Professional Documents

Culture Documents

JZ-500 / OZ-500: Technical Data

JZ-500 / OZ-500: Technical Data

Uploaded by

Maynor PadillaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JZ-500 / OZ-500: Technical Data

JZ-500 / OZ-500: Technical Data

Uploaded by

Maynor PadillaCopyright:

Available Formats

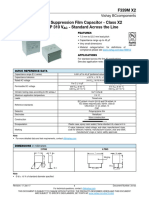

JZ-500 / OZ-500

• largely resistant to: oil,

TECHNICAL DATA for details, see "Technical Information"

• conditionally suitable for drag chains

PVC control and connection cable in alignment with DIN VDE

• conditionally torsional

0285-525-2-51 / DIN EN 50525-2-51

• the materials used during manufacturing are cadmium-free, con-

Temperature range flexible -15°C to +80°C tain no silicone and are free from substances harmful to the wetting

fixed -40°C to +80°C properties of lacquers

Nominal voltage AC Uo/U 300/500 V

Test voltage core/core 4000 V

TESTS

n

Breakdown voltage 8000 V

• flame-retardant acc. to DIN VDE 0482-332-1-2 / DIN EN 60332-

Minimum bending radius flexible 7,5x Outer-Ø

1-2 / IEC 60332-1-2

fixed 4x Outer-Ø

CABLE STRUCTURE

n APPLICATION

n

• Copper wire bare, finely stranded acc. to DIN VDE 0295 class 5 / Used for flexible applications involving medium mechanical stress

IEC 60228 class 5 with free movement, without tensile stress and without forced

• Core insulation: PVC, compound type Z 7225 motion control in dry, damp and wet rooms, however, not suitable

• Core identification acc. to DIN VDE 0293-334, black cores with for outdoor use. Used as a connection and control cable in machine

consecutive labeling in white digits tools, assembly lines and conveyor belts, production lines, in plant

• Protective conductor: starting with 3 cores, construction, air-conditioning technology, in smelters and steel

G = with protective conductor GN-YE, in the outer layer, mills. Select PVC compounds guarantee good flexibility, efficient and

x = without protective conductor (OZ) quick installation.

• Cores stranded in layers with optimal lay lengths

• Outer sheath: PVC acc. to DIN VDE 0207-363-4-1 /

DIN EN 50363-4-1 (compound type TM2) NOTES

n

• Sheath colour: grey (RAL 7001) • the conductor is metrically (mm²) constructed, AWG numbers are

• Length marking: in metres approximated, and are for reference only

05.11.2020 / We reserve the right to make technical changes; the imprint in the image is purely exemplary

• please note "cleanroom qualification" in your order

• VDE-Reg.-No. 7032

PROPERTIES

n

Part no. No. cores x AWG, Outer Cu-weight Weight Part no. No. cores x AWG, Outer Cu-weight Weight

cross-sec. approx. Ø mm, kg/km kg/km, cross-sec. approx. Ø mm, kg/km kg/km,

mm² approx. approx. mm² approx. approx.

10001 2 x 0.5 20 4.8 9.6 40.0 10023 40 G 0.5 20 15.3 192.0 434.0

10002 3 G 0.5 20 5.1 14.4 46.0 10024 42 G 0.5 20 15.8 202.0 449.0

10003 3 x 0.5 20 5.1 14.4 46.0 10025 50 G 0.5 20 17.3 240.0 513.0

10004 4 G 0.5 20 5.5 19.0 56.0 10169 52 G 0.5 20 17.3 252.0 534.0

10005 4 x 0.5 20 5.5 19.0 56.0 10026 61 G 0.5 20 18.5 293.0 625.0

10006 5 G 0.5 20 6.2 24.0 65.0 10027 65 G 0.5 20 19.2 312.0 682.0

10007 5 x 0.5 20 6.2 24.0 65.0 10028 80 G 0.5 20 21.3 384.0 780.0

10008 6 G 0.5 20 6.7 29.0 75.0 10029 100 G 0.5 20 23.8 480.0 980.0

10009 7 G 0.5 20 6.7 33.6 80.0 10030 2 x 0.75 19 5.3 14.4 46.0

10010 7 x 0.5 20 6.7 33.6 80.0 10031 3 G 0.75 19 5.6 21.6 54.0

10011 8 G 0.5 20 7.4 38.0 97.0 10032 3 x 0.75 19 5.6 21.6 54.0

10172 8 x 0.5 20 7.4 38.0 97.0 10033 4 G 0.75 19 6.3 28.8 66.0

10012 10 G 0.5 20 8.6 48.0 116.0 10034 4 x 0.75 19 6.3 28.8 66.0

10013 12 G 0.5 20 9.1 58.0 135.0 10035 5 G 0.75 19 6.9 36.0 80.0

10014 12 x 0.5 20 9.1 58.0 135.0 10036 5 x 0.75 19 6.9 36.0 80.0

10015 14 G 0.5 20 9.5 67.0 150.0 10037 6 G 0.75 19 7.7 43.0 99.0

10183 16 G 0.5 20 10.0 76.0 175.0 10177 6 x 0.75 19 7.7 43.0 99.0

10016 18 G 0.5 20 10.7 86.0 196.0 10038 7 G 0.75 19 7.7 50.0 110.0

10017 20 G 0.5 20 11.3 96.0 215.0 10039 7 x 0.75 19 7.7 50.0 110.0

10018 21 G 0.5 20 11.3 101.0 240.0 10040 8 G 0.75 19 8.3 58.0 130.0

10019 25 G 0.5 20 12.6 120.0 270.0 10173 8 x 0.75 19 8.3 58.0 130.0

10020 30 G 0.5 20 13.5 144.0 310.0 10041 9 G 0.75 19 9.1 65.0 153.0

10021 32 G 0.5 20 14.0 154.0 323.0 10042 10 G 0.75 19 9.8 72.0 162.0

10022 34 G 0.5 20 14.7 163.0 362.0 10043 12 G 0.75 19 10.1 86.0 179.0

Continued on next page

You might also like

- JZ-500 / OZ-500: Technical DataDocument3 pagesJZ-500 / OZ-500: Technical Datademetrio lopezNo ratings yet

- JZ-600 / OZ-600: Technical DataDocument3 pagesJZ-600 / OZ-600: Technical Datademetrio lopezNo ratings yet

- JZ-500 New SheetDocument3 pagesJZ-500 New SheetMay Oo MonNo ratings yet

- Helukabel M11464 en GBDocument2 pagesHelukabel M11464 en GBDaniel ChangNo ratings yet

- JZ 500Document3 pagesJZ 500maxlnw888888No ratings yet

- 1DB 10881 enDocument1 page1DB 10881 enFreddy MormontoyNo ratings yet

- Y-Cy-Jz / Y-Cy-Oz: EMC-preferred Type, With Inner SheathDocument2 pagesY-Cy-Jz / Y-Cy-Oz: EMC-preferred Type, With Inner SheathMARIA EUGENIANo ratings yet

- Helukabel M22989 en GBDocument2 pagesHelukabel M22989 en GBThirupura SundariNo ratings yet

- Tronic-Cy (Liy-Cy) / Tronic-Dy (Liy-Dy) : Colour Code DIN 47100, Without Colour Repetition, EMC-preferred TypeDocument3 pagesTronic-Cy (Liy-Cy) / Tronic-Dy (Liy-Dy) : Colour Code DIN 47100, Without Colour Repetition, EMC-preferred TypeJavier MiramontesNo ratings yet

- Oil Insulated Voltage TransformerDocument6 pagesOil Insulated Voltage TransformerJorge GutierrezNo ratings yet

- Helukabel H07 RN-FDocument2 pagesHelukabel H07 RN-FMay Oo MonNo ratings yet

- Jz-604 TC Tray Cable: PVC Power Cable, Open Installation TC-ER, NFPA 79, 90°C, 600 V, Meter MarkingDocument2 pagesJz-604 TC Tray Cable: PVC Power Cable, Open Installation TC-ER, NFPA 79, 90°C, 600 V, Meter MarkingAlejandro MoralesNo ratings yet

- Silicone Single Core, Finely Stranded, Tinned Wire, Increased Temperature ResistanceDocument2 pagesSilicone Single Core, Finely Stranded, Tinned Wire, Increased Temperature ResistanceSittiporn TamngamNo ratings yet

- Helukabel M37001 en GBDocument2 pagesHelukabel M37001 en GBMateusNo ratings yet

- YCYJZDocument2 pagesYCYJZŽarko MočnikNo ratings yet

- Mete R: AE CMD-144BDS SeriesDocument2 pagesMete R: AE CMD-144BDS SeriesWyn Power CorpNo ratings yet

- SABIX A 147 FRNC SABIX A 157 FRNC enDocument1 pageSABIX A 147 FRNC SABIX A 157 FRNC endsf gfdsgNo ratings yet

- Solarflex X h1z2z2 KDocument1 pageSolarflex X h1z2z2 KykuscuNo ratings yet

- We20 Ihd00 Le DatasheetDocument4 pagesWe20 Ihd00 Le Datasheetabdul qadirNo ratings yet

- F-Cy-Oz (Liy-Cy) : Flexible, Cu-Screened, Emc-Preferred Type, Meter MarkingDocument2 pagesF-Cy-Oz (Liy-Cy) : Flexible, Cu-Screened, Emc-Preferred Type, Meter MarkingDaniel GarciaNo ratings yet

- 21001en 17012Document2 pages21001en 17012Mahesh KumbharNo ratings yet

- VST 20 HF 220Document6 pagesVST 20 HF 22018EE25 - G.Sharan KrishnanNo ratings yet

- H07RN-F Helu KabelDocument2 pagesH07RN-F Helu KabelAshik M RasheedNo ratings yet

- HELUKABLE F-CY-JZ - Catalog PDFDocument2 pagesHELUKABLE F-CY-JZ - Catalog PDFRhey NaturalNo ratings yet

- Assured Automation R-SeriesDocument2 pagesAssured Automation R-SeriesBrandon TrocNo ratings yet

- H07RN FDocument1 pageH07RN FDuong BuiNo ratings yet

- Flexible, Number Coded, Meter MarkingDocument2 pagesFlexible, Number Coded, Meter MarkingJosé LopesNo ratings yet

- Pg032 - o Power LV (N) YyryDocument1 pagePg032 - o Power LV (N) YyryDolyNo ratings yet

- VS-GBPC.. Series: Vishay SemiconductorsDocument7 pagesVS-GBPC.. Series: Vishay SemiconductorsMohamed ReyadNo ratings yet

- 1DB 79641 enDocument1 page1DB 79641 enFreddy MormontoyNo ratings yet

- Helukabel M32480 en GBDocument2 pagesHelukabel M32480 en GBAshish bhattNo ratings yet

- Datasheet SOLARFLEX X H1Z2Z2 KDocument1 pageDatasheet SOLARFLEX X H1Z2Z2 KFerdi OfficeNo ratings yet

- BE46-122-03 J52 SwitchesDocument2 pagesBE46-122-03 J52 SwitchesMichaelNo ratings yet

- Tronic-Cy (Liy-Cy) : Flexible, Colour Coded To DIN 47100, Screened, Meter Marking, EMC-preferred TypeDocument2 pagesTronic-Cy (Liy-Cy) : Flexible, Colour Coded To DIN 47100, Screened, Meter Marking, EMC-preferred TypealexorigamiNo ratings yet

- 1DB 21001 enDocument2 pages1DB 21001 enSucii AnggraiiniiNo ratings yet

- Helukabel M32520 en GBDocument2 pagesHelukabel M32520 en GBivanramljakNo ratings yet

- ABB - Filament Wound ComponentDocument4 pagesABB - Filament Wound ComponentAbu Haydar Amin MustanginNo ratings yet

- VS-MB Series: Vishay SemiconductorsDocument7 pagesVS-MB Series: Vishay SemiconductorsMohammed Mosaad LyricsNo ratings yet

- Solarflex - X H1Z2Z2-K: 1500 V DC, EN 50618Document2 pagesSolarflex - X H1Z2Z2-K: 1500 V DC, EN 50618Solar ProjectsNo ratings yet

- Vishay 339M SpecDocument20 pagesVishay 339M SpecDino KaoNo ratings yet

- 1N5221B Won TopDocument5 pages1N5221B Won TopMarcos GuardiaNo ratings yet

- CatalogDocument131 pagesCatalogsmrasteg12No ratings yet

- VS 36mb100aDocument7 pagesVS 36mb100aatu wentNo ratings yet

- Ti 276997200 SK DCL 950 200 C en 4115 ScreenDocument3 pagesTi 276997200 SK DCL 950 200 C en 4115 ScreenyotruvustoNo ratings yet

- Paar-Tronic-Cy: Flexible, Screened, Colour Coded To DIN 47100, Meter Marking, EMC-preferred TypeDocument2 pagesPaar-Tronic-Cy: Flexible, Screened, Colour Coded To DIN 47100, Meter Marking, EMC-preferred TypeKelvin NgumbauNo ratings yet

- Nano SMD 462 Series FuseDocument3 pagesNano SMD 462 Series Fuseedgar_dauzonNo ratings yet

- Wandfluh SIN35VDocument2 pagesWandfluh SIN35VChairuddin SaidNo ratings yet

- Pg019-020 - Lapp Kabel h07v-K - Amend 290413Document2 pagesPg019-020 - Lapp Kabel h07v-K - Amend 290413Anonymous c5g3oQZ0No ratings yet

- Ce 362sbDocument2 pagesCe 362sbCRISENTENANo ratings yet

- Oil Insulated Current Transformers - 2022 WebDocument6 pagesOil Insulated Current Transformers - 2022 WebJuan Rodrigo Mamani PollogueriNo ratings yet

- Oil Insulated Current TransformersDocument6 pagesOil Insulated Current TransformersAndrea AtzeniNo ratings yet

- Rotary Encoder ENC Series Instruction ManualDocument1 pageRotary Encoder ENC Series Instruction ManualArie Cahyo UtomoNo ratings yet

- Vdrs Series: Vishay BccomponentsDocument20 pagesVdrs Series: Vishay BccomponentsAmir SoleimanyNo ratings yet

- VDRH Series: Vishay BccomponentsDocument25 pagesVDRH Series: Vishay BccomponentsAmir SoleimanyNo ratings yet

- DS Limitor P Back Up Fuse Links Without Controlled Power Dissipation ENDocument12 pagesDS Limitor P Back Up Fuse Links Without Controlled Power Dissipation ENGilberto MejiaNo ratings yet

- Ehr 4Document4 pagesEhr 4jorgeNo ratings yet

- "ZNR" Transient/Surge Absorbers, SMD Type: Features Recommended ApplicationsDocument5 pages"ZNR" Transient/Surge Absorbers, SMD Type: Features Recommended Applicationsکوروش بزرگNo ratings yet

- Vishay Bccomponents: FeaturesDocument6 pagesVishay Bccomponents: FeaturesDhaval PatelNo ratings yet

- Vdrs Series: Vishay BccomponentsDocument20 pagesVdrs Series: Vishay BccomponentssaikumarNo ratings yet

- Eportfolio Resume 20190325Document3 pagesEportfolio Resume 20190325api-452776602No ratings yet

- Scissor Lifts enDocument8 pagesScissor Lifts enrezaNo ratings yet

- SaludDocument16 pagesSaluddianamera84No ratings yet

- MFG Fiberglass Column Forms Product SheetDocument3 pagesMFG Fiberglass Column Forms Product SheetAboalmaail AlaminNo ratings yet

- Indigo Cadet Programme Course PriceDocument5 pagesIndigo Cadet Programme Course PriceSNo ratings yet

- Psychological TheoriesDocument19 pagesPsychological TheoriesYapieeNo ratings yet

- Manual Lists in Engine RoomDocument6 pagesManual Lists in Engine RoomAkhilvjohnNo ratings yet

- PolityDocument10 pagesPolityKedar BhasmeNo ratings yet

- Technical Data Sheet: Hanson Construction AggregatesDocument9 pagesTechnical Data Sheet: Hanson Construction AggregatesShaiful ZamriNo ratings yet

- Hương Fiona - Đề 2 (ĐÃ GIẢI)Document19 pagesHương Fiona - Đề 2 (ĐÃ GIẢI)Nguyen CuongNo ratings yet

- Project - Crime Scene ReportDocument7 pagesProject - Crime Scene Reportapi-328383794No ratings yet

- Receta PastelDocument5 pagesReceta PastelJesus BeltranNo ratings yet

- Tanda, Ciri-Ciri Dan Perbedaan Versi B InggrisDocument2 pagesTanda, Ciri-Ciri Dan Perbedaan Versi B Inggriselama natilaNo ratings yet

- PU LPH 80540 80553 Esite GBDocument7 pagesPU LPH 80540 80553 Esite GBAl-Alamiya TradeNo ratings yet

- Titration of Vinegar Lab ReportDocument8 pagesTitration of Vinegar Lab ReportIbrahim Abdulkadir JumaNo ratings yet

- 01 5 CF BFDocument357 pages01 5 CF BFblaiNo ratings yet

- Wordlist Level2Document3 pagesWordlist Level2SamiyaNo ratings yet

- Room Checksums: 01F-Phong Khach&Bep Heating Coil Peak CLG Space Peak Cooling Coil Peak TemperaturesDocument6 pagesRoom Checksums: 01F-Phong Khach&Bep Heating Coil Peak CLG Space Peak Cooling Coil Peak TemperaturesSieuNhanNo ratings yet

- January 2020Document64 pagesJanuary 2020Eric Santiago100% (1)

- Criminal Law 2008 Zone B PaperDocument5 pagesCriminal Law 2008 Zone B Paperశ్రీ లత Sri Lata100% (1)

- Fruit Serving Calculation PureesDocument2 pagesFruit Serving Calculation PureesRuben ViegasNo ratings yet

- Hardware - SoftwareDocument12 pagesHardware - SoftwareMarie Kelsey Acena MacaraigNo ratings yet

- HECAT Module AODDocument26 pagesHECAT Module AODririhenaNo ratings yet

- Throat AnatomyDocument70 pagesThroat AnatomyMegan ShanzuNo ratings yet

- SignStructuresGuide2010 PDFDocument54 pagesSignStructuresGuide2010 PDFindunil100% (1)

- Gaius SMW Incest Sister BrotherDocument5 pagesGaius SMW Incest Sister BrotherShyam BhatNo ratings yet

- Guptautkarsh@dsnlu Ac inDocument2 pagesGuptautkarsh@dsnlu Ac inUTKARSH GUPTANo ratings yet

- 3m ReportDocument22 pages3m Reportapi-321324040No ratings yet

- Injuries Diseases & Disorders of The Muscular SystemDocument22 pagesInjuries Diseases & Disorders of The Muscular SystemAngeli LozanoNo ratings yet

- Chem. Commun., 2014, 50, 1101-1103Document3 pagesChem. Commun., 2014, 50, 1101-1103RohanNo ratings yet