Professional Documents

Culture Documents

Abrar Ahmed CV

Abrar Ahmed CV

Uploaded by

abrar ahmedCopyright:

Available Formats

You might also like

- B207A - FTHE - Questions - 2020-2021-FirstDocument3 pagesB207A - FTHE - Questions - 2020-2021-FirstRama Naveed100% (1)

- Company OIL Saudi Arabian: MNL JUL 86Document1 pageCompany OIL Saudi Arabian: MNL JUL 86RanielNo ratings yet

- Your Hand Luggage in The Welding Jungle: MambaDocument2 pagesYour Hand Luggage in The Welding Jungle: MambaGabor VatoNo ratings yet

- Stoody 2019Document100 pagesStoody 2019Okan KöksalNo ratings yet

- 510 Practice Exam 5 OB QuestionsDocument0 pages510 Practice Exam 5 OB QuestionsGireesh Hegde100% (1)

- Assad Ullah Jan: ObjectiveDocument6 pagesAssad Ullah Jan: ObjectiveManda Khel Apna DesNo ratings yet

- AWG To SQ MM Conversion Chart 1.3.15.10Document1 pageAWG To SQ MM Conversion Chart 1.3.15.10Nantawat ThanadNo ratings yet

- Msds 0864 Aquafill Wallfiller Fine en 1Document10 pagesMsds 0864 Aquafill Wallfiller Fine en 1baseet gazaliNo ratings yet

- Uzair CVDocument3 pagesUzair CVJilani ShaikNo ratings yet

- Permit CoordinatorDocument4 pagesPermit CoordinatorTanzeel UR RehmanNo ratings yet

- Ishaq CV 1Document4 pagesIshaq CV 1Muhammed ThanzeelNo ratings yet

- JOB SAFETY ANALYSIS - Idler Frame StencilingDocument1 pageJOB SAFETY ANALYSIS - Idler Frame StencilingSajith C PauloseNo ratings yet

- KIMMCO ISOVER-TDS-COMFORT SA Slab 100Document2 pagesKIMMCO ISOVER-TDS-COMFORT SA Slab 100Hussain Godhrawala100% (1)

- Safety Check (Please Put Tick ( ) Mark in The Appropriate BoxDocument8 pagesSafety Check (Please Put Tick ( ) Mark in The Appropriate BoxAntony JebarajNo ratings yet

- UPDATE JHAH DETAILS Upgradation of HVAC System at Dental Lab at BLDG # 54 DHAHRANDocument37 pagesUPDATE JHAH DETAILS Upgradation of HVAC System at Dental Lab at BLDG # 54 DHAHRANjaheerasalam299No ratings yet

- Hazard Identification Plan (Hip) & Site Visit:: 16"U/G Hwyh Gosp-3 Downstream Disposal Header (Asphalt Road)Document9 pagesHazard Identification Plan (Hip) & Site Visit:: 16"U/G Hwyh Gosp-3 Downstream Disposal Header (Asphalt Road)javithNo ratings yet

- SA-924-2 Red PrintDocument2 pagesSA-924-2 Red PrintAbdus SamadNo ratings yet

- Job Safety Analysis: Equipment - Remove Nozzle From PumpDocument3 pagesJob Safety Analysis: Equipment - Remove Nozzle From PumpSKH CultureNo ratings yet

- Gulfraz - HSE Officer - CVDocument3 pagesGulfraz - HSE Officer - CVSajid0% (1)

- Toledo Power Company: Terms of ReferenceDocument8 pagesToledo Power Company: Terms of Referencejet toledo100% (1)

- PetrominHydraulic Oil AwDocument1 pagePetrominHydraulic Oil AwfaisiiNo ratings yet

- Curriculum Vitae: Mohammad Shahid IqbalDocument4 pagesCurriculum Vitae: Mohammad Shahid Iqbalshahid imamNo ratings yet

- Procedures For Gassing DegassingDocument7 pagesProcedures For Gassing DegassingASAF KHADERNo ratings yet

- Release Notes: RDL-3000 XP Edge v3.9Document8 pagesRelease Notes: RDL-3000 XP Edge v3.9alex BecerraNo ratings yet

- 01 Camp G.I. 0298 - 010Document73 pages01 Camp G.I. 0298 - 010iftikhar ahmadNo ratings yet

- Aqib Javed CV and DocumentsDocument15 pagesAqib Javed CV and DocumentsSher DilNo ratings yet

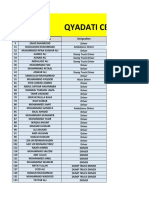

- Qyadati Certification DetailsDocument6 pagesQyadati Certification DetailsAli HassanNo ratings yet

- Amir KhanDocument11 pagesAmir KhanMunawar KhanNo ratings yet

- Health Hazards: CHB 4220 CHB 4220Document1 pageHealth Hazards: CHB 4220 CHB 4220MARKNo ratings yet

- WPR Ehsan CVDocument6 pagesWPR Ehsan CVShahid BhattiNo ratings yet

- GI 2.100 (2021) - Work Permit SystemDocument2 pagesGI 2.100 (2021) - Work Permit SystemAhmed RihanNo ratings yet

- Zamil TrainingDocument2 pagesZamil TrainingSmdharwnNo ratings yet

- SNC - Lavalin: To Whom It May ConcernDocument29 pagesSNC - Lavalin: To Whom It May ConcernDeshwa Saravanan33% (3)

- Erection Contractor's ScopeDocument4 pagesErection Contractor's ScopeasifaliabidNo ratings yet

- Permit To WorkDocument37 pagesPermit To WorkTayyab Hasnain Saadat JanjuaNo ratings yet

- F&AE - 5SemiAutomaticand AutomaticWeldingDocument8 pagesF&AE - 5SemiAutomaticand AutomaticWeldingFaiz IshakNo ratings yet

- 0002 703Document7 pages0002 703Buddharaju KiranNo ratings yet

- General Questions For The Preparation Of: WPR (Workpermitreceiver) TrainingDocument13 pagesGeneral Questions For The Preparation Of: WPR (Workpermitreceiver) TrainingsivakumarNo ratings yet

- PTW RemovedDocument71 pagesPTW RemovedSYED AHMEDNo ratings yet

- Power and Control Cable Laying, Glading and TerminationDocument9 pagesPower and Control Cable Laying, Glading and Terminationsalman100% (1)

- SMG 07-005 Application of Saudi Aramco Building Code To Contractors 2021-11-25Document38 pagesSMG 07-005 Application of Saudi Aramco Building Code To Contractors 2021-11-25baseet gazaliNo ratings yet

- Proximity Warning Alarm System - PWAS Daily Checklist: Hawiyah Unayzah Gas Reservoir Storage Project (HUGRS)Document1 pageProximity Warning Alarm System - PWAS Daily Checklist: Hawiyah Unayzah Gas Reservoir Storage Project (HUGRS)RabbanNo ratings yet

- Updated JSA For SAPMTofficeDocument30 pagesUpdated JSA For SAPMTofficeShaikh Abu bakarNo ratings yet

- Hvac CVDocument2 pagesHvac CVsarfaraz055No ratings yet

- Safety Interview Study Guide Updated VersionDocument24 pagesSafety Interview Study Guide Updated VersionakasalihseNo ratings yet

- Part II - 08 Abrasive BlastingDocument5 pagesPart II - 08 Abrasive Blastingsalah abddayemNo ratings yet

- Dellag La 3-36Document2 pagesDellag La 3-36FAIYAZ AHMEDNo ratings yet

- SAIC-X-3002 Rev 5Document3 pagesSAIC-X-3002 Rev 5aamirapiNo ratings yet

- G.I. 7 026 Crane and Heavy Equipment Incident and Investigation - 2018Document12 pagesG.I. 7 026 Crane and Heavy Equipment Incident and Investigation - 2018hasnainkhattakNo ratings yet

- ANCC ProfileDocument35 pagesANCC ProfileMohammad RawoofNo ratings yet

- 0002 100Document7 pages0002 100Ahmed FityanNo ratings yet

- Mos ScaffolidingDocument32 pagesMos ScaffolidingIMTIYAZ ALINo ratings yet

- Method For Installation of Protection Panels, Control Cable Pulling & Termination - GOSP 10Document6 pagesMethod For Installation of Protection Panels, Control Cable Pulling & Termination - GOSP 10Subhash Chekka SEC 115KV ProjectNo ratings yet

- Locked Switch/breaker Blinding Disconnect: Confined Space Entry Plan Best PracticeDocument3 pagesLocked Switch/breaker Blinding Disconnect: Confined Space Entry Plan Best PracticeREHAN IQBALNo ratings yet

- Risk Ass - ProcessDocument4 pagesRisk Ass - ProcessBalakrishnan Sivagnanam SNo ratings yet

- Iosh Osha Interveiw Session11Document45 pagesIosh Osha Interveiw Session11Sameer RajuNo ratings yet

- Glenn Dy: Safety Officer/Aramco Approved ID#8268060 and SABICDocument5 pagesGlenn Dy: Safety Officer/Aramco Approved ID#8268060 and SABICsmart_onyx17No ratings yet

- Method Statement For HDPE Pipe InstallationDocument19 pagesMethod Statement For HDPE Pipe Installationqwertykey3991No ratings yet

- Chemxseal 32-17 - MSDSDocument4 pagesChemxseal 32-17 - MSDSYASHICA VAITTIANATHAN0% (1)

- 4.JOB SAFETY ANALYSIS Lifting Project Title Installation of Wet Sprinkler System at Main WarehouseDocument8 pages4.JOB SAFETY ANALYSIS Lifting Project Title Installation of Wet Sprinkler System at Main WarehouseMuhammad Umar GondalNo ratings yet

- Sanjay Pandit Best Safety Employee Award Certificate For Month July 2017Document1 pageSanjay Pandit Best Safety Employee Award Certificate For Month July 2017api-349606419No ratings yet

- Instrument Engineer/Construction/commissioning/startupDocument6 pagesInstrument Engineer/Construction/commissioning/startupapi-77872275No ratings yet

- Lakshmipathi Raju CV-PipelineDocument5 pagesLakshmipathi Raju CV-Pipelinetshyam356No ratings yet

- GenSet Eng Part IDocument41 pagesGenSet Eng Part IpurushmicroNo ratings yet

- Weld SymbolsDocument26 pagesWeld SymbolsAju aju100% (1)

- AESS - Steel StructureDocument56 pagesAESS - Steel Structurevirginia_aureliaNo ratings yet

- TVL - Ia (Gas Metal Arc Welding) : Activity Sheet Quarter 3 - LO 1Document11 pagesTVL - Ia (Gas Metal Arc Welding) : Activity Sheet Quarter 3 - LO 1Joy BuycoNo ratings yet

- Deposition RateDocument4 pagesDeposition Rateahmed100% (1)

- Data Rates-CD Works Part 1Document20 pagesData Rates-CD Works Part 1vpmohammedNo ratings yet

- 03-Procedure For WeldingDocument8 pages03-Procedure For WeldingAyush AgarwalNo ratings yet

- Company Profile enDocument4 pagesCompany Profile enAbdul Samed NamemeNo ratings yet

- Calizar Technical Report 8Document14 pagesCalizar Technical Report 8Jazztine Andrei GecoleaNo ratings yet

- The Practical For Welding Engineer PDFDocument11 pagesThe Practical For Welding Engineer PDFRian Suari Aritonang0% (1)

- G10 ABDULAZIZ, DINSEFA, TOFIK, 2021 ProposalDocument10 pagesG10 ABDULAZIZ, DINSEFA, TOFIK, 2021 ProposalHabtamu Ye Asnaku LijNo ratings yet

- Type IV Cracking ReviewDocument9 pagesType IV Cracking ReviewKuthuraikaranNo ratings yet

- PR-1272 Standard Welding PQRs For On-Plot PipingDocument10 pagesPR-1272 Standard Welding PQRs For On-Plot Pipinghappale2002No ratings yet

- Rotary and Handling Tools Catalog PDFDocument190 pagesRotary and Handling Tools Catalog PDFjinyuan74100% (3)

- En 0011 1312 00 Ed5Document2 pagesEn 0011 1312 00 Ed5cybula.michalNo ratings yet

- Mos DcsDocument13 pagesMos DcsSudam PatraNo ratings yet

- CD-M Series 2 Manual - 2cDocument45 pagesCD-M Series 2 Manual - 2cpaulgtswNo ratings yet

- 1.2 Resistance and Special WeldingDocument14 pages1.2 Resistance and Special WeldingnikhilbathamNo ratings yet

- UNITOR Welding Handbook 10 EditionDocument550 pagesUNITOR Welding Handbook 10 Editionaegavriilidis100% (2)

- Iso 5817 Level PDFDocument19 pagesIso 5817 Level PDFbeto206123No ratings yet

- Is 5334 PDFDocument7 pagesIs 5334 PDFNav TalukdarNo ratings yet

- Waterstop Catalog 0411 PDFDocument12 pagesWaterstop Catalog 0411 PDFFrancisco EscuadraNo ratings yet

- MechanicalDocument173 pagesMechanicalKerx Endrano100% (1)

- 0361tq Bs 638 Black Welding CableDocument3 pages0361tq Bs 638 Black Welding CableAdnan KhanNo ratings yet

- 033-Itp For Piping Installation Ag and Ug PDFDocument13 pages033-Itp For Piping Installation Ag and Ug PDFKöksal Patan75% (4)

- Harmonised StandardsDocument104 pagesHarmonised StandardsccgccgNo ratings yet

- Trasformatori SGBDocument24 pagesTrasformatori SGBst_calvoNo ratings yet

Abrar Ahmed CV

Abrar Ahmed CV

Uploaded by

abrar ahmedOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Abrar Ahmed CV

Abrar Ahmed CV

Uploaded by

abrar ahmedCopyright:

Available Formats

ABRAR AHMED

EMAIL ID:

abrarahmed78607@gmail.com

CELL NO: +916362458815(whatsapp)

MECHANICAL FOREMAN

CAREER PROFILE:

Competent and diligent Mechanical Supervisor with 6+ years of experience (6+ BR CAT

INTERNATIONAL) in the Oil &Gas/ Power/Petrochemical sector in Plant Mechanical Maintenance,

Over haul, Shutdown, Industrial Construction.

To Execute –Erection/Installation/Assembly/Leveling/Alignment/ Pre commissioning of Mechanical

Equipments (Static & Rotary),its auxiliaries and Piping in Industrial Construction projects.

Installation of GAS TURBINE MS5002C DUAL FUEL and CENTRIFUGAL COMPRESSOR 3MCL 1006

Familiar with Codes like ASME, ASTM, API and Specifications regarding Piping, Welding, Material, Piping

Fabrication, Equipment Installation etc.

Involved in Shutdown activities with Replacement of pipes, Tie in activities, Over Hauling of Static &

Rotary Equipments.

EDUCATION:

DIPLOMA IN MECHANICAL ENGINEERING - MAY 2014

Board of Technical Education, Department of Technical Education, Bengaluru.

Y.K.D Polytechnic, Gulbarga- Karnataka-India.

Aggregate: 70. 01% Board level First class

PROFESSIONAL EXPERIENCE:

Since Jan-2016 to Feb-2016

Client : SAUDI ARAMCO (KSA)

Employer :BR CAT INTERNATIONAL (KSA)

Scope : SHUTDOWN OF SULPHUR RECOVERY UNIT (SRU), SHAYBAH

Mechanical Supervisor involved in Shutdown Maintenance of Heat Exchanger, Vessels, Tanks, replacement of

Piping and Hydro testing.

Since mar-2018 to nov-2018

Client : SAUDI ARAMCO (KSA)

Employer : ABENGOA COMPANY

Scope :MAINTENANCE OF SULPHUR RECOVERY UNIT (SRU), TURAIF

Mechanical Supervisor involved in Maintenance Rotary & Static Equipments. Responsible for Preventive,

Predictive, Breakdown Maintenance of Turbine-Compressor, HRSG units & its auxiliaries. Carried out Routine,

Periodic Repair & Maintenance of Pumps, Compressors, Gearboxes, Fans, Blowers, Valves, Vessels, Storage

Tanks & Exchangers, Columns, Filters.

Since Nov-2019 to AUG-2020

Client : SAUDI ARAMCO (KSA)

Employer : GLOBAL SOURCE (KSA)

Scope :SHUTDOWN OF UNIT- 68 PLPS

Mechanical Supervisor Involved in Shutdown Maintenance of Rotary Equipments includes Turbines, Pumps,

Compressors, Blowers & Fans

Since Oct 2020 to Oct 2021

Client : SAUDI ARAMCO (KSA)

Employer : PETROFAC SAUDI ARABIA LTD

Scope :SHUTDOWN & Gt4 Tie In

Mechanical Supervisor involved in Shutdown & Tie in of Process ,Service piping from Gt5 into Gt4 plants.

Since June-2016 to Sep-2017

Client : SABIC KSA

Consultant : AMEC FOSTER WHEELER. – PMC

Contractor : tecnicas reunidas (tr,Spain)

Employer :SENDAN

Scope :EPC&C of GAS TRAIN 5 PROJECT ,SATROP REFINERY, JUBAIL

Mechanical Supervisor involved in Erection, Installation, Assembly, Fabrication, Leveling, Alignment, Pre

commissioning of Static and Rotary Equipments and associated auxiliaries and spares, piping, pipe supports

associated with mechanical packages ,interconnecting Equipment skids ,Process piping and Pipe supports in

ISBL and OSBL(Brown field).Package preparation, punch list clearing (Grade A Grade B), and Pre

commissioning activities involves pipe cleanings (Air blowing, water & oil flushing ) and Re instatements

Fabrication & Modification of Equipment’s Enclosures and shelter structure, walk way structure,

platforms ,ladders ,railings Structure Assembly and welding.

Since Dec-2017 to feb-2018

Client : PETRO RABIQ (KSA)

Employer : ACIC

Scope :MAINTENANCE of SHUAIBA THERMAL POWER STATION

Mechanical Supervisor involved in Maintenance of GAS Fired Thermal Power Station. Responsible

Maintenance of Turbine, Boiler units & its auxiliaries, Pumps, Compressors, Gearboxes, Fans, Blowers, Valves,

Vessels, Storage Tanks & Exchangers

Since July-2015 to Oct-2015

Client : HINDUSTAN PETROLEUM LIMITED (HPCL),VIZAG.

Employer : BHAVANI ERECTORS PVT LTD

Scope : MAINTENANCE OF GAS PLANT

Mechanical Supervisor involved in Maintenance and repair of GAS PLANT Equipment’s. Well familiar with

the Maintenance of Static Equipment’s like columns, vessels, and all types of valves including pressure and

safety valves boilers, Rotary Equipment’s (pumps, compressors) and fabrication and welding activities.

Since July-2015 July- 2015

Client : HINDUSTAN PETROLEUM LIMITED (HPCL),VIZAG.

Employer : BHAVANI ERECTORS PVT LTD

Scope :SHUTDOWN OF GAS PLANT

Mechanical Supervisor involved in Shutdown Maintenance of Heat Exchanger, Vessels, Tanks, replacement of

Piping and Hydro testing.

Since May-2015 to June-2015

Client : ONGC MANGALORE PETROCHEMICALS LIMITED MANGALORE.

Employ : ELITE ENGINEERING INDUSTRIES.

Scope :SHUTDOWN OF SLPHUR RECOVERY UNIT.

Mechanical Supervisor Involved in Shutdown Maintenance of Rotary Equipments includes Turbines ,Pumps,

Compressors, Blowers & Fans.

Since June-2014 to Apr-2015

Client :ONGC MANGALORE PETROCHEMICALS LIMITED (OMPL)

MANGALORE.

Employer : ELITE ENGINEERING INDUSTRIES.

Contractor : THERMAX LTD.

Scope : EPC&C of Crude Distillation Unit & Vacuum Distillation Unit.

Mechanical Supervisor involved in Erection, Installation, Assembly, Leveling, Alignment, of Static and Rotary

Equipments and Erection, installation, fabrication piping, pipe supports associated with mechanical

packages ,interconnecting Equipment skids ,Process piping and Pipe supports.

Worked in Karnataka Power Corporation Limited (KPCL)Government of Karnataka India, at Raichur

Thermal Power Station as a Mechanical Supervisor in Maintenance of Boilers 2x210 MW coal fired thermal

power station. Responsible for Preventive, Predictive, Breakdown & Shutdown Maintenance of Turbine, Boiler

units & its auxiliaries.

Carried out Routine, Periodic Repair & Maintenance Rotary and Static Equipment’s like Pumps, Compressors,

Gearboxes, Fans, Blowers, Valves, Vessels, Storage Tanks & Exchangers.

Responsibility/Duties :-Mechanical Industrial Construction Projects.

Heavy Equipments Eretion, installation, leveling, preservation ,fabrication and modification of auxiliaries

parts as well as assembly:

o HRSG(Machi, Italy) ,GAS TURBINE and Propane Refrigerant Centrifugal GAS COMPRESSOR (GE) Skid

and its Auxiliary Skids ,Fresh air Fan ,Bypass Duct and Expansion Joint ,Filter House.

o Heat Exchangers, Storage tanks, Columns, Vessels, Dearators ,Drums, Condensers, Fin Fan

Coolers, Fired Heaters, all types of Centrifugal and Reciprocating Pumps, Compressors and Fans.

From Foundation to cement Grouting before piping connection and after piping connection ,Grout Voidness

check and Re-Filling.

Carried Shaft Alignment (primary & secondary) of GT & Gas Compressor ,driving assembly with gear box ,

fresh air fan assembly ,boiler feed water pump(Gould’s, Korea) turbine driven and e-motor driven, water

circulating pump ,plant air compressor, nitrogen compressor (Elliot).

Hands on Experience of Surface Leveling by Master Level, Rim and Face, Reverse and Laser Alignments of

connecting shafts before piping and after piping & Coupling parallelism check.

Responsible for Preservation of static equipments by Nitrogen filling and periodically monitoring. Rotary

equipments connecting shafts and bearing hubs greasing ,lubricating periodically maintain preservation by vpci

compound .

Complete erection, installation, preservation , pre commissioning and commissioning of mechanical packages –

demineralised water package & nitrogen packages.

Execution of on plot piping Fabrication\Erection \ Installation of the A/G (CS, LTCS, LAS& SS, FRP, GRV,

Cement lining Pipe) AND U/G Piping, piping systems, Piping Support.

Check and monitor tools, equipment and welding consumables, preservation, pipe internal cleaning of pipings.

Monitoring foremen, daily production fit up and welding records and report the status performed to the

Construction Manager.

Clearing the punch list items, construction activities and site modifications advices from client & Quality Control

department as well.

Supervised and ensure, manpower works scheduling to meet department objective.

Conduct safety meeting before job start, and ensure worksite are safe.

Prepare and make Inspection Reports (RFI) for Alignment/Bolt Tightening/Welding for Client Inspection.

Knowledge in Alloy Steel(P91&P22)&SS( 304,316,321,347 ) grades piping for execution and testing procedure.

Familiar with the WPS of ASTM A335 P91,P22& ASTM A312 TP304,TP316,TP321,TP347.

Knowledge of Preheat/Post heat & PWHT of welds. Repairing the inspection failure joints

Familiar the welding Procedures of Carbon Steels, Alloy steels &Stainless Steels.

Carrying out execution as per the set targets and monthly / weekly plan with the available manpower and

resources.

Raising all technical queries / field action report related to design as per construction code requirement with

consultant and clients engineers.

Verify of Pipe Fit up, Erection, Inspection of piping materials ,and welding. Review of weld parameters of

SMAW, GTAW according to WPS, Preparation of request for inspection.

Review of GAD’s with respect to P&ID, Isometric drawing with MTO, Piping support drawings, Equipment

layout development. Preparation of field piping system test packages

Fabrication and Erection of small bore Pipe and large bore Pipe, fire water hydrant line, underground DO line,

dilution skid piping, storage tank piping.

Planning and Conducting hydro test as per schedule and completion within time.

Prepared MTO & BOM from Isometric and GA Drawings for all materials required, additional materials for

hydro test etc. Preparation of as built drawing.

Provided technical assistance, guidance to QA/QC while inspection ,post inspection in clearing RFI with Main

contractor ,PMC ,PMT,PD, O&M clients.

Co-ordinate with KNPC operations in obtaining necessary approvals for construction activities in the operating

units.

Co-ordinate with all Disciplines (i.e., Scaffolding Electrical ,Civil ,NDT, Inspection, Insulation, Blasting and

Painting) for service requests & timely handover of job in respective disciplines

Following safe practice as per clients requirement to maximize production with minimum risk, House Keeping.

Responsibility/Duties :-Plant Mechanical Maintenance.

Mechanical Maintenance and repair of followings Refinery Equipment’s.

Strainer Cleaning, Valve Servicing, Blinding and De-Blinding jobs, Demister fixing jobs.

Maintenance of Heat exchangers of Fixed , Floating and U tube type which include activities right from blinding,

bundle pulling , cleaning , testing , repair works as per inspection , etc.,

Cleaning and Hydro test of Tanks and Vessels,

Maintenance of all major static equipment’s like heat exchangers, fin fan coolers, columns, and pressure vessels,

Steam trap servicing.

Carried out predictive maintenance, generated & planned preventive maintenance schedules for utility

equipments based on Criticality Ranking.

Overhauling of Major Rotating & Static Equipment, Trouble shooting problems of mechanical systems and plant

equipment & auxiliaries against breakdown failure

Maintenance and annual over hauling of 2x210 MW Boiler and its auxiliaries, especially in maintenance of High

Pressure Valves, Boiler Safety Valves, Boiler Drum and Drum internals, Soot Blowers, all types of Hangers, Pipe

Supports, Wall blowers, steam traps, Heating stations.

Ensure proper functioning of equipments, daily routine checkups and observations for lubrication systems,

temperature, seals for leakages, packing and gaskets, bearings, & vibration monitoring. And take corrective

action.

Observation of local spots includes CWP, HWMP, ACW Pumps, ACW Booster Pumps, Compressor, ID fan, FD

fan, PA fan, MILLS,, BFP, Seal oil system, etc.

Hands-on knowledge of Rotary shaft Alignments & Leveling of several equipments , knowledge of Dial indicator

methods (Rim &Face, Reverse) & Laser Alignments techniques.

Sound knowledge in fabrication processes of piping and machineries in corrective maintenance & repair such

Welding, Fit-up, Assembly, Milling, Turning, cutting, Grinding, Boring Electron Discharge Machining(EDM)

operations.

Preparation and guidance in making temporary Jigs, fixtures and Tools, to readily available during emergencies

occurred in failure of systems.

Good knowledge of NDT techniques (DPT MPT RT) DT techniques (Pressure test Leak test), capable of visual

inspection of weld joints, fit-up, machining operations.

Ensures good HSE practices and policies as per the client and project specifications.

Knowledge of cleaning methods of various equipments& heat exchangers (Hydro jetting, Air Blasting &

Chemical cleaning)

Allocation & arrangements of manpower as per shift schedule and requirements, availability tools, spares &

consumables at right time &right place.

Column maintenance and internal replacement (valve trays – bubble cap trays )

Preparing reports and life book for equipments as required.

Following the safety instructions in hazardous area & take proper precautions before starting the routine work.

Responsibility/Duties :-Plant Shutdowns

Mechanical Supervisor involved in Shutdown Maintenance of Heat Exchanger, Vessels, Tanks,

replacement of Piping and Hydro testing.

Overhauling of Major Rotating & Static Equipment, Trouble shooting problems of mechanical systems and

plant equipment & auxiliaries.

Overhauling of Centrifugal Compressor model 3MCL 1006, Gould’s Pumps Model no- 3600 3620 3640 3700.

Combustion - Hot gas path parts section - Axial compressor rotor and stator parts - Intake system - Exhaust

system - Gearboxes - Bearings and couplings - Driven motors.

Maintenance of high pressure shell and tube heat exchanger involving cleaning of fouled tubes with the help of

high pressure pumps/ water jetting up to 16,000 PSI pressure with the help of power lance and with the help of

hydrokinetic method.

Carrying out Hydro-Test for the Tanks as well as Pipes, witnessed sand blasting and painting of the tanks.

Complete work in Heat Exchangers ,start from the isolation of line unbolting of the channel heads, Floating head,

Bundle pull out of tubes up to 7 ton with tube numbers of 10000, Hydro-jetting of the bundles as well as of the

shell.

There of carrying repairing work in co-ordination with QC team in heat exchangers. Plugging of the tubes which

have leaks, patching of the shell plates which doesn’t met with the required thickness with approval of WPS

Experience to handle cleaning, repairing and hydro-jetting of the Vessels as well as in Drums.

SKILLS and CREDENTIALS:

AutoCAD-2008

Ms Office Internet Applications.

Fire Fighting & Fire Prevention.

Confined Space

First Aid.

H2S awareness.

PERSONAL DOSSIER:

Name : ABRAR AHMED

Passport No : V3024826

Date of Issue : 28/09/21

Date of Expiry : 27/09/2031

Marital status : Married

Address : MSK Mill Gulbarga Karnataka India

I hereby declare that the above written particulars are best of my knowledge and belief.

ABRAR AHMED

You might also like

- B207A - FTHE - Questions - 2020-2021-FirstDocument3 pagesB207A - FTHE - Questions - 2020-2021-FirstRama Naveed100% (1)

- Company OIL Saudi Arabian: MNL JUL 86Document1 pageCompany OIL Saudi Arabian: MNL JUL 86RanielNo ratings yet

- Your Hand Luggage in The Welding Jungle: MambaDocument2 pagesYour Hand Luggage in The Welding Jungle: MambaGabor VatoNo ratings yet

- Stoody 2019Document100 pagesStoody 2019Okan KöksalNo ratings yet

- 510 Practice Exam 5 OB QuestionsDocument0 pages510 Practice Exam 5 OB QuestionsGireesh Hegde100% (1)

- Assad Ullah Jan: ObjectiveDocument6 pagesAssad Ullah Jan: ObjectiveManda Khel Apna DesNo ratings yet

- AWG To SQ MM Conversion Chart 1.3.15.10Document1 pageAWG To SQ MM Conversion Chart 1.3.15.10Nantawat ThanadNo ratings yet

- Msds 0864 Aquafill Wallfiller Fine en 1Document10 pagesMsds 0864 Aquafill Wallfiller Fine en 1baseet gazaliNo ratings yet

- Uzair CVDocument3 pagesUzair CVJilani ShaikNo ratings yet

- Permit CoordinatorDocument4 pagesPermit CoordinatorTanzeel UR RehmanNo ratings yet

- Ishaq CV 1Document4 pagesIshaq CV 1Muhammed ThanzeelNo ratings yet

- JOB SAFETY ANALYSIS - Idler Frame StencilingDocument1 pageJOB SAFETY ANALYSIS - Idler Frame StencilingSajith C PauloseNo ratings yet

- KIMMCO ISOVER-TDS-COMFORT SA Slab 100Document2 pagesKIMMCO ISOVER-TDS-COMFORT SA Slab 100Hussain Godhrawala100% (1)

- Safety Check (Please Put Tick ( ) Mark in The Appropriate BoxDocument8 pagesSafety Check (Please Put Tick ( ) Mark in The Appropriate BoxAntony JebarajNo ratings yet

- UPDATE JHAH DETAILS Upgradation of HVAC System at Dental Lab at BLDG # 54 DHAHRANDocument37 pagesUPDATE JHAH DETAILS Upgradation of HVAC System at Dental Lab at BLDG # 54 DHAHRANjaheerasalam299No ratings yet

- Hazard Identification Plan (Hip) & Site Visit:: 16"U/G Hwyh Gosp-3 Downstream Disposal Header (Asphalt Road)Document9 pagesHazard Identification Plan (Hip) & Site Visit:: 16"U/G Hwyh Gosp-3 Downstream Disposal Header (Asphalt Road)javithNo ratings yet

- SA-924-2 Red PrintDocument2 pagesSA-924-2 Red PrintAbdus SamadNo ratings yet

- Job Safety Analysis: Equipment - Remove Nozzle From PumpDocument3 pagesJob Safety Analysis: Equipment - Remove Nozzle From PumpSKH CultureNo ratings yet

- Gulfraz - HSE Officer - CVDocument3 pagesGulfraz - HSE Officer - CVSajid0% (1)

- Toledo Power Company: Terms of ReferenceDocument8 pagesToledo Power Company: Terms of Referencejet toledo100% (1)

- PetrominHydraulic Oil AwDocument1 pagePetrominHydraulic Oil AwfaisiiNo ratings yet

- Curriculum Vitae: Mohammad Shahid IqbalDocument4 pagesCurriculum Vitae: Mohammad Shahid Iqbalshahid imamNo ratings yet

- Procedures For Gassing DegassingDocument7 pagesProcedures For Gassing DegassingASAF KHADERNo ratings yet

- Release Notes: RDL-3000 XP Edge v3.9Document8 pagesRelease Notes: RDL-3000 XP Edge v3.9alex BecerraNo ratings yet

- 01 Camp G.I. 0298 - 010Document73 pages01 Camp G.I. 0298 - 010iftikhar ahmadNo ratings yet

- Aqib Javed CV and DocumentsDocument15 pagesAqib Javed CV and DocumentsSher DilNo ratings yet

- Qyadati Certification DetailsDocument6 pagesQyadati Certification DetailsAli HassanNo ratings yet

- Amir KhanDocument11 pagesAmir KhanMunawar KhanNo ratings yet

- Health Hazards: CHB 4220 CHB 4220Document1 pageHealth Hazards: CHB 4220 CHB 4220MARKNo ratings yet

- WPR Ehsan CVDocument6 pagesWPR Ehsan CVShahid BhattiNo ratings yet

- GI 2.100 (2021) - Work Permit SystemDocument2 pagesGI 2.100 (2021) - Work Permit SystemAhmed RihanNo ratings yet

- Zamil TrainingDocument2 pagesZamil TrainingSmdharwnNo ratings yet

- SNC - Lavalin: To Whom It May ConcernDocument29 pagesSNC - Lavalin: To Whom It May ConcernDeshwa Saravanan33% (3)

- Erection Contractor's ScopeDocument4 pagesErection Contractor's ScopeasifaliabidNo ratings yet

- Permit To WorkDocument37 pagesPermit To WorkTayyab Hasnain Saadat JanjuaNo ratings yet

- F&AE - 5SemiAutomaticand AutomaticWeldingDocument8 pagesF&AE - 5SemiAutomaticand AutomaticWeldingFaiz IshakNo ratings yet

- 0002 703Document7 pages0002 703Buddharaju KiranNo ratings yet

- General Questions For The Preparation Of: WPR (Workpermitreceiver) TrainingDocument13 pagesGeneral Questions For The Preparation Of: WPR (Workpermitreceiver) TrainingsivakumarNo ratings yet

- PTW RemovedDocument71 pagesPTW RemovedSYED AHMEDNo ratings yet

- Power and Control Cable Laying, Glading and TerminationDocument9 pagesPower and Control Cable Laying, Glading and Terminationsalman100% (1)

- SMG 07-005 Application of Saudi Aramco Building Code To Contractors 2021-11-25Document38 pagesSMG 07-005 Application of Saudi Aramco Building Code To Contractors 2021-11-25baseet gazaliNo ratings yet

- Proximity Warning Alarm System - PWAS Daily Checklist: Hawiyah Unayzah Gas Reservoir Storage Project (HUGRS)Document1 pageProximity Warning Alarm System - PWAS Daily Checklist: Hawiyah Unayzah Gas Reservoir Storage Project (HUGRS)RabbanNo ratings yet

- Updated JSA For SAPMTofficeDocument30 pagesUpdated JSA For SAPMTofficeShaikh Abu bakarNo ratings yet

- Hvac CVDocument2 pagesHvac CVsarfaraz055No ratings yet

- Safety Interview Study Guide Updated VersionDocument24 pagesSafety Interview Study Guide Updated VersionakasalihseNo ratings yet

- Part II - 08 Abrasive BlastingDocument5 pagesPart II - 08 Abrasive Blastingsalah abddayemNo ratings yet

- Dellag La 3-36Document2 pagesDellag La 3-36FAIYAZ AHMEDNo ratings yet

- SAIC-X-3002 Rev 5Document3 pagesSAIC-X-3002 Rev 5aamirapiNo ratings yet

- G.I. 7 026 Crane and Heavy Equipment Incident and Investigation - 2018Document12 pagesG.I. 7 026 Crane and Heavy Equipment Incident and Investigation - 2018hasnainkhattakNo ratings yet

- ANCC ProfileDocument35 pagesANCC ProfileMohammad RawoofNo ratings yet

- 0002 100Document7 pages0002 100Ahmed FityanNo ratings yet

- Mos ScaffolidingDocument32 pagesMos ScaffolidingIMTIYAZ ALINo ratings yet

- Method For Installation of Protection Panels, Control Cable Pulling & Termination - GOSP 10Document6 pagesMethod For Installation of Protection Panels, Control Cable Pulling & Termination - GOSP 10Subhash Chekka SEC 115KV ProjectNo ratings yet

- Locked Switch/breaker Blinding Disconnect: Confined Space Entry Plan Best PracticeDocument3 pagesLocked Switch/breaker Blinding Disconnect: Confined Space Entry Plan Best PracticeREHAN IQBALNo ratings yet

- Risk Ass - ProcessDocument4 pagesRisk Ass - ProcessBalakrishnan Sivagnanam SNo ratings yet

- Iosh Osha Interveiw Session11Document45 pagesIosh Osha Interveiw Session11Sameer RajuNo ratings yet

- Glenn Dy: Safety Officer/Aramco Approved ID#8268060 and SABICDocument5 pagesGlenn Dy: Safety Officer/Aramco Approved ID#8268060 and SABICsmart_onyx17No ratings yet

- Method Statement For HDPE Pipe InstallationDocument19 pagesMethod Statement For HDPE Pipe Installationqwertykey3991No ratings yet

- Chemxseal 32-17 - MSDSDocument4 pagesChemxseal 32-17 - MSDSYASHICA VAITTIANATHAN0% (1)

- 4.JOB SAFETY ANALYSIS Lifting Project Title Installation of Wet Sprinkler System at Main WarehouseDocument8 pages4.JOB SAFETY ANALYSIS Lifting Project Title Installation of Wet Sprinkler System at Main WarehouseMuhammad Umar GondalNo ratings yet

- Sanjay Pandit Best Safety Employee Award Certificate For Month July 2017Document1 pageSanjay Pandit Best Safety Employee Award Certificate For Month July 2017api-349606419No ratings yet

- Instrument Engineer/Construction/commissioning/startupDocument6 pagesInstrument Engineer/Construction/commissioning/startupapi-77872275No ratings yet

- Lakshmipathi Raju CV-PipelineDocument5 pagesLakshmipathi Raju CV-Pipelinetshyam356No ratings yet

- GenSet Eng Part IDocument41 pagesGenSet Eng Part IpurushmicroNo ratings yet

- Weld SymbolsDocument26 pagesWeld SymbolsAju aju100% (1)

- AESS - Steel StructureDocument56 pagesAESS - Steel Structurevirginia_aureliaNo ratings yet

- TVL - Ia (Gas Metal Arc Welding) : Activity Sheet Quarter 3 - LO 1Document11 pagesTVL - Ia (Gas Metal Arc Welding) : Activity Sheet Quarter 3 - LO 1Joy BuycoNo ratings yet

- Deposition RateDocument4 pagesDeposition Rateahmed100% (1)

- Data Rates-CD Works Part 1Document20 pagesData Rates-CD Works Part 1vpmohammedNo ratings yet

- 03-Procedure For WeldingDocument8 pages03-Procedure For WeldingAyush AgarwalNo ratings yet

- Company Profile enDocument4 pagesCompany Profile enAbdul Samed NamemeNo ratings yet

- Calizar Technical Report 8Document14 pagesCalizar Technical Report 8Jazztine Andrei GecoleaNo ratings yet

- The Practical For Welding Engineer PDFDocument11 pagesThe Practical For Welding Engineer PDFRian Suari Aritonang0% (1)

- G10 ABDULAZIZ, DINSEFA, TOFIK, 2021 ProposalDocument10 pagesG10 ABDULAZIZ, DINSEFA, TOFIK, 2021 ProposalHabtamu Ye Asnaku LijNo ratings yet

- Type IV Cracking ReviewDocument9 pagesType IV Cracking ReviewKuthuraikaranNo ratings yet

- PR-1272 Standard Welding PQRs For On-Plot PipingDocument10 pagesPR-1272 Standard Welding PQRs For On-Plot Pipinghappale2002No ratings yet

- Rotary and Handling Tools Catalog PDFDocument190 pagesRotary and Handling Tools Catalog PDFjinyuan74100% (3)

- En 0011 1312 00 Ed5Document2 pagesEn 0011 1312 00 Ed5cybula.michalNo ratings yet

- Mos DcsDocument13 pagesMos DcsSudam PatraNo ratings yet

- CD-M Series 2 Manual - 2cDocument45 pagesCD-M Series 2 Manual - 2cpaulgtswNo ratings yet

- 1.2 Resistance and Special WeldingDocument14 pages1.2 Resistance and Special WeldingnikhilbathamNo ratings yet

- UNITOR Welding Handbook 10 EditionDocument550 pagesUNITOR Welding Handbook 10 Editionaegavriilidis100% (2)

- Iso 5817 Level PDFDocument19 pagesIso 5817 Level PDFbeto206123No ratings yet

- Is 5334 PDFDocument7 pagesIs 5334 PDFNav TalukdarNo ratings yet

- Waterstop Catalog 0411 PDFDocument12 pagesWaterstop Catalog 0411 PDFFrancisco EscuadraNo ratings yet

- MechanicalDocument173 pagesMechanicalKerx Endrano100% (1)

- 0361tq Bs 638 Black Welding CableDocument3 pages0361tq Bs 638 Black Welding CableAdnan KhanNo ratings yet

- 033-Itp For Piping Installation Ag and Ug PDFDocument13 pages033-Itp For Piping Installation Ag and Ug PDFKöksal Patan75% (4)

- Harmonised StandardsDocument104 pagesHarmonised StandardsccgccgNo ratings yet

- Trasformatori SGBDocument24 pagesTrasformatori SGBst_calvoNo ratings yet