Professional Documents

Culture Documents

General Intructions: Drawing Number Amdt 297 X 420 A3

General Intructions: Drawing Number Amdt 297 X 420 A3

Uploaded by

iamlpOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Intructions: Drawing Number Amdt 297 X 420 A3

General Intructions: Drawing Number Amdt 297 X 420 A3

Uploaded by

iamlpCopyright:

Available Formats

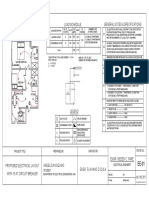

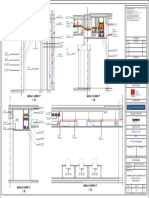

12kV

GENERAL INTRUCTIONS

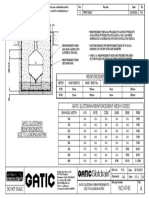

KIT NUMBER KIT RANGE a b c l

2

USE A PROPANE (PREFERRED) OR BUTANE GAS TORCH. mm mm mm mm mm

PAWA 22 95-240 170 470 320 60

ENSURE THE TORCH IS ALWAYS USED IN A WELL-VENTILATED ENVIRONMENT. PAWA 21 240-400 190 490 340 80

ADJUST THE TORCH TO OBTAIN A SOFT BLUE FLAME WITH A YELLOW TIP.

24kV

PENCIL LIKE BLUE FLAME SHOULD BE AVOIDED. KIT NUMBER KIT RANGE a b c l

2

mm mm mm mm mm

KEEP THE TORCH AIMED IN THE SHRINK DIRECTION TO PREHEAT THE MATERIAL. PAWA 24 25-95 160 460 310 30

PAWA 23 95-240 190 490 340 60

KEEP THE FLAME MOVING CONTINUOUSLY TO AVOID SCORCHING THE MATERIAL.

(TABLE 1)

CLEAN & DEGREASE ALL PARTS THAT WILL COME INTO CONTACT WITH ADHESIVE.

2

IF A SOLVENT IS USED FOLLOW THE MANUFACTURER’S HANDLING INSTRUCTIONS. b

REFERENCE LINE

Cable A.

a

TUBING SHOULD BE CUT SMOOTHLY WITH A SHARP KNIFE LEAVING NO JAGGED EDGES.

50 100 150 40

START SHRINKING THE TUBING AT THE POSITION RECOMMENDED IN THE INSTRUCTION.

ENSURE THAT THE TUBING IS SHRUNK SMOOTHLY ALL AROUND BEFORE CONTINUING ALONG THE CABLE.

TUBING SHOULD BE SMOOTH AND WRINKLE FREE WITH INNER COMPOENTS CLEARLY DEFINED.

NYLON CORE SCREEN

OVER SHEATH INNER SHEATH SCREEN WIRES

1 CABLE PREPARATION

CUT THE CABLE TO ALLOW A 500 mm OVERLAP AS SHOWN.

Cable A.

REMOVE THE OVERSHEATH "b" mm FROM THE REFERENCE LINE.

CLEAN THE REMAINING OVERSHEATH FOR ABOUT 600mm

REFERENCE LINE

REMOVE THE NYLON & INNER SHEATH TO THE DIMENSIONS AS SHOWN.

APPLY A WIRE BINDER AROUND THE SCREEN WIRES 150mm FROM THE END OF THE INNER SHEATH.

CABLE A CUT THE SCREEN WIRES LEVEL WITH THE WIRE BINDER.

CUT THE CORE AT THR REFERENCE LINE.

THOROUGHLY REMOVE THE CORE SCREEN 40mm FROM THE END OF THE SCREEN WIRES, SO THAT

CABLE B

THE INSULATION SURFACE IS FREE FROM ALL TRACES OF CONDUCTIVE MATERIAL.

500 NOTE: DO NOT NICK THE INSULATION!

DES R.S. POWER STANDARD DRAWING

DRN K.I

CABLE JOINTING & TERMINATION

CKD R.S.

RAYCHEM CABLE JOINING KIT FOR SINGLE

APPD S.C.

CORE CABLE WITH SHEAR BOLT

SCALE N.T.S.

1 SUPERSEDED A.T. DEC’12 B.C. B.C.

B RE-ISSUED FOR COMMENTS K.I. 11-4-07 R.S. S.C. ISSUED MAR’07 DRAWING

NO DESCRIPTION DRN DATE CKD APPD ALL DIM. IN mm

A3 NUMBER S02-2-2-49 1

AMENDMENTS DRAFTING STANDARD TO A.S.1100 CAD PRODUCT DO NOT AMEND MANUALLY AMDT

A3 297 X 420

5 Cable B. 5

20 10

c

40 100 50

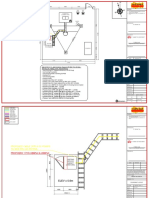

TAKE THE YELLOW VOID FILLING STRIP FROM THE ALU FOIL PACKET.

REMOVE THE RELEASE PAPERS FROM THE STRIP WITH THE POINTED ENDS.

OVER SHEATH

WRAP THE VOID FILLER AROUND THE CORE SCREEN STARTING 20mm

NYLON

CORE SCREEN FROM THE END OF THE SCREEN AND CONTINUE ONTO THE INSULATION

SCREEN

FOR 10mm.

INNER SHEATH

STRETCH THE STRIP TO HALF OF ITS ORIGINAL WIDTH TO ACHEIVE A FINE

THIN EDGE.

Cable B.

REMOVE THE OVERSHEATH "c" mm FROM THE REFERENCE LINE.

REMOVE THE NYLON & INNER SHEATH TO THE DIMENSIONS AS SHOWN.

BEND BACK THE SCREEN WIRES ONTO THE OVERSHEATH AND TEMPORARY TAPE INTO PLACE.

THOROUGHLY REMOVE THE CORE SCREEN 40mm FROM THE END OF INNER SHEATH SO THAT

THE INSULATION SURFACE IS FREE FROM ALL TRACES OF CONDUCTIVE MATERIAL.

NOTE: DO NOT NICK THE INSULATION!

6

l l

SLIDE THE STRESS CONTROL TUBING (BLACK) OVER THE PLASTIC CABLE

CORE LEVEL WITH THE END OF THE INSULATION CUT BACK.

SHRINK DOWN STARTING FROM THE INSULATION CUT BACK TOWARDS

MEASURE THE CONDUCTOR BORE DEPTH OF THE CONNECTOR AND REMOVE

THE OVERSHEATH AS SHOWN IN DRAWING.

THE INSULATION ON BOTH CORES EQUAL TO INSERT DEPTH l (SEE TABLE).

DES R.S. POWER STANDARD DRAWING

DRN K.I

CABLE JOINTING & TERMINATION

CKD R.S.

RAYCHEM CABLE JOINING KIT FOR SINGLE

APPD S.C.

CORE CABLE WITH SHEAR BOLT CONNECTOR

SCALE N.T.S.

1 SUPERSEDED A.T. DEC’12 B.C. B.C.

B RE-ISSUED FOR COMMENTS K.I. 11-4-07 R.S. S.C. ISSUED MAR’07 DRAWING S02-2-2-49

NO DESCRIPTION DRN DATE CKD APPD ALL DIM. IN mm

A3 NUMBER (SHEET 2 OF 5) 1

AMENDMENTS DRAFTING STANDARD TO A.S.1100 CAD PRODUCT DO NOT AMEND MANUALLY AMDT

A3 297 X 420

7 10 12

2 1

COMPLETION OF JOINT

CLEAN AND ABRADE SURFACE OF THE EXPOSED CONDUCTORS. REMOVE THE RELEASE PAPER FROM THE STRESS GRADING

SLIDE A COMBINED TUBING SET OVER ONE PLASTIC CABLE CORE. PATCH (BLACK). POSITION THE PATCH CENTRALLY OVER THE

1 - SCREENED INSULATION SLEEVE (BLACK & RED) CONNECTOR AREA.

INSERT CONDUCTORS SO THAT THE INSULATION BUTTS UP WITH THE

2 - OUTER SLEEVE (BLACK)

END OF THE CONNECTOR. HAND TIGHTEN THE SHEAR BOLTS SO THAT

THE CONNECTOR STAYS IN PLACE.

NOTE IN CASE OF RECTANGULAR PATCH APPLY THE LONG SIDE

FOR CONNECTORS USING MORE THAN ONE SHEAR BOLT PER SIDE,

ACROSS THE CONNECTOR.

8 TIGHTEN THE BOLTS ALTERNATELY AND SHEAR THEM OFF STARTING WITH

THE OUTER BOLTS (SEE ALSO SEQUENCE SHOWN IN THE DRAWING).

WRAP THE PATCH OVER THE CONNECTOR AREA STRATING AT

NOTES THE CONNECTOR BOLTS.

WHEN A CORDLESS IMPACT WRENCH IS IN USE THE TIGHTENING NOTE DO NOT STRECH THE PATCH.

INTERVALS SHOULD BE IN THE RANGE OF 2 SECONDS.

AVOID CORE BENDING ON SMALLER CROSS SECTIONS BY USING

INSERT SHELLS A SUPPORT TOOL AVAILABLE. 13 a

1

INSTALLATION OF THE MECHANICAL CONNECTOR SMOOTH OUT ANY SHARP EDGES OF PROTRUDING BOLTS WHERE

THE CONNECTOR IS SUPPLIED WITH INSERT HALF SHELLS WHICH HAVE TO BE APPROPRIATE. CLEAN AND DEGREASE THE CONNECTOR AREA AND

USED ON SMALL CROSS SECTIONS. THE INSUALTION WITH A CLEANING WIPE. 1

CHECK BEFORE INSTALLATION IF THE CONDUCTOR CAN BE INSERTED INTO

THE CONNECTOR WITH HALF SHELLS INSTALLED. IT COULD BE POSSIBLE THAT THE BOLT SHEARS BUT THE TOP IS

IN CASE THE CONDUCTOR CAN NOT BE INSERTED, REMOVE THE INSERTS FROM RETAINED IN THE CONNECTOR BODY. IN THAT CASE UNSCREW THE

THE CONNECTOR BORE. HEAD OF THE BOLT UNTIL IT IS REMOVED FROM THE CONNECTOR.

b c

2 3 4 5

50

9 11

POSITION THE SCREENED INSULATING SLEEVE (BLACK AND RED)

CENTRALLY OVER THE CONNECTOR AREA.

a. START SHRINKING THE SLEEVE IN THE CENTRE (1).

b. CONTINUE SHRINKING BY WORKING TOWARDS ONE SIDE (2).

STOPPING 50mm FROM THE END.

SHRINK THE OTHER HALF IN THE SAME WAY (3).

c. SHRINK DOWN THE FIRST END (4) AND FINALLY THE SECOND (5).

SUPPORT TOOL CLEAN AND DEGREASE THE CABLE CORES AND THE CONNECTOR.

THE SLEEVE SHOULD BE FULLY SHRUNK WITHOUT LEAVING

FILL RAYCHEM CLAY OVER THE SHEARED OFF BOLTS TO OBTAIN A

RIDGES.

SMOOTH FINISH.

DES R.S. POWER STANDARD DRAWING

DRN K.I

CABLE JOINTING & TERMINATION

CKD R.S.

RAYCHEM CABLE JOINING KIT FOR SINGLE

APPD S.C.

CORE CABLE WITH SHEAR BOLT CONNECTOR

SCALE N.T.S.

1 SUPERSEDED A.T. DEC’12 B.C. B.C.

B RE-ISSUED FOR COMMENTS K.I. 11-4-07 R.S. S.C. ISSUED MAR’07 DRAWING S02-2-2-49

NO DESCRIPTION DRN DATE CKD APPD ALL DIM. IN mm

A3 NUMBER (SHEET 3 OF 5) 1

AMENDMENTS DRAFTING STANDARD TO A.S.1100 CAD PRODUCT DO NOT AMEND MANUALLY AMDT

A3 297 X 420

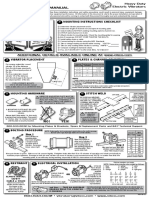

14 17 20

COPPER MESH COPPER MESH

REMOVE THE BINDER FROM THE END OF THE SCREEN WIRES ON

CABLE ’A’ AND TWIST THEM TOGETHER TO FORM A SINGLE EARTH

WRAP A SECOND LAYER OF COPPER MESH ROUND THE JOINT WRAP THE FLAP AROUND THE CABLE.

CONDUCTOR. WRAP A SHORT LENGTH OF OVERSHEATH OVER THE

WITH A 50% OVERLAP. COVER THE COMPLETE JOINT AREA

EXPOSED CORE SCREEN. WRAP ONE LAYER OF COPPER MESH

INCLUDING THE MECHANICIAL SHIELD CONNECTOR.

AROUND THE JOINT WITH A 50% OVERLAP DO THAT THE WHOLE JOINT

AREA IS COVERED FROM INNER SHEATH TO INNER SHEATH.

15 18 21

INNER SHEATH

CUT

CLEAN AND DEGREASE THE INNER SHEATH.

CENTRE THE OUTER SLEEVE (BLACK) OVER THE COPPER MESH AREA. WRAP THE ROLL SPRING AROUND THE END OF THE MESH IN THE SAME

CABLE SIDE WITH LONG SHIELD WIRES: START IN THE CENTRE, WORKING TOWARDS THE END. DIRECTION AS THE FLAP.

BEND THE SHIELD WIRES BACK OVER THE JOINT AREA. TIGHTEN THE ROLL SPRING WITH A TWISTING ACTION AND COVER WITH

CABLE SIDE WITH SHORT SHIELD WIRES: THE COTTON FABRIC TAPE.

BEND THE SHIELD WIRES BACK OVER THE JOINT AREA CLOSE TO THE

COPPER MESH.

GATHER THE WIRES TOGETHER AND CUT THEM IN PREPARATION FOR JOINING.

16 19 22 COTTON FABRIC TAPE

CENTRE THE TERMIMESH SLEEVE OVER THE JOINT WITH THE SEAM ON TOP.

THE SLEEVE SHOULD OVERLAP THE NYLON SHEATH EQUALLY ON BOTH

REPEAT 19 AND 21 ON THE OTHER SIDE OF THE JOINT.

SIDES OF THE JOINT. CUT THE TERMIMESH SLEEVE TO BE FLUSH WITH THE

INSERT EACH END INTO THE MECHANICAL SHIELD CONNECTOR SUPPLIED. NYLON OVERSHEATH CUTBACK.

THE EXCESS MESH IN THE CENTRE OF THE JOINT SHOULD BE

TIGHTEN THE BOLTS WITH AN ALLEN KEY UNTIL THE HEADS SHEAR OFF. NOTE: THE MESH SHOULD NOT OVERLAP ONTO THE OVERSHEATH.

FOLDED OVER AND HELD IN PLACE USING THE COTTON FABRIC TAPE.

NOTE: THE CONNECTOR SHOULD BE POSITIONED IN THE AREA PULL BACK THE MESH UP AGAINST THE CORE.

ABOVE THE SHORT LENGTH OF THE OVERSHEATH. SQUEEZE THE MESH TOGETHER ON TOP OF THE CABLE TO

FORM A FLAP.

DES R.S. POWER STANDARD DRAWING

DRN K.I

CABLE JOINTING & TERMINATION

CKD R.S.

RAYCHEM CABLE JOINING KIT FOR SINGLE

APPD S.C.

CORE CABLE WITH SHEAR BOLT CONNECTOR

SCALE N.T.S.

1 SUPERSEDED A.T. DEC’12 B.C. B.C.

B RE-ISSUED FOR COMMENTS K.I. 11-4-07 R.S. S.C. ISSUED MAR’07 DRAWING S02-2-2-49

NO DESCRIPTION DRN DATE CKD APPD ALL DIM. IN mm

A3 NUMBER (SHEET 4 OF 5) 1

AMENDMENTS DRAFTING STANDARD TO A.S.1100 CAD PRODUCT DO NOT AMEND MANUALLY AMDT

A3 297 X 420

23

CLEAN AND DEGREASE THE OVERSHEATH.

CENTRE THE OUTER SLEEVE (BLACK) OVER THE JOINT AREA.

START SHRINKING IN THE CENTRE, WORKING TOWARDS THE END.

INSTALL THE ROLL SPRING IN THE SAME DIRECTION AS THE MASH FLAP.

REPEAT THE ABOVE PROCEDURE ON THE OTHER SIDE OF THE JOINT.

24

JOINT COMPLETED.

ALLOW THE JOINT TO COOL BEFORE APPLYING ANY MECHANICAL STRAIN.

DES R.S. POWER STANDARD DRAWING

DRN K.I

CABLE JOINTING & TERMINATION

CKD R.S.

RAYCHEM CABLE JOINING KIT FOR SINGLE

APPD S.C.

CORE CABLE WITH SHEAR BOLT CONNECTOR

SCALE N.T.S.

1 SUPERSEDED A.T. DEC’12 B.C. B.C.

B RE-ISSUED FOR COMMENTS K.I. 11-4-07 R.S. S.C. ISSUED MAR’07 DRAWING S02-2-2-49

NO DESCRIPTION DRN DATE CKD APPD ALL DIM. IN mm

A3 NUMBER (SHEET 5 OF 5) 1

AMENDMENTS DRAFTING STANDARD TO A.S.1100 CAD PRODUCT DO NOT AMEND MANUALLY AMDT

A3 297 X 420

You might also like

- Lexus - GS300 - GS430 - Service - Manual 8Document88 pagesLexus - GS300 - GS430 - Service - Manual 8seregap8477% (13)

- Load Test On Series GeneratorDocument3 pagesLoad Test On Series Generatorkudupudinagesh88% (8)

- DALINO COMMERCIAL BUILDING - PLUMBING PLANDocument4 pagesDALINO COMMERCIAL BUILDING - PLUMBING PLANDenise DaneNo ratings yet

- General Notes & Specifications Load Schedule: StudentDocument1 pageGeneral Notes & Specifications Load Schedule: StudentAngelica NoquiaoNo ratings yet

- 26tdo043 Rbs (Exp Lte 15 20m Act l21 10m Add U21) Sid Ovly4g HwiDocument7 pages26tdo043 Rbs (Exp Lte 15 20m Act l21 10m Add U21) Sid Ovly4g HwiNurhayani Maiwa MatajangNo ratings yet

- Grounding Principle 3P-0036CDocument2 pagesGrounding Principle 3P-0036CAsif Majeed MalikNo ratings yet

- Plc Panel LayoutDocument1 pagePlc Panel LayoutMuhamad Faisul SulaimanNo ratings yet

- Injection Quill Instruction Sheet: Instructions For UseDocument1 pageInjection Quill Instruction Sheet: Instructions For UsesalcedopozasNo ratings yet

- ELECTRICAL MODEL SONCIO For A3 - E2-ModelDocument1 pageELECTRICAL MODEL SONCIO For A3 - E2-ModelChris ChanNo ratings yet

- Plumbing PlansDocument12 pagesPlumbing PlansEarl Darenz ZamoraNo ratings yet

- 16inchx 40.49MMDocument7 pages16inchx 40.49MMTechnical A-Star Testing & Inspection MalaysiaNo ratings yet

- Load Schedule Legend: Symbol DescriptionDocument1 pageLoad Schedule Legend: Symbol Descriptionzab04148114No ratings yet

- 02 SLAB MORENA FINAL SOIL SLAB-ModelDocument1 page02 SLAB MORENA FINAL SOIL SLAB-ModelShashikanthNo ratings yet

- Weekly Performance Calculation Report: Work Package: Fire ProtectionDocument10 pagesWeekly Performance Calculation Report: Work Package: Fire ProtectionnurfansyahNo ratings yet

- Drawing - 5000103556 - Reverie Power Bangladesh VBFNew 05 NosDocument18 pagesDrawing - 5000103556 - Reverie Power Bangladesh VBFNew 05 NosAl ImranNo ratings yet

- Everflow Performance Data November 2012Document44 pagesEverflow Performance Data November 2012Todd MolloyNo ratings yet

- EE - 02 (Revised) MalawaanDocument1 pageEE - 02 (Revised) MalawaanArnulfo Jose Pi DiNo ratings yet

- Typical Pump Installation Details: Iranian Petroleum StandardsDocument4 pagesTypical Pump Installation Details: Iranian Petroleum StandardsMahdiNo ratings yet

- Schematic DiagramDocument1 pageSchematic DiagramJoenyl Fernand CaingcoyNo ratings yet

- Typ. Computation of Load For Unit-1 & Unit 2 General Notes LegendsDocument1 pageTyp. Computation of Load For Unit-1 & Unit 2 General Notes LegendsRaniel Mark CastilloNo ratings yet

- Electrical Schedule and WiringDocument1 pageElectrical Schedule and WiringJeremy BuelbaNo ratings yet

- s333Document3 pagess333Alaa MansourNo ratings yet

- Vicinity Map: Panelboard-1 DesignationDocument1 pageVicinity Map: Panelboard-1 DesignationMatty IgtibenNo ratings yet

- Heavy Duty Electric Quick Reference ManualDocument2 pagesHeavy Duty Electric Quick Reference ManualFrancisco Ramírez TorresNo ratings yet

- Automatic Vent Station For Pipeline 8" Section B-B 1:50 Manual Vent Station For Pipeline 8" Section B-B 1:50Document1 pageAutomatic Vent Station For Pipeline 8" Section B-B 1:50 Manual Vent Station For Pipeline 8" Section B-B 1:50nawajhaNo ratings yet

- The Site: Electrical LegendsDocument1 pageThe Site: Electrical LegendsRenzelNo ratings yet

- s333Document3 pagess333Alaa MansourNo ratings yet

- Maska Catalog QD BushingDocument1 pageMaska Catalog QD Bushingkman548No ratings yet

- General Notes: As-Built Plan of One Storey Abdulin Store BuildingDocument1 pageGeneral Notes: As-Built Plan of One Storey Abdulin Store BuildingMark Ruby OpawonNo ratings yet

- Harn-Eng Isx15 2013 Bc (1)Document6 pagesHarn-Eng Isx15 2013 Bc (1)lzsemideyNo ratings yet

- Asher Garcia Plumbing - E1Document1 pageAsher Garcia Plumbing - E1Jayvee DividinaNo ratings yet

- Amphenol - 05022017 - TP 101 CP 1156596Document2 pagesAmphenol - 05022017 - TP 101 CP 1156596Fredson SidileneNo ratings yet

- Drawing1-Model pdf2Document1 pageDrawing1-Model pdf2KennethNo ratings yet

- ELLIPTICAL SPIRAL DUCTABLE LAYOUT FOR THE ROCKS-23-ModelDocument1 pageELLIPTICAL SPIRAL DUCTABLE LAYOUT FOR THE ROCKS-23-ModelAbdullah.N FAAliNo ratings yet

- Feman ABC Cable EquipmentDocument51 pagesFeman ABC Cable EquipmentousseynouNo ratings yet

- A3 PRINT COUPON Jed ModelDocument1 pageA3 PRINT COUPON Jed ModelRicher FinezNo ratings yet

- Evel Ommand With OmpressorDocument4 pagesEvel Ommand With Ompressortesslik SlavaNo ratings yet

- ET RCC Pavement DetailDocument1 pageET RCC Pavement DetailSaahil BaderNo ratings yet

- Slotdrain REINFORCEMENT - DETAILSDocument1 pageSlotdrain REINFORCEMENT - DETAILSSlavisa LukovicNo ratings yet

- SCHED TEMPLATE For A3-E3Document1 pageSCHED TEMPLATE For A3-E3Chris ChanNo ratings yet

- Magazine & Magazine Drive AssemblyDocument13 pagesMagazine & Magazine Drive Assemblybodhas8924No ratings yet

- Canal Milano 100x65-250 37kw, 2pole - r1Document1 pageCanal Milano 100x65-250 37kw, 2pole - r1rizky anugrahNo ratings yet

- Manuel Grue Ro Stringer-Tc150-2Document2 pagesManuel Grue Ro Stringer-Tc150-2Jean calvin KuateNo ratings yet

- AQC 600x600 1F 352 197 AQC 600x600 2F 276 197 AQC 600x600 3F 202 247 AQC 600x600 4F 127 247Document2 pagesAQC 600x600 1F 352 197 AQC 600x600 2F 276 197 AQC 600x600 3F 202 247 AQC 600x600 4F 127 247jazminNo ratings yet

- Diaz8 PDocument1 pageDiaz8 Pjesus lastNo ratings yet

- ITT American Electric Bay Beam Luminaire Series 56-57-156-157 Spec Sheet 9-81Document12 pagesITT American Electric Bay Beam Luminaire Series 56-57-156-157 Spec Sheet 9-81Alan MastersNo ratings yet

- MAKABUTAS-macabutas 4Document1 pageMAKABUTAS-macabutas 4Alex SatorreNo ratings yet

- Piusi Usa Ocio 20 - enDocument2 pagesPiusi Usa Ocio 20 - enJaime MunozNo ratings yet

- 2 Detail2Document1 page2 Detail2Opendi CharlesNo ratings yet

- 12kV VCB-ABB India PVT LTDDocument18 pages12kV VCB-ABB India PVT LTDSuMit MisHraNo ratings yet

- MRP 17-02-23Document2 pagesMRP 17-02-23sivagaaneshNo ratings yet

- Power Auxiliary LayoutDocument1 pagePower Auxiliary LayoutIvyNo ratings yet

- Isolation Unit (Poblacion) - Final-ModelDocument1 pageIsolation Unit (Poblacion) - Final-ModelEmman De los ReyesNo ratings yet

- General Notes: 2 Installation DetailDocument1 pageGeneral Notes: 2 Installation DetailMary FelicianoNo ratings yet

- General Notes: 2 Installation DetailDocument1 pageGeneral Notes: 2 Installation DetailMary FelicianoNo ratings yet

- Cathelco: Anode Length 100 8Document1 pageCathelco: Anode Length 100 8hakkıNo ratings yet

- EE9AL EE5D Celestial Mendoza PDF File 1Document8 pagesEE9AL EE5D Celestial Mendoza PDF File 1jenixson tamondongNo ratings yet

- Everyday Electronics 1975 12Document5 pagesEveryday Electronics 1975 12marcosscarato0% (1)

- Aa 036678 001Document1 pageAa 036678 001abou bakarNo ratings yet

- Ign Rfa Mep CSD 010.4Document1 pageIgn Rfa Mep CSD 010.4Abdul KarimNo ratings yet

- Australian Wood Review - December 2022Document84 pagesAustralian Wood Review - December 2022elmanpadillaNo ratings yet

- Te Terminais AluminioDocument2 pagesTe Terminais AluminioiamlpNo ratings yet

- H Proc Notices Notices 040 K Notice Doc 36620 666102031Document7 pagesH Proc Notices Notices 040 K Notice Doc 36620 666102031iamlpNo ratings yet

- Te Terminais CobreDocument2 pagesTe Terminais CobreiamlpNo ratings yet

- Industrial Batteries / Network Power: Sonnenschein A600Document16 pagesIndustrial Batteries / Network Power: Sonnenschein A600iamlpNo ratings yet

- Abb Spa COMEM Operating UnitDocument8 pagesAbb Spa COMEM Operating UnitiamlpNo ratings yet

- Annex A Technical Specification: OF 400V (750KVA) DIESELDocument10 pagesAnnex A Technical Specification: OF 400V (750KVA) DIESELiamlpNo ratings yet

- Power Cable Accessories: Catalogue 2006/2007Document11 pagesPower Cable Accessories: Catalogue 2006/2007iamlpNo ratings yet

- Tyco Joints Single Core Unarmoured XlpeDocument4 pagesTyco Joints Single Core Unarmoured XlpeiamlpNo ratings yet

- Cabelte Catalogo v7Document304 pagesCabelte Catalogo v7iamlpNo ratings yet

- ISO-TP Low Voltage Insulators, Metric Thread - ISOTP75M10 (548629)Document2 pagesISO-TP Low Voltage Insulators, Metric Thread - ISOTP75M10 (548629)iamlpNo ratings yet

- EFACEC FluofixManualDocument30 pagesEFACEC FluofixManualiamlpNo ratings yet

- BOLT LOCK Single Key Entry: FeaturesDocument6 pagesBOLT LOCK Single Key Entry: FeaturesiamlpNo ratings yet

- Erico - PCB Plain Copper Busbar - PCB-4M-40X5 (550630)Document1 pageErico - PCB Plain Copper Busbar - PCB-4M-40X5 (550630)iamlpNo ratings yet

- BOLT LOCK Single Key Entry: FeaturesDocument2 pagesBOLT LOCK Single Key Entry: FeaturesiamlpNo ratings yet

- Catalogue Interlocking RONISDocument45 pagesCatalogue Interlocking RONISiamlpNo ratings yet

- Product CAT BLMT - DatasheetDocument8 pagesProduct CAT BLMT - DatasheetiamlpNo ratings yet

- Hager General Catalogue 2016Document404 pagesHager General Catalogue 2016iamlpNo ratings yet

- Molded Rubber Test Report 2009-124Document28 pagesMolded Rubber Test Report 2009-124iamlpNo ratings yet

- 7673-S-8 IEEE Cert Test Report 4 - 2012Document31 pages7673-S-8 IEEE Cert Test Report 4 - 2012iamlpNo ratings yet

- 3M™ Cold Shrink QT-III Silicone Rubber Termination 7673-S-8-JCNDocument10 pages3M™ Cold Shrink QT-III Silicone Rubber Termination 7673-S-8-JCNiamlpNo ratings yet

- T Echnik Î D: Cable ClampsDocument2 pagesT Echnik Î D: Cable ClampsiamlpNo ratings yet

- How To Design Isolated CAN Systems With Correct Bus ProtectionDocument11 pagesHow To Design Isolated CAN Systems With Correct Bus ProtectionWee Chuan PoonNo ratings yet

- Belt-Drive Lecture Note 1Document44 pagesBelt-Drive Lecture Note 1Peter Owusu50% (2)

- ASHARE 36 Aee - April - 2021 - Ashrae - Guideline - 36Document42 pagesASHARE 36 Aee - April - 2021 - Ashrae - Guideline - 36Mike KennedyNo ratings yet

- Determination of Transformer Equivalent Circuit Parameters of A SingleDocument18 pagesDetermination of Transformer Equivalent Circuit Parameters of A SingleHaytham Kenway0% (1)

- Device Lab Report 10 PDFDocument6 pagesDevice Lab Report 10 PDFScribble RiYaDNo ratings yet

- GE105 Basics of Engineering and Technology-Introduction to Workshop - compressed.pdf ورشةDocument44 pagesGE105 Basics of Engineering and Technology-Introduction to Workshop - compressed.pdf ورشةعبدالله عبدالعزيزNo ratings yet

- Series N55B and LFN55B Installation InstructionsDocument2 pagesSeries N55B and LFN55B Installation InstructionsWattsNo ratings yet

- Robotics Write UpDocument19 pagesRobotics Write UpLarriie MayNo ratings yet

- Qicc MV Power CableDocument150 pagesQicc MV Power CableRaja MariyappanNo ratings yet

- Nemio XG Service ManualDocument127 pagesNemio XG Service ManualMULTIMED ENGINEERINGNo ratings yet

- White Paper Encoder Mounting 9-4-13Document4 pagesWhite Paper Encoder Mounting 9-4-13baaakNo ratings yet

- Mitsubishi Heavy Ac CatelogueDocument84 pagesMitsubishi Heavy Ac CatelogueYash JaisingNo ratings yet

- Zelio Control Relays - RM22TR33Document7 pagesZelio Control Relays - RM22TR33SIVARAMANJAGANATHANNo ratings yet

- Electric Scooter: Name Class TD1 Remarks TD2 Remarks TD3 RemarksDocument9 pagesElectric Scooter: Name Class TD1 Remarks TD2 Remarks TD3 RemarksJornel MandiaNo ratings yet

- Basic Components: CNC ControlsDocument34 pagesBasic Components: CNC ControlsShelton HodzieszNo ratings yet

- 2014 Subaru XV Crosstrek 88570 PDFDocument482 pages2014 Subaru XV Crosstrek 88570 PDFjuan arenasNo ratings yet

- UPSDocument6 pagesUPSTanmoy AcharyaNo ratings yet

- Freightliner CASCADIA 125Document1 pageFreightliner CASCADIA 125Diego GuerreroNo ratings yet

- Koganei Air-Piloted Valves FeaturesDocument4 pagesKoganei Air-Piloted Valves Featuresluthfie4uNo ratings yet

- Fuel Oil Service SystemDocument14 pagesFuel Oil Service Systemair1111No ratings yet

- Landcruiser 200: King Off The RoadDocument29 pagesLandcruiser 200: King Off The Roadengkj0% (1)

- Toshiba - Manual For Service Version 2.2Document72 pagesToshiba - Manual For Service Version 2.2VolvoxdjNo ratings yet

- 1996 OKI LCD Driver Controller DatabookDocument232 pages1996 OKI LCD Driver Controller Databookpiptendo100% (1)

- G210 (16 Speeds) CEI MERCEDES-4-307-165-174Document10 pagesG210 (16 Speeds) CEI MERCEDES-4-307-165-174mm6088873No ratings yet

- GSM Based Home Automation SystemDocument65 pagesGSM Based Home Automation SystemARDthon Technologies SpantechologiesNo ratings yet

- Optical System Performance of Large-Scale Photonic Integrated CircuitsDocument4 pagesOptical System Performance of Large-Scale Photonic Integrated CircuitsJuan Pablo RodríguezNo ratings yet

- X20 Breakout Board ManualDocument2 pagesX20 Breakout Board ManualjanwerbinskiNo ratings yet

- PX 3004Document27 pagesPX 3004abung teaNo ratings yet