Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

11 viewsPIT Binod Shah

PIT Binod Shah

Uploaded by

Pradeep PokhrelCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- CHP 10 CMDocument45 pagesCHP 10 CMPradeep PokhrelNo ratings yet

- Company profile-ZCRCDocument12 pagesCompany profile-ZCRCPradeep PokhrelNo ratings yet

- AshokDocument2 pagesAshokPradeep PokhrelNo ratings yet

- Assignment NoDocument3 pagesAssignment NoPradeep PokhrelNo ratings yet

- 4 Down 24HDocument5 pages4 Down 24HPradeep PokhrelNo ratings yet

- 5 RecDocument6 pages5 RecPradeep PokhrelNo ratings yet

- Viswa Consult Pvt. LTD.: Deflection (Loading With Time)Document6 pagesViswa Consult Pvt. LTD.: Deflection (Loading With Time)Pradeep PokhrelNo ratings yet

- Uses of TenseDocument2 pagesUses of TensePradeep PokhrelNo ratings yet

- 3 Down 24HDocument6 pages3 Down 24HPradeep PokhrelNo ratings yet

- 5 RecDocument6 pages5 RecPradeep PokhrelNo ratings yet

- 6 RepDocument7 pages6 RepPradeep PokhrelNo ratings yet

- Rebound Hammer Fast TrackDocument30 pagesRebound Hammer Fast TrackPradeep PokhrelNo ratings yet

- Eng AllDocument39 pagesEng AllPradeep PokhrelNo ratings yet

- Pile Load Test WorkDocument5 pagesPile Load Test WorkPradeep PokhrelNo ratings yet

- Viswa Consult Pvt. LTD.: Deflection (Loading With Time)Document7 pagesViswa Consult Pvt. LTD.: Deflection (Loading With Time)Pradeep PokhrelNo ratings yet

- 2-30 MinDocument11 pages2-30 MinPradeep PokhrelNo ratings yet

- PitDocument40 pagesPitPradeep PokhrelNo ratings yet

- Water Absorption Test of Bricks: Viswa Consult (PVT.) LTDDocument2 pagesWater Absorption Test of Bricks: Viswa Consult (PVT.) LTDPradeep PokhrelNo ratings yet

- Content: Annexes - Calculation of Test Results PhotographDocument8 pagesContent: Annexes - Calculation of Test Results PhotographPradeep PokhrelNo ratings yet

- Non-Destructive Testing of Concrete by Rebound HammerDocument7 pagesNon-Destructive Testing of Concrete by Rebound HammerPradeep PokhrelNo ratings yet

- Viswa Consult Pvt. LTD.: Bridge Load TestDocument8 pagesViswa Consult Pvt. LTD.: Bridge Load TestPradeep PokhrelNo ratings yet

- Non-Destructive Testing of Concrete-Methodology of Test (Rebound Hammer)Document11 pagesNon-Destructive Testing of Concrete-Methodology of Test (Rebound Hammer)Pradeep PokhrelNo ratings yet

- Project: Construction Work of Expansion of International Apron Southside of Day No:1 at TiaDocument1 pageProject: Construction Work of Expansion of International Apron Southside of Day No:1 at TiaPradeep PokhrelNo ratings yet

PIT Binod Shah

PIT Binod Shah

Uploaded by

Pradeep Pokhrel0 ratings0% found this document useful (0 votes)

11 views37 pagesOriginal Title

PIT binod shah

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

11 views37 pagesPIT Binod Shah

PIT Binod Shah

Uploaded by

Pradeep PokhrelCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 37

PROVINICAL GOVERNMENT

PROVINCE NO.2

MINISTRY OF PHYSICAL INFRASTRUCTURE DEVELOPMENT

TRANSPORT INFRASTRUCTURE DIRECTORATE

INFRASTRUCTURE DEVELOPMENT OFFICE

BIRGUNJ, PARSA

PILE INTEGRITY TE

REPORT ON

Sansarimai Khola Bridge along Kalay

Contract No. IDO/PAR/NCB/BRIDGE-25/077/078,

Client: INFRASTRUCTURE DEVELOPMENT OFFICE

Office Reg No.: EP043

sd By

Viswa Consult Put Ltd

P.O, Box 4316, Dillibazar, Kathmandu

Tel:-977-1-4533156E mail: viswaconsultlab@gmaiLcom

FALGUN, 2078

Project: Construction of Sansarimai Khola Bridge Along Kalayia-Prashtoka Road,Bara

Contract No.: IDO/PAR/NCB/BRIDGE-25/077/078.

Location: Sansarimai Khola, Kalaiya, Bara. (Left Abutment) Date : 2078/11/19

TABLE OF CONTENTS

PAGES

INTRODUCTION & PILE LITERATURE xen

‘BASIC TESTING RECOMMENDATIONS ono

PILE DETAILS AND DATA COLLECTION...

APPENDIX

APENDIX-A: PIT QFV Instruments and Pictorial Representation of the test

‘APENDIX-B: Summary

APENDIX-C: Photo Caption

1[Page

Project: Construction of Sansarimai Khola Bridge Along Kalayia-Prashtoka Road,Bara

Contract No.: IDO/PAR/NCB/BRIDGE-25/077/078

Location: Sansarimai Khola, Kalaiya, Bara. (Left Abutment) Date : 2078/11/19

PIT REPORT DesiGn aNo BuiLo oF Construction of Sansarimai Khola Bridge Along Kalayi

Road,Bara

PILE INTEGRITY TEST REPORT ON 20 NOS. BORED CAST-IN-SITU (Left Abutment)

-Prashtoka

1. INTRODUCTION

‘The Pile Integrity Tester (PIT) is an instrument for integrity testing of deep foundations by low-strain surface-

impact methods. It acquires, processes, enhances, and reports data. The test engineer must interpret the data

according to wave propagation theory. The results obtained are only as meaningful and reliable as the testing

engineer's understanding of the physical principles involved

The PIT is avaiiable in four models, namely, PIT-X, PIT-V, PIT-XFV and PIT-FV. The four models can be

distinguished from each other on the basis of their size, portability, number of input data channels and wireless

‘ransmission of data from the sensing device to the electronic units. All PIT models support the “Low Strain

Integrity Test" Method (see ASTM 5882) also called the Pulse-Echo Method (PEM), while PIT-XFV and PIT-

FV additionally support the Trensient Response Method (TRM). The user should become thoroughiy proficient

in PEM and TRM in order to achieve a higher level of confidence needed during data interpretation. Some

theory is discussed in this user manual as it relates to the PIT operation, but this discussion is neither definitive

nor exhaustive.

‘Test applications for PIT include integrity andlor length determination of most types of concrete deep

foundations such as drilled shafts or bored piles, Continuous Flight Auger (CFA) or Augured-Cast-in-Place

(ACIP) piles, driven concrete piles, individual concrete wall panels (barrettes), concrete filled pipe piles, and

timber piles. For simplicity we will refer to all of these foundation types as ‘piles’. Please note that the Pulse

Echo Method has pile length limitations which are a function of pile material type, pile uniformity, soil elastic

properties (elastic modulus), soil density etc. Also data taken on cylindrical piles, steel piles, jointed piles and

timber piles have either greater length limitations than solid ones or do not support clear and/or reliable data

interpretation. Similarly individual piles within a bored pile wall or panels of a diaphragm wall usually do not

provide satisfactory integrity assessments with the Pulse Echo Method. Other methods such as the Thermal

Integrity Profiler (TIP) or Cross Hole Sonic Logging are then much more successful,

21Page

Project: Construction of Sansarimai Khola Bridge Along Kalayia-Prashtoka Rond,Biara

Contract No.: IDO/PAR/NCB/BRIDGE-25/077/078

Location: Sansarimai Khola, Kalaiya, Bara, (Left Abutment) Date: 2078/11/19

2. PILE LITERATURE

“The Pulse Echo Method has been conceived in the 1970s both in Europe and in the United States (e.g, Steinbach and

Vey, 1975. "Caisson Evaluation by Stress Wave Propagation Method”, Journal of the Geotechnical Engineering Division,

ASCE), However, only after realtime, on-site digital data processing became practical did this method find general

acceptance. Numerous papers describing these developments are available on the PD! website www pile.com; click on

earning Center and select PIT. The PIT user is urged to review these publications starting maybe with following two

papers.

/wrww.pile.com/reference/3rdStresswave/pile inter by low and high strain impacts.péf

bet _nile.com/reference/TransportationResearchBoardAnnualMeeting/AComparisonOfPulseE

choAndTransientRé if

‘Another important reading s also the ASTM 5882 Standard as wel as other applicable

national testing standards or building codes. Some of these are listed in

htto://Avww.pile.com/reference/StressWaveZ008/CH-12-063 -001.puf; however it should be

expected that various code and standards have either been modified or added since the

writing of that paper.

3|Page

Project: Construction of Sansarimai Khola Bridge Along Kalayia-Prashtoka Road,Bara

Contract No.: IDO/PAR/NCB/BRIDGE-25/077/078

Location: Sansarimai Khola, Kalaiya, Bara. (Left Abutment) Date: 2078/11/19

3, PIT TEST THEROY

‘light impact is administered to the ple's surface, generally using a special hand-held hammer, and as a result

‘an acoustic wave from the impact propagates down through the pile. Variations in the shape and material quality of the

pile produce reflections of the wave, which are observed as they return to the surface, Surface vibrations are recorded

nti al primary reflections have been observed. Reflections are then interpreted considering their nature and times of

observation to assess pile integrity.

“The surface vibrations are measured by means of an accelerometer attached to the top of the pile. Although the

acceleration curve could be interpreted directly, integration to velocity generally enhances the record by bringing out

details otherwise overlooked. The pile top acceleration signal, a, is therefore digitized and stored in the PIT memory,

‘and itis numerically integrated to produce a velocity signal, v. Note that v is a particle velocity, Le. the actual velocity of

movement of the pile top surface.

‘The deepest reflector is the ple's toe, so its reflection should be the last one observed at the pile top. Given estimates

of the wave speed c and pile length L, the toe reflection is expected at the top at time 2h/¢ after impact. Thus 2L/cis the

‘time it takes the stress wave to travel to the pile bottom and then, after reflection, back to the pile top. Observation,

i.e, measurement, continues until well after this time, but the first 2L/c is the most important part and provides most of

the information about the pile. Note that the wave speed, c, is several orders of magnitudes greater (typically 3,000 to

5,000 m/s than the pile particle velocity, v (typically 1 to 20 mm/s),

‘The signal is acquired as a function of time, and the time scale is known accurately. To facilitate locating the reflectors,

the signal s presented as a function of distance x from the pile top. However, the distance scale completely depends

upon accurate estimation of the wave speed c: x=%¢ t. The distance scale has a physical meaning only for reflectors

within the shaft, not for soil below the toe, nor can it correctly be applied to the impact pulse, which is not strictly 2

reflection.

Reflections are caused by variations in the pile's impedance. Impedance Z may be calculated as where A is the cross-

sectional area, Eis the elastic modulus and is the mass density of the material of the pile. Thus, reflections can be due to

changes in either the cross-section (siz) or in the elastic modulus or specific weight (quality) ofthe material, A region of

decreasing impedance generates a tensile reflection, producing a velocity peak in the same direction as the impact. A

region of increasing impedance causes a compressive reflection, producing a velocity peak in the direction opposite the

impact.

“The reflections must be interpreted to determine whether the associated changes are acceptable or of serious concern

to the integrity of the shaft. All interpretation should also consider installation records of concrete volume, design

length and other observations

4) Page

Project: Construction of Sansarimai Khola Bridge Along Kalayia-Prashtoka Road,Bara

Contract No.: IDO/PAR/NCB/BRIDGE-25/077/078

Location: Sansarimai Khola, Kalaiya, Bara. (Left Abutment) Date : 2078/11/19

4, PROCEDURE OF PILE INTEGRITY TEST

‘The SE method is a low strain integrity test conducted from the top (or upper side) of the shaft as shown in

the figure below. test equipment includes a 3 pound(1.36kg) hammer (instrumented or mechanical),

receiverlaccelerometer and/or geophone) mounted on the top (or upper side) of the shaft, and a data

‘acquisition platform. the test involves hitting the foundation top with the hammer to generate wave energy

that travels to the bottom of the foundation. The wave reflects off irregularities (cracks, necks, bulbs, soil

intrusions, voids, etc.) and/or the bottom of the foundation and travels back along the foundation to the top.

the receiver measures the vibration response of the foundation to each impact. The data collection platform

‘acquires, processes and displays the receiver ouputs. Foundation length and integrity of concrete are

‘evaluated by identifying and analyzing the arrival times, direction and amplitude of reflections measured by

the receivers in time. The Eco Depth (0) is calculated by multiplying the reflection time(t) by the compression

‘wave velocity(V) and dividing this quantity by 2 to account for the fact that the wave has gone down and

reflected back, ie. D=V"t/2.

‘Analysis of the length determination and the integrity evaluation of s foundation with the SE method is based,

‘on the identification and evaluation of reflections. Test results are analysed in the time domain for the SE test.

‘The SE test method Is sensitive to changes in the shaft impedance(shaft concrete area*velocity*mass density

where mass density equals unit weight divided by gravity), which case the reflections of the compression

‘wave energy. Compression wave energy(hammer impact energy) reflects differently from increased shaft

impedance than from decreased shaft impedance. This phenomenon allows the type of reflector to be

identified as follows. Soil intrusions, honeycomb, breaks, cracks, cold koints, poor quality concrete and similar

defects are identified as reflections that correspond to a decrease in shaft impedance. Increases in the shaft

cross-section or the competency of surrounding materials such as bedrock and stiffer soil strata are identified

{3s reflections corresponding to increases in the shaft impedance. A decrease in impedance is indicated by a

downward initial break of a reflection event in an SE record and frequency peaks positioned in 2 record such

that a peak could be extrapolated to be near OHz in the mobility plot. Conversely, an increase in shaft

impedance is identified by an upward initial break for an SE reflector.

‘When length to diameter ratio exceeds 20:1 to 30:1 for shafts in stifer soils/bedrock. the attenuation of

compression wave energy is high and bottom echoes are weak or unidentifiable in SE test results. if the shaft

is embedded in a material which has similar impedance to that of the shaft, it may not be possible to see @

reflection from the bottom of.the-shaft,

5|Page

Project: Construction of Sansarimai Khola Bridge Along Kalayia-Prashtoka Road,Bara

Contract No.: IDO/PAR/NCB/BRIDGE-25/077/078

Location: Sansarimai Khola, Kalaiya, Bara. (Left Abutment) Date : 2078/11/19

Velocity ofthe pile top surface isin most instances the most important data collected during 2 pile integrity test. It

requires a light hammer impact and the recording of acceleration. In order to obtain an accurate record of the pile

top surface motion the location where the acceleration is measured has to be a sound, clean pile material

‘Contamination by soil, loose debris or surface layers, poorty hardened pile material a very rough surface are

‘among the conditions that provide poor records which are difficult or in most instances impossible to interpret

clearly. Obviously, the concrete has to be hardened to a point where itis much harder (or having a higher elastic.

‘modulus) than the surrounding soil

For clean impact pulses without ringing of other spurious signals the impact surface also has to be of clean and

preferably smoothened. Thus, grinding down to good concrete several impact and accelerometer locations is the

best assurance to obtain meaningful results. t saves on data interpretation time and/or a repeat trip to the site.

‘The accelerometer should be bonded to the pile top surface with a thin layer ofa “sticky” material. Depending on

pile temperature and/or moisture content, different materials may have to be tried. Under no circumstances

should a thick layer of bonding material separate the sensor from the pile material. In fact, pressing the

accelerometer down far enough until one feels it touching the concrete makes for the best records,

Ideally, the hammer impact would cause the whole pile diameter to achieve a uniform axial motion. However, only

a small pile top area is subjected to the impact causing a non-plane deformation of the pile cross sections below

‘the pile top. Thus, testing on the westside of the pile top will not reveal what is happening on the east side within

one or two pile diameters below the pile top and for larger pile it is therefore strongly recommended that the pile

top is tested and impacted at several locations. Ideally impacting and testing is done at the third points of the pile

‘top surface. The worst location for testing is the edge of the pile,

However, the larger the pile diameter the greater the motions generated at the pile top by shear (or Rayleigh)

waves. These pile top motions may appear as noise in the basic compressive wave record. Spurious record

components can also be created by reinforcement extending above the pile toe or small cracks within a short

distance below the pile top. Larger hammers or more cushioned hammers possibly improve the record appearance

in such cases.

Longer ples produce weaker pile toe signals than shorter ones because of losses of wave energy due to pile

internal or soil external damping. However, hammer impact pulses with lower frequency contents (those that have

longer lasting impact pulses either because of a greater hammer weight or a softer cushioning) travel longer

distances with less energy dissipation than those that are sharper

‘And shorter. Unfortunately, the smoother longer pulses do not allow for as clear a resolution as the sharper ones.

Itis best practice, therefore, ta test with several hammers, for example, using hammer weights of 5, 10, 30.N (0.5,

11, and 3 kg or 1, 2 and 6 Ib) for more and clearer information,

6[Page

Project: Construction of Sansarimai Khola Bridge Along Kalayia-Prashtoka Road,Bara

Contract No.: IDO/PAR/NCB/BRIDGE-25/077/078

Location: Sansarimai Khola, Kalaiya, Bara. (Left Abutment) Date : 2078/11/19

6. PILE DETAILS AND DATA COLLECTION

‘The Pile integrity Test was conducted at Sansarimai Khola, Kalaiya, Bara. The pile graphs had

measured diameter of 800 mm and was reported of having depth of 18.00 m at Left Abutment

which is the basis of this report.

20 piles were tested from foundation at 18.00 m at Left Abutment from the PCC

level.

Respective Engineer and technicians were on site in order to perform the PIT test from 2078-

41-04 to 2078-11-05. All field records were transferred to computer at office. Then necessary

filtering, magnification was done to data and corresponding velocity curves were plotted. The

shafts were processed using a concrete wave speed of 3400 m/this to 4000 m/s range of wave

speed variations (as the lower range of wave speed was recorded) is within the +/- 4% which may

be encountered at site.

TlPage

Project: Construction of Sansarimai Khola Bridge Along Kalayi-Prashtoka Road,Bara

Contract No.: [DO/PAR/NCB/BRIDGE-25/077/078.

Location: Sansarimai Khola, Kalaiya, Bara, (Left Abutment) Date : 2078/11/19

7.LIMITATION OF PIT

Limitation of Pile Integrity Test are as follows:

1) Pile Integrity Test does not provide any information on the load bearing capacity

of piles and deep foundations.

2) Integrity Testing cannot be conducted over pile caps

3) Integrity testing of cross sections below a major crack (that crosses the entire

cross-sectional area) is not possible.

4) This test is not effective in piles with highly variable cross sections.

5) Itis not effective in evaluating sections of piles below cracks that crosses the

entire cross-sectional area of the pile.

6) Pile integrity is generally not suitable for testing steel sheets, H-section, or

unfilled pipe piles.

7) When the toe reflection is not evident, integrity evaluation may not be

conclusive.

8) In some cases, its difficult to distinguish the soil response, and the (pile) toe

response.

9) Presence of water in site during testing affects good data acquisition.

‘The records were evaluated for reflections from the shaft toe and for variations in the

impedance above the shaft toe

‘The depth accuracy may vary from +/- 4% due to site conditions or human error or machine error

Bl Page

Project: Construction of Sansarimai Khola Bridge Along Kalayia-Prashtoka Road,Bara

Contract No.: IDO/PAR/NCB/BRIDGE-25/077/078

Location: Sansarimai Khola, Kalaiya, Bara. (Left Abutment) Date : 2078/11/19

CONCLUSION:

‘The wave speed for this report is from 3400-4000 m/s. 20 piles were tested from PCC level. The

concrete grade is M25.

From above report it can be deduced for Left Abutment the maximum diameter is 1.13 at 5.44 m of

pile 19a, The minimum diameter 0.89 at 6.80 m of pile 1. The maximum depth is found out to be

118.35 m of pile 3a and minimum depth is 17.60 of pile 8b.

‘The PIT as stated above has many limitations also the field conditions and technicians are

responsible for quality of the data taken. Also, PIT doesn’t give any information regarding the

bearing capacity of the pile. It only gives the structural integrity of the pile structure.

Considering all of these no major cracking was observed in the field data. Slight bulging of piles was

observed. As per International Journal of GEOMATE, July 2018 vol 15 and DOR requirement the

beta analysis is within the limits.

Keeping in mind the relevant code that has been followed and the guidelines of 1S code and

ASTM code it can be safe to say the 20 Piles recorded do not show any major defects.

9) Page

APENDIX-A: PIT

QFV Instruments

and Pictorial

Representation of

the test

1A SANE

(sav) suo sire A

(su ova) w sees eo 50

—r00

| I

. a 2hO

Mid Brivo: zeoeaue spud

‘SHWE b Dd ceil

26002 eIold i rH Valid

2z02/91/2 ‘payayoy bid eld ay

ez0zeie ‘PHT Ag JINSUOD eMs|A,

worere ‘yale uM

960

Wwoo01 001 :eubid xen

00: seany "onsisu0g

004 :10A yonAsUeD

850 "TOA SMBH

(ave'0) snuo vBV0 A

mH Lu8e wory yoonenn

Ne Sr'soie 2e02/9H2

26002 80d

2z0ZI9LIZ ‘PaWAIOD

zz0z/ere

azaid

Q@ Fld 29d AV

‘PHT a aNsUCO BMSIA,

weost e960 tHo%d wi

‘WQ0'018 00" :euOle ¥EVN

Oot seaxy pmsueD

OO #10A yonsU0D

96

fon eneeu

ws |

180 \

°

ea

+ fi

wby

(esz0) suo esz0 A (sw oore) w seat aio i

|

—s00-

|

i —s00

> aro

Wa Heco:e zz0er94e sub

zw:0-PC aTId [Olle

76002 Aid : eae

Zz0z/94/2 ;PAIEIIOD beeper

pr Wad UNSUOD EMsIA

zzoziere

‘yas Ue

‘

Wirrie sot eyoid xen

Oot seeny voneuen

(001 H10A ‘pAHsueD,

Zot ejaMeey

(209) $49 veLZ A (sy oove) ws oV'@H! ated soe

|

“a

ot

18

Wa ¥9:80: zz02/0172 ial

S#¢-9p aid :0lld

6002 aNOId raid

ZZOZI9LIE ‘PEDALS,

zzoziee

2p ald “ld ay

“PHL Ad UNsUOD EMSA

DOL :1eA vensisu0D

950 “TOA aNIEeR

I wos

i 160

°

' eed

+ 1 ToT t

I woe we = wos SE :

(ror'0) 80 v6K'0 A: {enw oore) w 0z84 Sead ae 10

i

+120

Wn ogee zz0z/01 sun

Twounngy y= bea e-a9 311d 20d

26002 140d 9g Fld

COLLIE PeAIOD 9g aiid ad av

zeousele

PLT Td JIMSUOD EMSA,

wgorieeso elves uv

UIEDEI OL ood xe

004 ayy yonisu0D

(00's "eq yonasu09

560 "TON eneeH

listo) sau esr0 A.

Wid oo 8e°4 zz0er9/e

waunnay Wer

26002 Sod

ZzOZI9LIZ ‘DEI

ze0ziele

lew e-e9 31ld “elle

100

sy 700

e9 31d

29 Fld Ald 9ay

PIT Vid aNsUED EMSIA,

weer e60

Wor 00

00)

oot

180

wen wre

lo

=

:

t ott ttt

Sea

(eve'0) SMD EEO A (Snu Ove) WOO'SL 986°0 860 650 ‘460 950860 zz

i

1

a

sla

iif ivbeseowiate aus

sheers ceoss-peawaiond

2-600 B1YOld PL ad

ZzOzIOLIe ‘Pee

zzoziere

PL Ald ‘ltd 'oay

‘PIT Ae HNSUOD EMSA,

wizztie 160 eho

wzg pie cot “Odd xe

00°4 ay YonNSUID

zvo) 2 120 A

(su oose) 1 09°24

aqua?

a Love zzo291

Tusuanay 1246-48 ANd ‘ll

26002 101d Hi i a3 Sid

zZOZIOLIZ PEED ee ak

Feozere PIT Ad JINSUOD EMSIA,

wggzieoot — “ouoid UW

weLere SO eivald xen

(Oot seary wonasu0D

001 “10A vonsisu0D

yO "WA @MBOH

(zv'0) $140 0¢+'0 A (srw ove) w 00°84) v0

—s10

“sro

9r0

WW eOPL:2 ZzozIshe a

ce €- G6 Fld ‘ltd

96 ad

96 31ld lid ‘Sav

ze00e Bod

ZZOZI9LIZ PAID

zzoziee

“PIT Wad NSUED EMSIA

ea

1 T :

wou way |

(i¥00) sto o»00 A (snaore) wove 160 $60 i

—sr0-

| |

500

i 300

mowiz — wow reronem “svo

Wha ion zz0zre12 aie

weuandy ve 6420-80 Bld lle

EE 201 ald

20} 31d ‘ld ‘OV

IT Wd ¥MSUOD ENSIA

F800 S1NSid

zz0z/91/2 PaHeIOD

ezozsere

wep of

tyoid

ayo EW

Go swany vnasu09

OO “Ion nnsu0D

960 "1en@nEIee

ozo) sme 2670 A

(srw gore) w oo Bt

ae

| —s00-

—90

abo

wa es:ieu ezozene ane

wounay We oee-Gh) ald Od

F6002 SHOld

Zz0UISb/Z ‘PAPAICD aL atid

TZOCEIE ‘PIT Wd UNSUOD EMS!

TOA Yonutsuoy

@izo suozizo A

Ne Lee 2202/01

wuauangy Ye

wen |

380 |

°

weg

tt ;

wewes

(1 00¥6) 06:28 96.0650

oro

no

0

|

|

ua”?

ee -GZL ad 20lld

Z-600e A0Id

ZzOzIgLIe ‘Pee

zeoziee

et Td

ZL 31d “lle '9av

PIT Wad YNSUED EMSIA,

“Stole WN

680

weer zo) oid xen

05 :eary venssv00

(001 0A verwsv0D

Oot Ten anneee

i eg

t b

| woo

(e1v0) sma eivo A (nu pore) w 5624! 650 Pee

| oe:

|

! ovo

(

| ovo

|

|

meee = wo90 orem eo

Wa es'6r 2202/012 ”

‘waunngy 4= ee ic- GEL Bd lle

E8002 ayoid ‘Ge 311d

Zz0zI9LI ‘PaaS

zeozieie

el ld ‘eld ‘9aV

PIT a UNsuED EMSA,

(020) su voz'0 A

oro

—s00

I 00°

i

i

i

(smu ove) w 00 @1

910"

Wid se'geu ze0zoVe we

‘wounngy 47 se#¢-GpL TTId lid

E6002 aW0Id ‘Oph aid

220Z/9H/Z ‘PaAIOD pL Fld ld 9qv

zzozsere YT Aa jinsuog ems,

wos

oo

t °

I Pe

1 iat ete, ;

wg wer wee, Sor woss worwez

G4v0) su2 140 A——— (euoore) woes) 980 860 OHO 9600 650 850 eee

soo

—s00

|

oro

sno

wa vee 2202/1 Mu

‘wouanay vr cow e-QSL Td Old

ast aid

26002 S0Id

Zz0z/9L/z ‘Pa!eaOD

zzose/e

G1 31d ‘elld ‘oay

"PIT 3g INSUOD EMsIA,

Tob "eA ante

| wrol

| 980 i

I °

ea

T 1 i

(00) 8740 5020, ——— woot

4 <0

(1a ne) wor ai

\

|

coo

|

00

* ea

00

wa ose zeozne sus

wounnay We) se '¢-B9) Bld “elle

01 Fd

26002 SHOld

ZZOZ/OLIZ ‘PAINCD

zzozrere

29) 31ld lid OAV

PIT Ad YNSUOD EMsIA,

wep

waver aso “aod wn

Wyle LOL ood xeW

D0 seary vonwsued

| eee

| to

(ecz0) sno 9020 A ceo ‘S60

z | 960

| ae a)

| |

| —100

i

(su 000s) woos

aH Pe woot reionenn +90

wa eziozie 2207/92 sal

wouanay Y= se w'e-QLb ald 20d

600 Sold pole

ZZOZ9LIZ P2ANCD

zzoziele

LL ad id av

“PHT Ina tInsUoD EMsIA

st o

OR aaneiou

(sro) suo esto A (sn ose) w oo 8b

|

|

: ; ah

| |

I |

i |

| | —se0

|

ti

|

| —eeo

| |

|

|

we

5

wa zzz ez0z/eue oe

veauninay Y= 61 #°¢- PBL Bld 20lld

76002 @1Od - 8h Tid

IL/z ‘PRIOR|IOD 81 Tid eld ‘av

eevee on hea trsieg enon

wopove 00+ auld UI

Ot “Ten antes

(es0'0) snue gg00 A

8

1 T ;

\ gut wee |

a 0 950

(score) 00 cs

1 lege

240058 wio0z yeronenn a)

Wie bois 2202081 swe

nueuanay We LL: B6L Fld 29d

76002 ed 86 Tid

861 Fld ‘Alld ‘Odv

2z0z/91/2 ‘PAPAIOD

zz0z/ee

"prT Wad ANSUOD EMSIA,

were

woeeie 960 “ayola uN

woeSIE LOT ood xen

00+ eany yonvjsu0p

901 "TeA ypnuisU0D

660" TPASNIOIRL

(2500) sno e600 A

(score w 00 i

ao

|

1 HO

ae ws

rasan a

27-6002 A}Old 902 Sid

2ZOZ/OL/Z ‘PROD 90Z Fd Ald ‘ay

ez0z/e/e

YT Ad NsuoD eMs!A,

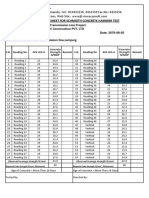

APENDIX-B:

Summary

Ore

(acy 395 sea} yer0 30 96ys wos Aven Aes 19) a4 J 4AOp 94: 3LON

—worswe0 [arse mt J

cost | _wazereoot | _weszrvesot |

cost] _werewaso | wrcewrot |

oer | worstwaso | _wasceeot |

arena [—azrereceo | eset |

wmmgr [-esereyy Af Yes pourgunfreseN gj) ¢ AOHDEAHUOD,

outvscot : ea wsang‘funig 99yJ0 Wwoudojpsag aumonsystsuy

mung'proy Eoystad-eIepey BuoLY apg wOUN HuUNLESUES Jo WoHIMASHOS + 199ford

Joys ATeuMNg

OSTEEHE-I-LLG *X¥A 9S)

npueuney “ezequITC “91h X08 “O'd

“GLT “LAd LTASNOO VMSIA

It fs assumed that the wave transmission is one-dimensional. This requires that the ple is long

‘compared withthe diameter. For large diameter shafts, a defect near the tcp might be missed ifthe

‘accelerometer is attached far from the defect, and thus several locations for each large shaft should

be tested. The PIT units with the force-measuring option allow better defniion of shaft properties

‘ear the top of the shaft during the width of the hammer signal, and thus is @ definite improvement

‘over systoms lacking this capably (s00 also a. above.)

It should be clearly understood that the main purpose of this test is to locate piles with serious

defects. Minor defects could easily be missed (and may not be important anyway to the overall load

Carrying performance ofthe pile shaft as the soll resistance is usualy the limiting factor inthe pile

cepacity)

Classification of PIT Records

‘Adopting @ cassificaton system forthe PIT records is highly recommended, both as a guideline to

‘inal nterpretaton and as an indication ofthe capabilites and limitations ofthe method. Diferent

Classification systems have been adopted by codes and specifications around the world. The

Classification system below is provided 2s an example only

‘AA Sound shaft integrity indicated: a clear toe reflection can be ideniied corresponding to tho

reported length and wave speed within acceptable range: records in this category may indicate

normally accepted variations of size or material quality.

AB _No major defect indicated; the records indicate neither reflections from significant

reductions of pile size or material quality nor a clear toe response. Records inthis category do not

sive indications of a significant deficiency, however, nelther do they yield posite evidence of the

‘haf being lawless over its full length.

ABX No major defect indicated to a depth of x ft (mm). because of method limitations

interpretation of the record for the full length is not possible. For example, long pies or shafts and

‘those with high sol resistance and/or major bulges fall under this category

PFx Indication of a probable flaw at an approximate depth of x ft (m); a toe reflection Is

‘apparent in addition to at least one reflection corresponding to an unplanned reduction of size or

material quality. Additional quanttative analysis may help identify the severity of the apparent flaw.

PDx Indication of a probable defect at an approximate depth of x ft (m; the records show a

strong reflection corresponding to a major reduction of size or material qualty Occurring, a clear toe

reflection is net apparent.

Vx _Inconelusive record below depth of x ft (m) due to spurious vibrations; data is

inconclusive due to vibrations generated by construction machinery or heavy reinforcement

‘extending above the pile top concrete; retestng is advisable under certain ckcumstances,

IR inconclusive record; data is inconclusive, possibly for reasons such as:

* poor pileishaft top quality or low concrete strength (lest has been conducted too early);

retestng after walting and/or pile top cleaning is advisable,

‘planned impedance changes or joints generate signals which prevent toe signal

‘entfication.

APENDIX-C: Photo

Caption

(@39NGNOD ONI3E 1S3L ALIHDAINI 31d

‘S3AILVLN3S2¥d3¥ YOLDVYLNOD ONY NOISIAIC 4O SON3SRNd 3HL NI G3LINGNOD ONI3S 1S3L

G219NGNOD ONI3E 1531 ALIYOIINI Tid

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- CHP 10 CMDocument45 pagesCHP 10 CMPradeep PokhrelNo ratings yet

- Company profile-ZCRCDocument12 pagesCompany profile-ZCRCPradeep PokhrelNo ratings yet

- AshokDocument2 pagesAshokPradeep PokhrelNo ratings yet

- Assignment NoDocument3 pagesAssignment NoPradeep PokhrelNo ratings yet

- 4 Down 24HDocument5 pages4 Down 24HPradeep PokhrelNo ratings yet

- 5 RecDocument6 pages5 RecPradeep PokhrelNo ratings yet

- Viswa Consult Pvt. LTD.: Deflection (Loading With Time)Document6 pagesViswa Consult Pvt. LTD.: Deflection (Loading With Time)Pradeep PokhrelNo ratings yet

- Uses of TenseDocument2 pagesUses of TensePradeep PokhrelNo ratings yet

- 3 Down 24HDocument6 pages3 Down 24HPradeep PokhrelNo ratings yet

- 5 RecDocument6 pages5 RecPradeep PokhrelNo ratings yet

- 6 RepDocument7 pages6 RepPradeep PokhrelNo ratings yet

- Rebound Hammer Fast TrackDocument30 pagesRebound Hammer Fast TrackPradeep PokhrelNo ratings yet

- Eng AllDocument39 pagesEng AllPradeep PokhrelNo ratings yet

- Pile Load Test WorkDocument5 pagesPile Load Test WorkPradeep PokhrelNo ratings yet

- Viswa Consult Pvt. LTD.: Deflection (Loading With Time)Document7 pagesViswa Consult Pvt. LTD.: Deflection (Loading With Time)Pradeep PokhrelNo ratings yet

- 2-30 MinDocument11 pages2-30 MinPradeep PokhrelNo ratings yet

- PitDocument40 pagesPitPradeep PokhrelNo ratings yet

- Water Absorption Test of Bricks: Viswa Consult (PVT.) LTDDocument2 pagesWater Absorption Test of Bricks: Viswa Consult (PVT.) LTDPradeep PokhrelNo ratings yet

- Content: Annexes - Calculation of Test Results PhotographDocument8 pagesContent: Annexes - Calculation of Test Results PhotographPradeep PokhrelNo ratings yet

- Non-Destructive Testing of Concrete by Rebound HammerDocument7 pagesNon-Destructive Testing of Concrete by Rebound HammerPradeep PokhrelNo ratings yet

- Viswa Consult Pvt. LTD.: Bridge Load TestDocument8 pagesViswa Consult Pvt. LTD.: Bridge Load TestPradeep PokhrelNo ratings yet

- Non-Destructive Testing of Concrete-Methodology of Test (Rebound Hammer)Document11 pagesNon-Destructive Testing of Concrete-Methodology of Test (Rebound Hammer)Pradeep PokhrelNo ratings yet

- Project: Construction Work of Expansion of International Apron Southside of Day No:1 at TiaDocument1 pageProject: Construction Work of Expansion of International Apron Southside of Day No:1 at TiaPradeep PokhrelNo ratings yet