Professional Documents

Culture Documents

SECTION 15410 Plumbing Fixtures

SECTION 15410 Plumbing Fixtures

Uploaded by

Munir RasheedCopyright:

Available Formats

You might also like

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- BOP Drawings by Sections, RevDocument10 pagesBOP Drawings by Sections, RevberrouiNo ratings yet

- Simbologia Norma KKSDocument8 pagesSimbologia Norma KKSEsteban David L. PulgarinNo ratings yet

- Unit Cost Estimate: 1.0 MaterialsDocument30 pagesUnit Cost Estimate: 1.0 MaterialsGenevieve GayosoNo ratings yet

- ObjectiveDocument15 pagesObjectiveIkhmal FirdausNo ratings yet

- Lucius Learning Series - MOV Seismic Weak Link PDFDocument0 pagesLucius Learning Series - MOV Seismic Weak Link PDFDana GuerreroNo ratings yet

- SECTION 15175 Swimming Pool Piping and Equipment General 1.1Document14 pagesSECTION 15175 Swimming Pool Piping and Equipment General 1.1fatREVITNo ratings yet

- PDFDocument7 pagesPDFMuhammad Ali SakrNo ratings yet

- 224215, Commercial Plumbing FixturesDocument13 pages224215, Commercial Plumbing Fixturessrp. mohammed100% (1)

- Plumbing Fixtures StandardDocument12 pagesPlumbing Fixtures StandardPamela Joyce MaddumaNo ratings yet

- Plumbing FixturesDocument30 pagesPlumbing Fixturesadel rihanaNo ratings yet

- 224105, Residential Plumbing FixturesDocument15 pages224105, Residential Plumbing Fixturessrp. mohammedNo ratings yet

- Domestic Water SystemsDocument20 pagesDomestic Water Systemsabdullah sahibNo ratings yet

- Section 21 05 00Document6 pagesSection 21 05 00Ismail MohammadNo ratings yet

- Sanitary Waste and Vent Piping 15150Document15 pagesSanitary Waste and Vent Piping 15150Munir RasheedNo ratings yet

- 221005, Plumbing SpecialtiesDocument16 pages221005, Plumbing Specialtiessrp. mohammedNo ratings yet

- SECTION 15640 Packaged Cooling Towers General 1.1Document7 pagesSECTION 15640 Packaged Cooling Towers General 1.1Munir RasheedNo ratings yet

- ORK Ncluded Related Work Eferenced Tandards Ubmittals Eneral EquirementsDocument8 pagesORK Ncluded Related Work Eferenced Tandards Ubmittals Eneral EquirementsLui TCC BariaNo ratings yet

- Domestic Water Filtration EquipmentDocument10 pagesDomestic Water Filtration EquipmentElie HajjNo ratings yet

- 15440Document7 pages15440uddinnadeemNo ratings yet

- Plumbing SectionDocument16 pagesPlumbing SectionJanNo ratings yet

- Section 21 11 00Document10 pagesSection 21 11 00Ismail MohammadNo ratings yet

- SF - Domestic Water PipingDocument16 pagesSF - Domestic Water PipingJahat AtencioNo ratings yet

- 102113.17-Phenolic Core Toilet CompartmentsDocument6 pages102113.17-Phenolic Core Toilet Compartmentstaghreed shabanNo ratings yet

- SECTION 15190 Fuel Piping General 1.1Document14 pagesSECTION 15190 Fuel Piping General 1.1Munir RasheedNo ratings yet

- 22 40 00 - Plumbing FixturesDocument22 pages22 40 00 - Plumbing Fixturesmd zubairNo ratings yet

- Section 223200 - Domestic Water Treatment EquipmentDocument10 pagesSection 223200 - Domestic Water Treatment EquipmentniklausNo ratings yet

- Revised 4/2008Document10 pagesRevised 4/2008Richabson OsmanNo ratings yet

- Ductile Iron Pipe For Sewers 012221Document9 pagesDuctile Iron Pipe For Sewers 012221สุภรัตน์ จันทร์คุณาภาสNo ratings yet

- SECTION 15520 Feedwater Equipment General 1.1Document6 pagesSECTION 15520 Feedwater Equipment General 1.1fatREVITNo ratings yet

- Section 21 05 23Document6 pagesSection 21 05 23Ismail MohammadNo ratings yet

- 221119.fl - JR SmithDocument36 pages221119.fl - JR SmithSreekanthNo ratings yet

- Facility Sanitary SewersDocument14 pagesFacility Sanitary SewerssamNo ratings yet

- SECTION 13975 Standpipes and Hoses General 1.1: - Page 1 of 4Document4 pagesSECTION 13975 Standpipes and Hoses General 1.1: - Page 1 of 4fatREVITNo ratings yet

- Mep Spec8Document13 pagesMep Spec8fatREVITNo ratings yet

- 11/20/2018 /conversion/tmp/scratch/402494814Document13 pages11/20/2018 /conversion/tmp/scratch/402494814Anonymous NR3qZ30No ratings yet

- Domestic and Industrial Water Piping Guide DesignDocument7 pagesDomestic and Industrial Water Piping Guide DesignEddito Cacho100% (1)

- Project Standard Specification: Potable-Water Storage Tanks 15450 - Page 1/12Document12 pagesProject Standard Specification: Potable-Water Storage Tanks 15450 - Page 1/12adel rihanaNo ratings yet

- Section 15060 - Hangers and SupportsDocument9 pagesSection 15060 - Hangers and SupportsLuciano SalituriNo ratings yet

- SECTION 15120 Piping Specialties 1.1Document18 pagesSECTION 15120 Piping Specialties 1.1Munir RasheedNo ratings yet

- SECTION 15140 Domestic Water Piping General 1.1Document20 pagesSECTION 15140 Domestic Water Piping General 1.1Munir RasheedNo ratings yet

- SPC Occ 221319 MeDocument9 pagesSPC Occ 221319 Metarekhisham1234No ratings yet

- Water and ArregationDocument9 pagesWater and ArregationYasser FathiNo ratings yet

- PipingDocument7 pagesPipingAshar HassanNo ratings yet

- Project Standard Specification: Decorative Fountain 15495 - Page 1/7Document7 pagesProject Standard Specification: Decorative Fountain 15495 - Page 1/7adel rihanaNo ratings yet

- ITEM 615.01090003 - WATER FEATURE Scope of WorkDocument13 pagesITEM 615.01090003 - WATER FEATURE Scope of Workemiediray03No ratings yet

- 22 11 13 - Facility Water Distribution Piping PDFDocument11 pages22 11 13 - Facility Water Distribution Piping PDFmasoodaeNo ratings yet

- UtilitiesDocument31 pagesUtilitiesjia wangNo ratings yet

- FL - Ta2860 - Iff Otista - Toilet, Bath, and Laundry AccessoriesDocument5 pagesFL - Ta2860 - Iff Otista - Toilet, Bath, and Laundry AccessoriesBack to SumateraNo ratings yet

- Section 21 12 00Document3 pagesSection 21 12 00Ismail MohammadNo ratings yet

- Fuel Handling SystemDocument4 pagesFuel Handling SystemRoel FranciscoNo ratings yet

- SECTION 15440 Plumbing Pumps General 1.1Document6 pagesSECTION 15440 Plumbing Pumps General 1.1Munir RasheedNo ratings yet

- Elevated TanksDocument8 pagesElevated TanksChâu TúNo ratings yet

- Central-Station Air-Handling UnitsDocument4 pagesCentral-Station Air-Handling Unitssidparikh254No ratings yet

- Fire Protection SpecificationDocument34 pagesFire Protection Specification22-09441No ratings yet

- Section 15430 - Plumbing Specialties PDFDocument21 pagesSection 15430 - Plumbing Specialties PDFMahmoud GwailyNo ratings yet

- Bart Facilities StandardDocument8 pagesBart Facilities StandardBehnam AshouriNo ratings yet

- Pipe & Pipe FittingsDocument10 pagesPipe & Pipe FittingsSalim BakhshNo ratings yet

- Part 1 - General: SECTION 21 13 13 Wet-Pipe Sprinkler SystemsDocument16 pagesPart 1 - General: SECTION 21 13 13 Wet-Pipe Sprinkler SystemsNelson VargasNo ratings yet

- FL - Whitehall.CleanDocument59 pagesFL - Whitehall.CleanHossain TanjilaaNo ratings yet

- Toilet and Bath Accessories - MSTDocument7 pagesToilet and Bath Accessories - MSTwafikmh4No ratings yet

- 21 10 00 Fire Suppression SystemsDocument17 pages21 10 00 Fire Suppression SystemsKim Duy DoanNo ratings yet

- SECTION 10 2800 Toilet, Bath, and Laundry Accessories: 0.1 Related DocumentsDocument6 pagesSECTION 10 2800 Toilet, Bath, and Laundry Accessories: 0.1 Related DocumentsHan HanNo ratings yet

- Chapter 5Document18 pagesChapter 5arsiajanNo ratings yet

- SECTION 15970 Building Management System (BMS) Part 1 GeneralDocument75 pagesSECTION 15970 Building Management System (BMS) Part 1 GeneralMunir RasheedNo ratings yet

- SECTION 15855 Air Outlets and Inltes Part 1 - General 1.1 Related DocumentsDocument4 pagesSECTION 15855 Air Outlets and Inltes Part 1 - General 1.1 Related DocumentsMunir RasheedNo ratings yet

- SECTION 15815 Sheet Metal Duct Work Part 1 - General 1.1 Related DocumentsDocument14 pagesSECTION 15815 Sheet Metal Duct Work Part 1 - General 1.1 Related DocumentsMunir RasheedNo ratings yet

- SECTION 15622 Package Water Chillers - Centrifugal and Screw General 1.1Document10 pagesSECTION 15622 Package Water Chillers - Centrifugal and Screw General 1.1Munir RasheedNo ratings yet

- SECTION 15761 Electrical Heaters Part 1 - General 1.1 General RequirementsDocument3 pagesSECTION 15761 Electrical Heaters Part 1 - General 1.1 General RequirementsMunir RasheedNo ratings yet

- Sanitary Waste and Vent Piping 15150Document15 pagesSanitary Waste and Vent Piping 15150Munir RasheedNo ratings yet

- SECTION 15763 Fan Coils Units Part 1 - General 1.1 Related DocumentsDocument4 pagesSECTION 15763 Fan Coils Units Part 1 - General 1.1 Related DocumentsMunir RasheedNo ratings yet

- Water Treatment and Chemical Cleaning System 15189Document2 pagesWater Treatment and Chemical Cleaning System 15189Munir RasheedNo ratings yet

- SECTION 15411 Hvac Piping and Fitting Materials Part 1 - General 1.1 Related DocumentsDocument10 pagesSECTION 15411 Hvac Piping and Fitting Materials Part 1 - General 1.1 Related DocumentsMunir RasheedNo ratings yet

- SECTION 15440 Plumbing Pumps General 1.1Document6 pagesSECTION 15440 Plumbing Pumps General 1.1Munir RasheedNo ratings yet

- SECTION 15075 Mechanical Identification: 1-1/2 Inches 1.9 X 0.75 InchesDocument4 pagesSECTION 15075 Mechanical Identification: 1-1/2 Inches 1.9 X 0.75 InchesMunir RasheedNo ratings yet

- SECTION 15110 Valves Part 1 - General 1.01 Related DocumentsDocument9 pagesSECTION 15110 Valves Part 1 - General 1.01 Related DocumentsMunir RasheedNo ratings yet

- Meters and Gauges 15122 - PageDocument4 pagesMeters and Gauges 15122 - PageMunir RasheedNo ratings yet

- SECTION 11450 Residential Equipment Rev 0Document21 pagesSECTION 11450 Residential Equipment Rev 0Munir RasheedNo ratings yet

- Mechancial Process PacakgeDocument8 pagesMechancial Process PacakgeMunir RasheedNo ratings yet

- SECTION 15850 Air Outlets and Inlets Rev 0Document31 pagesSECTION 15850 Air Outlets and Inlets Rev 0Munir RasheedNo ratings yet

- Alys - Technical-Datasheet - en CATALOGDocument2 pagesAlys - Technical-Datasheet - en CATALOGMunir RasheedNo ratings yet

- SECTION 11470 Darkroom Equipment Rev 0Document12 pagesSECTION 11470 Darkroom Equipment Rev 0Munir RasheedNo ratings yet

- SECTION 11130 Audio-Visual Equipment Rev 0Document14 pagesSECTION 11130 Audio-Visual Equipment Rev 0Munir RasheedNo ratings yet

- Design Basis Format: First Seven (7) Chapter Are Same in Specification and MRDocument3 pagesDesign Basis Format: First Seven (7) Chapter Are Same in Specification and MRMunir RasheedNo ratings yet

- Electrical ScheduleDocument4 pagesElectrical ScheduleMunir RasheedNo ratings yet

- PumpsDocument6 pagesPumpsMunir RasheedNo ratings yet

- DIALux Module InformationDocument5 pagesDIALux Module InformationMunir RasheedNo ratings yet

- SECTION 15935 Building Systems Controls Rev 0Document70 pagesSECTION 15935 Building Systems Controls Rev 0Munir RasheedNo ratings yet

- With - Load - New Equipment Data (Main File)Document8 pagesWith - Load - New Equipment Data (Main File)Munir RasheedNo ratings yet

- SECTION 15410 Plumbing Fixtures Rev 0Document38 pagesSECTION 15410 Plumbing Fixtures Rev 0Munir RasheedNo ratings yet

- SECTION 15670 Refrigerant Condensing Units Rev 0Document24 pagesSECTION 15670 Refrigerant Condensing Units Rev 0Munir RasheedNo ratings yet

- SECTION 15340 Water Spray Fixed Systems Rev 0Document43 pagesSECTION 15340 Water Spray Fixed Systems Rev 0Munir RasheedNo ratings yet

- SECTION 15920 Pneumatic Controls Rev 0Document39 pagesSECTION 15920 Pneumatic Controls Rev 0Munir RasheedNo ratings yet

- SECTION 15955 Testing, Adjusting and Balancing Rev 0Document40 pagesSECTION 15955 Testing, Adjusting and Balancing Rev 0Munir RasheedNo ratings yet

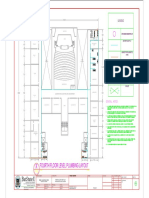

- Batstateu: Fourth Floor Level Plumbing Layout ADocument1 pageBatstateu: Fourth Floor Level Plumbing Layout AEasy WriteNo ratings yet

- ASME B16.21 Ring and Full Face Dimensions 150 2500# B16.5 & 16.47 Series A&bDocument13 pagesASME B16.21 Ring and Full Face Dimensions 150 2500# B16.5 & 16.47 Series A&bMONo ratings yet

- Neyveli Uttar Pradesh Power Limited (Nuppl) Desein Private LimitedDocument23 pagesNeyveli Uttar Pradesh Power Limited (Nuppl) Desein Private LimitedSimran singhNo ratings yet

- CLASS 11441: DEP 31.38.01.15-Gen Class 11441, Rev. K Page 1 of 15Document15 pagesCLASS 11441: DEP 31.38.01.15-Gen Class 11441, Rev. K Page 1 of 15SaguesoNo ratings yet

- Stella Chewy - Schedule - 10-29-13Document1 pageStella Chewy - Schedule - 10-29-13api-238954560No ratings yet

- Electrical and Plumbing BOQDocument2 pagesElectrical and Plumbing BOQLynGarciaPaulinoNo ratings yet

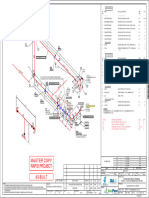

- To Match Tie-Ins Location: See SHT 200-PB-13F-219-BK1 SHT 1 F4 G5 B6Document1 pageTo Match Tie-Ins Location: See SHT 200-PB-13F-219-BK1 SHT 1 F4 G5 B6ABDERRAZZAKNo ratings yet

- Metric Handbook Planning and Design Data PDFDocument8 pagesMetric Handbook Planning and Design Data PDFAhmed NabilNo ratings yet

- Coefficient Discharge of VenturimeterDocument12 pagesCoefficient Discharge of Venturimeter2K20-ME-161 Mridul AnandNo ratings yet

- Gate Valve Parts CatalogueDocument12 pagesGate Valve Parts CatalogueLeandroNo ratings yet

- Globe & Electric Globe Valve: ApplicationDocument20 pagesGlobe & Electric Globe Valve: ApplicationvuvnkraftscgNo ratings yet

- Notes:: Piping Standards CommitteeDocument1 pageNotes:: Piping Standards CommitteeMustapha SedikNo ratings yet

- Water Reticulation Pipe Design ReportDocument24 pagesWater Reticulation Pipe Design Reportrozita kadirNo ratings yet

- SA-4820M00350-70541-10 - 00 - Markup DrawingDocument1 pageSA-4820M00350-70541-10 - 00 - Markup DrawingMohd Effiezool YaserNo ratings yet

- T - Productos Krom 2016Document80 pagesT - Productos Krom 2016Chelito Ix0% (1)

- 01.25 - Planning - The - Kitchen PDFDocument168 pages01.25 - Planning - The - Kitchen PDFJaimasaNo ratings yet

- D103 Appendix D List of Approved Products February 2011Document17 pagesD103 Appendix D List of Approved Products February 2011AssetNo ratings yet

- Katup (Valve)Document41 pagesKatup (Valve)Raka BarcelonistaNo ratings yet

- UntitledDocument53 pagesUntitledJose PrietoNo ratings yet

- Cast Iron Pipe Fittings EngDocument112 pagesCast Iron Pipe Fittings EngpoimandresNo ratings yet

- 3-Plumbing FixturesDocument2 pages3-Plumbing FixturesEugene MicarandayoNo ratings yet

- API 6A Flange ChartsDocument6 pagesAPI 6A Flange ChartsDanDeMarcoNo ratings yet

- Backflow Prevention Devices: Continuing Education From The American Society of Plumbing EngineersDocument8 pagesBackflow Prevention Devices: Continuing Education From The American Society of Plumbing Engineersexfireex1No ratings yet

- Edusah's ProfileDocument7 pagesEdusah's Profileengsam777No ratings yet

SECTION 15410 Plumbing Fixtures

SECTION 15410 Plumbing Fixtures

Uploaded by

Munir RasheedOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SECTION 15410 Plumbing Fixtures

SECTION 15410 Plumbing Fixtures

Uploaded by

Munir RasheedCopyright:

Available Formats

SECTION 15410

PLUMBING FIXTURES

PART 1 GENERAL

1.1 SUMMARY

A. Section includes water closets, urinals, lavatories, sinks, service sinks,

electric water coolers, drinking fountains, bathtubs, showers, wash fountains, eye

[and face] wash fountains, emergency showers.

B. Related Sections:

1. Domestic Water Piping: Supply connections to plumbing fixtures.

2. Sanitary Waste and Vent Piping: Waste connections to plumbing

fixtures.

3. Wiring Connections: Execution requirements for electric

connections to sensor valves and faucets specified by this section.

4. Joint Sealers: Product requirements for calking between fixtures

and building components for placement by this section.

1.2 REFERENCES

A. ANSI Z124.1 - Gel-Coated Glass-Fiber Reinforced Polyester Resin

Bathtub Units.

B. ANSI Z124.2 - Gel-Coated Glass-Fiber Reinforced Polyester Resin

Shower Receptor and Shower Stall Units.

C. ANSI Z358.1 - Emergency Eye Wash and Shower Equipment.

D. ARI 1010 (Air-Conditioning and Refrigeration Institute) - Drinking

Fountains and self-contained Mechanically Refrigerated Drinking Water Coolers.

E. ASME A112.6.1 (American Society of Mechanical Engineers) - Supports

for Off-the-Floor Plumbing Fixtures for Public Use.

F. ASME A112.18.1 (American Society of Mechanical Engineers) - Finished

and Rough Brass Plumbing Fixture Fittings.

G. ASME A112.19.1 (American Society of Mechanical Engineers) -

Enameled Cast Iron Plumbing Fixtures.

H. ASME A112.19.2 (American Society of Mechanical Engineers) - Vitreous

China Plumbing Fixtures.

Plumbing Fixtures 15410– Page 1 of 13

I. ASME A112.19.3 (American Society of Mechanical Engineers) - Stainless

Steel Plumbing Fixtures (Designed for Residential Use).

J. ASME A112.19.4 (American Society of Mechanical Engineers) -

Porcelain Enameled Formed Steel Plumbing Fixtures.

K. ASME A112.19.5 (American Society of Mechanical Engineers) - Trim for

Water-Closet Bowls, Tanks, and Urinals.

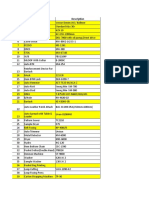

1.3 SUBMITTALS

A. Submittal Procedures: Submittal procedures.

B. Product Data: Submit catalog illustrations of fixtures, sizes, [rough-in

dimensions,] utility sizes, trim, and finishes.

C. Samples: Submit two lavatory supply fittings , fixtures for color matching

and sets of color chips for each standard color

D. Manufacturer's Installation Instructions: Submit installation methods and

procedures.

E. Manufacturer's Certificate: Certify products meet or exceed specified

requirements.

1.4 CLOSEOUT SUBMITTALS

A. Execution Requirements: Closeout procedures.

B. Operation and Maintenance Data: Submit fixture, trim, exploded view

and replacement parts lists.

1.5 QUALITY ASSURANCE

A. Provide products requiring electrical connections listed and classified by

Underwriters Laboratories Inc., testing firm acceptable to authority having

jurisdiction as suitable for purpose specified and indicated.

B. Maintain one copy of each document on site.

1.6 QUALIFICATIONS

A. Manufacturer: Company specializing in manufacturing products specified

in this section with minimum three years experience, and with service facilities

within 100 miles of Project.

B. Installer: Company specializing in performing Work of this section with

minimum three years experience

Plumbing Fixtures 15410– Page 2 of 13

1.7 MOCKUP

A. Quality Requirements: Mockup requirements.

B. Construct mockup of typical bathroom group.

C. Locate where directed by Architect/Engineer .where indicated on

Drawings.

D. Incorporate accepted mockup as part of Work.

E. Remove mockup when directed by Architect/Engineer.

1.8 PRE-INSTALLATION MEETING

A. Administrative Requirements: Preinstallation meeting.

B. Convene minimum one week prior to commencing Work of this section.

1.9 DELIVERY, STORAGE, AND HANDLING

A. Product Requirements: Product storage and handling requirements.

B. Accept fixtures on site in factory packaging. Inspect for damage.

C. Protect installed fixtures from damage by securing areas and by leaving

factory packaging in place to protect fixtures and prevent use.

1.10 WARRANTY

A. Execution Requirements: Product warranties and product bonds.

B. Furnish fiveyear manufacturer warranty for plumbing fixtures.

1.11 EXTRA MATERIALS

A. Execution Requirements: Spare parts and maintenance products.

B. Furnish twosets of faucet washers flush valve service kits lavatory supply

fittings shower heads, toilet seats

PART 2 PRODUCTS

2.1 FLUSH VALVE WATER CLOSETS

A. Manufacturers:

1. American Standard Plumbing

2. Bradley Corp.

3. Briggs Industries, Inc.

Plumbing Fixtures 15410– Page 3 of 13

4. Chicago Faucet Co

5. Delta Faucet Co., Commercial Div.

6. Eller Plumbingware

7. Kohler Co.

8. Plumberex Specialty Products

9. Sloan Valve Co.

10. T & S Brass & Bronze Works Inc.

11. Truebro

Or approved equal

B. Bowl: ASME A112.19.2; floor mounted, siphon jet wall hung, siphon jet

blow out vitreous china closet bowl, with elongated rim, 1-1/2 inchtop spud, china

bolt caps.

C. Exposed Flush Valve: ASME A112.18.1; exposed chrome plated,

diaphragm type with oscillating handle, escutcheon, seat bumper, integral

screwdriver stop and vacuum breaker; maximum 1.6 flush volume.

D. Concealed Flush Valve: ASME A112.18.1; concealed rough brass,

diaphragm type with exposed chrome plated push button oscillating handle and

escutcheon, screw driver stop and vacuum breaker; maximum1.6 gallonflush

volume.

E. Sensor Operated Flush Valve: ASME A112.18.1; concealed rough brass,

diaphragm type with low voltage battery operated solenoid operator, infrared

sensor and over-ride button in chrome plated plate, wheel handle stop and vacuum

breaker ; maximum 1.6 gallonflush volume.

F. Seat: Solid black or white plastic, open front, extended back, self-

sustaining hinge, brass bolts, with or without cover.

G. Wall Mounted Carrier: ASME A112.6.1; non-adjustable cast iron frame,

integral drain hub and vent, adjustable spud, lugs for floor and wall attachment,

threaded fixture studs with nuts and washers.

2.2 TANK TYPE WATER CLOSETS

A. Manufacturers:

1. American Standard Plumbing

2. Bradley Corp.

3. Briggs Industries, Inc.

4. Chicago Faucet Co

5. Delta Faucet Co., Commercial Div.

6. Eller Plumbingware

7. Kohler Co.

8. Plumberex Specialty Products

Plumbing Fixtures 15410– Page 4 of 13

9. Sloan Valve Co.

10. T& S Brass & Bronze Works Inc.

11. Truebro

Or approved equal

B. Bowl: ASME A112.19.2; wall hung, vitreous china, reverse trap,

whirlpool action close-coupled closet combination with regular rim, insulated

vitreous china closet tank with fittings and lever flushing valve, chrome plated

bolt caps.

C. Bowl: ASME A112.19.2; floor mounted, siphon jet, vitreous china,

incheshighincheshigh close-coupled closet combination with elongated rim,

insulated vitreous china closet tank with fittings and lever flushing valve, bolt

caps vandal proof cover locking device.

2.3 WALL HUNG URINALS

A. Manufacturers:

1. American Standard Plumbing

2. Bradley Corp

3. Briggs Industries, Inc

4. Chicago Faucet Co

5. Delta Faucet Co., Commercial Div

6. Eller Plumbingware

7. Kohler Co

8. Plumberex Specialty Products.

9. Sloan Valve Co.

10. T & S Brass & Bronze Works Inc

11. Truebro

Or approved equal

B. Urinal: ASME A112.19.2; vitreous china, wall hung [washout] [blowout]

[siphon jet] urinal with shields, integral trap, removable stainless steel strainer,3/4

inchtopspud, steel supporting hanger.

C. Exposed Flush Valve: ASME A112.18.1; exposed chrome plated,

diaphragm type with oscillating handle, push plate, escutcheon, integral

screwdriver stop, vacuum breaker; maximum 1 gallonflush volume.

D. Concealed Flush Valve: ASME A112.18.1; concealed rough brass,

diaphragm type with exposed chrome plated push button oscillating handle and

escutcheon, wheel handle stop and vacuum breaker; maximum 1 gallonflush

volume.

E. Sensor Operated Flush Valve: ASME A112.18.1; concealed rough

brass ,exposed chrome plated], diaphragm type with low voltageoperated solenoid

Plumbing Fixtures 15410– Page 5 of 13

operator, infrared sensor and over-ride button in chrome plated plate, wheel

handle stop and vacuum breaker; maximum 1 gallonflush volume.

F. Flush (Metering) Valve: ASME A112.18.1; exposed chrome plated, porous

felt type for 1/2 inchsupply with oscillating handle ,push button,screwdriver stop

and vacuum breaker].

G. Wall Mounted Carrier: ASME A112.6.1; cast iron and steel frame with

tubular legs, lugs for floor and wall attachment, threaded fixture studs for fixture

hanger, bearing studs.

2.4 STALL URINALS

A. Manufacturers:

1. American Standard Plumbing

2. Bradley Corp

3. Briggs Industries, Inc.

4. Chicago Faucet Co.

5. Delta Faucet Co., Commercial Div.

6. Eller Plumbingware

7. Kohler Co.

8. Plumberex Specialty Products

9. Sloan Valve Co.

10. T & S Brass & Bronze Works Inc.

11. Truebro

Or approved equal

B. Urinal: ASME A112.19.2; vitreous china slope front stall urinal with

integral flushing rim, removable stainless steel strainer 3/4 inchtop spud.

C. Exposed Flush Valve: ASME A112.18.1; exposed chrome plated,

diaphragm type with oscillating handle, push plate, escutcheon, integral

screwdriver stop, vacuum breaker; maximum 1 gallonflush volume.

D. Concealed Flush Valve: ASME A112.18.1; concealed rough brass,

diaphragm type with exposed chrome plated push button oscillating handle and

escutcheon, wheel handle stop and vacuum breaker; maximum 1 gallon flush

volume.

E. Sensor Operated Flush Valve: ASME A112.18.1; concealed rough brass]

[exposed chrome plated], diaphragm type with low voltageoperated solenoid

operator, infrared sensor and over-ride button in chrome plated plate, wheel

handle stop and vacuum breaker; maximum 1 gallonflush volume.

F. Flush Tank: ASME A112.19.5; vitreous china insulated tank with

concealed cover, bottom over rim supply, siphon valve.

Plumbing Fixtures 15410– Page 6 of 13

2.5 LAVATORIES

A. Manufacturers:

1. American Standard Plumbing

2. Bradley Corp.

3. Briggs Industries, Inc.

4. Chicago Faucet Co.

5. Delta Faucet Co., Commercial Div.

6. Eller Plumbingware

7. Kohler Co.

8. Plumberex Specialty Products

9. Sloan Valve Co.

10. T & S Brass & Bronze Works Inc.

11. Truebro

Or approved equal

B. Supply Fitting: ASME A112.18.1; chrome plated combination supply

fitting with [pop-up waste, chain and plug ,open grid strainer, water economy

aerator with maximum 2.0 gpmflow, indexed handles single lever handle.

C. Metered Faucet: ASME A112.18.1; chrome plated metered mixing faucet

with low voltageoperated solenoid operator and infrared sensor, aerator and cover

plate, open grid strainer.

D. Accessories:

1. Chrome plated 17 gagebrass P-trap with clean-out plug and arm

with escutcheon.

2. Offset waste with perforated open strainer plug and strainer.

3. Wheel handle Screwdriver stops.

4. Flexible supplies.

E. Wall Mounted Carrier: ASME A112.6.1; cast iron and steel frame with

tubular legs, lugs for floor and wall attachment, [threaded studs for fixture

hanger,concealed arm supports, bearing plate and studs.

2.6 SINKS

A. Manufacturers:

1. American Standard Plumbing

2. Bradley Corp.

3. Briggs Industries, Inc.

4. Chicago Faucet Co.

5. Delta Faucet Co., Commercial Div.

6. Eller Plumbingware

7. Kohler Co.

8. Plumberex Specialty Products

9. Sloan Valve Co.

10. [T & S Brass & Bronze Works Inc

Plumbing Fixtures 15410– Page 7 of 13

11. Truebro

B. Trim: ASME A112.18.1; chrome plated brass supply with [high rise]

swing spout, vandal proof water economy aerator with maximum 2.2 gpmflow,

[indexed lever handles single lever handle and retractable spray.

C. Accessories: Chrome plated17 gagebrass P-trap with clean-out plug and

arm with escutcheon, screwdriver stop, flexible supplies.

2.7 BATHTUBS AND SHOWERS

A. Manufacturers:

1. American Standard Plumbing

2. Bradley Corp.

3. Briggs Industries, Inc.

4. Chicago Faucet Co

5. Delta Faucet Co., Commercial Div.

6. Eller Plumbingware

7. Kohler Co.

8. Plumberex Specialty Products

9. Sloan Valve Co.

10. T & S Brass & Bronze Works Inc

11. Truebro

B. Bath Trim: ASME A112.18.1; concealed over rim supply with spout and

indexed handles, lever operated pop-up waste and overflow.

C. Bath and Shower Trim: ASME A112.18.1; concealed shower and over rim

supply with diverter spout, indexed handles, bent shower arm with [flow control

and] [adjustable spray] ball joint showerhead with maximum 2.5 gpmflow and

escutcheon, lever operated pop-up waste and overflow.

D. Bath and Shower Trim: ASME A112.18.1; concealed shower and over rim

supply with diverter spout, pressure balanced or thermostatic mixing valve, bent

shower arm with flow control and adjustable spray ball joint showerhead with

maximum2.5 gpmflow and escutcheon, lever operated pop-up waste and

overflow.

2.8 SHOWERS

A. Manufacturers:

1. American Standard Plumbing

2. Bradley Corp.

3. Briggs Industries, Inc.

4. Chicago Faucet Co

5. Delta Faucet Co., Commercial Div

6. Eller Plumbingware

7. Kohler Co.

Plumbing Fixtures 15410– Page 8 of 13

8. Plumberex Specialty Products

9. Sloan Valve Co

10. T& S Brass & Bronze Works Inc.

11. Truebro.

Or approved equal

B. Trim: ASME A112.18.1; concealed shower supply with indexed handles,

bent shower arm with flow control and adjustable spray ball joint showerhead

with maximum 2.5 gpmflow, and escutcheon.

C. Trim ASME A112.18.1; concealed straight way pattern valve with indexed

cross handle.

D. Trim: ASME A112.18.1; concealed rough brass metering valve with

closed fluid metering system adjustable from 5 to 120 seconds, chrome plated

push button and escutcheon, wheel handle stop.

E. Trim: ASME A112.18.1; concealed shower supply with pressure balanced

thermostatic mixing valves, integral service stops, bent shower arm with flow

control and adjustable spray ball joint shower head with maximum 2.5 gpm flow,

and escutcheon.

F. Showerhead: ASME A112.18.1; chrome plated vandal-proof institutional

head with integral wall bracket, built-in 2.5 gpmflow control.

2.9 DRINKING FOUNTAINS

A. Manufacturers:

1. American Standard Plumbing

2. Bradley Corp

3. Briggs Industries, Inc.

4. Chicago Faucet Co.

5. Delta Faucet Co., Commercial Div.

6. Eller Plumbingware

7. Kohler Co.

8. Plumberex Specialty Products

9. Sloan Valve Co.

10. T & S Brass & Bronze Works Inc.

11. Truebro

Or approved equal

B. Fountain: Molded white reinforced glass fiber with underside vandal proof

cowling, hooded elevated anti-squirt bubbler with stream guard, automatic stream

regulator, cross or lever handle, mounting bracket, screwdriver stop.

C. Fountain: White reinforced glass fiber, vitreous china, semi-recessed,

fully-recessed, with elevated anti-squirt bubbler with stream guard, automatic

Plumbing Fixtures 15410– Page 9 of 13

stream regulator, cross lever handle, access cover plate, mounting bracket,

screwdriver stop.

2.10 ELECTRIC WATER COOLERS

A. Manufacturers:

1. American Standard Plumbing

2. Bradley Corp.

3. Briggs Industries, Inc.

4. Chicago Faucet Co.

5. Delta Faucet Co., Commercial Div.

6. Eller Plumbing ware

7. Kohler Co.

8. Plumberex Specialty Products

9. Sloan Valve Co.

10. T & S Brass & Bronze Works Inc.

11. Truebro

Or approved equal

B. Fountain:

1. ARI 1010; surface mounted electric water cooler with stainless

steel top, vinyl on steelstainless steel body, elevated anti-squirt bubbler

with stream guard, automatic stream regulator, push button, mounting

bracket, refrigerated with integral air cooled condenser and stainless steel

grille.

2.11 WASH FOUNTAINS

A. Manufacturers:

1. American Standard Plumbing

2. Bradley Corp.

3. Briggs Industries, Inc.

4. Chicago Faucet Co.

5. Delta Faucet Co., Commercial Div.

6. Eller Plumbingware

7. Kohler Co.

8. Plumberex Specialty Products

9. Sloan Valve Co.

10. T& S Brass & Bronze Works Inc.

11. Truebro

Or approved equal

B. Accessories: Foot controlled self-closing valve, spray head, liquid soap

dispenser, manual mixing valve, supporting tube, spud and strainer, operating

mechanism, foot levers and rail, combination stop, strainer and check valves.

Plumbing Fixtures 15410– Page 10 of 13

2.12 SERVICE SINKS

A. Manufacturers:

1. American Standard Plumbing

2. Bradley Corp.

3. Briggs Industries, Inc

4. Chicago Faucet Co.

5. Delta Faucet Co., Commercial Div

6. Eller Plumbingware

7. Plumberex Specialty Products

8. Sloan Valve Co.

9. T& S Brass & Bronze Works Inc.

10. Truebro

Or approved equal.

B. Bowl: ASME A112.19.1; 22 x 18 x 12 inchdeep, porcelain enameled

(inside only) cast iron roll-rim sink, with 12 inchhigh back, concealed hanger,

chrome plated strainer, stainless steel rim guard, cast iron P-trap with adjustable

floor flange.

C. Bowl: 36 x 24 x 10 inchhigh white molded stone, floor mounted, with one

inchwide shoulders, vinyl bumper guard,and stainless steel strainer.

D. Trim: ASME A112.18.1 exposed wall type supply with cross handles,

spout wall brace, vacuum breaker, hose end spout, strainers, eccentric adjustable

inlets, integral screwdriver stops with covering caps and adjustable threaded wall

flanges.

E. Accessories:

1. 5 feetof 1/2 inchdiameter plain end reinforced rubber hose.

2. Hose clamp hanger.

3. Mop hanger.

2.13 SAFETY SHOWER

A. Manufacturers:

1. American Standard Plumbing

2. Bradley Corp.

3. Briggs Industries, Inc.

4. Chicago Faucet Co.

5. Delta Faucet Co., Commercial Div.

6. Eller Plumbingware

7. Kohler Co.

8. Plumberex Specialty Products

9. [Sloan Valve Co.

10. T& S Brass & Bronze Works Inc.

11. Truebro

Or approved equal

Plumbing Fixtures 15410– Page 11 of 13

B. ANSI Z358.1; wall-mounted ,free standing, self- cleaning, non-clogging 8

inch (200 diameter stainless steeldeluge shower head with elbow, one inchfull

flow valve with pull chain and 8 inchdiameter ring, one inchinterconnecting

fittings.

PART 3 EXECUTION

3.1 EXAMINATION

A. Administrative Requirements: Coordination and project conditions.

B. Verify walls and floor finishes are prepared and ready for installation of

fixtures.

C. Verify electric power is available and of correct characteristics.

D. Confirm millwork is constructed with adequate provision for installation

of counter top lavatories and sinks.

3.2 PREPARATION

A. Rough-in fixture piping connections in accordance with minimum sizes

indicated in fixture rough-in schedule for particular fixtures.

3.3 INSTALLATION

A. Install each fixture with trap, easily removable for servicing and cleaning.

B. Provide chrome plated rigid or flexible supplies to fixtures with loose

keystops, reducers, and escutcheons.

C. Install components level and plumb.

D. Install and secure fixtures in place with wall supportsand bolts.

E. Seal fixtures to wall and floor surfaces with sealant as specified in Section

07900, color to match fixture.

F. Solidly attach water closets to floor with lag screws. Lead flashing is not

intended hold fixture in place.

3.4 INTERFACE WITH OTHER PRODUCTS

A. Review millwork shop-drawings. Confirm location and size of fixtures

and openings before rough in and installation.

3.5 ADJUSTING

A. Execution Requirements: Testing, adjusting, and balancing.

Plumbing Fixtures 15410– Page 12 of 13

B. Adjust stops or valves for intended water flow rate to fixtures without

splashing, noise, or overflow.

3.6 CLEANING

A. Execution Requirements: Final cleaning.

B. Clean plumbing fixtures and equipment.

3.7 PROTECTION OF INSTALLED CONSTRUCTION

A. Execution Requirements: Protecting installed construction.

B. Do not permit use of fixtures before final acceptance.

END OF SECTION 15410

Plumbing Fixtures 15410– Page 13 of 13

You might also like

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- BOP Drawings by Sections, RevDocument10 pagesBOP Drawings by Sections, RevberrouiNo ratings yet

- Simbologia Norma KKSDocument8 pagesSimbologia Norma KKSEsteban David L. PulgarinNo ratings yet

- Unit Cost Estimate: 1.0 MaterialsDocument30 pagesUnit Cost Estimate: 1.0 MaterialsGenevieve GayosoNo ratings yet

- ObjectiveDocument15 pagesObjectiveIkhmal FirdausNo ratings yet

- Lucius Learning Series - MOV Seismic Weak Link PDFDocument0 pagesLucius Learning Series - MOV Seismic Weak Link PDFDana GuerreroNo ratings yet

- SECTION 15175 Swimming Pool Piping and Equipment General 1.1Document14 pagesSECTION 15175 Swimming Pool Piping and Equipment General 1.1fatREVITNo ratings yet

- PDFDocument7 pagesPDFMuhammad Ali SakrNo ratings yet

- 224215, Commercial Plumbing FixturesDocument13 pages224215, Commercial Plumbing Fixturessrp. mohammed100% (1)

- Plumbing Fixtures StandardDocument12 pagesPlumbing Fixtures StandardPamela Joyce MaddumaNo ratings yet

- Plumbing FixturesDocument30 pagesPlumbing Fixturesadel rihanaNo ratings yet

- 224105, Residential Plumbing FixturesDocument15 pages224105, Residential Plumbing Fixturessrp. mohammedNo ratings yet

- Domestic Water SystemsDocument20 pagesDomestic Water Systemsabdullah sahibNo ratings yet

- Section 21 05 00Document6 pagesSection 21 05 00Ismail MohammadNo ratings yet

- Sanitary Waste and Vent Piping 15150Document15 pagesSanitary Waste and Vent Piping 15150Munir RasheedNo ratings yet

- 221005, Plumbing SpecialtiesDocument16 pages221005, Plumbing Specialtiessrp. mohammedNo ratings yet

- SECTION 15640 Packaged Cooling Towers General 1.1Document7 pagesSECTION 15640 Packaged Cooling Towers General 1.1Munir RasheedNo ratings yet

- ORK Ncluded Related Work Eferenced Tandards Ubmittals Eneral EquirementsDocument8 pagesORK Ncluded Related Work Eferenced Tandards Ubmittals Eneral EquirementsLui TCC BariaNo ratings yet

- Domestic Water Filtration EquipmentDocument10 pagesDomestic Water Filtration EquipmentElie HajjNo ratings yet

- 15440Document7 pages15440uddinnadeemNo ratings yet

- Plumbing SectionDocument16 pagesPlumbing SectionJanNo ratings yet

- Section 21 11 00Document10 pagesSection 21 11 00Ismail MohammadNo ratings yet

- SF - Domestic Water PipingDocument16 pagesSF - Domestic Water PipingJahat AtencioNo ratings yet

- 102113.17-Phenolic Core Toilet CompartmentsDocument6 pages102113.17-Phenolic Core Toilet Compartmentstaghreed shabanNo ratings yet

- SECTION 15190 Fuel Piping General 1.1Document14 pagesSECTION 15190 Fuel Piping General 1.1Munir RasheedNo ratings yet

- 22 40 00 - Plumbing FixturesDocument22 pages22 40 00 - Plumbing Fixturesmd zubairNo ratings yet

- Section 223200 - Domestic Water Treatment EquipmentDocument10 pagesSection 223200 - Domestic Water Treatment EquipmentniklausNo ratings yet

- Revised 4/2008Document10 pagesRevised 4/2008Richabson OsmanNo ratings yet

- Ductile Iron Pipe For Sewers 012221Document9 pagesDuctile Iron Pipe For Sewers 012221สุภรัตน์ จันทร์คุณาภาสNo ratings yet

- SECTION 15520 Feedwater Equipment General 1.1Document6 pagesSECTION 15520 Feedwater Equipment General 1.1fatREVITNo ratings yet

- Section 21 05 23Document6 pagesSection 21 05 23Ismail MohammadNo ratings yet

- 221119.fl - JR SmithDocument36 pages221119.fl - JR SmithSreekanthNo ratings yet

- Facility Sanitary SewersDocument14 pagesFacility Sanitary SewerssamNo ratings yet

- SECTION 13975 Standpipes and Hoses General 1.1: - Page 1 of 4Document4 pagesSECTION 13975 Standpipes and Hoses General 1.1: - Page 1 of 4fatREVITNo ratings yet

- Mep Spec8Document13 pagesMep Spec8fatREVITNo ratings yet

- 11/20/2018 /conversion/tmp/scratch/402494814Document13 pages11/20/2018 /conversion/tmp/scratch/402494814Anonymous NR3qZ30No ratings yet

- Domestic and Industrial Water Piping Guide DesignDocument7 pagesDomestic and Industrial Water Piping Guide DesignEddito Cacho100% (1)

- Project Standard Specification: Potable-Water Storage Tanks 15450 - Page 1/12Document12 pagesProject Standard Specification: Potable-Water Storage Tanks 15450 - Page 1/12adel rihanaNo ratings yet

- Section 15060 - Hangers and SupportsDocument9 pagesSection 15060 - Hangers and SupportsLuciano SalituriNo ratings yet

- SECTION 15120 Piping Specialties 1.1Document18 pagesSECTION 15120 Piping Specialties 1.1Munir RasheedNo ratings yet

- SECTION 15140 Domestic Water Piping General 1.1Document20 pagesSECTION 15140 Domestic Water Piping General 1.1Munir RasheedNo ratings yet

- SPC Occ 221319 MeDocument9 pagesSPC Occ 221319 Metarekhisham1234No ratings yet

- Water and ArregationDocument9 pagesWater and ArregationYasser FathiNo ratings yet

- PipingDocument7 pagesPipingAshar HassanNo ratings yet

- Project Standard Specification: Decorative Fountain 15495 - Page 1/7Document7 pagesProject Standard Specification: Decorative Fountain 15495 - Page 1/7adel rihanaNo ratings yet

- ITEM 615.01090003 - WATER FEATURE Scope of WorkDocument13 pagesITEM 615.01090003 - WATER FEATURE Scope of Workemiediray03No ratings yet

- 22 11 13 - Facility Water Distribution Piping PDFDocument11 pages22 11 13 - Facility Water Distribution Piping PDFmasoodaeNo ratings yet

- UtilitiesDocument31 pagesUtilitiesjia wangNo ratings yet

- FL - Ta2860 - Iff Otista - Toilet, Bath, and Laundry AccessoriesDocument5 pagesFL - Ta2860 - Iff Otista - Toilet, Bath, and Laundry AccessoriesBack to SumateraNo ratings yet

- Section 21 12 00Document3 pagesSection 21 12 00Ismail MohammadNo ratings yet

- Fuel Handling SystemDocument4 pagesFuel Handling SystemRoel FranciscoNo ratings yet

- SECTION 15440 Plumbing Pumps General 1.1Document6 pagesSECTION 15440 Plumbing Pumps General 1.1Munir RasheedNo ratings yet

- Elevated TanksDocument8 pagesElevated TanksChâu TúNo ratings yet

- Central-Station Air-Handling UnitsDocument4 pagesCentral-Station Air-Handling Unitssidparikh254No ratings yet

- Fire Protection SpecificationDocument34 pagesFire Protection Specification22-09441No ratings yet

- Section 15430 - Plumbing Specialties PDFDocument21 pagesSection 15430 - Plumbing Specialties PDFMahmoud GwailyNo ratings yet

- Bart Facilities StandardDocument8 pagesBart Facilities StandardBehnam AshouriNo ratings yet

- Pipe & Pipe FittingsDocument10 pagesPipe & Pipe FittingsSalim BakhshNo ratings yet

- Part 1 - General: SECTION 21 13 13 Wet-Pipe Sprinkler SystemsDocument16 pagesPart 1 - General: SECTION 21 13 13 Wet-Pipe Sprinkler SystemsNelson VargasNo ratings yet

- FL - Whitehall.CleanDocument59 pagesFL - Whitehall.CleanHossain TanjilaaNo ratings yet

- Toilet and Bath Accessories - MSTDocument7 pagesToilet and Bath Accessories - MSTwafikmh4No ratings yet

- 21 10 00 Fire Suppression SystemsDocument17 pages21 10 00 Fire Suppression SystemsKim Duy DoanNo ratings yet

- SECTION 10 2800 Toilet, Bath, and Laundry Accessories: 0.1 Related DocumentsDocument6 pagesSECTION 10 2800 Toilet, Bath, and Laundry Accessories: 0.1 Related DocumentsHan HanNo ratings yet

- Chapter 5Document18 pagesChapter 5arsiajanNo ratings yet

- SECTION 15970 Building Management System (BMS) Part 1 GeneralDocument75 pagesSECTION 15970 Building Management System (BMS) Part 1 GeneralMunir RasheedNo ratings yet

- SECTION 15855 Air Outlets and Inltes Part 1 - General 1.1 Related DocumentsDocument4 pagesSECTION 15855 Air Outlets and Inltes Part 1 - General 1.1 Related DocumentsMunir RasheedNo ratings yet

- SECTION 15815 Sheet Metal Duct Work Part 1 - General 1.1 Related DocumentsDocument14 pagesSECTION 15815 Sheet Metal Duct Work Part 1 - General 1.1 Related DocumentsMunir RasheedNo ratings yet

- SECTION 15622 Package Water Chillers - Centrifugal and Screw General 1.1Document10 pagesSECTION 15622 Package Water Chillers - Centrifugal and Screw General 1.1Munir RasheedNo ratings yet

- SECTION 15761 Electrical Heaters Part 1 - General 1.1 General RequirementsDocument3 pagesSECTION 15761 Electrical Heaters Part 1 - General 1.1 General RequirementsMunir RasheedNo ratings yet

- Sanitary Waste and Vent Piping 15150Document15 pagesSanitary Waste and Vent Piping 15150Munir RasheedNo ratings yet

- SECTION 15763 Fan Coils Units Part 1 - General 1.1 Related DocumentsDocument4 pagesSECTION 15763 Fan Coils Units Part 1 - General 1.1 Related DocumentsMunir RasheedNo ratings yet

- Water Treatment and Chemical Cleaning System 15189Document2 pagesWater Treatment and Chemical Cleaning System 15189Munir RasheedNo ratings yet

- SECTION 15411 Hvac Piping and Fitting Materials Part 1 - General 1.1 Related DocumentsDocument10 pagesSECTION 15411 Hvac Piping and Fitting Materials Part 1 - General 1.1 Related DocumentsMunir RasheedNo ratings yet

- SECTION 15440 Plumbing Pumps General 1.1Document6 pagesSECTION 15440 Plumbing Pumps General 1.1Munir RasheedNo ratings yet

- SECTION 15075 Mechanical Identification: 1-1/2 Inches 1.9 X 0.75 InchesDocument4 pagesSECTION 15075 Mechanical Identification: 1-1/2 Inches 1.9 X 0.75 InchesMunir RasheedNo ratings yet

- SECTION 15110 Valves Part 1 - General 1.01 Related DocumentsDocument9 pagesSECTION 15110 Valves Part 1 - General 1.01 Related DocumentsMunir RasheedNo ratings yet

- Meters and Gauges 15122 - PageDocument4 pagesMeters and Gauges 15122 - PageMunir RasheedNo ratings yet

- SECTION 11450 Residential Equipment Rev 0Document21 pagesSECTION 11450 Residential Equipment Rev 0Munir RasheedNo ratings yet

- Mechancial Process PacakgeDocument8 pagesMechancial Process PacakgeMunir RasheedNo ratings yet

- SECTION 15850 Air Outlets and Inlets Rev 0Document31 pagesSECTION 15850 Air Outlets and Inlets Rev 0Munir RasheedNo ratings yet

- Alys - Technical-Datasheet - en CATALOGDocument2 pagesAlys - Technical-Datasheet - en CATALOGMunir RasheedNo ratings yet

- SECTION 11470 Darkroom Equipment Rev 0Document12 pagesSECTION 11470 Darkroom Equipment Rev 0Munir RasheedNo ratings yet

- SECTION 11130 Audio-Visual Equipment Rev 0Document14 pagesSECTION 11130 Audio-Visual Equipment Rev 0Munir RasheedNo ratings yet

- Design Basis Format: First Seven (7) Chapter Are Same in Specification and MRDocument3 pagesDesign Basis Format: First Seven (7) Chapter Are Same in Specification and MRMunir RasheedNo ratings yet

- Electrical ScheduleDocument4 pagesElectrical ScheduleMunir RasheedNo ratings yet

- PumpsDocument6 pagesPumpsMunir RasheedNo ratings yet

- DIALux Module InformationDocument5 pagesDIALux Module InformationMunir RasheedNo ratings yet

- SECTION 15935 Building Systems Controls Rev 0Document70 pagesSECTION 15935 Building Systems Controls Rev 0Munir RasheedNo ratings yet

- With - Load - New Equipment Data (Main File)Document8 pagesWith - Load - New Equipment Data (Main File)Munir RasheedNo ratings yet

- SECTION 15410 Plumbing Fixtures Rev 0Document38 pagesSECTION 15410 Plumbing Fixtures Rev 0Munir RasheedNo ratings yet

- SECTION 15670 Refrigerant Condensing Units Rev 0Document24 pagesSECTION 15670 Refrigerant Condensing Units Rev 0Munir RasheedNo ratings yet

- SECTION 15340 Water Spray Fixed Systems Rev 0Document43 pagesSECTION 15340 Water Spray Fixed Systems Rev 0Munir RasheedNo ratings yet

- SECTION 15920 Pneumatic Controls Rev 0Document39 pagesSECTION 15920 Pneumatic Controls Rev 0Munir RasheedNo ratings yet

- SECTION 15955 Testing, Adjusting and Balancing Rev 0Document40 pagesSECTION 15955 Testing, Adjusting and Balancing Rev 0Munir RasheedNo ratings yet

- Batstateu: Fourth Floor Level Plumbing Layout ADocument1 pageBatstateu: Fourth Floor Level Plumbing Layout AEasy WriteNo ratings yet

- ASME B16.21 Ring and Full Face Dimensions 150 2500# B16.5 & 16.47 Series A&bDocument13 pagesASME B16.21 Ring and Full Face Dimensions 150 2500# B16.5 & 16.47 Series A&bMONo ratings yet

- Neyveli Uttar Pradesh Power Limited (Nuppl) Desein Private LimitedDocument23 pagesNeyveli Uttar Pradesh Power Limited (Nuppl) Desein Private LimitedSimran singhNo ratings yet

- CLASS 11441: DEP 31.38.01.15-Gen Class 11441, Rev. K Page 1 of 15Document15 pagesCLASS 11441: DEP 31.38.01.15-Gen Class 11441, Rev. K Page 1 of 15SaguesoNo ratings yet

- Stella Chewy - Schedule - 10-29-13Document1 pageStella Chewy - Schedule - 10-29-13api-238954560No ratings yet

- Electrical and Plumbing BOQDocument2 pagesElectrical and Plumbing BOQLynGarciaPaulinoNo ratings yet

- To Match Tie-Ins Location: See SHT 200-PB-13F-219-BK1 SHT 1 F4 G5 B6Document1 pageTo Match Tie-Ins Location: See SHT 200-PB-13F-219-BK1 SHT 1 F4 G5 B6ABDERRAZZAKNo ratings yet

- Metric Handbook Planning and Design Data PDFDocument8 pagesMetric Handbook Planning and Design Data PDFAhmed NabilNo ratings yet

- Coefficient Discharge of VenturimeterDocument12 pagesCoefficient Discharge of Venturimeter2K20-ME-161 Mridul AnandNo ratings yet

- Gate Valve Parts CatalogueDocument12 pagesGate Valve Parts CatalogueLeandroNo ratings yet

- Globe & Electric Globe Valve: ApplicationDocument20 pagesGlobe & Electric Globe Valve: ApplicationvuvnkraftscgNo ratings yet

- Notes:: Piping Standards CommitteeDocument1 pageNotes:: Piping Standards CommitteeMustapha SedikNo ratings yet

- Water Reticulation Pipe Design ReportDocument24 pagesWater Reticulation Pipe Design Reportrozita kadirNo ratings yet

- SA-4820M00350-70541-10 - 00 - Markup DrawingDocument1 pageSA-4820M00350-70541-10 - 00 - Markup DrawingMohd Effiezool YaserNo ratings yet

- T - Productos Krom 2016Document80 pagesT - Productos Krom 2016Chelito Ix0% (1)

- 01.25 - Planning - The - Kitchen PDFDocument168 pages01.25 - Planning - The - Kitchen PDFJaimasaNo ratings yet

- D103 Appendix D List of Approved Products February 2011Document17 pagesD103 Appendix D List of Approved Products February 2011AssetNo ratings yet

- Katup (Valve)Document41 pagesKatup (Valve)Raka BarcelonistaNo ratings yet

- UntitledDocument53 pagesUntitledJose PrietoNo ratings yet

- Cast Iron Pipe Fittings EngDocument112 pagesCast Iron Pipe Fittings EngpoimandresNo ratings yet

- 3-Plumbing FixturesDocument2 pages3-Plumbing FixturesEugene MicarandayoNo ratings yet

- API 6A Flange ChartsDocument6 pagesAPI 6A Flange ChartsDanDeMarcoNo ratings yet

- Backflow Prevention Devices: Continuing Education From The American Society of Plumbing EngineersDocument8 pagesBackflow Prevention Devices: Continuing Education From The American Society of Plumbing Engineersexfireex1No ratings yet

- Edusah's ProfileDocument7 pagesEdusah's Profileengsam777No ratings yet