Professional Documents

Culture Documents

Geh - Ows

Geh - Ows

Uploaded by

Mohammed KaleemOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Geh - Ows

Geh - Ows

Uploaded by

Mohammed KaleemCopyright:

Available Formats

Oily Water Separator General Engineering Knowledge

________________________________________________________________________________

Lesson Overview

Lesson covers on oily water separator, the constructional details and the operation.

Key Words

Oily water separator.

0bjectives

2.1 Definition of a oily water separator.

2.2 The construction of the oily water separator.

2.3 The operation of the oily water separator.

2.4 The associated equipment.

2.4 The pollution control - MARPOL.

2.5 Procedures to overhaul and inspect the oily water separator.

Ref: Jackson and Morton, 1978, General Engineering Knowledge of'

Marine Engineers, Vol 8, Thomas Reed, London.

Taiko Oily Water Separator

GEH March 2006 1 Singapore Maritime Academy

Oily Water Separator General Engineering Knowledge

________________________________________________________________________________

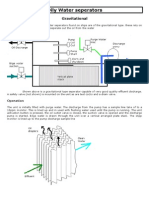

1 Oily Water Separators

Oily water separators are used to ensure that vessels do not discharge oil when pumping out bilges, oil

tanks or any oil-contaminated space.

International legislation relating to oil pollution is becoming more and more stringent in the limits set for

oil discharge. Clean water suitable for discharge is defined as that containing less than 15 parts per

million of oil. Oil/water separators using the gravity system can only achieve 100 parts per million and

must therefore be used in conjunction with some form of filter.

2 Construction

Please see the drawing for details.

Please note that all the internal surfaces are coated with tar epoxy.

GEH March 2006 2 Singapore Maritime Academy

Oily Water Separator General Engineering Knowledge

________________________________________________________________________________

GEH March 2006 3 Singapore Maritime Academy

Oily Water Separator General Engineering Knowledge

________________________________________________________________________________

To Alarm

Electrical Source

Light W. L.

Bilge Alarm

To Bilge

Control Air

Pure Water

Source

Strainer Bilge

Pump

Oily Water Separator

Three Way Valve

From From From

Bilge Bilge Sea

Tank Well Chest

To Bilge To Waste Oil Tank

To Bilge Tank

GEH March 2006 4 Singapore Maritime Academy

Oily Water Separator General Engineering Knowledge

________________________________________________________________________________

Operation

Preparation for running

1. Change over the bilge pump suction to seawater, and, open all valves in the pipeline from the bilge

pump to the overboard valve, through the oily water separator. Shut the valves or cocks for the oil

drain pipe of the OWS and the drain pipe in the bilge line.

2. Start the bilge pump and fill the OWS with seawater. Vent all the chambers.

Operation

1. Energize the automatic oil drain system in the OWS to start the operation.

2. Switch on the oil monitor.

3. Open all stop valves on the bilge drain pipe line and start the bilge pump.

4. If the OWS has been stopped for a long time, the oil content, suspended maters, deposits or

bacteria might be decomposed, and as a result, the oil concentration of treated water when drained

could be unusually high at the initial stage of the operation. Therefore to restart, pump the seawater

through the OWS for 5 to 10 minutes.

5. The OWS utilizes the differences of specific gravity between seawater and oil. Therefore, when

bilge is supplied to the OWS, it must have been filled with seawater. If the bilge is supplied with the

OWS being empty, no separation will take effect.

6. For concentrated oil in the bilge tank, do not pass through the OWS but pump directly into the bilge

tank.

Stopping

1. After stopping the operation of the OWS, flushed the OWS with seawater for about 10 minutes, so

that the oil residues will be washed away instead of decomposing in the system.

Stop the bilge pump and shut the stop valve.

2. After flushing, isolate all the valves and open the oil drain valve and drain as much as possible the

remaining oil in the system. Switch off the automatic drain valve system.

3. Switch off the oil monitoring console.

Maintenance

1. Clean the strainer.

2. Check the bilge pump for any abnormalities.

3. Check all pressure gauges readings.

4. Check the oil content monitoring control panel.

5. Check the sample of the treated water from the oil content monitor.

Maintenance of the Coalescers

When the coalescers have reached its life span, replace them.

1. If the oil content of the treated water exceeds the specific value, or the increase in pressure loss is

more than 0.2 kgf/cmf, the coalescers are to be replaced.

2. Before replacement, remove the old coalescers, clean the internal.

3. Replace the new coalscers carefully.

Disassembly

1. Prior to disassembly, discharge the remaining bilges in the OWS.

2. Open and clean the inside. Repaint the damaged area with tar epoxy.

3. Use diesel or gasoline to clean the 2nd and 3rd chambers.

4. Renew the coalescers.

5. After assembly, fill the OWS with seawater to check for leakages.

GEH March 2006 5 Singapore Maritime Academy

You might also like

- Filling Up Hermetically Sealed TransformerDocument7 pagesFilling Up Hermetically Sealed TransformerDist Tx100% (3)

- Practical Guide To SAP Material LedgerDocument224 pagesPractical Guide To SAP Material LedgerMaurilio100% (5)

- Hyundai 35-40-45DS 50da-7e PDFDocument1,042 pagesHyundai 35-40-45DS 50da-7e PDFMichał LicznerskiNo ratings yet

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- Golf R: Model Year 2020 SpecificationsDocument3 pagesGolf R: Model Year 2020 SpecificationsDark CenobiteNo ratings yet

- Produced Water TreatmentDocument53 pagesProduced Water TreatmentMahathir Che Ap83% (6)

- Basic Tank Battery DesignDocument14 pagesBasic Tank Battery Designgermangsilva100% (2)

- Subscriber MGMT Access NetworkDocument734 pagesSubscriber MGMT Access NetworkNelsonbohrNo ratings yet

- Separator (Grs-10eb 100eb) Manual (Rev4)Document16 pagesSeparator (Grs-10eb 100eb) Manual (Rev4)voinea ionut75% (4)

- Owspresentation 2021Document18 pagesOwspresentation 2021arunNo ratings yet

- Marpower Week 13 To 16Document11 pagesMarpower Week 13 To 16Haeisy SimsuangcoNo ratings yet

- MM-18 - Bilge Separator - OPERATION MANUALDocument24 pagesMM-18 - Bilge Separator - OPERATION MANUALKyaw Swar Latt100% (2)

- 3 Quarterly Presentation: Presented by MentorDocument33 pages3 Quarterly Presentation: Presented by MentorRishiNo ratings yet

- Faculty of Engineering Petroleum Engineering Department Third Stage Drilling Engineering LabDocument9 pagesFaculty of Engineering Petroleum Engineering Department Third Stage Drilling Engineering LabAkar muhammadNo ratings yet

- CBTR Unit 1 Unit 2Document51 pagesCBTR Unit 1 Unit 2Vandio DE TorresNo ratings yet

- 06 - Ows & SweageDocument5 pages06 - Ows & SweageAisha Zaheer100% (1)

- 'Oy' JptotDocument4 pages'Oy' JptotJEHAN ROSE DIMPLE ALINo ratings yet

- 10 Oily Water Separator (OWS) Maintenance Tips Every Ship Engineer Must Kn222248Document10 pages10 Oily Water Separator (OWS) Maintenance Tips Every Ship Engineer Must Kn222248Bagas Abhimanyu100% (1)

- Khaksar KhanDocument36 pagesKhaksar KhanAlsamad Borkar100% (1)

- Optimal Processing Parameters of Electrostatic Crude Oil DesaltingDocument7 pagesOptimal Processing Parameters of Electrostatic Crude Oil DesaltingElbahi DjaalabNo ratings yet

- EC Lab Manualprint123Document38 pagesEC Lab Manualprint123Logic ManjuNo ratings yet

- Oily Water SeperatorDocument31 pagesOily Water SeperatorSandeep Malakar100% (1)

- Imai Ek General Q ADocument88 pagesImai Ek General Q APranjyoti SaikiaNo ratings yet

- Oily Water Separator, DifferentDocument6 pagesOily Water Separator, DifferentSaurabh Saw100% (2)

- Chennai Oral With AnsDocument43 pagesChennai Oral With AnsSahil Mishra100% (5)

- Topic 2 Introduction To OWS and Bilge Water System ContentDocument24 pagesTopic 2 Introduction To OWS and Bilge Water System Contentmorena777No ratings yet

- 7.15 NYK Engine Cadet Course Handouts (OWS)Document6 pages7.15 NYK Engine Cadet Course Handouts (OWS)TowfiqNo ratings yet

- US Army AED Design Requirements - Oil-Water Separator - Mar - 09Document8 pagesUS Army AED Design Requirements - Oil-Water Separator - Mar - 09decio ventura rodrigues miraNo ratings yet

- Week 2-Oilwater Separators Working PrinciplesDocument12 pagesWeek 2-Oilwater Separators Working PrinciplesCriswin Malazarte100% (1)

- Oily Water SeparatorDocument5 pagesOily Water SeparatorFe Capricho100% (2)

- Alfa Laval MAB 340PD18en - MABDocument2 pagesAlfa Laval MAB 340PD18en - MABSundarNo ratings yet

- Ek GeneralDocument24 pagesEk GeneralPRASHANT SAWANTNo ratings yet

- Polimeric LawDocument5 pagesPolimeric LawFranklin Ivan Archer MartinezNo ratings yet

- Vert Oil StorageDocument12 pagesVert Oil StorageIkhy TakaendenganNo ratings yet

- Centrifuge: Code: Brpp/Turbine/008/CentrifugeDocument3 pagesCentrifuge: Code: Brpp/Turbine/008/CentrifugePrakash ChoudharyNo ratings yet

- Lub OIl Flushing Procedure PDFDocument44 pagesLub OIl Flushing Procedure PDFSubrahmanyam100% (1)

- Oil Water Sep Design ArmyDocument9 pagesOil Water Sep Design ArmyJose A. Marti100% (1)

- Experiment 4-Oil Water SeparationDocument10 pagesExperiment 4-Oil Water SeparationFaris Hamir67% (3)

- Ek GeneralDocument24 pagesEk GeneralCadet ABDUL REHMANNo ratings yet

- Oily Water SeparatorDocument12 pagesOily Water SeparatorAvriane Dela CruzNo ratings yet

- CairnDocument5 pagesCairnsamcat2009No ratings yet

- EW OfflineDocument289 pagesEW OfflineBillyjeTadlasNo ratings yet

- Qdoc - Tips - Class-4 EoowDocument74 pagesQdoc - Tips - Class-4 EoowShamsad alamNo ratings yet

- Operation of Fresh Water GeneratorDocument3 pagesOperation of Fresh Water GeneratoralexdenychenkoNo ratings yet

- Oily Water SeparatorDocument24 pagesOily Water Separatormodisunami100% (1)

- Oily - Water - Separator FINALDocument13 pagesOily - Water - Separator FINALprashantwagh207No ratings yet

- Lesson 5. Blow Down ProcedureDocument3 pagesLesson 5. Blow Down ProcedureАртем БабенкоNo ratings yet

- HFM 15ppm Bilge Separator - Operation ManualDocument24 pagesHFM 15ppm Bilge Separator - Operation ManualÖzgürMetin100% (5)

- Redwood ViscometerDocument3 pagesRedwood Viscometerghambira85% (34)

- English CatalogDocument42 pagesEnglish CatalogKim Myoung EunNo ratings yet

- PURIFIERSDocument7 pagesPURIFIERSjames dogelioNo ratings yet

- Oily Water SeperatorsDocument2 pagesOily Water SeperatorsJitendra KumarNo ratings yet

- Oily Water SeperatorDocument18 pagesOily Water SeperatorNiksa Kusijanovic100% (1)

- Auxiliary Machinery 1: Assignment Reseach inDocument6 pagesAuxiliary Machinery 1: Assignment Reseach inFernando CruzNo ratings yet

- HFM 15ppm Bilge Separator Operation ManualDocument24 pagesHFM 15ppm Bilge Separator Operation ManualNguyen Phuoc HoNo ratings yet

- Say Bolt ViscometerDocument3 pagesSay Bolt Viscometerghambira75% (4)

- Descripción Del Equipamiento para SLOP OILDocument25 pagesDescripción Del Equipamiento para SLOP OILLilianaNo ratings yet

- Oil Movement Notes 1Document42 pagesOil Movement Notes 1shaz100% (1)

- Naval Mechanical Engineering: Gas Turbine Propulsion, Auxiliary, and Engineering Support SystemsFrom EverandNaval Mechanical Engineering: Gas Turbine Propulsion, Auxiliary, and Engineering Support SystemsNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Oil Spill Remediation: Colloid Chemistry-Based Principles and SolutionsFrom EverandOil Spill Remediation: Colloid Chemistry-Based Principles and SolutionsNo ratings yet

- E23Sep15 The Story of Prophet Yusuf AS Lessons in Managing Wealthv2Document6 pagesE23Sep15 The Story of Prophet Yusuf AS Lessons in Managing Wealthv2Mohammed KaleemNo ratings yet

- E23Oct13 Following in The Footsteps of The Prophet Safeguarding Prosperity and Peace11Document8 pagesE23Oct13 Following in The Footsteps of The Prophet Safeguarding Prosperity and Peace11Mohammed KaleemNo ratings yet

- GEH-Steering Gear. UpdateDocument40 pagesGEH-Steering Gear. UpdateMohammed KaleemNo ratings yet

- MEO COC Exam Schedule For 2022 Rev 1Document1 pageMEO COC Exam Schedule For 2022 Rev 1Mohammed KaleemNo ratings yet

- Touchless Touch Screen TechnologyDocument23 pagesTouchless Touch Screen TechnologyIndupriya KatariNo ratings yet

- Brochure Flowlink 5.1Document8 pagesBrochure Flowlink 5.1JulioNo ratings yet

- DrumIt Five User Manual OS 1.30 PDFDocument6 pagesDrumIt Five User Manual OS 1.30 PDFRolando Sepúlveda GonzálezNo ratings yet

- BRKDCN-2712 (䵩捲潳潦璮⁐潷敲偯楮璮′〱㤻潤楦楥搠畳楮朠楔數琠㈮ㄮ㜠批‱吳塔 - Microsoft® PowerPoint® 2019)Document94 pagesBRKDCN-2712 (䵩捲潳潦璮⁐潷敲偯楮璮′〱㤻潤楦楥搠畳楮朠楔數琠㈮ㄮ㜠批‱吳塔 - Microsoft® PowerPoint® 2019)faisal juwailesNo ratings yet

- CSE101-Lec#1: Computer OrganizationDocument33 pagesCSE101-Lec#1: Computer OrganizationGarima Kumar SinghNo ratings yet

- A Project Report On Free Space Optical Link: Submitted By, Nikunj GabaniDocument13 pagesA Project Report On Free Space Optical Link: Submitted By, Nikunj GabaniNikunj GabaniNo ratings yet

- A Review of Current Micro Drilling ProcessesDocument5 pagesA Review of Current Micro Drilling ProcessesDr-Asit Kumar ParidaNo ratings yet

- 1 - Basics of CBs For Khandala SMDocument17 pages1 - Basics of CBs For Khandala SMnageswara_mutyalaNo ratings yet

- UnSupervised LearningDocument40 pagesUnSupervised LearningPandu KNo ratings yet

- Simple / Hardwired / Logic Controller / Zelio: System User GuideDocument64 pagesSimple / Hardwired / Logic Controller / Zelio: System User GuideJimi DbonoNo ratings yet

- C++ Programming From Problem Analysis To Program Design (5th Edition) BookDocument17 pagesC++ Programming From Problem Analysis To Program Design (5th Edition) BookEndalkachew EmareNo ratings yet

- FCS12000CHDocument15 pagesFCS12000CHGöran RosbyNo ratings yet

- Heater & Air Conditioning Control System: SectionDocument164 pagesHeater & Air Conditioning Control System: SectionPablo CoronelNo ratings yet

- Introduction To Supply Chain Management: Dr. Rachna Gangwar TAPMI School of Business, JaipurDocument85 pagesIntroduction To Supply Chain Management: Dr. Rachna Gangwar TAPMI School of Business, JaipurAarav SinghNo ratings yet

- BST and Its SolutionsDocument12 pagesBST and Its SolutionsLovish MiglaniNo ratings yet

- Service Manual - HVAC (HEATING, VENTILATION, AND AIR CONDITIONING)Document40 pagesService Manual - HVAC (HEATING, VENTILATION, AND AIR CONDITIONING)Jairo Morales100% (1)

- B7S Troubleshootings 10534 PDFDocument22 pagesB7S Troubleshootings 10534 PDFGábor Kovács0% (1)

- Samsung LE32B550+Document479 pagesSamsung LE32B550+BElectric75% (8)

- 1762 Ob8 PDFDocument16 pages1762 Ob8 PDFRodríguez EdwardNo ratings yet

- Maxwell Brochure PDFDocument2 pagesMaxwell Brochure PDFERNESTONo ratings yet

- Introduction To Direct Drive - BrochureDocument10 pagesIntroduction To Direct Drive - BrochureCentrifugal SeparatorNo ratings yet

- Internet Security Solved MCQs (Set-1)Document6 pagesInternet Security Solved MCQs (Set-1)AnkitNo ratings yet

- VAG Pressure Management ChecklistDocument3 pagesVAG Pressure Management ChecklistColleen MurphyNo ratings yet

- NMSA App BriefDocument8 pagesNMSA App BriefAdhiraj GautamNo ratings yet

- BS en 62114 2001Document12 pagesBS en 62114 2001LECTORNo ratings yet

- Relevance of ICT To AccountancyDocument1 pageRelevance of ICT To AccountancyCreamo HolicNo ratings yet