Professional Documents

Culture Documents

Mse g521 World Class Manufacturing

Mse g521 World Class Manufacturing

Uploaded by

lokesh prakashOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mse g521 World Class Manufacturing

Mse g521 World Class Manufacturing

Uploaded by

lokesh prakashCopyright:

Available Formats

BIRLA INSTITUTE OF TECHNOLOGY AND SCIENCE, Pilani

Pilani Campus

First Semester 2017-2018

Instruction Division

Course Handout (Part II)

Date: 02/08/2017

In addition to Part I (General Handout for all courses appended to the Time Table), this portion

gives further specific details regarding the course.

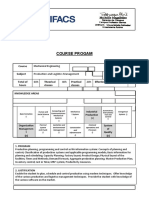

Course No. : MSE G521

Course Title : WORLD CLASS MANUFACTURING

Instructor In-charge : ABHIJEET K. DIGALWAR

1. Course Description

The world-class manufacturing challenge, Developing world-class manufacturing strategy, Lean, Green

and Agile manufacturing strategy, Total quality management, Total employee involvement, Total

productive maintenance, Decision making methods, World-class information systems, Knowledge

management, Managing the change, Monitoring the world-class performance.

2. Scope and Objectives

To promote a good foundation in World-class Manufacturing,

To explain the various concepts and philosophies in more detail for design of strategies

for World-class Manufacturing,

To develop familiarity with different decision making tools for evaluation and selection

of best practices for world class manufacturing.

To develop skills for implementation of World-class Manufacturing concepts and

philosophies

3. Prescribed Text Book

T1. Jim Todd, “World-class Manufacturing”, McGraw Hill, London, 1995

T2. Nicholas, John M., “Competitive Manufacturing Management”, Tata McGraw Hill Education Pvt.

Ltd. New Delhi, 2012.

T3. Sahay, B.S., Saxena, K.B.C. and Kumar, A., World-class Manufacturing- A Strategic Perspective,

Macmillan India Limited, New Delhi, 2005.

T4. Research papers published in WCM domain.

Please Consider Your Environmental Responsibilities

Do Not Print Unless Necessary

BIRLA INSTITUTE OF TECHNOLOGY AND SCIENCE, Pilani

Pilani Campus

4. Reference Books

R1. Voss C.A., "Manufacturing Strategy: Process and Content", Chapman & Hall, London, 1992.

R2. Besterfield D. H., et al., "Total Quality Management", Pearson Education, 1999.

R3. Nakajima, S., “Introduction to Total Productive Maintenance”, Productivity Press, 1988.

R4. Pascal, D., “Lean production simplified”, 2nd Edition, Productivity Press, 2007

5. Course Plan

Module Number Lecture session/Tutorial Session. Reference Learning Outcome

1. Introduction to World L1.1.Introduction to WCM, Evolution T1, T2 and To understand the

Class Manufacturing of manufacturing T4 importance of world

(WCM). class manufacturing

L 1.2. Craft production to mass T1, T2 and and how the

production, tools and techniques, T4. evolution of

strategies manufacturing taken

place

L1.3. Mass production to Lean T1, T2 and

production to digital manufacturing, T4

tools, techniques and strategies

2. Introduction to basic L2.1 Tools and Techniques (Planning T1, T2 and To understand the

WCM tools and techniques and Design) T4 various tools and

techniques available

L2.2.Tools and Techniques T1, T2 and for WCM practices

(Manufacturing and Distribution) T4

L2.3 Cases discussion T4

3. Manufacturing Strategy. L3.1 Operations strategy, strategic R1 To understand

approaches to manufacturing, various

manufacturing

L3.2 Benchmarking processes T4 and R2 strategies and to to

learn how to

L3.3 Process of manufacturing strategy R1

formulate and

formulation and implementation

implement the

L3.4 Case studies T4 strategy

4. Decision making tools L4.1 Introduction to decision making T4 Understanding the

,techniques and tools, MCDM, MADM and MODM various decision

methodologies making tools,

L4.2. AHP, TOPSIS, ISM, VIKOR, T4 techniques and

ELECTRE etc. methodologies and

Please Consider Your Environmental Responsibilities

Do Not Print Unless Necessary

BIRLA INSTITUTE OF TECHNOLOGY AND SCIENCE, Pilani

Pilani Campus

L4.3 Fuzzy Set of Theory, Integrated T4 their applications

and Hybrid Approaches

L4.5 TOC, Six Sigma, QFD, DoE etc. T4

5. Total Quality L5.1. Introduction, Quality evolution, R2 and T4 To understand the

Management tools and techniques, importance and

applications of TQM

L5.2. principles and processes of TQM R2 and T4 for WCM practices.

formulation and implementation

L 5.3 TQM Frameworks R2 and T4

T5.4 Case studies T4

6. Lean Manufacturing L6.1. Introduction to lean, 5S, wastes R4 and T4 To understand the

identifications and elimination importance and

techniques applications of LM

for WCM practices.

L6.2. Jidoka, Kanban, mistake proofing, R4 and T4

Kaizen, Hoshin planning, Line

balancing etc.

L 6.3 Value engineering and analysis, R4 and T4

value stream mapping

L6.4 Lean manufacturing T4

implementation frameworks

L6.5 Case studies R4 and T4

7. Total Productive L7.1. Introduction to various R3 and T4 To understand the

Maintenance maintenance system, overview of TPM, importance and

applications of TPM

L7.2 Pillars, Reliability, maintainability, R3 and T4 for WCM practices.

MTBF, MTTR, OEE,

L 7.3 TPM implementation frameworks R3 and T4

L 7.4 Case studies T4

8. Other Issues of WCM L8.1 Overview of sustainability aspects T4 To understand the

Please Consider Your Environmental Responsibilities

Do Not Print Unless Necessary

BIRLA INSTITUTE OF TECHNOLOGY AND SCIENCE, Pilani

Pilani Campus

L8.2. Overview of Green Manufacturing T4 advances and recent

and circular economy developments in the

manufacturing

L8.3 Overview of sustainable supply T4 organizations

chain

9. Corporate Social L 9.1 Role of CSR in WCM T4 To understand CSR

Responsibility importance and need

10 Industry 4.0 L10.1 Industry 4.0 and readiness of T4 To understand

Indian manufacturing industries Industry 4.0 and

readiness of Indian

manufacturing

industries

11. Standards, L 11.1 ISO standards T4 To understand the

Certifications and various standards,

Performance Measurement L11.2 MBNAQA, Deming, Golden T4 awards, certifications

Systems Peacock National Quality Award, and PMS and their

Business Excellence Award, other best importance for WCM

practices awards and criteria for awards

and certifications

L11.3 Overview of performance T 4

measurement systems

L11.4 Comparison of various PMS for T4

WCM

L11.5 Development and validation of T4

PM for WCM

6. Evaluation Scheme:

Evaluation Weightage

Date & Time Remarks

Component (Marks)

Mid-Sem. 30% (30) 14/10 11:00 - 12:30 PM Closed Book

13/12 AN Closed Book/Open

Comprehensive 40% (40)

Book

Project, Assignments, Class To be announced in the

30 % (30) Open Book

tests/presentations class

Please Consider Your Environmental Responsibilities

Do Not Print Unless Necessary

BIRLA INSTITUTE OF TECHNOLOGY AND SCIENCE, Pilani

Pilani Campus

After completing this course the students will be able to

1) Understand the fundamental concepts, strategies, principles and philosophy for world

class manufacturing

2) Select appropriate manufacturing strategy in terms of required situations

3) Able to use different decision making tools.

4) Able to identify and validate the performance measurements for world class

manufacturing.

Closed Book Test: No reference material of any kind will be permitted inside the exam hall.

Open Book Exam: Use of any printed / written reference material (books and notebooks) will

be permitted inside the exam hall. Loose sheets of paper will not be permitted. Computers of any

kind will not be allowed inside the exam hall. Use of calculators will be allowed in all exams. No

exchange of any material will be allowed.

Note:

It shall be the responsibility of the individual student to be regular in maintaining the self study

schedule as given in the course handout, attend lectures as per the schedule announced in

Nalanda. Mid Semester Test and Comprehensive Examination are according to the Evaluation

Scheme given in the respective Course Handout. If the student is unable to appear for the

Regular Test/Examination due to genuine exigencies, the student must refer to the procedure for

applying for Make-up Test/Examination. No make up for the class tests/presentations.

(Abhijeet K. Digalwar)

Instructor In charge

MSE G521.

Please Consider Your Environmental Responsibilities

Do Not Print Unless Necessary

You might also like

- Fred D. Davis, Andrina Granić - The Technology Acceptance Model - 30 Years of TAM (Human-Computer Interaction Series) - Springer (2024)Document125 pagesFred D. Davis, Andrina Granić - The Technology Acceptance Model - 30 Years of TAM (Human-Computer Interaction Series) - Springer (2024)2010631020088No ratings yet

- SBSA Statement 2024-02-17 3monthsDocument13 pagesSBSA Statement 2024-02-17 3monthsadonisthasneenNo ratings yet

- Project Selection, Approval and Activation E. AgtarapDocument29 pagesProject Selection, Approval and Activation E. AgtarapEvangeline Chua Agtarap67% (3)

- Soap Maling GhanaDocument38 pagesSoap Maling GhanaAlan Winston SedzeNo ratings yet

- Pilani Campus: Birla Institute of Technology and Science, Pilani AUGS/ AGSR DivisionDocument3 pagesPilani Campus: Birla Institute of Technology and Science, Pilani AUGS/ AGSR DivisionHIMANSHU JAINNo ratings yet

- Handbook of Lecture and Response - or 2022Document177 pagesHandbook of Lecture and Response - or 2022Raihan Rivellino AdzaniNo ratings yet

- MF f418 Lean Manufacturing1Document4 pagesMF f418 Lean Manufacturing1Stephen Wilson E.No ratings yet

- TEDocument9 pagesTEkeshavuvceNo ratings yet

- Management: To Provide Theoretical Insights and Practical Tools Within The Area of ManagementDocument5 pagesManagement: To Provide Theoretical Insights and Practical Tools Within The Area of ManagementSAFAL R CH19-23No ratings yet

- CS 413 SE First Semester HandoutDocument3 pagesCS 413 SE First Semester Handoutmeghana minnuNo ratings yet

- Pilani Campus: Birla Institute of Technology and Science, Pilani AUGS/ AGSR DivisionDocument3 pagesPilani Campus: Birla Institute of Technology and Science, Pilani AUGS/ AGSR DivisionSIDDHARTH JAINNo ratings yet

- Ae Zg531 Course HandoutDocument9 pagesAe Zg531 Course HandoutAbhigyan KashyapNo ratings yet

- DE ZG541 HandoutDocument10 pagesDE ZG541 Handoutkiranada15No ratings yet

- Economics of Business Environment-Suniti NagpurkarDocument4 pagesEconomics of Business Environment-Suniti NagpurkarRiya ChaturvediNo ratings yet

- Course Plan - DTT - Dr. Madhubala RajagopalDocument22 pagesCourse Plan - DTT - Dr. Madhubala RajagopalJOEMON RANJAN 2027461No ratings yet

- MF F418 Lean Manufacturing - AKGuptaDocument3 pagesMF F418 Lean Manufacturing - AKGuptaSAMARTH patilNo ratings yet

- AM ME725 SyllabusDocument3 pagesAM ME725 SyllabusNishant MayekarNo ratings yet

- Engineering Management MS-401Document4 pagesEngineering Management MS-401Anonymous oItSEpsNo ratings yet

- Hindusthan College of Engineering and Technology: (An Autonomous Institution, Affiliated To Anna University, Chennai)Document12 pagesHindusthan College of Engineering and Technology: (An Autonomous Institution, Affiliated To Anna University, Chennai)kiranNo ratings yet

- MOBILE COMPUTING - Academic Plan (2020-21)Document17 pagesMOBILE COMPUTING - Academic Plan (2020-21)Srinivas KanakalaNo ratings yet

- KIX2004 - EPMWeek1 - HHDocument79 pagesKIX2004 - EPMWeek1 - HHJia Hui JoanaNo ratings yet

- A Study of Additive Manufacturing Technology's Development and Impact Through The Multi-Level Perspective Framework and The Case of AdidasDocument50 pagesA Study of Additive Manufacturing Technology's Development and Impact Through The Multi-Level Perspective Framework and The Case of AdidasWesley SupervilleNo ratings yet

- A Research Agenda For Embedding 4IRDocument6 pagesA Research Agenda For Embedding 4IRMuhammad Shehr YarNo ratings yet

- From Taylor To ToyotaDocument13 pagesFrom Taylor To ToyotashubhamNo ratings yet

- Textile Technology - IVDocument11 pagesTextile Technology - IVRākēśḥ ŚḥāNo ratings yet

- Marketing in The World of Hi-Tech & Innovation (MWHTI) : Prakash BagriDocument13 pagesMarketing in The World of Hi-Tech & Innovation (MWHTI) : Prakash BagriAkshayNo ratings yet

- IV Year Vii Sem Cs6704 Resource Management TechniquesDocument67 pagesIV Year Vii Sem Cs6704 Resource Management TechniquesMithran SNo ratings yet

- ManagementDocument5 pagesManagementJulie MaxNo ratings yet

- DesignDocument45 pagesDesignedris farahNo ratings yet

- Course No.: CS F469 Course Title: Information Retrieval Instructor-In-Charge: POONAM GOYAL (Document4 pagesCourse No.: CS F469 Course Title: Information Retrieval Instructor-In-Charge: POONAM GOYAL (likhitgatagatNo ratings yet

- 2018 Syllabus 8th SEMDocument40 pages2018 Syllabus 8th SEM18ME045No ratings yet

- Studying The Requirements of (TPM) Total Productive Maintenance in Production SystemDocument119 pagesStudying The Requirements of (TPM) Total Productive Maintenance in Production SystemMarcos Javier Palomino CusiNo ratings yet

- 2nd Sem PDM SyllabusDocument11 pages2nd Sem PDM SyllabusVinay AlagundiNo ratings yet

- BS Lab ManualDocument59 pagesBS Lab Manualnajmuus786No ratings yet

- Uttarakhand Technical University Dehradun: Study and Evaluation Scheme (B.Tech. Iii Year)Document7 pagesUttarakhand Technical University Dehradun: Study and Evaluation Scheme (B.Tech. Iii Year)Ankit SharmaNo ratings yet

- Course Curriculum CourseDocument11 pagesCourse Curriculum CourseMayur PatelNo ratings yet

- Electrical Machines-IiDocument47 pagesElectrical Machines-IiSunilkumarNo ratings yet

- SMM Course HandoutDocument23 pagesSMM Course HandoutMohammed IsmailNo ratings yet

- Drive 123Document6 pagesDrive 123Karen AyeskaNo ratings yet

- Operational Research - Linear Programming Part IDocument55 pagesOperational Research - Linear Programming Part IIraguha FaustinNo ratings yet

- Time and Motion Syllabusfall2020 2021Document6 pagesTime and Motion Syllabusfall2020 2021Gfzz TfszNo ratings yet

- Cost Evaluation of RTMDocument118 pagesCost Evaluation of RTMAnonymous VRspXsmNo ratings yet

- Overcoming - The - Valley - of - Death - An Industrial Case Study of Barriers and ...Document77 pagesOvercoming - The - Valley - of - Death - An Industrial Case Study of Barriers and ...Paulo De Melo MacedoNo ratings yet

- 2.me 8462-Mt-II Lab ManualDocument48 pages2.me 8462-Mt-II Lab ManualMURALI KRISHNAN RNo ratings yet

- TBBT Syllabus Course Outline 2022-24Document5 pagesTBBT Syllabus Course Outline 2022-24Gaurav Varshney (PGDM 22-24)No ratings yet

- 18ME653 - Syllabus - CO - PODocument4 pages18ME653 - Syllabus - CO - PORameshkumarNo ratings yet

- PM Course OutlineDocument3 pagesPM Course OutlineAashir IqbalNo ratings yet

- ICT For Development Goals: Session 3-5Document37 pagesICT For Development Goals: Session 3-5Sudipto RajNo ratings yet

- Taylortotoyota-đã chuyển đổiDocument21 pagesTaylortotoyota-đã chuyển đổiTrần Thu HuyềnNo ratings yet

- Esd Cdf-A70440 PDFDocument7 pagesEsd Cdf-A70440 PDFramanjulunNo ratings yet

- Ashishjangid18ejcec026py 201231030536Document39 pagesAshishjangid18ejcec026py 201231030536soumya.mettagalNo ratings yet

- 00dissertation PDFDocument131 pages00dissertation PDFyune yunoNo ratings yet

- M.E (FT) 2021 Regulation-Cse SyllabusDocument88 pagesM.E (FT) 2021 Regulation-Cse SyllabusbsudheertecNo ratings yet

- 7 MF F473 - de G531Document2 pages7 MF F473 - de G531Aakash GoelNo ratings yet

- CS F342 - CA - Dr. Nikumani ChowdhuryDocument3 pagesCS F342 - CA - Dr. Nikumani ChowdhuryHarsh GuptaNo ratings yet

- Dkte SyllabusDocument52 pagesDkte SyllabusDhiraj TelvekarNo ratings yet

- Strategic Management and Business PolicyDocument10 pagesStrategic Management and Business Policysrinivas rao rayuduNo ratings yet

- Birla Institute of Technology and Science, Pilani Pilani Campus AUGS/AGSR DivisionDocument3 pagesBirla Institute of Technology and Science, Pilani Pilani Campus AUGS/AGSR DivisionStephen Wilson E.No ratings yet

- Anna University 2019Document140 pagesAnna University 2019Arun KarthickNo ratings yet

- Lesson Plan-Cs6701Document6 pagesLesson Plan-Cs6701Viswanath JayaramNo ratings yet

- Municipal Accounting 2Document26 pagesMunicipal Accounting 2Marius BuysNo ratings yet

- Process Analytical Technology: Spectroscopic Tools and Implementation Strategies for the Chemical and Pharmaceutical IndustriesFrom EverandProcess Analytical Technology: Spectroscopic Tools and Implementation Strategies for the Chemical and Pharmaceutical IndustriesKatherine A. BakeevNo ratings yet

- Tsion SisayDocument67 pagesTsion Sisaymubarek kemalNo ratings yet

- BANK RECONCILIATION NotesDocument9 pagesBANK RECONCILIATION NotesNicole DomingoNo ratings yet

- FACTURA Folio FiscalDocument1 pageFACTURA Folio FiscalKarnak ProducerNo ratings yet

- Accountant TPIA Analysis Muhammad Reza HandyansyahDocument4 pagesAccountant TPIA Analysis Muhammad Reza HandyansyahMuhammad Reza HandyansyahNo ratings yet

- Churn Analytics: What Is Customer Churn?Document5 pagesChurn Analytics: What Is Customer Churn?AkshatNo ratings yet

- Business English-FinalDocument37 pagesBusiness English-FinalLee's WorldNo ratings yet

- 2.0 How The Firms Report The Measuring and Managing Their Exchange Rate RisksDocument6 pages2.0 How The Firms Report The Measuring and Managing Their Exchange Rate Risksamirul asyrafNo ratings yet

- Madlena Korkeliia ResumeDocument2 pagesMadlena Korkeliia ResumeGosha DimitrovNo ratings yet

- Tax For Rental Income in The PhilippinesDocument3 pagesTax For Rental Income in The PhilippinesRESIE GALANGNo ratings yet

- FIN 370T WK 5 - Apply Homework HTTPS://WWW - Hwtutorial.com/category/fin-370Document57 pagesFIN 370T WK 5 - Apply Homework HTTPS://WWW - Hwtutorial.com/category/fin-370Donny JobNo ratings yet

- Legal Notice To Syndicate Bank-01 (Sai Sikshan Sanstha)Document5 pagesLegal Notice To Syndicate Bank-01 (Sai Sikshan Sanstha)hariomNo ratings yet

- CIX 2005 Entrepreneurship Essay Covid-19Document8 pagesCIX 2005 Entrepreneurship Essay Covid-19Tan WzzzNo ratings yet

- Vul QuestionnaireDocument14 pagesVul QuestionnaireKyla Bianca Cuenco TadeoNo ratings yet

- Real Estate Mortgage Know All Men by These PresentsDocument2 pagesReal Estate Mortgage Know All Men by These PresentsKatrine ManaoNo ratings yet

- Biffa 2023 Sustainability ReportDocument60 pagesBiffa 2023 Sustainability ReportpeachyceriNo ratings yet

- EconomicsDocument69 pagesEconomicsNikithaNo ratings yet

- Maila Rosario College: College of Business Administration Major in Financial ManagementDocument9 pagesMaila Rosario College: College of Business Administration Major in Financial ManagementEleine AlvarezNo ratings yet

- PHS For Philippine Coast Guard AuxillaryDocument7 pagesPHS For Philippine Coast Guard AuxillaryRj Hush EsguerraNo ratings yet

- Air Waybill: Original 3 (For Shipper)Document1 pageAir Waybill: Original 3 (For Shipper)Duy NguyễnNo ratings yet

- Aggregate Planning: OMII, Term III, Sessions 8-10 Harpreet KaurDocument44 pagesAggregate Planning: OMII, Term III, Sessions 8-10 Harpreet Kaurayushmehar22No ratings yet

- If Socialists Understood Economics They Woudn't Be SocialistsDocument3 pagesIf Socialists Understood Economics They Woudn't Be SocialistsLorenzo WangNo ratings yet

- Module 7Document28 pagesModule 7Tin ZamudioNo ratings yet

- Essay - Digital MarketingDocument9 pagesEssay - Digital MarketingSieng MenghongNo ratings yet

- Solution To Ch14 P13 Build A ModelDocument6 pagesSolution To Ch14 P13 Build A ModelALI HAIDERNo ratings yet

- Group 7 - SCM Assignment 2Document14 pagesGroup 7 - SCM Assignment 2Rahul DattaNo ratings yet

- Salvador P. Escaño and Mario M. Silos, Petitioners, vs. Rafael Ortigas, JR., Respondent. (G.R. No. 151953. June 29, 2007.)Document3 pagesSalvador P. Escaño and Mario M. Silos, Petitioners, vs. Rafael Ortigas, JR., Respondent. (G.R. No. 151953. June 29, 2007.)YPENo ratings yet

- WEO DataDocument14 pagesWEO DataPrypiat 0No ratings yet

- Ty Baf TaxationDocument4 pagesTy Baf TaxationAkki GalaNo ratings yet