Professional Documents

Culture Documents

SECTION 15670 Refrigerant Condensing Units General 1.1: - Page 1 of 5

SECTION 15670 Refrigerant Condensing Units General 1.1: - Page 1 of 5

Uploaded by

Munir RasheedOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SECTION 15670 Refrigerant Condensing Units General 1.1: - Page 1 of 5

SECTION 15670 Refrigerant Condensing Units General 1.1: - Page 1 of 5

Uploaded by

Munir RasheedCopyright:

Available Formats

SECTION 15670

REFRIGERANT CONDENSING UNITS

PART 1 GENERAL

1.1 SUMMARY

A. Section includes refrigerant condenser package, charge of refrigerant and oil,

controls and control connections, refrigerant piping and connections, motor starters,

electrical power connections.

B. Related Sections:

1. Wiring Connections: Execution requirements for connection to electrical

service specified by this section.

2. Heating and Cooling Piping: Execution requirements for connection to

refrigeration piping specified by this section.

3. Cast-in-Place Concrete: Execution requirements for concrete

foundations specified by this section

4. Mechanical Sound, Vibration, and Seismic Control: Product

requirements for vibration isolation for placement by this section.

1.2 REFERENCES

A. ARI 210/240 (Air-Conditioning and Refrigeration Institute) - Unitary Air

Conditioning and Air-Source Heat Pump Equipment.

B. ASHRAE 15 (American Society of Heating, Refrigerating and Air-Conditioning

Engineers) - Safety Code for Mechanical Refrigeration.

C. ASHRAE 20 (American Society of Heating, Refrigerating and Air-Conditioning

Engineers) - Methods of Testing for Rating Remote Mechanical Air Cooled Refrigerant

Condensers.

D. ASHRAE 90A (American Society of Heating, Refrigerating and Air-

Conditioning Engineers) - Energy Conservation in New Building Design.

E. NEMA 250 (National Electrical Manufacturers Association) - Enclosures for

Electrical Equipment (1000 Volts Maximum).

F. UL 207 (Underwriters Laboratories, Inc.) - Refrigerant-Containing Components

and Accessories, Non-electrical.

G. UL 303 (Underwriters Laboratories, Inc.) - Refrigeration and Air Conditioning

Condensing and Compressor Units.

1.3 SUBMITTALS

A. Submittal Procedures: Submittal procedures.

Submittal Refrigerant Condensing Units 15670 – Page 1 of 5

B. Shop Drawings: Indicate components, assembly, dimensions, weights and

loading, required clearances, and location and size of field connections. Include

schematic layouts showing condenser, refrigeration compressors, cooling coils,

refrigerant piping and accessories required for complete system.

C. Product Data: Submit rated capacities, weights, accessories, electrical

requirements, and wiring diagrams.

D. Manufacturer's Certificate: Certify products meet or exceed specified

requirements.

1.4 CLOSEOUT SUBMITTALS

A. Execution Requirements: Closeout procedures.

B. Operation and Maintenance Data: Submit start-up instructions, maintenance

instructions, parts lists, controls, and accessories.

1.5 QUALIFICATIONS

A. Manufacturer: Company specializing in manufacturing products specified in this

section with minimum three years experience.

B. Installer: Company specializing in performing Work of this section with

minimum three years experience

1.6 PRE-INSTALLATION MEETING

A. Administrative Requirements: Pre-installation meeting.

B. Convene minimum one week prior to commencing Work of this section.

1.7 DELIVERY, STORAGE, AND HANDLING

A. Product Requirements: Product storage and handling requirements.

B. Comply with manufacturer's installation instruction for rigging, unloading and

transporting units.

C. Protect units on site from physical damage.

1.8 FIELD MEASUREMENTS

A. Verify field measurements prior to fabrication.

1.9 WARRANTY

A. Execution Requirements: Product warranties and product bonds.

B. Furnish fiveyears manufacturer warranty for compressors.

Submittal Refrigerant Condensing Units 15670 – Page 2 of 5

1.10 MAINTENANCE SERVICE

A. Execution Requirements: Maintenance service.

B. Furnish service and maintenance of Condensing Units from Date of Substantial

Completion.

1.11 EXTRA MATERIALS

A. Execution Requirements: Spare parts and maintenance products.

B. Furnish two sets of fan belts.

PART 2 PRODUCTS

2.1 Condensing units

A. Manufacturers:

1. Baltimore Aircoil Company

2. Carrier Corp.

3. Frick Co.

4. The Trane Co.

Or approved equal

B. Description:

1. Packaged, factory assembled, pre-wired unit, suitable for outdoor or

indoor use consisting of casing, condensing coil and fans, integral sub-cooling

coil, liquid accumulator screens, and controls.

2. Construction and Ratings: In accordance with ARI 210/240 , UL 207,

and UL 303. Testing in accordance with ASHRAE 20.

3. Performance Ratings: , Energy Efficiency Rating (EER) not less than

prescribed by ASHRAE 90A when used in combination with compressors and

evaporator coils.

2.2 HOUSING

A. House components in galvanized steel panels with weather resistant, baked

enamel finish.

B. Mount starters, disconnects, and controls in weatherproof panel with full opening

access doors. Furnish mechanical interlock to disconnect power when door is opened.

C. Furnish removable access doors or panels with quick fasteners.

D. Furnish welded steel floor mounting stand and duct collars at coil inlet and fan

outlet.

Submittal Refrigerant Condensing Units 15670 – Page 3 of 5

2.3 CONDENSER COILS

A. Coils: Aluminum fins mechanically bonded to seamless copper tubing. Furnish

sub-cooling circuits as applicable. Air test under water to 425 psig, and vacuum

dehydrate. Seal with holding charge of refrigerant.

B. Coil Guard: Expanded metal with lint screens.

C. Configuration: Two refrigeration circuits each with receiver.

2.4 FANS AND MOTORS

A. Vertical or horizontal discharge belt driven propeller type condenser fans with

fan guard on discharge, equipped with roller or ball bearings with grease fittings

extended to outside of casing.

B. Weatherproof motors suitable for outdoor use, single phase permanent split

capacitor or 3 phase, with permanent lubricated ball bearings and built-in thermal

overload protection

C. Horizontal discharge, double width, double inlet forward curvedcentrifugal type

condenser fans, equipped with roller or ball bearings with grease fittings extended to

outside of casing, V-belt drive with belt guard.

2.5 CONTROLS

A. Factory wired and mounted control panel, NEMA 250, containing fan motor

starters, fan cycling thermostats, head pressure controls, compressor interlock and control

transformer.

B. Furnish controls to permit operation down to ambient temperature.

C. Furnish thermostat to cycle fan motors in response to outdoor temperature.

D. Furnish head pressure switch to cycle fan motors in response to refrigerant

condensing pressure.

E. Furnish solid state control to vary speed of one condenser fan motor in response

to refrigerant condensing pressure.

F. Furnish electronic low ambient control consisting of mixing damper assembly,

controlled to maintain constant refrigerant condensing pressure.

Submittal Refrigerant Condensing Units 15670 – Page 4 of 5

PART 3 EXECUTION

3.1 INSTALLATION

A. Install in accordance with ASHRAE 15.

B. Connect to refrigeration piping and electrical service.

3.2 INTERFACE WITH OTHER PRODUCTS

A. Install units on vibration isolators on concretefoundations.

3.3 FIELD QUALITY CONTROL

A. Quality Requirements: Testing and Inspection Services , Execution

Requirements: Testing, adjusting, and balancing.

B. Furnish cooling season start-up and winter season shutdown service, for first

year of operation. If initial start-up and testing takes place in winter and machines are to

remain inoperative. Repeat start-up and testing operation at beginning of first cooling

season.

3.4 ADJUSTING

A. Execution Requirements: Testing, adjusting, and balancing.

B. Furnish cooling season start-up, winter season shutdown service, for first year of

operation.

3.5 DEMONSTRATION AND TRAINING

A. Demonstrate low ambient operation during winter testing or service specified

above.

END OF SECTION 15670

Submittal Refrigerant Condensing Units 15670 – Page 5 of 5

You might also like

- SECTION 15622 Package Water Chillers - Centrifugal and Screw General 1.1Document10 pagesSECTION 15622 Package Water Chillers - Centrifugal and Screw General 1.1Munir RasheedNo ratings yet

- Condensing UnitsDocument7 pagesCondensing Unitsadel rihana100% (1)

- Project Standard Specification: Split-System Air-Conditioning Units 15738 - Page 1/6Document6 pagesProject Standard Specification: Split-System Air-Conditioning Units 15738 - Page 1/6adel rihanaNo ratings yet

- SECTION 15640 Packaged Cooling Towers General 1.1Document7 pagesSECTION 15640 Packaged Cooling Towers General 1.1Munir RasheedNo ratings yet

- Project Standard Specification: Packaged Terminal Air-Conditioning Units 15784 - Page 1/5Document5 pagesProject Standard Specification: Packaged Terminal Air-Conditioning Units 15784 - Page 1/5adel rihanaNo ratings yet

- Project Standard Specification: Condensers) (Integral Air-Cooled Condensers)Document6 pagesProject Standard Specification: Condensers) (Integral Air-Cooled Condensers)adel rihanaNo ratings yet

- Project Standard Specification: Rooftop Units 15782 - Page 1/8Document8 pagesProject Standard Specification: Rooftop Units 15782 - Page 1/8adel rihanaNo ratings yet

- Fan Coil UnitsDocument3 pagesFan Coil Unitshussam_98No ratings yet

- Project Standard Specification: Rotary-Screw Chillers 15684 - Page 1/11Document11 pagesProject Standard Specification: Rotary-Screw Chillers 15684 - Page 1/11adel rihana0% (1)

- Fan Coil Units PDFDocument4 pagesFan Coil Units PDFAnonymous hxj75CHM5No ratings yet

- ZLC ARTCC AC SPECS PT 3 of 4 PDFDocument88 pagesZLC ARTCC AC SPECS PT 3 of 4 PDFAhmed NabilNo ratings yet

- Section 238126 - Mini Split System Air ConditionersDocument11 pagesSection 238126 - Mini Split System Air ConditionersChase GietterNo ratings yet

- Attachment 1 - Section 15620 Centrifugal ChillersDocument21 pagesAttachment 1 - Section 15620 Centrifugal ChillersMohammad Ali DiabNo ratings yet

- Air Cooled Screw Liquid Free Cooling Chiller - YORK YVFA R134a 50Hz & 60HzDocument6 pagesAir Cooled Screw Liquid Free Cooling Chiller - YORK YVFA R134a 50Hz & 60Hzalf_haroNo ratings yet

- Project Standard Specification: Packaged Cooling Towers 15640 - Page 1/9Document9 pagesProject Standard Specification: Packaged Cooling Towers 15640 - Page 1/9adel rihanaNo ratings yet

- 23 82 19 - Fan Coil UnitsDocument4 pages23 82 19 - Fan Coil UnitsLoraine AnnNo ratings yet

- Section 15183 - Refrigerant PipingDocument11 pagesSection 15183 - Refrigerant PipingJavier BarbosaNo ratings yet

- Project Standard Specification: Heat Exchangers 15710 - Page 1/3Document3 pagesProject Standard Specification: Heat Exchangers 15710 - Page 1/3adel rihanaNo ratings yet

- SECTION 15763 Fan Coils Units Part 1 - General 1.1 Related DocumentsDocument4 pagesSECTION 15763 Fan Coils Units Part 1 - General 1.1 Related DocumentsMunir RasheedNo ratings yet

- Project Standard Specification: Condensers)Document7 pagesProject Standard Specification: Condensers)adel rihanaNo ratings yet

- Project Standard Specification: Compressed-Air Equipment 15465 - Page 1/9Document9 pagesProject Standard Specification: Compressed-Air Equipment 15465 - Page 1/9adel rihanaNo ratings yet

- 15780-Hvac-Unitary Air Conditioners (Mini Split.& VRF)Document9 pages15780-Hvac-Unitary Air Conditioners (Mini Split.& VRF)aaquilNo ratings yet

- Scroll Chillers - Record SpecificationDocument4 pagesScroll Chillers - Record SpecificationEagle MayNo ratings yet

- Guide Spec Summary: Option ListDocument20 pagesGuide Spec Summary: Option ListRamachandra Reddy ChinthamreddyNo ratings yet

- 23 6418 Oil Free Centrifugal Water Chillers 111001Document11 pages23 6418 Oil Free Centrifugal Water Chillers 111001Mohd RizalNo ratings yet

- Cooling TowersDocument11 pagesCooling Towerszarzoura001No ratings yet

- General-Service Packaged Air Compressors and ReceiversDocument11 pagesGeneral-Service Packaged Air Compressors and ReceiversElie HajjNo ratings yet

- EnglishDocument19 pagesEnglishKrishna PATELNo ratings yet

- ATC-E Unit SpecificationsDocument3 pagesATC-E Unit SpecificationsgamunozdNo ratings yet

- Crac Specification For CUCDocument12 pagesCrac Specification For CUCLi LiuNo ratings yet

- Dartmouth College Design November 15, 2007 & Construction GuidelinesDocument4 pagesDartmouth College Design November 15, 2007 & Construction GuidelinesIndira SharanNo ratings yet

- A-ACMV SpecDocument50 pagesA-ACMV Specchong khengNo ratings yet

- Water Cooled Chiller (SHUBAILY GRAND MALL)Document40 pagesWater Cooled Chiller (SHUBAILY GRAND MALL)kdpmansiNo ratings yet

- SECTION 23 65 00 Cooling TowersDocument9 pagesSECTION 23 65 00 Cooling TowersPhasin ChitutsahaNo ratings yet

- Chiller & FahuDocument12 pagesChiller & FahuHafnazSabeerNo ratings yet

- Air Cooled ChillerDocument6 pagesAir Cooled ChillerObaidAliKhanNo ratings yet

- AES Vol 2 P15007 Split AC UnitsDocument5 pagesAES Vol 2 P15007 Split AC UnitsShreejith PanickerNo ratings yet

- 2-Solar Water HeaterDocument124 pages2-Solar Water Heaterp4p7 projectsNo ratings yet

- 19DV - Guide SpecsDocument6 pages19DV - Guide SpecsVijay BaskaranNo ratings yet

- 15730-DX Cooling Units Rev 01Document10 pages15730-DX Cooling Units Rev 01abdullah amanullahNo ratings yet

- Project Standard Specification: Computer-Room Air-Conditioning Units 15783 - Page 1/11Document11 pagesProject Standard Specification: Computer-Room Air-Conditioning Units 15783 - Page 1/11adel rihanaNo ratings yet

- Section 237416-11 - Packaged Small Capacity Rooftop Air Conditioning UnitsDocument15 pagesSection 237416-11 - Packaged Small Capacity Rooftop Air Conditioning UnitsChase GietterNo ratings yet

- 15-1-1 - Air Conditioning SystemDocument12 pages15-1-1 - Air Conditioning Systemfarshan296015No ratings yet

- Section 23 81 24Document5 pagesSection 23 81 24Ismail MohammadNo ratings yet

- p021.46 Db54 Mat Mep Mech 030 DX Split Ac UnitDocument283 pagesp021.46 Db54 Mat Mep Mech 030 DX Split Ac Unitp4p7 projectsNo ratings yet

- Mechanical Draft Cooling TowerDocument6 pagesMechanical Draft Cooling TowerNoushad P HamsaNo ratings yet

- Cooling TowersDocument4 pagesCooling TowersAmando GonzalesNo ratings yet

- Fans & VentilatorsDocument10 pagesFans & Ventilatorsahmedbhit04No ratings yet

- 23 21 14 Hydronic SpecialtiesDocument7 pages23 21 14 Hydronic SpecialtiesSoumojit SamantaNo ratings yet

- 15860-HVAC FANSDocument6 pages15860-HVAC FANSaaquilNo ratings yet

- Heat Exchangers SpecsDocument4 pagesHeat Exchangers SpecsElias RizkNo ratings yet

- Section 235400 - FurnacesDocument9 pagesSection 235400 - FurnacesChase GietterNo ratings yet

- HVAC Guide Specifications 06D and 06E Semi-Hermetic Reciprocating Compressor Unit 3 To 15 Tons 06D 20 To 40 Tons 06E Part 1 - GeneralDocument1 pageHVAC Guide Specifications 06D and 06E Semi-Hermetic Reciprocating Compressor Unit 3 To 15 Tons 06D 20 To 40 Tons 06E Part 1 - Generallincoln cunhaNo ratings yet

- Standard Updated-VRF Specification-Crown Home ConsultantDocument41 pagesStandard Updated-VRF Specification-Crown Home ConsultantneamatallahNo ratings yet

- Highlighted-VRF Specification-Crown Home ConsultantDocument41 pagesHighlighted-VRF Specification-Crown Home ConsultantneamatallahNo ratings yet

- 23 2300 - Refrigerant Piping PDFDocument6 pages23 2300 - Refrigerant Piping PDFMohamed FawzyNo ratings yet

- Sample Chiller SpecificationDocument5 pagesSample Chiller Specificationjlcheefei9258No ratings yet

- Variable Refrigerant FlowDocument15 pagesVariable Refrigerant FlowHoward RoarkNo ratings yet

- Fan & Motor SpecsDocument15 pagesFan & Motor SpecsMahmoud GwailyNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- SECTION 15855 Air Outlets and Inltes Part 1 - General 1.1 Related DocumentsDocument4 pagesSECTION 15855 Air Outlets and Inltes Part 1 - General 1.1 Related DocumentsMunir RasheedNo ratings yet

- SECTION 15622 Package Water Chillers - Centrifugal and Screw General 1.1Document10 pagesSECTION 15622 Package Water Chillers - Centrifugal and Screw General 1.1Munir RasheedNo ratings yet

- SECTION 15970 Building Management System (BMS) Part 1 GeneralDocument75 pagesSECTION 15970 Building Management System (BMS) Part 1 GeneralMunir RasheedNo ratings yet

- SECTION 15761 Electrical Heaters Part 1 - General 1.1 General RequirementsDocument3 pagesSECTION 15761 Electrical Heaters Part 1 - General 1.1 General RequirementsMunir RasheedNo ratings yet

- SECTION 15411 Hvac Piping and Fitting Materials Part 1 - General 1.1 Related DocumentsDocument10 pagesSECTION 15411 Hvac Piping and Fitting Materials Part 1 - General 1.1 Related DocumentsMunir RasheedNo ratings yet

- SECTION 15815 Sheet Metal Duct Work Part 1 - General 1.1 Related DocumentsDocument14 pagesSECTION 15815 Sheet Metal Duct Work Part 1 - General 1.1 Related DocumentsMunir RasheedNo ratings yet

- Alys - Technical-Datasheet - en CATALOGDocument2 pagesAlys - Technical-Datasheet - en CATALOGMunir RasheedNo ratings yet

- SECTION 15440 Plumbing Pumps General 1.1Document6 pagesSECTION 15440 Plumbing Pumps General 1.1Munir RasheedNo ratings yet

- SECTION 15763 Fan Coils Units Part 1 - General 1.1 Related DocumentsDocument4 pagesSECTION 15763 Fan Coils Units Part 1 - General 1.1 Related DocumentsMunir RasheedNo ratings yet

- Water Treatment and Chemical Cleaning System 15189Document2 pagesWater Treatment and Chemical Cleaning System 15189Munir RasheedNo ratings yet

- SECTION 11130 Audio-Visual Equipment Rev 0Document14 pagesSECTION 11130 Audio-Visual Equipment Rev 0Munir RasheedNo ratings yet

- Meters and Gauges 15122 - PageDocument4 pagesMeters and Gauges 15122 - PageMunir RasheedNo ratings yet

- Design Basis Format: First Seven (7) Chapter Are Same in Specification and MRDocument3 pagesDesign Basis Format: First Seven (7) Chapter Are Same in Specification and MRMunir RasheedNo ratings yet

- SECTION 15110 Valves Part 1 - General 1.01 Related DocumentsDocument9 pagesSECTION 15110 Valves Part 1 - General 1.01 Related DocumentsMunir RasheedNo ratings yet

- Sanitary Waste and Vent Piping 15150Document15 pagesSanitary Waste and Vent Piping 15150Munir RasheedNo ratings yet

- SECTION 11470 Darkroom Equipment Rev 0Document12 pagesSECTION 11470 Darkroom Equipment Rev 0Munir RasheedNo ratings yet

- Mechancial Process PacakgeDocument8 pagesMechancial Process PacakgeMunir RasheedNo ratings yet

- SECTION 15075 Mechanical Identification: 1-1/2 Inches 1.9 X 0.75 InchesDocument4 pagesSECTION 15075 Mechanical Identification: 1-1/2 Inches 1.9 X 0.75 InchesMunir RasheedNo ratings yet

- PumpsDocument6 pagesPumpsMunir RasheedNo ratings yet

- SECTION 15850 Air Outlets and Inlets Rev 0Document31 pagesSECTION 15850 Air Outlets and Inlets Rev 0Munir RasheedNo ratings yet

- SECTION 11450 Residential Equipment Rev 0Document21 pagesSECTION 11450 Residential Equipment Rev 0Munir RasheedNo ratings yet

- DIALux Module InformationDocument5 pagesDIALux Module InformationMunir RasheedNo ratings yet

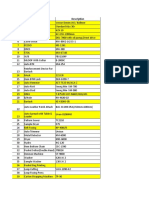

- With - Load - New Equipment Data (Main File)Document8 pagesWith - Load - New Equipment Data (Main File)Munir RasheedNo ratings yet

- SECTION 15935 Building Systems Controls Rev 0Document70 pagesSECTION 15935 Building Systems Controls Rev 0Munir RasheedNo ratings yet

- Electrical ScheduleDocument4 pagesElectrical ScheduleMunir RasheedNo ratings yet

- SECTION 15670 Refrigerant Condensing Units Rev 0Document24 pagesSECTION 15670 Refrigerant Condensing Units Rev 0Munir RasheedNo ratings yet

- SECTION 15410 Plumbing Fixtures Rev 0Document38 pagesSECTION 15410 Plumbing Fixtures Rev 0Munir RasheedNo ratings yet

- SECTION 15955 Testing, Adjusting and Balancing Rev 0Document40 pagesSECTION 15955 Testing, Adjusting and Balancing Rev 0Munir RasheedNo ratings yet

- SECTION 15340 Water Spray Fixed Systems Rev 0Document43 pagesSECTION 15340 Water Spray Fixed Systems Rev 0Munir RasheedNo ratings yet

- SECTION 15920 Pneumatic Controls Rev 0Document39 pagesSECTION 15920 Pneumatic Controls Rev 0Munir RasheedNo ratings yet

- Steam Absorption ChillerDocument3 pagesSteam Absorption ChillerAbd AbdulNo ratings yet

- Standards Actions: Interim Meetings Cont. Public Review-Call For CommentsDocument2 pagesStandards Actions: Interim Meetings Cont. Public Review-Call For Commentsapi-124799407No ratings yet

- Relative Humidity-Temperature Relationships of Some Saturated Salt Solutions in The Temperature Range 0 To 50 CDocument8 pagesRelative Humidity-Temperature Relationships of Some Saturated Salt Solutions in The Temperature Range 0 To 50 Chendry taputraNo ratings yet

- Details Model: Cooling PerformanceDocument2 pagesDetails Model: Cooling Performanceعامر شیخ100% (1)

- LM20020 A AHF AHK Installation Instructions 02 15Document12 pagesLM20020 A AHF AHK Installation Instructions 02 15Lisa TerzoNo ratings yet

- Chiller Check ListDocument3 pagesChiller Check ListMohammed ErshadNo ratings yet

- Armstrong 4SCU14LB-OMNIGUARD SPECSHEETDocument9 pagesArmstrong 4SCU14LB-OMNIGUARD SPECSHEETMichael MartinNo ratings yet

- Mitsubishi Mr. Slim M Series Mini Split SystemsBrochureDocument24 pagesMitsubishi Mr. Slim M Series Mini Split SystemsBrochuree-ComfortUSANo ratings yet

- UATYQ-CY1 - Product Flyer - ECPEN17-118A - EnglishDocument2 pagesUATYQ-CY1 - Product Flyer - ECPEN17-118A - EnglishhamedNo ratings yet

- EW (A - Y) T-CZ (N - P - H) - Data Book - EEDEN23 - EnglishDocument64 pagesEW (A - Y) T-CZ (N - P - H) - Data Book - EEDEN23 - EnglishFrancisco Javier GuiradoNo ratings yet

- BMS Concept (What Is BMS)Document25 pagesBMS Concept (What Is BMS)cauvongkhongmauNo ratings yet

- Performance Evaluation of The Floor Mounted Air-Conditioning UnitDocument14 pagesPerformance Evaluation of The Floor Mounted Air-Conditioning Unitroronoa zoroNo ratings yet

- Psychrometric BasicsDocument87 pagesPsychrometric BasicstayyabNo ratings yet

- As of March 2021 List of Certified RefrigeratorsDocument23 pagesAs of March 2021 List of Certified RefrigeratorsnikerNo ratings yet

- Mine Ventilation Act. 10Document7 pagesMine Ventilation Act. 10Loren Mae DetaloNo ratings yet

- AERMECDocument2 pagesAERMECNedžadDžokoNo ratings yet

- User Manual: PolocoolDocument19 pagesUser Manual: PolocoolColin LeakeNo ratings yet

- Report On Cascade Refrigeration SystemsDocument11 pagesReport On Cascade Refrigeration SystemsJashandeep SinghNo ratings yet

- Chilled Water Cooling Plant Quarterly Insepction ReportDocument1 pageChilled Water Cooling Plant Quarterly Insepction ReportFaisal MuneerNo ratings yet

- Product List GeneralDocument12 pagesProduct List GeneralAriantoNo ratings yet

- NA15695A Aquaciat Power HEEDocument22 pagesNA15695A Aquaciat Power HEEMohamed MouslimNo ratings yet

- Review Phase Equilibrium and VLE ModelingDocument65 pagesReview Phase Equilibrium and VLE ModelingW_LinNo ratings yet

- Hvac Design Sourcsecond Edition W Larsen Angel Full ChapterDocument67 pagesHvac Design Sourcsecond Edition W Larsen Angel Full Chaptergregory.ray965100% (11)

- Catalogo Compresores DaewooDocument22 pagesCatalogo Compresores DaewooJose Luis PellerinoNo ratings yet

- Datenblatt Vitocal 200-S - GBDocument10 pagesDatenblatt Vitocal 200-S - GBVlastimir PejićNo ratings yet

- Hvac Factsheet Cleaning Coils 09 13Document3 pagesHvac Factsheet Cleaning Coils 09 13razali131266No ratings yet

- Daikin Pocket Guide To Air ConditioningDocument84 pagesDaikin Pocket Guide To Air ConditioningEm Mar100% (3)

- Qfta MRTR No. 1. TL: 6r Orq Inr L+: 5ffi Ftql'traerraDocument2 pagesQfta MRTR No. 1. TL: 6r Orq Inr L+: 5ffi Ftql'traerraSauravDagurNo ratings yet

- Humidification and DryingDocument2 pagesHumidification and DryingAstra Beckett0% (1)

- Alternative RefrigerantsDocument39 pagesAlternative RefrigerantsnbaddepudiNo ratings yet