Professional Documents

Culture Documents

Cesi 00 Atex 036 U Ing

Cesi 00 Atex 036 U Ing

Uploaded by

Yupi Setiawan0 ratings0% found this document useful (0 votes)

38 views4 pagesOriginal Title

cesi-00-atex-036-u-ing

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

38 views4 pagesCesi 00 Atex 036 U Ing

Cesi 00 Atex 036 U Ing

Uploaded by

Yupi SetiawanCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 4

CESI

afiSTIES,

cest spa.

Vie Rubactino 54

"36 lla ay

39 02 21281

Fave £3002 21258000

‘email infosco it

A

\JE

/

i:

CES

Reaa

te

ae

a

iO

bl

BI)

4

6

(6

a

8)

iO}

Lo}

wa

1124

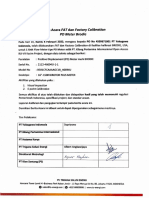

CERTIFICATE ©

SUPPLEMENTARY EU-TYPE EXAMINATION CERTIFICATE

‘Component intended for use on/in equipment or protective system

intended for use in potentially explosive atmospheres,

Directive 2014/34/EU

Supplementary EU-Type Examination Certificate number:

CESI 00 ATEX 036 U /07

Component: Empty enclosures series CCF and EJB for control and signalling

equipment

Manufactures:

Address: ‘Via Aquileia, 12 -34070 Villesse (GO) - Italy

‘This supplementary certificate extends. EC-Type Examination _Cetficate

CESI 00 ATEX 036U, to apply to products designed and constructed in accordance with the

specification set out in the Schedule of the said certificate but having any variations specified in

the Schedule attached to this certificate and the documents therein referred to,

CESI, notified body n, 0722 in accordance with Article 17 of the Directive 2014/34/EU of the

Parliament and Council of 26 February 2014, certifies that this component has been found to

comply with the Essential Health and Safety Requirements relating to the design and

construction of equipment and protective systems intended for use in potentially explosive

atmospheres given in Annex II to the Directive.

‘The cxamination and test results are recorded in confidential report n. EX-B6023467.

In accordance with Article 41 of Directive 2014/34/EU, EC-Type Examination Certificates

referring 10 94/9/EC that were in exislence prior to the date of application of 2014/34/BU (20

April 3016) may be referenced as if they were. issued in accordance with Directive

2014/34/EU. Supplementary certificates to such EC-Type Examination Certificates, and new

issues of such certificates, may continue to bear the original certificate number issued prior to

20 April 2016,

‘The sign "U" placed after the certificate number indicates that this certificate must not be

mistaken for a certificate intended for an equipment or protective system. This partial

certification may be used as a basis for certification of an equipment or protective system,

‘This EU-TYPE EXAMINATION CERTIFICATE relates only to the design, examination and

tests of the specified component in accordance to the Directive 2014/34/EU. Further

requirements of the Directive apply to the manufacturing process and supply of this

component. These are not covered by this certificate.

‘The marking of the component shall include the followis

€ 2G ExabmBop or Ex db IB+H2 Gb

® we exam (Stet Se entanre on)

@ GD kxab UB Gb or Ex db 11B+H2 Gb

Ex tb ICD» Ext THC Db

1P66i67 TR66'67

‘This certificate may only be reoroduced in its entirety and without any change, schedule induced,

Date 2016.09.26 - Translation issued the 2016.09.26

Prepared Verified Approved

Alessandro Fedato Mirko Balaz Roberto Piccin

MinekEhy Aybninl~ CEST one

sting & ftation Division

Businesy/ ira CAflfication

W

Page 1/5

CESI

013] Schedule

(14) SUPPLEMENTARY EU-TYPE EXAMINATION CERTIFICATE 1, CESI 00 ATEX 036 U /07

[15] Deseription of the variation to the component

+ Updating to standards EN 6079-0; 2012 + A11:2013, FN60079-1:2014 and EN60079-31:2014,

- New minimum ambient temperature -60°C.

- Upgrade to EJB design (new 2015 series) and EJBX series,

+ New enclosures type EIBX-01 was added,

- New enclosures EIBT... series was added.

Description of component

‘The FJB-.. empty enclosures series have the body and the cover made in aluminium alloy or stainless steel and

are in Ex d I (siainless steel only), Ex d IIB, Ex d IIB# Hf; and Ex tb IUIC execution,

‘The EJB... series is available in two particular execution:

‘+ with external flange for type BJB-.;

‘+ with internal flange for type AQS-1.

‘They can be equipped with command and signalling operators series M-0.. certified as components with separate

certificate, mounted on the cover or on the enclosure wall and with circular or rectangular transparent tempered

glass windows sealed on the cover. Gaskets between cover and body flanged joint and for all other accessories

fare made in silicon and they guarantee the protection degree 1P66 while [P67 for enclosures without operators

only. The flanged joint between the body of EJB-.. empty enclosures series and the cover is fixed with quality

A2-10 stainless steel screws,

The walls of the enclosures can be drilled and threaded with maximum size and maxiarum number of hubs as

specified in the manufacturer documents annexed. Each enclosure is provided with internal and external earthing

serew or bolt and an internal bottom plate for equipment mounting.

“Model identification:

Stainless steol

Aluminium alloy enclosures eae

EBT series EJBX series

EBIO EIBX-O1

7 Pees EIBX.OIB__|

EIB-T HBT EIBX-1

EIB2 EIBIZ EJBX2

7 “EIBT2CB 7

EIBT2C =

EB3 EIBI3 EBX

EIB-33 EBTSB, EIBX.3B,

EIB _EIBTS EIBX-4

EIB4B_ ‘EIBT4B EIBX-4B

EIB-AS EIBTAS EIBX-AS

EIB-458 EIBTASB__ EIBX-45B

EIB-48BA - ~

EBS EyBIS EIBX-5

ENB-SB _|_EIBISE EIBXSB

EIB-55 EIBTSS EIBX.55

EVB-558 EIBISSB, EIBX-55B

EB-503 - =

EJB-55C : |

EIB-6 ENTS EBX

EJB-6B EIBIGB EIBX-6B.

[__EvB-7 EJBIT EIBX-)

EIB-7B : =

“This certificate may only be reproduced in its entirety and wathout any change, schedule included.

Page 2/4

Prot 86023469 Pid

CESI

13) Schedule

[14] SUPPLEMENTARY EU-TYPE EXAMINATION CERTIFICATE n. CESI 00 ATEX 036 U /07

Ambient temperature ranges

* from -20°C up to +60°C: all versions of empty enclosures for group I (made in stainless steel only), group

IB, IIB+H, and group HC:

* from -40°C up to H60°C: all Yersions of empty enclosures for group IIB, IIB+H; and group IC with

polycarbonate pilot lights;

* from -60°C up to +60°C: all versions of empty enclosures for group IIB, IB+H, and group TIIC without

polyearbonate pilot lights;

* fiom -60°C up to +100°C: all versions of empty enclosures (types EJB-O1 and AQS-1 excluded) for group

TB and group TIC with or without glass windows sealed on the cover and

without contol-signal operators.

Cable entries

‘The accessories used for cable entrios and plugs for not used holes shall be subject of separate certification,

suitable for type of enclosure execution, according to the applicable standards.

[16] Report n. EX- 36023467

Routine tests

‘The routine overpressure test shall be carried out on empty enclosure with the static method (paragraph 15.2.3.2 of

EN 60079-1 Standard), at:

* 14.0 bar on all EJB enclosures for minimum ambient temperature until -20 °C;

= 16.0 ber on all EIB enclosures for minimum ambient temperature until -60 °C.

[17] Schedule of limitations

# The accessories used for cable entries and for closing unused openings shall be certified according to

EN 60079-0, EN 60079-1 and EN 60079-31. A minimum degree of protection 1P66/67 shall be guarastecd

according to EN 60529 standard

+ The empty enclosures shall be used in the following ambient temperature range:

‘© from -20°C up to ~60°C: all versions of empty enclosures for group I (made in stainless steel only), group

IIB, IB +H and group UIC;

© from -40°C up to +60°C: all versions of empty enclosures for group HIB, IB+H and group HIC with

polycarbonate pilot lights;

«from -60°C up to +60°C all versions of empty enclosures for group IIB, IIB+H; and group TIIC without

polycarbonate pilot lights.

‘= from -60°C up to 100°C: all versions of empty enclosures (types EJB-O1 and AQS-1 excluded) for group

IIB andi group TIIC with or without glass windows sealed on the cover and without control-signal operators,

‘* Maximum service temperature of the empty enclosures:

* +100°C forall versions of empty enclosures.

‘+ +150°C for empty enclosures of group II and I, without control-signal operators and windows.

+ The service temperature range of the components instalied into the enclosures shall be taking into account.

«The minimum distanco between flameproof flanged joint of the enclosure and extemal obstacle should be:

© 20mm for IBB execution,

+ 30:mm for IIB1HL execution,

+ According to EN 60079-1 annex D, the content of the Foc component enclosure equipment may be placed in

any arrangement, provided that:

‘+ for group Ian area of at least 20% of each cross-sectional area remains frees

‘+ for groups IIB and IIB+H; an area of atleast 40% of each cross-sectional area remains fee,

“Tis certifcate may only be reproduced in its entirely and without any change, scheclue included.

Page 3/4

CESI

013)

Schedule

(14) SUPPLEMENTARY EU-TYPE EXAMINATION CERTIFICATE 1, CEST 00 ATEX 036 U /07

[18] Essential Health and Safety Requirements

‘Compliance with the Essential Health and Safety Requirements has been assured by compliance to the following

standards:

EN 60079.

EN 60079.

!: 2012 + ALL:2013 — Explosive atmospheres — Part 0: Equipment - General requirements;

|:2014 Explosive atmospheres — Part 1: Equipment protection by flameproof enclosure “¢";

EN 60079-31: 2014 Explosive atmospheres — Part 31: Equipment dust ignition protection by enclosure “t”.

[19] Descriptive documents (prot. EX-B6023470).

- Technical note A4-6356 (pg. 8) rev.0. dated 2016.06.16

+ Safety, maintenance and mounting instructions F-276A (pg. 9) rev.d dated 2016.06.16

~ Attestation of Conformity Facsimile no. 0018 (pg. 1) dated 2016.06.16

- Drawing no. A3-6355 (3 sheets) rev. dated 2015.04.16

- Drawing no. A3-3604 (2 sheets) rev.l dated 2015.04.16

- Drawing no. A3-5025 (4 sheets) rey2 dated 2015.04.16

= Drawing no. A1-4232 (1 sheet) rey.6 dated 2015.04.16

~ Drawing no. A1-4097 (1 sheet) rev dated 2015.04.16

- Drawing no, A3-5044 (3 sheets) rev. dated 2015.04.16

- Drawing no, A2-4137 (2 sheets) rev4 dated 2015.06.01

- Drawing no. A3-5028 (2 sheets) rev.l dated 2015.04.16

~ Drawing no. A1-4098 (1 sheet) rev4 dated 2015.04.16

~ Drawing no. A1-4094 (1 sheet) rev dated 2015.04.16

= Drawing no. A4-4129 (2 sheets) rov.2 dated 2013.01.25

- Drawing no. A1-4096 (1 sheet) rev3 dated 2015.04.16

= Drawing no, A1-4095 (1 sheet) rev3 dated 2015.04.16

- Drawing no. A3-5916 (3 sheets) rov.l dated 2015.04.16

= Drawing no, A3-5422 (1 sheet) rev2 dated 2015.04.16

= Datasheet of materials (21 shocts) rev.0 dated 2015.04.16

‘One copy of all documents is kept in CEST files.

Centficate histor

Issue ar Issue Date ‘Summary description of variation

7 2016.09.26 | Updating to Aandarde EN 60079-0; 2012 + AII-2013, ENGDO7.1:2014 and ENGOOTS

31:2014, New minimum ambient temperature ~60°C, Upgrade to EIB design (new 2015

series) and ESBX series. Now enclosures type EJBX.0} and FBT... series were added.

06 7012.03.16 | Updating to standards EN60079-0:2009, ENGOO79-1:2007 and EN60079-31:2009. New

Size EJB-S5B was added, updating to EJB-S5 and EJB-SSC codes.

05 20090723 | Updating to standard EN 60079-1: 2007, positioning of O-ring on the cover, new sizes

type FJB-7 and EJB-73 were added, new min. ambient temperature ranges for group I.

m7 DOOT.AL19 | Ureating to standards EN60079-0:2006, ENG0O79-1:2004, ENOI241-0:2006 and

ENGL241-1:2008, New models of box type EIB.. and EJBX.., new exee. IIB+H and I M2,

Now service and ambient temperature ranges. ee

@ 2003.10.08 | Use of recangular glass windows with major dimensions.

a2 "2003.02.26 | New degre> of proteation IPGS or IPG6/67. New category NRGD for gases and dusts and

use of rectangular glass windows

a 2002.06.26 | New CCFE-01 and AQS.I type were added,

io 2000.07.24 | First Issue ofthe Certificate,

“This certificate may only be reproduced in its entirety and without any change, schedule included.

Page 4/4

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Cesi 03 Atex 015 IngDocument6 pagesCesi 03 Atex 015 IngYupi SetiawanNo ratings yet

- Ejb Ejbx DNV 16.0099uDocument5 pagesEjb Ejbx DNV 16.0099uYupi SetiawanNo ratings yet

- Ejb DNV 14.0140Document5 pagesEjb DNV 14.0140Yupi SetiawanNo ratings yet

- Cesi 01 Atex 026 IngDocument15 pagesCesi 01 Atex 026 IngYupi SetiawanNo ratings yet

- Cesi 02 Atex 073x IngDocument7 pagesCesi 02 Atex 073x IngYupi SetiawanNo ratings yet

- Cesi 01 Atex 027x IngDocument8 pagesCesi 01 Atex 027x IngYupi SetiawanNo ratings yet

- Psu and Diode QuintDocument6 pagesPsu and Diode QuintYupi SetiawanNo ratings yet

- Small Volume Prover Data Sheet FMD 045 1.7!09!21Document2 pagesSmall Volume Prover Data Sheet FMD 045 1.7!09!21Yupi SetiawanNo ratings yet

- Ba Fat BrodieDocument2 pagesBa Fat BrodieYupi SetiawanNo ratings yet