Professional Documents

Culture Documents

Tabla de Eslingas

Tabla de Eslingas

Uploaded by

leo floresOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tabla de Eslingas

Tabla de Eslingas

Uploaded by

leo floresCopyright:

Available Formats

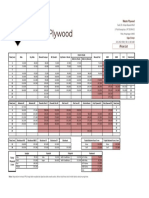

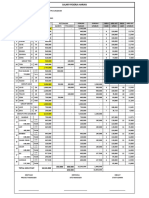

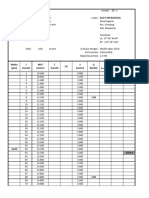

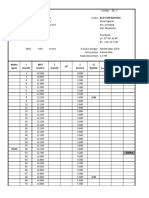

WIRE ROPE SLINGS

Wire Rope Slings, 6 x 19 or 6 x 36 Classification

Extra Improved Plow Steel (EIPS) 120/130, Independent Wire Rope Core (IWRC) Branch Locations

Working Load Limit (WLL) in pounds, 5:1 design factor

Single-Leg Two-Leg Bridle or Basket Choker Three-Leg Four-Leg Nova Scotia - Dartmouth (Head Office)

Hitch Type Vertical Choker Vertical

Basket

Vertical 60° 45° 30° 60° 30° Vertical 60° 45° 30° Vertical 60° 45° 30°

Newfoundland & Labrador - Mount

Pearl/Lab City/Wabush

New Brunswick - Moncton/Saint John

Rope Diameter

Inches S M MS MS MS MS MS MS MS MS MS MS MS MS MS MS MS MS

Quebec - Quebec City/Pointe-Claire/

1/4 1 360 1 300 960 2 600 2 600 2 200 1 820 1 300 1 640 960 3 800 3 400 2 800 1 940 5 200 4 400 3 600 2 600 Gaspe/Saguenay/Sept-Iles

5/16 2 200 2 000 1 480 4 000 4 000 3 400 2 800 2 000 2 600 1 480 6 000 5 200 4 200 3 000 8 000 7 000 5 600 4 000

3/8

7/16

3 000

4 000

2 800

3 800

2 200

2 800

5 600

7 600

5 800

7 800

5 000

6 800

4 000

5 400

2 800

3 800

3 600

5 000

2 200

2 800

8 600

11 600

7 400

10 000

6 000

8 200

4 400

5 800

11 400

15 600

10 000

13 400

8 200

11 000

5 800

7 800

Ontario - Mississauga/Sarnia

1/2 5 400 5 000 3 800 10 000 10 200 8 800 7 200 5 000 6 400 3 800 15 200 13 200 10 800 7 600 20 000 17 600 14 200 10 200

9/16 6 800 6 400 4 800 12 800 12 800 11 000 9 000 6 400 8 200 4 800 19 200 16 600 13 600 9 600 26 000 22 000 18 000 12 800 Alberta - Edmonton/Calgary

5/8 8 200 7 800 5 800 15 600 15 600 13 600 11 000 7 800 10 000 5 800 24 000 20 000 16 600 11 800 32 000 28 000 22 000 15 600

3/4 11 800 11 200 8 200 22 400 22 000 19 400 15 800 11 200 14 200 8 200 34 000 30 000 24 000 16 800 44 000 38 000 32 000 22 000

7/8 16 000 15 200 11 200 30 400 30 000 26 000 22 000 15 200 19 400 11 200 46 000 40 000 32 000 22 000 60 000 52 000 42 000 30 000

Toll Free: (877) 461-4876

1 20 000 19 600 14 400 39 200 40 000 34 000 28 000 19 600 26 000 14 400 58 000 52 000 42 000 30 000 78 000 68 000 56 000 40 000

1 1/8 26 000 24 000 18 200 48 000 48 000 42 000 34 000 24 000 32 000 18 200 72 000 62 000 52 000 36 000 96 000 84 000 68 000 48 000

1 1/4 32 000 30 000 22 000 60 000 60 000 52 000 42 000 30 000 38 000 22 000 88 000 76 000 62 000 44 000 118 000 102 000 84 000 60 000

1 3/8 38 000 36 000 26 000 72 000 72 000 62 000 50 000 36 000 46 000 26 000 106 000 92 000 76 000 54 000 142 000 124 000 100 000 72 000

1 1/2 46 000 42 000 32 000 84 000 84 000 74 000 60 000 42 000 56 000 32 000 126 000 110 000 90 000 64 000 168 000 146 000 120 000 84 000

Cc rtTrackc r

1 5/8 52 000 48 000 36 000 96 000 98 000 84 000 70 000 48 000 64 000 36 000 146 000 126 000 104 000 74 000 196 000 170 000 138 000 98 000 ®

1 3/4

1 7/8

62 000

70 000

56 000

64 000

42 000

48 000

112 000

128 000

114 000

128 000

98 000

112 000

80 000

92 000

56 000

64 000

74 000

84 000

42 000

48 000

170 000

194 000

148 000

168 000

120 000

136 000

84 000

96 000

226 000

258 000

196 000

224 000

160 000

182 000

114 000

128 000 A virtual lifeline to safety !

2 80 000 74 000 56 000 148 000 146 000 126 000 104 000 74 000 96 000 56 000 220 000 190 000 156 000 110 000 294 000 254 000 208 000 146 000

MS = Mechanical Splice S = Swaged or poured socket.

www.herculesslr.com

Rated loads based on minimum D/d ratio of 25/1. Rated load based on pin diameter no larger than natural eye width or less than the nominal sling diameter.

For choker hitch, the angle of choke shall be 120 degrees or greater.

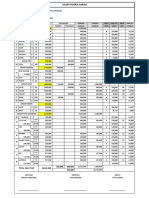

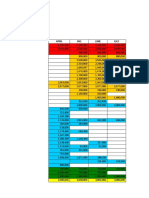

Custom Fittings ASME B30.9 (9-2.10 Rigging Practices) ASME B30.9 (9-2.9 Inspection)

Open Swage Socket Closed Swage Socket Steel Ferrule a) Slings shall be shortened or adjusted only by methods approved by the sling Initial Inspection

Mechanically Swaged manufacturer or a qualified person. Prior to use, all new, altered, modified, or repaired slings shall be

b) Slings shall not be shortened or lengthened by knotting, twisting or by wire rope inspected by a designated person.

clips.

c) The sling shall be hitched in a manner providing control of the load.

d) Slings in contact with edges, corners, or protrusions should be protected with a Frequent Inspection

material of sufficient strength, thickness and construction to prevent damage to A visual inspection for damage shall be performed by the user or

the sling. other designated person each day or shift the sling is used.

e) Shock loading should be avoided.

f) Loads should not be rested on the sling. Periodic Inspection Sling Capacity Decreases as the Sling Angle

Loss

g) Slings should not be pulled from under a load when the load is resting on the A complete inspection for damage of the sling shall be periodically Degrees

Closed Spelter Socket Open Spelter Socket Thimble Eye Hand Spliced Angle from Horizontal Decreases Factor

sling. performed by a designated person. Horizontal

h) Twisting and and kinking shall be avoided.

i) During lifting, with or without load, personnel shall be alert for possible snagging. 90 1.000

j) When using multiple basket or choker hitches, the load should be rigged to AMSE B30.9 (9-2.9 Removal Criteria) 85 0.996

prevent the sling from slipping or sliding along the load.

A wire rope sling shall be removed from service if conditions such 80 0.985

k) When using a basket hitch, the legs of the sling should contain or support the

load from the sides, above the center of gravity, so that the load remains under as the following are present: 75 0.966

control. a) Missing or illegible sling identification (see Section 9-2.7).

70 0.940

l) Slings should not be dragged on the floor or over an abrasive surface. b) Broken wires.

Vertical Vertical Basket Choker

m) In a choker hitch, the choke point should only be on the sling body, not on a c) Severe localized abrasion or scraping. 65 0.906

Soft Eye Thimble Eye Soft Eye Hand Spliced splice or a fitting. d) Kinking, crushing, birdcaging, or any other damage resulting in 60 0.866

Mechanically Swaged Mechanically Swaged n) In a choker hitch, an angle of choke less than 120 degrees should not be used damage to the rope structure.

used without reducing the rated load. e) Evidence of heat damage. 30o 55 0.819

45o

f) End attachments that are cracked, deformed or worn to the 500 lbs

o) Slings should not be constricted, bunched, or pinched by the load, hook, or any 60o 707 lbs 50 0.766

fitting. extent that the strength of the sling is substantially affected. 90o

866 lbs 45 0.707

p) The load applied to the hook should be centered in the base (bowl) of the hook g) Severe corrosion of the rope, end attachments or fittings. 1 000 lbs

to prevent point loading on the hook, unless the hook is designed for point h) For hooks, removal criteria as stated in ASME B30.10. 40 0.643

loading. i) For rigging hardware, removal criteria as stated in ASME B30.26. A sling capable of lifting 1 000 lbs in a 90o vertical

q) An object in the eye of the sling should not be wider than one half the length of j) Other conditions, including visible damage, that cause doubt as basket hitch can only lift 866 lbs at a 60o angle, 707 lbs

35 0.574

the eye. to the continued use of the sling. at a 45o angle and 500 lbs at a 30o angle. 30 0.500

You might also like

- Pricelist 110722Document1 pagePricelist 110722Dody SusantoNo ratings yet

- Pricelist Terbaru Feb 2023Document1 pagePricelist Terbaru Feb 2023Attantion everyNo ratings yet

- Tugas 1Document4 pagesTugas 1AdeNo ratings yet

- 22.4. K Harga (09-04-2022) Email KeDocument1 page22.4. K Harga (09-04-2022) Email KeYUSRON MotoVlogNo ratings yet

- AR-3 2.stāva PlānsDocument1 pageAR-3 2.stāva PlānsSergej PushkinNo ratings yet

- Daf Bapok 2020 - 24 FEBDocument1 pageDaf Bapok 2020 - 24 FEBRico CalestoNo ratings yet

- Vupdate PL Reg (Adv, PCX, Forza) Nov 2022 - Area Banua 6Document18 pagesVupdate PL Reg (Adv, PCX, Forza) Nov 2022 - Area Banua 6fajrinNo ratings yet

- Review Desain & RabDocument46 pagesReview Desain & RabYansen FrasawiNo ratings yet

- SPJDocument4 pagesSPJJoris ZhivaGo C SiregarNo ratings yet

- BX50Document6 pagesBX50Rafał HubczakNo ratings yet

- Catatan Kerja TukangDocument5 pagesCatatan Kerja TukangTopikNo ratings yet

- First FloorDocument1 pageFirst FloorbeatriceNo ratings yet

- Harvester Folder Webb - SeDocument4 pagesHarvester Folder Webb - SeTiago SilvaNo ratings yet

- Daf Bapok 18 April 2024Document5 pagesDaf Bapok 18 April 2024Skripsi LukmanNo ratings yet

- vUPDATE PL REG SCOOPY NOV 2022 - AREA BANUA 6Document31 pagesvUPDATE PL REG SCOOPY NOV 2022 - AREA BANUA 6fajrinNo ratings yet

- Harga KecDocument7 pagesHarga KecPradityo Harry W.No ratings yet

- Hiab 220 C: Kapacitet 21 TMDocument4 pagesHiab 220 C: Kapacitet 21 TMGerald Leon FloresNo ratings yet

- Price List CV. Ultima KaroseriDocument5 pagesPrice List CV. Ultima KaroseriAchmadNurunNajmiNo ratings yet

- Praktek Audit Piutang Usaha (Tiori Kesia)Document4 pagesPraktek Audit Piutang Usaha (Tiori Kesia)novisinagaa.5233351032No ratings yet

- Daf Bapok 04 April 2024Document3 pagesDaf Bapok 04 April 2024Skripsi LukmanNo ratings yet

- ScopDocument6 pagesScopHime GotoNo ratings yet

- Rekap SPP TerbaruDocument16 pagesRekap SPP Terbarukhasanudinfc123No ratings yet

- SsssDocument1 pageSsssNurul HudaNo ratings yet

- SimulasiDocument3 pagesSimulasivrezasukmaNo ratings yet

- Kericho 104616Document1 pageKericho 104616kimutaikelvin67No ratings yet

- R1 Form Perhitungan HOK - TPMDocument6 pagesR1 Form Perhitungan HOK - TPMivanNo ratings yet

- Cash Flow @Document2 pagesCash Flow @mejakursi600No ratings yet

- 2 Potonganx2Document1 page2 Potonganx2M Lutfi GunawanNo ratings yet

- 4.dödviktsskala White SeaDocument1 page4.dödviktsskala White SeakkkkNo ratings yet

- Trafik İşaretleri (İsveç)Document1 pageTrafik İşaretleri (İsveç)AdamNo ratings yet

- Rab BorDocument1 pageRab Borkhoirul bahriNo ratings yet

- Rekapitulasi HOKDocument3 pagesRekapitulasi HOKMuhamad BastianNo ratings yet

- Market DayDocument2 pagesMarket Daydrg DewiNo ratings yet

- Rekap Pendapatan Umum-Bpjs 2023Document26 pagesRekap Pendapatan Umum-Bpjs 2023nomanNo ratings yet

- Absen HarianDocument2 pagesAbsen HarianAchmad SyairoziNo ratings yet

- Absensi & Salary 31 Maret - 06 AprilDocument1 pageAbsensi & Salary 31 Maret - 06 AprilAl-mubaraqi ArtNo ratings yet

- Perhitungan PupukDocument6 pagesPerhitungan PupukTur YantoNo ratings yet

- Analisis Escenarios BaseDocument6 pagesAnalisis Escenarios BaseLaiss PizarroNo ratings yet

- Simulasi SPJ BimtekDocument3 pagesSimulasi SPJ BimtekEka LidyanaNo ratings yet

- Second FloorDocument1 pageSecond FloorbeatriceNo ratings yet

- Absensi & Salary 31 Maret - 06 April 2023Document1 pageAbsensi & Salary 31 Maret - 06 April 2023Al-mubaraqi ArtNo ratings yet

- Price Fitting PVCDocument10 pagesPrice Fitting PVCangry monkeyNo ratings yet

- Rekap Iuran Kelompok Swadaya MasyarakatDocument2 pagesRekap Iuran Kelompok Swadaya Masyarakatdonald robertoNo ratings yet

- PT IntegroDocument4 pagesPT IntegroRezita ElyaNo ratings yet

- Kentang TradingDocument52 pagesKentang TradingSupriyanto HNo ratings yet

- Contoh Perhitungan HOK Dan Indeks Tanam-1Document5 pagesContoh Perhitungan HOK Dan Indeks Tanam-1Muhamad WakilNo ratings yet

- 02 Denah BGN LT Satu - UlsaDocument1 page02 Denah BGN LT Satu - UlsaHarry NovieNo ratings yet

- E - Daftar Harga Fiting Pipa PVC Rucika 2017Document10 pagesE - Daftar Harga Fiting Pipa PVC Rucika 2017rony 2222No ratings yet

- VPL REG SCOOPY JAN 2023 - AREA BANUA 6Document12 pagesVPL REG SCOOPY JAN 2023 - AREA BANUA 6fajrinNo ratings yet

- Wiring Diagram Power Room BATDocument1 pageWiring Diagram Power Room BATanugerahjaya elektrindoNo ratings yet

- Daftar Aktiva 2023-1Document2 pagesDaftar Aktiva 2023-1Istana PhotoNo ratings yet

- UntitledDocument2 pagesUntitledRafid FiermanNo ratings yet

- A3 AC PosterDocument2 pagesA3 AC PosterSurya FahrizhaNo ratings yet

- Data BaruDocument4 pagesData BaruSilvi HongNo ratings yet

- Rab Perpipaan Langko 2018 NamoDocument19 pagesRab Perpipaan Langko 2018 NamoRudhy SetiawanNo ratings yet

- Pumping KUD Tani BahagiaDocument11 pagesPumping KUD Tani Bahagianusantaraanindya8No ratings yet

- Final Saran KUD Tani BahagiaDocument12 pagesFinal Saran KUD Tani Bahagianusantaraanindya8No ratings yet

- Analisa Uji Pemompaan Beserta grafik-KUD Tani BahagiaDocument11 pagesAnalisa Uji Pemompaan Beserta grafik-KUD Tani Bahagianusantaraanindya8No ratings yet

- PPH 21 Pegawai Tetap BonussDocument6 pagesPPH 21 Pegawai Tetap BonussERIK SETIYAWANNo ratings yet