Professional Documents

Culture Documents

Segment 031 of S21000192-Interpretative Report - Optimized

Segment 031 of S21000192-Interpretative Report - Optimized

Uploaded by

Desai NileshOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Segment 031 of S21000192-Interpretative Report - Optimized

Segment 031 of S21000192-Interpretative Report - Optimized

Uploaded by

Desai NileshCopyright:

Available Formats

CP28: Proposed Schematic Design and Master Planning for North District at Lusail

If very loose or soft materials are encountered at the foundation level, it should be removed

completely.

9.2 Bearing Pressure for the Shallow Foundations

The calculation of bearing capacity is based on the results of the uniaxial compression strength tests

on the rock core samples obtained from the boreholes. The design UCS & RQD values were

extracted after statistical calculation of the mean, standard deviation and the lower and upper bound

limits of all results and taking into consideration the degree of weathering and fracturing nature, the

percentages of the secondary materials of the bored materials and our practical experience, in

addition to using suitable factor of safety of twenty. The method of calculations is presented in

Appendix E; accordingly, allowable bearing pressure value is presented in Table 15.

Table 15: Allowable Bearing Capacity Values

Subgrade

Foundation Bearing

Foundation Reaction

Location Foundation Type Depth Capacity

Materials (KN/m3)

(m, bgl) (KN/m2)

Isolated Footings/Strip 1.0-2.0 370 -

All BHs except Footing

Simsima

locations of BHs (B<5.0m) 2.0-3.0 385 -

Limestone

(04, 05 & 15)

Raft Foundation 1.0-2.0 400 48,000

Isolated Footings/Strip 1.0-1.5 280 -

Footing

BH-04, BH-05 & Simsima 1.5-2.5 300 -

(B<5.0m)

BH-15 Limestone

Raft Foundation 1.0-2.0 330 40,000

9.3 Deep Foundation (Pile Foundations)

Based on the borehole’s logs, it is observed that the rock quality is very poor to excellent. This can

be observed from the values of Rock Quality Designation (RQD), which are ranging from 0 % to

92%. The Uniaxial Compressive Strength (UCS) values for the bedrock vary between very weak to

strong. The pile socket shall be started from the Simsima Limestone Member depth, and extends

through Rus Formation.

The method for determining of the design values for the ultimate skin friction value for rock formation

types (i.e., namely Simsima Limestone & Rus Formation) were based on all information available

from the current study, statistical analysis especially for the UCS (uniaxial compression strength)

total core recovery (TCR) and rock quality designation (RQD).

Accordingly, it is considered that bored cast-in-situ piles can be used for the ground conditions

encountered at this site. The in-situ or static pile capacity computations are necessary to estimate

the number of piles for a job and the required pile lengths for the design of the substructure elements.

All the static pile formulas may be expressed by the following basic equations:

Pile Carrying Capacity

Qp=Qb+Qs-Wp

Qp: Ultimate resistance of the pile

Qb: Ultimate resistance of the base

Qs: Ultimate resistance of the shaft

Wp: weight of the pile

S21000192 26 of 37

You might also like

- Lug Support DesignDocument11 pagesLug Support Designimrancenakk100% (6)

- Load Carrying Capacity of PilesDocument29 pagesLoad Carrying Capacity of PilesMalik Rizwan100% (1)

- Modulus of Subgrade Reaction KsDocument1 pageModulus of Subgrade Reaction Ksazamislam726537100% (1)

- CAUSON Assignment 1MDocument5 pagesCAUSON Assignment 1MEmmanuel CausonNo ratings yet

- Create An Awesome Hangman Game in Flash Using ActionScript 3Document53 pagesCreate An Awesome Hangman Game in Flash Using ActionScript 3riestathenaNo ratings yet

- Topic 2.1 Dr. KamruzzamanDocument70 pagesTopic 2.1 Dr. KamruzzamanCEG BangladeshNo ratings yet

- Subject Information:: Superstructure Type:-Simple Four Span R.C.Box Girder Clear Span: M Clear Roadway M Sidewalk MDocument8 pagesSubject Information:: Superstructure Type:-Simple Four Span R.C.Box Girder Clear Span: M Clear Roadway M Sidewalk MteweldeNo ratings yet

- Session11 - Rock Socketed Pile - Shekhar VaishampayanDocument25 pagesSession11 - Rock Socketed Pile - Shekhar VaishampayanPratik ParekhNo ratings yet

- Concrete Works Installation and Design: SPEC 00-C-02Document19 pagesConcrete Works Installation and Design: SPEC 00-C-02ismael.lorandi623No ratings yet

- Best Consultant, Unit PriceDocument2 pagesBest Consultant, Unit PriceInsanul HaqueNo ratings yet

- Design of RCC Structures Review PDFDocument55 pagesDesign of RCC Structures Review PDFAshish OjhaNo ratings yet

- Grade Slab Design For Centeral Service Building PDFDocument14 pagesGrade Slab Design For Centeral Service Building PDFDavidQNo ratings yet

- Pakistan Air Force: Development of Paf Base Bholari Kashif Aslam & Associates Pakistan (PVT) LimitedDocument2 pagesPakistan Air Force: Development of Paf Base Bholari Kashif Aslam & Associates Pakistan (PVT) LimitedWaqas AnjumNo ratings yet

- Design 250MM Micropile (Rev.1) 10-3-21Document9 pagesDesign 250MM Micropile (Rev.1) 10-3-21AlsonChin100% (2)

- Performance Study For Reinforced Concrete Bridge Piers Considering Seismic Capacity and DemandDocument37 pagesPerformance Study For Reinforced Concrete Bridge Piers Considering Seismic Capacity and DemandAslam KyonNo ratings yet

- Modulus of Subgrade Reaction KsDocument1 pageModulus of Subgrade Reaction KsmohamedabdelalNo ratings yet

- Comminution Ore TestingDocument35 pagesComminution Ore TestingHarrison Antonio Mira NiloNo ratings yet

- Description of The ProjectDocument8 pagesDescription of The ProjectCompass GreenNo ratings yet

- Grade Slab DesignDocument6 pagesGrade Slab DesignMALAY MRIDHANo ratings yet

- Concrete RatioDocument1 pageConcrete RatioKiel BuenconsejoNo ratings yet

- 295 PDFDocument3 pages295 PDFعبد القادر جمالNo ratings yet

- 2020 LEC 3 Deep FoundationDocument135 pages2020 LEC 3 Deep FoundationSky FireNo ratings yet

- REPORTDocument46 pagesREPORTS SathiyarubanNo ratings yet

- Long Side Failure: Ultimate Bearing Capacity, Q Net Bearing Capacity, Q Computed Factor of Safety, FS N Value N ValuesDocument24 pagesLong Side Failure: Ultimate Bearing Capacity, Q Net Bearing Capacity, Q Computed Factor of Safety, FS N Value N ValuesPervy SageNo ratings yet

- 1-GT Report of Interchange at CH. KM 0+000 - VPP-263Document1 page1-GT Report of Interchange at CH. KM 0+000 - VPP-263Umesh MishraNo ratings yet

- Uns Ever 2016Document19 pagesUns Ever 2016hamed karimpoorNo ratings yet

- From ASCE - Recommendations For Seismic Design of Hybrid Coupled Wall SystemsDocument3 pagesFrom ASCE - Recommendations For Seismic Design of Hybrid Coupled Wall SystemsNemanja RandelovicNo ratings yet

- Note On SBCDocument2 pagesNote On SBCPortland GeoNo ratings yet

- Sr. No. Description Qty. Unit SSR Rate (RS.) Lead Complete Rate (RS) Amount (RS.)Document5 pagesSr. No. Description Qty. Unit SSR Rate (RS.) Lead Complete Rate (RS) Amount (RS.)Vaijul DesaiNo ratings yet

- CBC - Design Assisstant - June 2019Document36 pagesCBC - Design Assisstant - June 2019G. S. YadavNo ratings yet

- A2-Pile Calculation - BH M1Document90 pagesA2-Pile Calculation - BH M1Priya GopalNo ratings yet

- Theory and AppliDocument6 pagesTheory and AppliDeep EngineeringNo ratings yet

- Research Paper Study On Comparative Analysis of The TDocument14 pagesResearch Paper Study On Comparative Analysis of The Tlilharerakesh12No ratings yet

- Estimate of Asif Masood BhaiDocument5 pagesEstimate of Asif Masood Bhaishaikh sarfarazNo ratings yet

- Shearing Strength of Plain Concrete Based of Push Off Tests - 2017Document6 pagesShearing Strength of Plain Concrete Based of Push Off Tests - 2017Young HeeNo ratings yet

- Extended Abstract Single Set of Joints 13 06 2019Document5 pagesExtended Abstract Single Set of Joints 13 06 2019Rajni SharmaNo ratings yet

- Basis of DesignDocument7 pagesBasis of DesignZohaib Sattar NagraNo ratings yet

- CES522 A 04 - Topic 2b - 1. RC Beam Design - NotesDocument13 pagesCES522 A 04 - Topic 2b - 1. RC Beam Design - NotesAizuddinNo ratings yet

- Column Load Take Down & Design For Symmetrically Reinforced Rect Columns Bent About Two AxesDocument8 pagesColumn Load Take Down & Design For Symmetrically Reinforced Rect Columns Bent About Two AxesDavid LoorNo ratings yet

- Mohammad Azhad Ukail Bin Mat Nasir - 2022855516 - Ceec2223c3 - Ecs416 - PosterDocument1 pageMohammad Azhad Ukail Bin Mat Nasir - 2022855516 - Ceec2223c3 - Ecs416 - Poster2022855516No ratings yet

- c464 Info SheetsDocument2 pagesc464 Info SheetshumaNo ratings yet

- Truss Bearing Loading - R1Document173 pagesTruss Bearing Loading - R1ANKUR GHOSHNo ratings yet

- Drilled Shaft in Rock Analysis and Design - Part3Document109 pagesDrilled Shaft in Rock Analysis and Design - Part3rshaghayan100% (2)

- Highload Anchor SZDocument10 pagesHighload Anchor SZKha PhucNo ratings yet

- Chapter 6 - Foundation in RockDocument52 pagesChapter 6 - Foundation in RockKoh Jia Jie100% (1)

- Vax Consultants Pvt. LTD.Document4 pagesVax Consultants Pvt. LTD.mohana tNo ratings yet

- Numerical Simulation of A Stage Constructed Rockfill Dam On Plastic Clay Foundation - Ashwani Kumar Verma - CWCDocument13 pagesNumerical Simulation of A Stage Constructed Rockfill Dam On Plastic Clay Foundation - Ashwani Kumar Verma - CWCdeepakverma33546No ratings yet

- 06 Calcs 10 R1 RepliesDocument110 pages06 Calcs 10 R1 RepliesAnirudh SabooNo ratings yet

- Elastomeric Bearings - CosmecDocument6 pagesElastomeric Bearings - CosmecGermar PorquerinoNo ratings yet

- Anchor Bolt DesignDocument3 pagesAnchor Bolt Designvaibhavd123No ratings yet

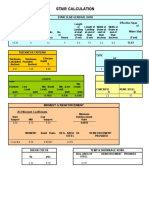

- Stair Calculation: Stair Slab General Data Effective Span of Waist Slab (Feet)Document3 pagesStair Calculation: Stair Slab General Data Effective Span of Waist Slab (Feet)Omer HayatNo ratings yet

- Estimate For The Proposed XyzDocument1 pageEstimate For The Proposed Xyzsantoshkumar gurmeNo ratings yet

- Foundation Chapter 2Document6 pagesFoundation Chapter 2Shakil AkhterNo ratings yet

- Ntanya Boq FinalDocument7 pagesNtanya Boq Finalmadhusudan GNo ratings yet

- Material Take-Off List: Wbs-4 Expense (Demolition/Sec)Document135 pagesMaterial Take-Off List: Wbs-4 Expense (Demolition/Sec)Jonald DagsaNo ratings yet

- Alan Sir - Master Qty2Document5 pagesAlan Sir - Master Qty2SuvithaNo ratings yet

- SLABS DesignDocument23 pagesSLABS DesignDeepak Kumawat100% (1)

- Column Load Take-Down Design 2Document9 pagesColumn Load Take-Down Design 2Barnabas jabiryNo ratings yet

- BSCS (BS 5930) & AASHTO Soil ClassificationDocument1 pageBSCS (BS 5930) & AASHTO Soil ClassificationDesai NileshNo ratings yet

- Segment 018 of Geophysics - Capabilities - Rev06-Without LogoDocument2 pagesSegment 018 of Geophysics - Capabilities - Rev06-Without LogoDesai NileshNo ratings yet

- Segment 004 of Geophysics - Capabilities - Rev06-Without LogoDocument2 pagesSegment 004 of Geophysics - Capabilities - Rev06-Without LogoDesai NileshNo ratings yet

- Gypsum Karst of Great BritainDocument8 pagesGypsum Karst of Great BritainDesai NileshNo ratings yet

- Laboratory and Field Evaluations of Recycled Gypsum As A Stabilizer Agent in Embankment ConstructionDocument16 pagesLaboratory and Field Evaluations of Recycled Gypsum As A Stabilizer Agent in Embankment ConstructionDesai NileshNo ratings yet

- Year 4 Optional Maths SAT Paper ADocument18 pagesYear 4 Optional Maths SAT Paper Apace_saNo ratings yet

- Momentum Assignment Class 9Document4 pagesMomentum Assignment Class 9Apex Institute0% (1)

- Math Grade 12 QuestionDocument68 pagesMath Grade 12 QuestionVî Çt ØrNo ratings yet

- NASA CoefficientsDocument94 pagesNASA CoefficientsFélix Gallo CruzNo ratings yet

- SQL Commands Glossary PDFDocument6 pagesSQL Commands Glossary PDFSCRBDusernm100% (1)

- Jeffmalpas 2012Document18 pagesJeffmalpas 2012RitaMaldonadoNo ratings yet

- Modelo de Simulación Inventario en C++Document6 pagesModelo de Simulación Inventario en C++xLordJoroxNo ratings yet

- Quantproblemset 2Document11 pagesQuantproblemset 2perxeptonNo ratings yet

- Stuvia-3924160-edexcel-as-level-statistics-paper-20232024-actual-solutionDocument14 pagesStuvia-3924160-edexcel-as-level-statistics-paper-20232024-actual-solutionKeixedsNo ratings yet

- Four Lectures On Computational Statistical Physics: February 2009Document38 pagesFour Lectures On Computational Statistical Physics: February 2009Tim JohnsonNo ratings yet

- List of Trigonometric IdentitiesDocument16 pagesList of Trigonometric IdentitiesArnab NandiNo ratings yet

- HiggsDocument36 pagesHiggsAchilleas Kapartzianis100% (1)

- Official: To Determine The Number of Top-Over Lashings Required To Prevent TippDocument4 pagesOfficial: To Determine The Number of Top-Over Lashings Required To Prevent TippJurie_sk3608No ratings yet

- 1 PDFDocument6 pages1 PDFMohamed MansourNo ratings yet

- Name: Teacher: Date: Score:: Properties of EllipsesDocument2 pagesName: Teacher: Date: Score:: Properties of EllipsesBEAL1519No ratings yet

- Florence J. Lin - Overall Rotation Due To Internal Motion in The Three-Body Problem: Applications in Molecular Dissociation and CollisionsDocument19 pagesFlorence J. Lin - Overall Rotation Due To Internal Motion in The Three-Body Problem: Applications in Molecular Dissociation and CollisionsMaxnamewNo ratings yet

- 10.3.2 Infinite Square Well: −Iωt −Iet/¯ HDocument4 pages10.3.2 Infinite Square Well: −Iωt −Iet/¯ HChandler LovelandNo ratings yet

- 特 集 有機 反応 と高圧 カ Molecular Theories Of Partial Molar: 高 圧 力 の 科 学 と技 術Vol.8,No.2 (1998)Document8 pages特 集 有機 反応 と高圧 カ Molecular Theories Of Partial Molar: 高 圧 力 の 科 学 と技 術Vol.8,No.2 (1998)wasayrazaNo ratings yet

- The Core Ideas in Our Teaching: Gilbert StrangDocument3 pagesThe Core Ideas in Our Teaching: Gilbert StrangAnonymous OrhjVLXO5sNo ratings yet

- FVM Crash IntroDocument202 pagesFVM Crash IntroThierry Gnasiri Godwe HinsouNo ratings yet

- Normal DistributionDocument25 pagesNormal DistributionARUPARNA MAITYNo ratings yet

- Australian Standard: 1 ScopeDocument12 pagesAustralian Standard: 1 Scopeyu yanNo ratings yet

- Project 2 Yeoh Jia Hui A19be0297Document46 pagesProject 2 Yeoh Jia Hui A19be0297UhGuanHongNo ratings yet

- Classification Algorithms Used in Data Mining. This Is A Lecture Given To MSC Students.Document63 pagesClassification Algorithms Used in Data Mining. This Is A Lecture Given To MSC Students.Sushil Kulkarni100% (5)

- Equivalent SPICE Circuits With Guaranteed Passivity From Nonpassive ModelsDocument8 pagesEquivalent SPICE Circuits With Guaranteed Passivity From Nonpassive ModelsAnonymous rsGzBBiqkNo ratings yet

- Instruction Set of C2xx DSP CoreDocument9 pagesInstruction Set of C2xx DSP Coreanju_prajuNo ratings yet

- c04 Proe WF 5.0Document40 pagesc04 Proe WF 5.0kamran akmalNo ratings yet

- Routing Overlay Case of Study: PASTRY: Andrea MarinDocument31 pagesRouting Overlay Case of Study: PASTRY: Andrea MarinZahra KhaerunnisaNo ratings yet

- 0580 IGCSE 22 MARCH 2024 FullDocument17 pages0580 IGCSE 22 MARCH 2024 FullArminda Sofia AzevedoNo ratings yet