Professional Documents

Culture Documents

SMDC Controller: Mobile Lubrication Systems

SMDC Controller: Mobile Lubrication Systems

Uploaded by

DedeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SMDC Controller: Mobile Lubrication Systems

SMDC Controller: Mobile Lubrication Systems

Uploaded by

DedeCopyright:

Available Formats

SMDC Controller

Mobile Lubrication Systems

Operation

The SMDC Controller is a multi-purpose programmable controller used with on-board mobile

lubrication systems. The unit is energized by the vehicle or machine’s ignition switch. Controller

settings are saved whenever power is interrupted. Up to four operating modes can be selected

which allows the controller to be used with various lubrication system designs. A voltage selector

switch is located inside the enclosure for both 12 and 24 VDC service.

Features

++ Digital status display on front cover for easy programming

++ System monitoring capabilities

++ Data memory function initiated at power down

++ Compact design

Technical Data Controller Status LEDs

Operating Voltage 12 VDC, 24 VDC (factory setting) Red Steady Lubrication cycle

IP Enclosure Rating External terminal strip IP-47 Yellow Steady Low Level

Liquid tight connector IP-67 Green Steady Power supply on

Fault Relay Contacts 24 VDC, 1 amp None Lit No input power

to controller

Ambient Temperature -4°F to 104°F (-20ºC to 40ºC)

Weight 0.3 kg

Electrical Fuse 10 amp

Installation

Mount the controller in a clean area with easy access for programming and visual checking.

Mount controller on a flat surface.

How to Order

Name Description Part #

SMDC Controller Controller with external terminal strip 33346ME

Controller with liquid tight connector 33346E

When ordering, specify by name, description and part number, e.g. SMDC Controller with external NOTE:

terminal strip, Part #33346ME.

++ Part number will be labeled with

Accessories Rev #“R3”

Description Part #

Replacement Fuse 31076-5 BIJUR DELIMON INTERNATIONAL

(919) 465 4448 LOCAL

(800) 631 0168 TOLL-FREE

(919) 465 0516 FAX

WWW.BIJURDELIMON.COM

1 Copley Parkway, Suite 104

Morrisville, NC 27560

1 46911 • R10 09/21

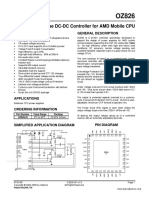

Electrical Terminal Connections

Legend

Motor Driven Lubricators Pneumatically-activated Lubricators Chassis ground

Power supply

(12 or 24 VDC)

DC motor

DC solenoid

Connection # Description

Cycle switch or

1 Positive (+) 12 or 24 VDC supply

pressure switch

2 Negative (–) chassis ground

Low level switch

3 Motor output 12 or 24 VDC (closed at low level)

4 Common (for cycle completion and low level inputs) Alarm light (Typ.)

5 Input- cycle completion Mode 2 (pressure switch)

Mode 3 (cycle switch)

6 Input- low level (closed at low level) Or Machine Count Input Wiring an NPN Cycle Switch

7&8 Fault switch (normally open contact rating 1 amp max)

BR BL BK

Operation

Voltage Selection Cycle Switch

Before connecting with the power supply, set the voltage switch on the top-left of main circuit board

to the correct position for desired input voltage (12 or 24 VDC).

Keys Description

S Select R Enter and reset tu Step selection p Adjustment

With the controller energized:

++ Press keys S and R simultaneously and release to enter control mode.

++ The display panel will now show a fixed letter for the selected mode and a flashing number (1-4).

++ To select the required mode press the p key.

++ Press the S key to advance to the next parameter of the selected mode.

++ Repeat steps 3 and 4 above using the tu key to move across the digits and the p key to change

the value of the selected flashing digit.

++ On completion, press the R key to save the data and initiate a lubrication cycle.

Manual Override

++ With the controller energized press the R key to initiate a lubrication cycle.

Program Review

++ To review the preset data, press the S key repeatedly with the controller energized. BIJUR DELIMON INTERNATIONAL

++ To return to operating condition display, press R key or release S key for 5 seconds. (919) 465 4448 LOCAL

(800) 631 0168 TOLL-FREE

Fault Alarm (919) 465 0516 FAX

++ In any alarm condition, e.g. low level, low pressure etc., the pump will not be able to operate and WWW.BIJURDELIMON.COM

the alarm will be displayed. For low level, the level LED will illuminate. The fault condition must be 1 Copley Parkway, Suite 104

rectified to cancel the alarm and reactivate the system. Morrisville, NC 27560

2 46911 • R10 09/21

Operation Mode SET-UP MODE “S”+”R” REVIEW ”S”

* For lubricators fitted with

low level switch

Timer Control Mode (d 1) CONTROL MODE 1~4 X

Recommended for Systems without 1 2 3 4

a Pressure Switch or Cycle Switch “S” “S” “S” “S”

RUN TIME X X X MONITOR X X X CYCLE X X X PRESSURE X X

Low level alarm function enabled* 1~999

“S”

TIME

1~999(S)

COUNT

1~999(C)

COUNT

1~99(C) “S”

X X

“S” “S”

In this mode, the lubricating system 1: SECOND

HOLD

“S” PRESSURE X X X MONITOR

TIME

X X X PULSE ON X X

2: MINUTE 1~99(S)

runs according to the preset run 3: HOUR

1~99(S)

“S” 1~999(S) “S” “S”

time and idle time. PULSE OFF

1~99(S)

X X

IDLE TIME “S”

1~9999

Pressure Control Mode (d 2) X X X X

“S”

Recommended for Injector Systems 1: SECOND X

2: MINUTE “R” “S”

3: HOUR

Pressure switch function enabled/ 4: x1 CYCLE RETURN TO SET UP MODE

5: x10 CYCLES

Low level alarm function enabled* 6: x100 CYCLES

RUN

A pressure switch installed

downstream from the pump

functions as the key monitoring device for the entire system. Normally the system will build up

sufficient pressure required to activate the pressure switch (normally open) in a predetermined

period of time (called monitor time) once the pump starts. The user can adjust the monitor time to a

setting greater than the time required to satisfy the pressure switch (normally 1.5 times greater). If

the system fails to reach sufficient pressure during that time period an alarm signal will be displayed

(EEPP appears on the digital readout). Possible causes for this type of alarm could be pump

malfunction, broken supply line or crushed supply line prior to pressure switch. Lubrication intervals

are adjustable from 1 to 9999 (seconds/minutes/hours). An adjustable run delay (1-99 seconds)

following a pressure switch closure assures adequate pressure downstream from the pump.

Cycle Control Mode (d 3)

Recommended for Progressive systems

Cycle switch function enabled/ Low level alarm function enabled*

The cycle switch mounted on a progressive divider valve is the key monitoring device for the entire

system. Normally when grease is being discharged from the outlets of the divider valve, a cycle pin

engages with the switch, confirming a successful lubrication cycle. The controller can be programmed

to allow for a predetermined number of cycle counts (1-999). Once the preset number of counts is

obtained the controller will stop the pump and revert back to the idle time setting (1-9999 seconds/

minutes/hours). If there is no activity from the cycle switch within a specified period of time

(Monitor time: 1-999 seconds), an alarm signal will be displayed (EEcY appears on the digital

readout). Possible causes for this type of alarm could be pump malfunction, divider valve malfunction,

broken supply line or blocked supply line or feed line.

Pulse Control Mode (d 4)

Recommended for Pulse systems

Low level alarm function enabled*

BIJUR DELIMON INTERNATIONAL

This mode is designed for pulse systems where the pump doesn’t run continuously, such as a (919) 465 4448 LOCAL

pneumatically actuated piston pump. The controller can be programmed to initiate multiple on/off (800) 631 0168 TOLL-FREE

signals to a solenoid valve for frequent cycling of the pump. (919) 465 0516 FAX

WWW.BIJURDELIMON.COM

1 Copley Parkway, Suite 104

Morrisville, NC 27560

3 46911 • R10 09/21

Operation Mode Cont.

Advanced Setup Mode

In Advanced Setup Mode, additional PRESS AND HOLD KEYS.

features may be set to suit special WHILE HOLDING , PRESS THE S KEY.

application requirements. ADVANCED SETUP MODE

Upon power on, lubrication resumes

To enter Advance Setup Mode: PRE-LUBE AT at last know position. (default)

POWER ON

“S” Upon power on, a lube cycle will

initiate. (Pre-lube)

LOW LEVEL Alarm when closed. (default)

POLARITY

“S” Alarm when open.

Fault contacts (7,8) close during alarm

FAULT RELAY condition. For use with alarm light. (default)

STATE

“S” Fault contacts (7,8) open during alarm

condition. Fail-safe, for use with PLC.

RUN TIME 0: Disable. (default)

MONITOR 1: Enable. If there is no low level during

“S” the set operation monitoring time, it

FUNCTION

indicated that the oil output does not

meet the expectation & will alarm.

nc: Disable. (default) When low level occurs,

LOW LEVEL the low level alarm will be eliminated

ALARM LOCK automatically.

“S”

FUNCTION no: Enable. After low level occurs (even

if full oil is added) the low level will not

be eliminated automatically. It is

necessary to press “R” key for reset.

“S”

“R”

RUN

Fault Conditions:

• ”EEPP”-Monitor time-out

(Mode d2 - Injectors) Pressure switch did not activate within monitor time.

• ”EEHP”-Pressure switch failure

(Mode d2 - Injectors) Pressure switch was activate at the beginning of a lube cycle. Once customer

fixes pressure switch - alarm will clear automatically.

• ”EEcY”-Monitor time-out

(Mode d3 - Progressive) Cycle switch did not activate within monitor time.

• ”EE”-Internal memory failure

(Checked at power up) No recovery. Turn off power and try again. If problem persists, replace

control.

• ”EELL”-“Yellow LED” -Low Level

(Steady Yellow) Low lubricant level has been detected.

• ”LLPP”-”Green LED” -Low Voltage BIJUR DELIMON INTERNATIONAL

Check and apply correct voltage (919) 465 4448 LOCAL

(800) 631 0168 TOLL-FREE

(919) 465 0516 FAX

WWW.BIJURDELIMON.COM

1 Copley Parkway, Suite 104

Morrisville, NC 27560

4 46911 • R10 09/21

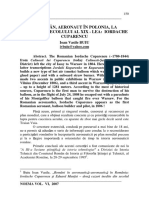

Dimensional Schematics Measurements shown in millimeters.

EXTERNAL TERMINAL STRIP

88 47.8

60

Ø5.5 MOUNTING HOLES

154

142

NUMERICAL DISPLAY

ADJUSTMENT KEYS

LIQUID TIGHT CONNECTOR

BIJUR DELIMON INTERNATIONAL

(919) 465 4448 LOCAL

(800) 631 0168 TOLL-FREE

(919) 465 0516 FAX

WWW.BIJURDELIMON.COM

1 Copley Parkway, Suite 104

Morrisville, NC 27560

5 46911 • R10 09/21

You might also like

- Manual DCP 10Document32 pagesManual DCP 10Janko Gardašević88% (8)

- A4 AC WiringDocument3 pagesA4 AC WiringDedeNo ratings yet

- 9.4 Dynamic BrakingDocument22 pages9.4 Dynamic BrakingCarlos Alberto RuedaNo ratings yet

- Amplificador de Audio Samsung MAX DC650Document9 pagesAmplificador de Audio Samsung MAX DC650Enya Andrea Ribba HernandezNo ratings yet

- Ebook NutriliteDocument15 pagesEbook Nutrilitecreovation100% (1)

- Clamped, Square Isotropic Plate With A Uniform Pressure LoadDocument3 pagesClamped, Square Isotropic Plate With A Uniform Pressure LoadLucas MartinsNo ratings yet

- SMAC Controller: Industrial Lubrication SystemsDocument5 pagesSMAC Controller: Industrial Lubrication Systemsl01363No ratings yet

- AD5245BRJZ10-R2 Potenţiometre DigitaleDocument20 pagesAD5245BRJZ10-R2 Potenţiometre DigitaleFaulhaber AdrianNo ratings yet

- AL8812Document11 pagesAL8812julio cesar calveteNo ratings yet

- Low Cost, Complete 12-Bit Resolver-to-Digital Converter: CS Is Logic HIDocument12 pagesLow Cost, Complete 12-Bit Resolver-to-Digital Converter: CS Is Logic HIFrantsiskoNo ratings yet

- Ob 2223 HCDocument11 pagesOb 2223 HCRivaldyNo ratings yet

- Cargador Enercell cr623xDocument11 pagesCargador Enercell cr623xcuco777No ratings yet

- Programmable DC/DC Controller For Advanced Microprocessors: Device Package Temp Range (T)Document6 pagesProgrammable DC/DC Controller For Advanced Microprocessors: Device Package Temp Range (T)ibrahim başderNo ratings yet

- CAT5132Document12 pagesCAT5132khaldonalwafi0No ratings yet

- Draft Sight Getting Started GuideDocument70 pagesDraft Sight Getting Started Guidesteviej85No ratings yet

- D D D D D D D D D D D D: TLV5618A 2.7-V TO 5.5-V LOW-POWER DUAL 12-BIT Digital-To-Analog Converter With Power DownDocument23 pagesD D D D D D D D D D D D: TLV5618A 2.7-V TO 5.5-V LOW-POWER DUAL 12-BIT Digital-To-Analog Converter With Power DownJulio Rafael GamboaNo ratings yet

- BD94062FDocument35 pagesBD94062FMazalan HectorNo ratings yet

- MP Hydrolic ElevatorDocument22 pagesMP Hydrolic ElevatorBjorn De BenNo ratings yet

- CH 2Document14 pagesCH 2PeterhayatNo ratings yet

- AMHHHGFDocument21 pagesAMHHHGFmadoNo ratings yet

- LUB Multiport-II PROG DS-R10Document8 pagesLUB Multiport-II PROG DS-R10Henry SuarezNo ratings yet

- Hx712 English Datasheet PDFDocument9 pagesHx712 English Datasheet PDFkibriaNo ratings yet

- Bic 2200 eDocument24 pagesBic 2200 eHassan NaveedNo ratings yet

- Hysteretic Boost-Buck (Ćuk) LED Driver IC: Features General DescriptionDocument16 pagesHysteretic Boost-Buck (Ćuk) LED Driver IC: Features General DescriptionJohnNo ratings yet

- TLV 62085Document25 pagesTLV 62085Ramón MartinezNo ratings yet

- LP339 Ultra-Low Power Quad Comparator: General DescriptionDocument10 pagesLP339 Ultra-Low Power Quad Comparator: General DescriptionahmedNo ratings yet

- Acer s220hql SMDocument50 pagesAcer s220hql SMПавел Пашко-ПащенкоNo ratings yet

- Dual-Phase DC-DC Controller For AMD Mobile CPU: Features General DescriptionDocument7 pagesDual-Phase DC-DC Controller For AMD Mobile CPU: Features General Descriptionlordycarlos8588No ratings yet

- Panasonic Cn-Tm4290a MazdaDocument18 pagesPanasonic Cn-Tm4290a Mazdaani huseinNo ratings yet

- Am 640480GTMQW T00HDocument18 pagesAm 640480GTMQW T00HHelderDosSantosNo ratings yet

- Vacon NX Heat Exchanger Application Manual DPD01890A UKDocument55 pagesVacon NX Heat Exchanger Application Manual DPD01890A UKleandroNo ratings yet

- Operation: Demo Manual Dc326BDocument5 pagesOperation: Demo Manual Dc326BMes BenNo ratings yet

- Wandfluh D - PPM22 - ME Proportional Throttle ValveDocument4 pagesWandfluh D - PPM22 - ME Proportional Throttle ValveGabriel OyedemiNo ratings yet

- Notifier FCM 1 Supervised Control ModuleDocument2 pagesNotifier FCM 1 Supervised Control ModuleAhmedNo ratings yet

- 4 Sony Monitor PDFDocument84 pages4 Sony Monitor PDFu3a96e na1susNo ratings yet

- AD7819Document12 pagesAD7819IrvinRamAltNo ratings yet

- ZT 8132Document8 pagesZT 8132Henry PalNo ratings yet

- MT7842 MaxicTechnologyDocument6 pagesMT7842 MaxicTechnologyHeart of mountainNo ratings yet

- HMK7 Intelligentized Controller: Operating InstructionsDocument16 pagesHMK7 Intelligentized Controller: Operating InstructionsRayan IbrahimNo ratings yet

- Vector Control Inverter: SeriesDocument8 pagesVector Control Inverter: SeriesEdin MahmutagicNo ratings yet

- SF-H25G Plasma Height ControlDocument23 pagesSF-H25G Plasma Height ControlgabrielNo ratings yet

- LD7523 PDFDocument18 pagesLD7523 PDFAmalio MamaniNo ratings yet

- Dynadrive: Information Manual SDFP (S) 1525-17Document15 pagesDynadrive: Information Manual SDFP (S) 1525-17Doug WilsonNo ratings yet

- Compact Display User ManualDocument17 pagesCompact Display User Manualabhi kannanNo ratings yet

- Mm74hct00 DDocument6 pagesMm74hct00 Dhouseinmohamadzade37No ratings yet

- 150 MHZ Pixel Video Controller For Monitors: FeatureDocument19 pages150 MHZ Pixel Video Controller For Monitors: Featurezerquera3000No ratings yet

- CLC5957 12-Bit, 70 MSPS Broadband Monolithic A/D Converter: General Description FeaturesDocument16 pagesCLC5957 12-Bit, 70 MSPS Broadband Monolithic A/D Converter: General Description FeaturesPeter SolyomNo ratings yet

- 3PD5651EDocument14 pages3PD5651Easousa534No ratings yet

- LM2403 Monolithic Triple 4.5 NS CRT Driver: General Description FeaturesDocument11 pagesLM2403 Monolithic Triple 4.5 NS CRT Driver: General Description FeaturesAbel RodriguezNo ratings yet

- Tp-Pwr-Dc48-400a DS V2.0.0 CombaDocument2 pagesTp-Pwr-Dc48-400a DS V2.0.0 CombaJoão SpinaNo ratings yet

- Advanced Motion Controls Dzcante 012l080 SpecsheetDocument7 pagesAdvanced Motion Controls Dzcante 012l080 Specsheetstustu242No ratings yet

- Huong Dan REC DPR2700Document16 pagesHuong Dan REC DPR2700Chim ConNo ratings yet

- Circuito Regulador de Voltaje Ob2216Document9 pagesCircuito Regulador de Voltaje Ob2216Wcarlos Ob RodriguezNo ratings yet

- 54122/DM74122 Retriggerable Resettable Multivibrator: General DescriptionDocument6 pages54122/DM74122 Retriggerable Resettable Multivibrator: General DescriptionRed SafireNo ratings yet

- Datasheet PDFDocument16 pagesDatasheet PDFMarco Pilaguano LogañaNo ratings yet

- CAN Interface: Prototype InformationDocument8 pagesCAN Interface: Prototype InformationjahenNo ratings yet

- Owners Manual: Aacd #3Document22 pagesOwners Manual: Aacd #3carlos pachecoNo ratings yet

- R1283x SERIES: 2ch DC/DC For CCD & OLEDDocument26 pagesR1283x SERIES: 2ch DC/DC For CCD & OLEDarnaud.herbertNo ratings yet

- DYN2 BrakeALM Wiring Diagram 002Document1 pageDYN2 BrakeALM Wiring Diagram 002Henrik Sandaker PalmNo ratings yet

- Driver MC34152Document4 pagesDriver MC34152William RamírezNo ratings yet

- LM392 Low Power Operational Amplifier/Voltage Comparator: General DescriptionDocument7 pagesLM392 Low Power Operational Amplifier/Voltage Comparator: General DescriptionAndrés Cely AgudeloNo ratings yet

- Rekap Mahasiswa Bayar SPP Melalui PokjarDocument6 pagesRekap Mahasiswa Bayar SPP Melalui PokjarDedeNo ratings yet

- Modul Engine Monitoring System PDFDocument64 pagesModul Engine Monitoring System PDFDedeNo ratings yet

- Dedek Saputra PDFDocument2 pagesDedek Saputra PDFDedeNo ratings yet

- USA 380SL Ignition Timing Specs 3Document1 pageUSA 380SL Ignition Timing Specs 3DedeNo ratings yet

- 5 Trouble Shoot PDFDocument26 pages5 Trouble Shoot PDFDedeNo ratings yet

- 6 Disassy AssyDocument54 pages6 Disassy AssyDedeNo ratings yet

- PrescriptionDocument1 pagePrescriptionDedeNo ratings yet

- E1 Wiring WithoutDocument3 pagesE1 Wiring WithoutDedeNo ratings yet

- E2 Wiring WithoutDocument3 pagesE2 Wiring WithoutDedeNo ratings yet

- Fuse Assignment of Fuse and Relay Box in Left Engine CompartmentDocument4 pagesFuse Assignment of Fuse and Relay Box in Left Engine CompartmentDedeNo ratings yet

- Finding The Top Center Position For The No. 1 Piston: Testing and AdjustingDocument3 pagesFinding The Top Center Position For The No. 1 Piston: Testing and AdjustingDedeNo ratings yet

- Russia 2020 Three ScenariosDocument60 pagesRussia 2020 Three ScenariosPepeNo ratings yet

- Fs p611 Sparkplug Ijb-222027-EnDocument2 pagesFs p611 Sparkplug Ijb-222027-EnwaltsdavinNo ratings yet

- Grow As We GoDocument68 pagesGrow As We GoEg MemoriaNo ratings yet

- Fire Pump Field Acceptance TestDocument23 pagesFire Pump Field Acceptance Testwalitedison100% (1)

- Membean RootsDocument14 pagesMembean RootsMuhammad Sohail SialNo ratings yet

- V 0226012420 0007 PDFDocument6 pagesV 0226012420 0007 PDFKhairulNo ratings yet

- Little Baguio Building Rules and Regulations DraftDocument7 pagesLittle Baguio Building Rules and Regulations DraftJun Dela CruzNo ratings yet

- Class 10 National Genius Search Examination: Advanced: Check The Correctness of The Roll No. With The Answer SheetDocument4 pagesClass 10 National Genius Search Examination: Advanced: Check The Correctness of The Roll No. With The Answer SheetPPNo ratings yet

- 4.1 Foundation SettlementDocument49 pages4.1 Foundation SettlementRadifan HalifNo ratings yet

- BS 873-7 - 1984 Road Traffic Signs and Internally Illuminated Bollards Specification For Posts and FittingsDocument16 pagesBS 873-7 - 1984 Road Traffic Signs and Internally Illuminated Bollards Specification For Posts and Fittingspaul reyesNo ratings yet

- Kong Long Huat Borax Decahydrate, BI GHSDocument14 pagesKong Long Huat Borax Decahydrate, BI GHSOsh 0717No ratings yet

- Practice Test 1: (Code: B1T1)Document16 pagesPractice Test 1: (Code: B1T1)Sách Pháp Hiếu NhânNo ratings yet

- Ketu in Jaimini-4Document8 pagesKetu in Jaimini-4Ramesh DoddaNo ratings yet

- Vendor Directory ICF - 2019-20 - Regular PDFDocument108 pagesVendor Directory ICF - 2019-20 - Regular PDFpadmanaban100% (1)

- Un Român, Aeronaut În Polonia, La Începutul Secolului Al Xix - Lea: Iordache CuparencuDocument26 pagesUn Român, Aeronaut În Polonia, La Începutul Secolului Al Xix - Lea: Iordache CuparencuCodrin Codrin100% (1)

- Margo Lanagan - Sea Hearts (Extract)Document7 pagesMargo Lanagan - Sea Hearts (Extract)Allen & UnwinNo ratings yet

- New Developments in Satcom Amplifiers and Antennas Ebook PDFDocument20 pagesNew Developments in Satcom Amplifiers and Antennas Ebook PDFlinoNo ratings yet

- Storytelling Theme: FutureDocument7 pagesStorytelling Theme: FutureA SharanyaNo ratings yet

- Dairy Farm Project Report - Buffalo (Large Scale)Document2 pagesDairy Farm Project Report - Buffalo (Large Scale)VIJAYJKNo ratings yet

- Additive OF: Physical Characteristics FeaturesDocument1 pageAdditive OF: Physical Characteristics Featuresmarco_ravelo_10No ratings yet

- EthambutolDocument1 pageEthambutolSibel ErtuğrulNo ratings yet

- Resource Pack - Science - Year 1 - Human Body and SensesDocument19 pagesResource Pack - Science - Year 1 - Human Body and Sensesnur fazlynaNo ratings yet

- D4 InfanciaDocument3 pagesD4 InfanciaPedroPocasNo ratings yet

- Demontare Oglinda InterioaraDocument9 pagesDemontare Oglinda InterioaraabutufeiNo ratings yet

- Cambridge Secondary 1 Checkpoint: Cambridge Assessment International EducationDocument7 pagesCambridge Secondary 1 Checkpoint: Cambridge Assessment International Educationigloo79No ratings yet

- Swahili LanguageDocument14 pagesSwahili LanguagenedNo ratings yet

- Cvsu Thesis FormatDocument4 pagesCvsu Thesis Formatsew0m0muzyz3100% (2)

- B1900d LimitationsDocument3 pagesB1900d LimitationsMikeParsonsNo ratings yet