Professional Documents

Culture Documents

Statistical Process Control Study: CP CPK Remarks: Process Is Accepted

Statistical Process Control Study: CP CPK Remarks: Process Is Accepted

Uploaded by

Sanjeev ChakrobortyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Statistical Process Control Study: CP CPK Remarks: Process Is Accepted

Statistical Process Control Study: CP CPK Remarks: Process Is Accepted

Uploaded by

Sanjeev ChakrobortyCopyright:

Available Formats

Doc.

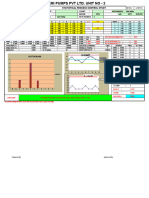

NO - HOU/QA/14

STATISTICAL PROCESS CONTROL STUDY Rev. No - ………….

Rev.Date - ………….

Issue Date - 21.03.21

PART NAME: CAM SEAT LOCK (KWPA) INSTRUMENT: DVC L.COUNT: 0.01

PART NO.: 40134-00-02 SPECIFICATION: 6.20 ± 0.20 MACHINE: INJECTION MOULDING

SAMPLE SIZE: 125 NO OPERATION: Injection Moulding Date 05.06.21

USL 6.40 RANGE

X - CHART X- R - CHART HISTOGRAM DIFF. 0.4 0.033

CHART LSL 6.00 FOR 12

UCL AVG LCL 6.240 UCL AVG LCL RANGE 43

FREQ. HISTOGRAM

6.236 6.234 6.116 0.020 0.010 0.010 FIRST LAST

6.200

RANGE

6.236 6.214 6.116 0.020 0.010 0.010 6.00 6.03 0 0

6.160 50.00

6.236 6.158 6.116 0.020 0.020 0.010 6.03 6.07 0 0

6.236 6.232 6.116 6.120 0.020 0.010 0.010 6.07 6.10 0 0 40.00

Column A

6.236 6.232 6.116 6.080 Column B 0.020 0.020 0.010 6.10 6.13 17 17 30.00

6.236 6.164 6.116 Column C 0.020 0.010 0.010 6.13 6.17 31 31 20.00

6.040

6.236 6.174 6.116 1 3 5 7 9 0.020 0.010 0.010 6.17 6.20 12 12

11 13 15 17 19 21 23 25 10.00

6.236 6.134 6.116 0.020 0.010 0.010 6.20 6.23 47 47

6.116 6.23 6.27 17 0.00

6.236 6.232 0.020 0.020 0.010 17

SAMPLES 1 2 3 4 5 6 7 8 9

6.236 6.234 6.116 0.020 0.010 0.010 6.27 6.30 0 0 10 11 12

6.236 6.214 6.116 0.020 0.010 0.010 6.30 6.33 0 0

6.236 6.158 6.116 0.020 0.020 0.010 6.33 6.37 0 0

6.236 6.116 6.116 0.020 0.010 0.010 6.37 6.40 0 0

6.116 R - CHART

6.236 6.210 0.020 0.020 0.010

6.116 0.025 CALCULATION FOR Cp/Cpk

6.236 6.236 0.020 0.010 0.010

6.236 6.214 6.116 0.020 0.010 0.010 FOR N - SAMPLE SIZE = 5

6.236 6.158 6.116 0.020 0.020 0.020 0.010 A2 D3 D4 d2

CONSTANT :

6.236 6.134 6.116 0.020 0.010 0.010 0.577 0 2.114 2.325

6.116 0.015

RANGE

6.236 6.234 UCL 0.020 0.020 0.010

6.236 6.234 6.116 AVG 0.020 0.010 0.010 154.712 0.350

0.010 X = 6.188 R= 0.0139999999999998

6.236 6.214 6.116 LCL 0.020 0.010 0.010 25 25

6.236 6.158 6.116 0.020 0.020 0.010 0.014 A2.R = 0.577

6.236 6.134 6.116 0.005 0.020 0.010 0.010

s = R / d2 2.325

0.006

X

0.014 0.008

6.236 6.228 6.116 0.020 0.020 0.010

0.000 UCLX = X + A2.R 6.197 UCLR = D4 .R 0.030

6.236 6.160 6.116 0.020 0.020 0.010

1 2 3 4 5 6 7 8 9 1 1 1 1 1 1 1 1 1 1 2 2 2 2 2 2

Graphical X UCL 6.236 0 1 2 3 4 5 6 7 8 9 0 1 2 3 4 5 Graphical R UCL 0.020

SAMPLES LCLX = X - A2.R 6.180 LCLR = D3 .R 0.000

Graphical X LCL 6.116 Graphical R LCL 0.010

T = TOTAL TOLERANCE

PROCESS CAPABILITY IS EXCELLENT Cp 11.071 Cp = T/ 6 s 11.07 ( USL-LSL )

0.4

PROCESS CAPABILITY INDEX IS EXCELLENT Cpk 10.434 Cpk = ( USL X - X )/ 3 s 11.71 FOR Cpk TAKE MINIMUM VALUE FOR BOTH SIDE

TOLERANCE & FOR SINGLE SIDE TOLERANE DO

Remarks : Process is accepted Cpk = ( X - LSL X )/ 3 s 10.43 NOT CONSIDER MINIMUM VALUE.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

X1 6.23 6.21 6.17 6.13 6.24 6.16 6.18 6.13 6.24 6.24 6.21 6.17 6.11 6.21 6.24 6.21 6.17 6.14 6.24 6.23 6.21 6.17 6.13 6.22 6.15

X2 6.24 6.22 6.15 6.14 6.23 6.17 6.17 6.14 6.23 6.23 6.22 6.15 6.12 6.21 6.24 6.22 6.15 6.13 6.24 6.24 6.22 6.15 6.14 6.23 6.16

X3 6.24 6.21 6.16 6.14 6.22 6.17 6.17 6.14 6.22 6.24 6.21 6.16 6.12 6.20 6.24 6.21 6.16 6.14 6.22 6.24 6.21 6.16 6.14 6.22 6.17

X4 6.23 6.22 6.15 6.13 6.24 6.16 6.17 6.13 6.24 6.23 6.22 6.15 6.12 6.22 6.23 6.22 6.15 6.13 6.24 6.23 6.22 6.15 6.13 6.24 6.16

X5 6.23 6.21 6.16 6.13 6.23 6.16 6.18 6.13 6.23 6.23 6.21 6.16 6.11 6.21 6.23 6.21 6.16 6.13 6.23 6.23 6.21 6.16 6.13 6.23 6.16

SX 31.170 31.070 30.790 30.670 31.160 30.820 30.870 30.670 31.160 31.170 31.070 30.790 30.580 31.050 31.180 31.070 30.790 30.670 31.170 31.170 31.070 30.790 30.670 31.140 30.800

X 6.234 6.214 6.158 6.134 6.232 6.164 6.174 6.134 6.232 6.234 6.214 6.158 6.116 6.210 6.236 6.214 6.158 6.134 6.234 6.234 6.214 6.158 6.134 6.228 6.160

R 0.010 0.010 0.020 0.010 0.020 0.010 0.010 0.010 0.020 0.010 0.010 0.020 0.010 0.020 0.010 0.010 0.020 0.010 0.020 0.010 0.010 0.020 0.010 0.020 0.020

You might also like

- SPC L.O.I %Document2 pagesSPC L.O.I %Dhananjay PatilNo ratings yet

- 1 Informe San Rafael Febrero .Document1 page1 Informe San Rafael Febrero .Evelyn BasilioNo ratings yet

- SBVT - Ils U or Loc U Rwy 24 - Iac - 20231130Document1 pageSBVT - Ils U or Loc U Rwy 24 - Iac - 20231130João Pedro Santos da CruzNo ratings yet

- Expensas 07-2023 Pag 4Document1 pageExpensas 07-2023 Pag 4maria veraNo ratings yet

- Ilovepdf MergedDocument13 pagesIlovepdf MergedChoque Villca JuanNo ratings yet

- 1 No. Ver Bracing Required As Drawn MKD' - 2Vb-36: Bolt List For Assembly MKD' 2Vb-36 X 1 Dia. Qty. Bolt GradeDocument1 page1 No. Ver Bracing Required As Drawn MKD' - 2Vb-36: Bolt List For Assembly MKD' 2Vb-36 X 1 Dia. Qty. Bolt Grademo3azNo ratings yet

- Current Revision Approved: C'Shaft Box Assy, 68H/SbsDocument2 pagesCurrent Revision Approved: C'Shaft Box Assy, 68H/Sbscapslive_001100% (1)

- FC-280SC: Output: 0.1W 4.0W (Approx)Document1 pageFC-280SC: Output: 0.1W 4.0W (Approx)Jordi MarsàNo ratings yet

- Crown Block Type Continental EmscoDocument19 pagesCrown Block Type Continental Emscorigsme032No ratings yet

- FR23-036 MTCDocument1 pageFR23-036 MTCPércy RodriguezNo ratings yet

- CV Equations Used in HysysDocument3 pagesCV Equations Used in HysysBesan LaduNo ratings yet

- Metrados Tanques T-480Document7 pagesMetrados Tanques T-480Leonardo Flores CaleroNo ratings yet

- MS-R6-1 - COLUMN - Rev 00b (Rack - 6)Document1 pageMS-R6-1 - COLUMN - Rev 00b (Rack - 6)Muhammad YousufNo ratings yet

- Instruction Manual: Turbine Flow SensorDocument20 pagesInstruction Manual: Turbine Flow Sensornew587No ratings yet

- T9-Catalogo Tecnico Alberi Scanalati e BoccoleDocument4 pagesT9-Catalogo Tecnico Alberi Scanalati e BoccoleAlberto Paico LinarezNo ratings yet

- Birla Institute of Technology, Mesra, Ranchi - 835215 (India) Submit QueryDocument2 pagesBirla Institute of Technology, Mesra, Ranchi - 835215 (India) Submit Queryvivek kumarNo ratings yet

- Process Capability Analysis: Rohtas Fasteners PVT - LimitedDocument2 pagesProcess Capability Analysis: Rohtas Fasteners PVT - LimitedVikas KashyapNo ratings yet

- Expensas 06-2023 Pag 4Document1 pageExpensas 06-2023 Pag 4maria veraNo ratings yet

- Khanay 2 Working Drawing Final 31.01.2022Document1 pageKhanay 2 Working Drawing Final 31.01.2022Mayur ChauhanNo ratings yet

- List of TablesDocument33 pagesList of TablesRizka Dwi FauziNo ratings yet

- Baroda Stock Audit ReportDocument4 pagesBaroda Stock Audit Reportjayesh jarwaniNo ratings yet

- Navsea s0600 Aa Pro 060Document147 pagesNavsea s0600 Aa Pro 060opruzhak-boxNo ratings yet

- SPC Afs No.Document2 pagesSPC Afs No.Dhananjay PatilNo ratings yet

- Min Max Ok EksekutifDocument43 pagesMin Max Ok Eksekutifratih83No ratings yet

- DPR Oq Pipemill 19 May 2021Document125 pagesDPR Oq Pipemill 19 May 2021kbpatel123No ratings yet

- Two - Phase Line Sizing GelamDocument5 pagesTwo - Phase Line Sizing GelamElias EliasNo ratings yet

- HCU 2 Fan Submittal R1Document1 pageHCU 2 Fan Submittal R1Dirt FilterNo ratings yet

- Retail Price List - May2023Document56 pagesRetail Price List - May2023Shoeb MdNo ratings yet

- Sae08 2Document1 pageSae08 2pavankumarNo ratings yet

- Progress Report 27.06.23 PT - Taro Rakaya Tasyra (Boiler)Document2 pagesProgress Report 27.06.23 PT - Taro Rakaya Tasyra (Boiler)Teknik Informatika VINA AZIZAHNo ratings yet

- Accumulator Catalogue 2016 HY10 4004 Rev6Document224 pagesAccumulator Catalogue 2016 HY10 4004 Rev6szystNo ratings yet

- Report IgfDocument38 pagesReport IgfMiftah MasrurNo ratings yet

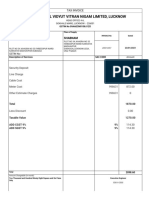

- Madhyanchal Vidyut Vitran Nigam Limited, Lucknow: Shabnam ShabnamDocument2 pagesMadhyanchal Vidyut Vitran Nigam Limited, Lucknow: Shabnam ShabnamYadav Manish KumarNo ratings yet

- Apron N Perimeter DrainDocument4 pagesApron N Perimeter Drainbuloque 86No ratings yet

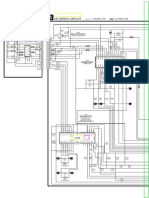

- Schematic Diagram - 1: Q701 2SA1037AKSTXDocument14 pagesSchematic Diagram - 1: Q701 2SA1037AKSTXKarloNo ratings yet

- X5000 Gas Detector - Drawing-ENDocument6 pagesX5000 Gas Detector - Drawing-ENpasckyNo ratings yet

- TABLA SAN KARMANDA FinalDocument84 pagesTABLA SAN KARMANDA FinalHugo PeraltaNo ratings yet

- LJULJADocument2 pagesLJULJAnebojsas.No ratings yet

- Total Rincian TGL 20 (5c)Document1 pageTotal Rincian TGL 20 (5c)rian qnetNo ratings yet

- c21 I y II Dist Por Camp de Los Vol Exp Al BR 2009 PDFDocument2 pagesc21 I y II Dist Por Camp de Los Vol Exp Al BR 2009 PDFMiguel Angel Apaza Q.No ratings yet

- Metering Class Current Transformer: Features 600V Class SpecificationsDocument1 pageMetering Class Current Transformer: Features 600V Class SpecificationsDavid RojasNo ratings yet

- InvoiceDocument1 pageInvoicelakhan jethaniNo ratings yet

- SPC (Dim 4)Document1 pageSPC (Dim 4)shobha shelarNo ratings yet

- Tablas de CloacasDocument38 pagesTablas de CloacasHector Leonardo PerazaNo ratings yet

- Rheo Coupling 4 TestsDocument1 pageRheo Coupling 4 TestsSandeep BhutadaNo ratings yet

- Report NSF ADocument38 pagesReport NSF AMiftah MasrurNo ratings yet

- WW Linear Veneered Planks Master SheetDocument2 pagesWW Linear Veneered Planks Master SheetChiara NaderNo ratings yet

- Rutin STD - Rawdata Blanko - RawdataDocument1 pageRutin STD - Rawdata Blanko - RawdataM Zainuddin M SaputraNo ratings yet

- Rebar Quantity - Cleres&mech DeckDocument5 pagesRebar Quantity - Cleres&mech DeckJohn Ricky Exequiel CalaraNo ratings yet

- Customer 1Document1 pageCustomer 1api-345772423No ratings yet

- End of Run Analysis Report: Chart TitleDocument1 pageEnd of Run Analysis Report: Chart Titleapi-345772423No ratings yet

- Quality Control ChartDocument15 pagesQuality Control Chart4M CoatingsNo ratings yet

- Rreport NSF BDocument38 pagesRreport NSF BMiftah MasrurNo ratings yet

- Recuperacion 2da Unidad-Alarcon YeysonDocument19 pagesRecuperacion 2da Unidad-Alarcon YeysonYeyson Alarcon AmachiNo ratings yet

- EST2751Document2 pagesEST2751subin sujathanNo ratings yet

- AnilBhai Mali at Deoder (Alt - 002) 11-02-2023Document1 pageAnilBhai Mali at Deoder (Alt - 002) 11-02-2023ARTI DEVLOPERNo ratings yet

- F-17 y F-18 Mov. de Almacen IIDocument110 pagesF-17 y F-18 Mov. de Almacen IIcarlosNo ratings yet

- Wa 380Document1 pageWa 380pablitoxNo ratings yet

- EST2738Document2 pagesEST2738subin sujathanNo ratings yet

- Training Calnder-QC FINAL CHECKERDocument3 pagesTraining Calnder-QC FINAL CHECKERSanjeev ChakrobortyNo ratings yet

- Record of Fire Fighting Equipments: RefillingDocument2 pagesRecord of Fire Fighting Equipments: RefillingSanjeev ChakrobortyNo ratings yet

- Monthly Analysis Report UpdatedDocument58 pagesMonthly Analysis Report UpdatedSanjeev ChakrobortyNo ratings yet

- Display June '19 - Maruti AuditDocument2 pagesDisplay June '19 - Maruti AuditSanjeev ChakrobortyNo ratings yet

- Grade 6 EnglishDocument249 pagesGrade 6 Englishgetacheweyob74No ratings yet

- Internal Control PSA315Document8 pagesInternal Control PSA315John Lexter Macalber100% (1)

- ICT in Teaching LearningDocument3 pagesICT in Teaching LearningElizalde PiolNo ratings yet

- GTB Jeremiah DownloadDocument87 pagesGTB Jeremiah DownloadEdwin PitangaNo ratings yet

- VSP Final ReportDocument53 pagesVSP Final ReportAnand GautamNo ratings yet

- Answers To Questions: MishkinDocument8 pagesAnswers To Questions: Mishkin?ᄋᄉᄋNo ratings yet

- Distance Learning Programme: Jee (Main) : Leader Test Series / Joint Package CourseDocument32 pagesDistance Learning Programme: Jee (Main) : Leader Test Series / Joint Package Coursekraken monsterNo ratings yet

- Synopsys Design Vision TutorialDocument23 pagesSynopsys Design Vision TutorialferrariNo ratings yet

- ICMsystem DS E102Document4 pagesICMsystem DS E102Renato CapeliniNo ratings yet

- Zhao - An Intertextual Approach To Translation at The Macro-LevelDocument9 pagesZhao - An Intertextual Approach To Translation at The Macro-LevelangielskiajNo ratings yet

- Tube To Tube SheetDocument9 pagesTube To Tube Sheetcmpatel_00100% (2)

- IDOT 2020 Bridge Design Updates - Revised PPC Beam DetailsDocument34 pagesIDOT 2020 Bridge Design Updates - Revised PPC Beam DetailsJoe AndrewsNo ratings yet

- Historia The FelidsDocument5 pagesHistoria The Felidsbalim01100% (1)

- Islamic Studies Grade 08Document342 pagesIslamic Studies Grade 08Aamir67% (3)

- Geography Sba FinalDocument22 pagesGeography Sba FinalPreciousNo ratings yet

- In Concrete ReportDocument1 pageIn Concrete ReportSophia AmbunanNo ratings yet

- Eadership and AnagementDocument1 pageEadership and AnagementAmol MahajanNo ratings yet

- Stan 2012Document4 pagesStan 2012Gerson OrtegaNo ratings yet

- 11 - PC8000 - 6 ApplDocument37 pages11 - PC8000 - 6 Appljhon jairo trujillo100% (1)

- HLB SME 1form (Original)Document14 pagesHLB SME 1form (Original)Mandy ChanNo ratings yet

- English For Academic and Professional Purposes Nov. 30-Dec 4Document5 pagesEnglish For Academic and Professional Purposes Nov. 30-Dec 4Princess Lynn Aquino PaduaNo ratings yet

- Answer Key For The 11th Grade English Final TestDocument1 pageAnswer Key For The 11th Grade English Final TestMyagmarsuren NyamtaivanNo ratings yet

- Marketing Moguls Gartons IIM Kashipur FinalsDocument22 pagesMarketing Moguls Gartons IIM Kashipur FinalsTarun SinghNo ratings yet

- RealVNC Enterprise Edition 4Document2 pagesRealVNC Enterprise Edition 4fannybrawijayaNo ratings yet

- Project 2 Wikipedia Project ReflectionDocument2 pagesProject 2 Wikipedia Project Reflectionapi-659259835No ratings yet

- Analyzer SiteHawkDocument2 pagesAnalyzer SiteHawknickNo ratings yet

- People v. RiveraDocument36 pagesPeople v. RiveraAemel de LeonNo ratings yet

- Desert Explorer1Document44 pagesDesert Explorer1Wes ChambersNo ratings yet

- Causation Syllabus 2016Document4 pagesCausation Syllabus 2016Hana CurcicNo ratings yet

- The Champion Legal Ads: 08-24-23Document53 pagesThe Champion Legal Ads: 08-24-23Donna S. SeayNo ratings yet