCC selection and assembly. H030474 for ground

Sleeve H036384 wires

10. Slide the bell housing over the rope socket Rotation Lower head

Bell housing H030798 H030464

and electrical connections.

Plug the BCC connector onto the fluid-to-air Long Boot

connector using boot retainer pliers(H268423). Retainer

Slide the long boot retainer (100593948) onto the

boot. Orient the boot retainer gas vent slot at Spirol pin 3/16" dia

the downhole end of the boot. 1-1/4" lg B013392 Spirol pin 1/18" dia - 3/4" lg B015067

11. Screw the bell housing onto the lower head. Install the spirol pin (B015067) through the bell

Insert the ground terminal into the hole in the housing near the junction of the housing and head (H030464). Install one spirol pin (B013392) fully

lower head and clamp it with set screw through the bell housing (H030798) just below the rope socket. Install another spirol pin (B013392)

(B013811). halfway through the bell housing (H030798) just below the rope socket.

Fishing head Lower head w/thread protector

Hexagonal collar H034903

Wireline cable

Key H030772

Spirol pin 3/16-in dia. 3/4 lg B013813

12. Mount the hexagonal collar (H034903) on the hex collar tool (H036971). Slip these parts over

13. While holding the key, screw the fishing head down tight, locking the key in place. Back off the

the cable and insert them into the top of the bell housing. Slide the hex collar onto the hex end of

fishing head 1/6 turn or less as needed to align the hex with the spiral pin holes in the bell housing.

the rope socket with the slot aligned as nearly as possible with the window in the bell housing.

Use the 3/16-in diameter punch to assist alignment if necessary. Insert the spirol pin (B013813)

Rotate the hex collar tool for exact alignment of the hex collar slot with the window. Insert the key

through the uphole end of the bell housing and fishing head.

(H030772) downhole end first.

Final inspection

1. Perform insulation check @ 500 VDC with the sope socket assembly in saline water. Check continuity.

2 2. Pump the head full of DC-111 through the hole of the spirol pin (B013392) that was inserted

half way in step 9. When the head is full of grease, finish installing the spirol pin.

3. Recheck the conductor insulation (>500 Meg) and verify continuity.

1 3

4. File all spirol pins off flush with the bell housing.

5. Install two O-rings (B011968) on the downhole end of the lower head assembly (H122373).

4 6. Screw the proper thread protector (H122375) onto the lower head assembly.

1. H712995: Contact Assy, 62S socket 7. Coat the threads at fishing head and the threads at upper and lower on the lower head

2. H712972: Boot liner assembly with Lubriplate grease (B013366).

H712098: Cone Kit for 1-42 Cable 3. H400313: Female boot, .078 DIA 1-3/16-in cables fishing sub-assemblies used with MH-22

4. Long boot retainer (100593948) Fishing head and rope socket sub-assembly

Cable dia (inches)

Rope Socket Part No.

Sub-assembly Part No. Fishing Head Part No.

0.42 H136157 H035324 H036476

Table-1 0.31 / 0.32 H136159 H035593 H036477

0.25 H701925 H035593 H136166

Protector P070961 0.23 H701923 H407338 H701998

12. Create rope socket using 1-42 cone kit , boot, liner and pin contact. Protect the 0.20 / 0.22 H136160 H035073 H036464

rope socket using protector P070961. 0.18 H136161 H125567 H036475

Additional Information (Table-2)

* No Experimental data available on these cable types. Break

strengths are not adjusted per 12/93 model. Future testing

planned.

** +/- 15%

*** +/- 25%

Date Released - 23-Jun-2013 Approved By - Scott Carson Version - 1.7

You might also like

- Parte Manual Focus Rs 2016 5Document96 pagesParte Manual Focus Rs 2016 5Garikoitz FranciscoeneNo ratings yet

- Manual TLC SlimDocument444 pagesManual TLC SlimJose Antonio AcostaNo ratings yet

- Split Shot ManualDocument179 pagesSplit Shot ManualJose Antonio AcostaNo ratings yet

- Wpsa ManualDocument128 pagesWpsa ManualJose Antonio AcostaNo ratings yet

- Swi Rope SocketDocument54 pagesSwi Rope SocketJose Antonio Acosta100% (2)

- Banshee AC To DC ConversionDocument2 pagesBanshee AC To DC ConversiondannoxyzNo ratings yet

- 1-Custom Undetectable Macro DevelopmentDocument10 pages1-Custom Undetectable Macro DevelopmentSaw GyiNo ratings yet

- Msa5t0124a27668 PDFDocument5 pagesMsa5t0124a27668 PDFJeff PascoeNo ratings yet

- Generator: ComponentsDocument8 pagesGenerator: Componentsjuan riveraNo ratings yet

- ST 6Document2 pagesST 6Mega VentasNo ratings yet

- Chapter 2-Coupling and ClutchesDocument40 pagesChapter 2-Coupling and Clutcheskibromgidey12No ratings yet

- MSA5T0205A11493Document6 pagesMSA5T0205A11493anibalbelltNo ratings yet

- Rotary Joint Unit: Supplementary Instruction ManualDocument17 pagesRotary Joint Unit: Supplementary Instruction ManualAntonio Montesinos ChavarríaNo ratings yet

- Removal: Torx Screw Screw CaseDocument2 pagesRemoval: Torx Screw Screw CasejuanNo ratings yet

- ST 11Document4 pagesST 11Mega VentasNo ratings yet

- Philips N2213-00-15 SMDocument13 pagesPhilips N2213-00-15 SMFranco DurantNo ratings yet

- Bliss Wire Stitcher Head ManualDocument28 pagesBliss Wire Stitcher Head ManualAnonymous 2MRGC0w1No ratings yet

- DRRM 31Document32 pagesDRRM 31Yurii LembergNo ratings yet

- N80 160 15 2 WOS ModelDocument1 pageN80 160 15 2 WOS Modeldaney1985010No ratings yet

- Replacement: - StarterDocument2 pagesReplacement: - StartersalusfrankNo ratings yet

- AR Series ACB UVT RemovalDocument3 pagesAR Series ACB UVT RemovalGeorgios MariolisNo ratings yet

- Bda 462 - Ne8mx T - Ethercon C6a - Cable ConnectorDocument2 pagesBda 462 - Ne8mx T - Ethercon C6a - Cable ConnectoremilioNo ratings yet

- MSA5T0205A11494Document4 pagesMSA5T0205A11494anibalbelltNo ratings yet

- 1972 A Strain-Gauge Brushless TorqueDocument5 pages1972 A Strain-Gauge Brushless TorqueLuana FortesNo ratings yet

- Power-Lock Splice Kit 261821: Instructions - PartsDocument4 pagesPower-Lock Splice Kit 261821: Instructions - Partsyon naNo ratings yet

- Reassembly: See Page SR 1 0Document4 pagesReassembly: See Page SR 1 0Moh DeBrNo ratings yet

- Overhaul: 1. Inspect Connecting Rod Thrust ClearanceDocument29 pagesOverhaul: 1. Inspect Connecting Rod Thrust ClearanceEdU RECTIFICANo ratings yet

- Rack and Pinion2Document18 pagesRack and Pinion2Romy MNo ratings yet

- LONG FIRING HEAD 3 - 125-In 3 - 375-In 3 - 5-In - OPERATOR SWI V - 1 - 0 - 6536227 - 01Document1 pageLONG FIRING HEAD 3 - 125-In 3 - 375-In 3 - 5-In - OPERATOR SWI V - 1 - 0 - 6536227 - 01Jose Antonio AcostaNo ratings yet

- Caterpillar 3508, 3508B, 3508CDocument11 pagesCaterpillar 3508, 3508B, 3508CGazNo ratings yet

- Engine Hood DoorDocument113 pagesEngine Hood DoorJustin CosbyNo ratings yet

- Nobo Swi Wpsa-Aaversion 1.2Document1 pageNobo Swi Wpsa-Aaversion 1.2Jose Antonio AcostaNo ratings yet

- 10 - Design of Screw FasteningDocument36 pages10 - Design of Screw FasteningMiguel Ocampo100% (1)

- Aluminum Welding Kit: DescriptionDocument8 pagesAluminum Welding Kit: DescriptionA delca-No ratings yet

- Starter (ST) Lexus Is300 2JZGE VVTIDocument17 pagesStarter (ST) Lexus Is300 2JZGE VVTIJapanCars LooverNo ratings yet

- Instruction Sheet Is Js1615: - Style Number Js1615Bn:: Package ContentsDocument3 pagesInstruction Sheet Is Js1615: - Style Number Js1615Bn:: Package Contentsdayshift5No ratings yet

- MT Series - ServiceDocument8 pagesMT Series - ServiceВаня БойкоNo ratings yet

- Disassembly: Screw ExtractorDocument3 pagesDisassembly: Screw ExtractorMoh DeBrNo ratings yet

- Starter Assy (1.2Kw) (1Az-Fe) : OverhaulDocument8 pagesStarter Assy (1.2Kw) (1Az-Fe) : OverhaulHenry SilvaNo ratings yet

- Aumentar Suspension Colorado 2010 4x2Document2 pagesAumentar Suspension Colorado 2010 4x2Marco Antonio GutiérrezNo ratings yet

- Pages From FJ HDJ Hzj-80 Series Chassis-WinchDocument55 pagesPages From FJ HDJ Hzj-80 Series Chassis-WinchcharNo ratings yet

- TNC ConectorDocument2 pagesTNC ConectorLong ComtechNo ratings yet

- Generator Assy (1Az-Fe) : OverhaulDocument5 pagesGenerator Assy (1Az-Fe) : OverhaulHenry SilvaNo ratings yet

- Wi 08 M EngDocument3 pagesWi 08 M EngFlavio SanchezNo ratings yet

- Instruction Sheet Is-Ctr1717 Style Number: Ctr1717Is: Package ContentsDocument3 pagesInstruction Sheet Is-Ctr1717 Style Number: Ctr1717Is: Package Contentsdayshift5No ratings yet

- Verado 200-275 Workshop-2Document90 pagesVerado 200-275 Workshop-2Servicios Luna LSNo ratings yet

- Disassembly: 1. Remove Rear End CoverDocument2 pagesDisassembly: 1. Remove Rear End CoverMiguel ruizNo ratings yet

- Catalogo Vibradores ZFDocument13 pagesCatalogo Vibradores ZFrubenNo ratings yet

- RHOWPA Pole Mount: Installation GuideDocument2 pagesRHOWPA Pole Mount: Installation GuideunstrainNo ratings yet

- Connector: Series 1051 A004-9: I - Tool RequiredDocument3 pagesConnector: Series 1051 A004-9: I - Tool RequiredRodolfo Victor Barrios CastilloNo ratings yet

- CB Igh 1Document6 pagesCB Igh 1Leo BoschiazzoNo ratings yet

- Dss qb1Document7 pagesDss qb1Sushma ThakurNo ratings yet

- At-Sealing Replacement (GB)Document4 pagesAt-Sealing Replacement (GB)George LapusneanuNo ratings yet

- 035 - 36 - Technical Manual 11-Speed Chain - Campagnolo - REV01!11!13Document7 pages035 - 36 - Technical Manual 11-Speed Chain - Campagnolo - REV01!11!13asfilbike bicicletasNo ratings yet

- Camshaft (1Nz Fe/2Nz Fe) : ReplacementDocument8 pagesCamshaft (1Nz Fe/2Nz Fe) : ReplacementMaung KyawNo ratings yet

- Man B&W Engine Studty NotesDocument135 pagesMan B&W Engine Studty NotesGabriel CiorbaruNo ratings yet

- Instruction Sheet Is-Brb1717 Style Number: Brb1717K: Package ContentsDocument3 pagesInstruction Sheet Is-Brb1717 Style Number: Brb1717K: Package Contentsdayshift5No ratings yet

- Tilt Steering Column ReassemblyDocument2 pagesTilt Steering Column ReassemblyjuanNo ratings yet

- kx80 Página 191Document1 pagekx80 Página 191PabloNo ratings yet

- DensoR5Starter Installation For Mercedes BenzDocument8 pagesDensoR5Starter Installation For Mercedes BenzJosé gamer MorenoNo ratings yet

- Procedures For Rotational Capacity Testing For High Strength BoltsDocument15 pagesProcedures For Rotational Capacity Testing For High Strength Boltsefmartin1321No ratings yet

- 4523 Micro Adjuster: Please Read Carefully!Document2 pages4523 Micro Adjuster: Please Read Carefully!unoNo ratings yet

- Overhaul: 1. Inspect Connecting Rod Thrust ClearanceDocument17 pagesOverhaul: 1. Inspect Connecting Rod Thrust ClearanceHenry SilvaNo ratings yet

- Installing Coaxial Connectors (Tnote04)Document4 pagesInstalling Coaxial Connectors (Tnote04)Douglas A. Joslyn Jr.No ratings yet

- Nobo Swi Wpsa-Aaversion 1.2Document1 pageNobo Swi Wpsa-Aaversion 1.2Jose Antonio AcostaNo ratings yet

- Peh-L ManualDocument405 pagesPeh-L ManualJose Antonio Acosta100% (1)

- Manual SLS 1 Del Cal-BDocument62 pagesManual SLS 1 Del Cal-BJose Antonio AcostaNo ratings yet

- Radiation Operator Swi Intouch Id # 6545284: Example! Replace With A Photo of WrenchDocument1 pageRadiation Operator Swi Intouch Id # 6545284: Example! Replace With A Photo of WrenchJose Antonio AcostaNo ratings yet

- LONG FIRING HEAD 3 - 125-In 3 - 375-In 3 - 5-In - OPERATOR SWI V - 1 - 0 - 6536227 - 01Document1 pageLONG FIRING HEAD 3 - 125-In 3 - 375-In 3 - 5-In - OPERATOR SWI V - 1 - 0 - 6536227 - 01Jose Antonio AcostaNo ratings yet

- Pccl-La Fit: The Diode Should Read Between 6.0 V To 7.9 V, Both PolaritiesDocument1 pagePccl-La Fit: The Diode Should Read Between 6.0 V To 7.9 V, Both PolaritiesJose Antonio AcostaNo ratings yet

- Manual Pivot GunDocument161 pagesManual Pivot GunJose Antonio AcostaNo ratings yet

- Numero de Partes de Todos Los YenkosDocument1 pageNumero de Partes de Todos Los YenkosJose Antonio AcostaNo ratings yet

- Leh - QT - Fit NuevoDocument18 pagesLeh - QT - Fit NuevoJose Antonio Acosta100% (1)

- Manual Upct-HDocument131 pagesManual Upct-HJose Antonio Acosta100% (2)

- Perforating Equipment Head (PEH-L) Maintenance SWI SLS-1 SetDocument32 pagesPerforating Equipment Head (PEH-L) Maintenance SWI SLS-1 SetJose Antonio AcostaNo ratings yet

- Puntos Debiles Actualizados 25 Junio2018Document261 pagesPuntos Debiles Actualizados 25 Junio2018Jose Antonio AcostaNo ratings yet

- Swi para Pesca ReversadaDocument87 pagesSwi para Pesca ReversadaJose Antonio AcostaNo ratings yet

- Casing Packer Setting Tool (CPST) : WL Equipment Guidelines CPSTDocument9 pagesCasing Packer Setting Tool (CPST) : WL Equipment Guidelines CPSTJose Antonio AcostaNo ratings yet

- Firing Heads (BST/CPST) : Parts Lists and Exploded ViewsDocument48 pagesFiring Heads (BST/CPST) : Parts Lists and Exploded ViewsJose Antonio AcostaNo ratings yet

- Swi Canon de 7 Pulgadas NuevoDocument81 pagesSwi Canon de 7 Pulgadas NuevoJose Antonio AcostaNo ratings yet

- Enerjet Spare Part Selection V1.1: General Tool StringDocument1 pageEnerjet Spare Part Selection V1.1: General Tool StringJose Antonio AcostaNo ratings yet

- Rope Socket Assembly Intouch Id # 5978209: Eag WL SwiDocument3 pagesRope Socket Assembly Intouch Id # 5978209: Eag WL SwiJose Antonio Acosta100% (1)

- Casing Packer Setting Tool (CPST) : Parts Lists and Exploded ViewsDocument14 pagesCasing Packer Setting Tool (CPST) : Parts Lists and Exploded ViewsJose Antonio Acosta100% (1)

- Drawing JaimeDocument1 pageDrawing JaimeJose Antonio AcostaNo ratings yet

- SFT-709 Fishing Kit ChecklistDocument1 pageSFT-709 Fishing Kit ChecklistJose Antonio Acosta100% (1)

- Split Shaft Pto: Installation InstructionsDocument12 pagesSplit Shaft Pto: Installation InstructionsAhmad ShaheenNo ratings yet

- Sic Mosfet Replace IgbtDocument3 pagesSic Mosfet Replace IgbtGilberto ManhattanNo ratings yet

- Research Needs Vehicle TrackDocument33 pagesResearch Needs Vehicle TrackBhuvanesh KumarNo ratings yet

- Transmittal: Design Document Transmittal Document No Rev Titles StatusDocument2 pagesTransmittal: Design Document Transmittal Document No Rev Titles Statushasan shahriarNo ratings yet

- BSBSTR601 Project PortfolioDocument20 pagesBSBSTR601 Project PortfolioJojoNo ratings yet

- Saep 334Document48 pagesSaep 334jubairNo ratings yet

- How To Calculate UPS Battery Backup - Backup HowToDocument5 pagesHow To Calculate UPS Battery Backup - Backup HowToRaj ChavanNo ratings yet

- Khartoum Masterplan Phase-1Document82 pagesKhartoum Masterplan Phase-1Beya BoueNo ratings yet

- Hangcha R Series Operator Maintenance ManualDocument105 pagesHangcha R Series Operator Maintenance ManualCocam CocamNo ratings yet

- Atm Error Code With Solutions-1Document6 pagesAtm Error Code With Solutions-1greggtldivisionNo ratings yet

- IGHR System - Plantilla - GuideDocument9 pagesIGHR System - Plantilla - GuideConan EdogawaNo ratings yet

- Requirements GatheringDocument57 pagesRequirements GatheringJohnLuceNo ratings yet

- B436-Y2 Mitsubishi 730 VSL BIGLIA LATHESDocument153 pagesB436-Y2 Mitsubishi 730 VSL BIGLIA LATHESGHZMANNo ratings yet

- GR00001100 55Document140 pagesGR00001100 55Elza PutriNo ratings yet

- 35 - Phani SRSDocument15 pages35 - Phani SRSryangosling350350No ratings yet

- Twine SugarCube CheatsheetDocument15 pagesTwine SugarCube CheatsheetanggarwantoaNo ratings yet

- Design To ValueDocument27 pagesDesign To ValueWilliam100% (1)

- Cv-050 Conversion Test PlansDocument18 pagesCv-050 Conversion Test PlansosmanmirNo ratings yet

- Hotkeys - ExocadDocument6 pagesHotkeys - Exocadlaboratorio dental san martin100% (1)

- 2018PSLEM025 ArchivageDocument190 pages2018PSLEM025 ArchivageBrayan GonzalezNo ratings yet

- Ent 189 C ProgrammingDocument47 pagesEnt 189 C ProgrammingSeng Soon100% (1)

- EmpTech: Quarter 1 - Module 4Document22 pagesEmpTech: Quarter 1 - Module 4Jenalyn GazoNo ratings yet

- Training For LTBDocument20 pagesTraining For LTBrpshvjuNo ratings yet

- 5991 8252enDocument8 pages5991 8252enRocketManNo ratings yet

- Sony Z7 BrochureDocument20 pagesSony Z7 BrochureTodorNo ratings yet

- LAB211 Assignment: Title: Background ContextDocument3 pagesLAB211 Assignment: Title: Background ContextVu Quang HuyNo ratings yet

- MapR Certified Cluster Administrator Study Guide v.5.1Document28 pagesMapR Certified Cluster Administrator Study Guide v.5.1Vijay ReddyNo ratings yet

- Project TutorialDocument16 pagesProject TutorialKhalid AlmutairiNo ratings yet