Professional Documents

Culture Documents

Surflex: N - M F H

Surflex: N - M F H

Uploaded by

John ShaneOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Surflex: N - M F H

Surflex: N - M F H

Uploaded by

John ShaneCopyright:

Available Formats

SURFLEX

N -M

ON F ETALLIC LOOR HARDENER

DESCRIPTION

SURFLEX is a quartz-silica mixture of finely graded non-metallic aggregates, plasticizer and cement binder. It is an

economical concrete floor hardener recommended for both interior and exterior use. It is particularly valuable

DRY SHAKE FLOOR HARDENERS

because of its non-rusting characteristics when floors will be frequently wet. SURFLEX is available in non-fading

colors as well as a natural cement color.

PRIMARY APPLICATIONS

Ÿ Lobbies and waiting rooms of commercial Ÿ Factory and warehouse floors

andpublic buildings Ÿ Commercial and industrial facilities

Ÿ Corridors and washrooms in institutional and Ÿ Restaurants and dairies

publicbuildings

Ÿ Auto showrooms and service centers

FEATURES/BENEFITS

Ÿ Hardens concrete in one economical operation Ÿ Eucon dispersing agent contained in SURFLEX

Ÿ Use of hard and properly graded aggregates increases makes it possible to incorporate SURFLEX into the

the wear resistance over plain concrete floors surface oflow slump concretes resulting in

exceptionally high surface strengths for

Ÿ Ready-to-use factory blend eliminates messy and

maximum wear resistance

expensive job mixing and minimizes errors

Ÿ Non-rusting materials make it possible to use SURFLEX

outdoors as well as indoors

TECHNICAL INFORMATION

Typical Engineering Data

SURFLEX

Compressive Strength ASTM C 109, (25 mm) cubes Mixed at 2.62 kg of water per 25 kg bag Age Strength MPa

7 days 60

28 days 67.5

Appearance: SURFLEX is a free flowing powder as packaged. It is available in a natural cement color (standard).

It is also available in tile red, terra cotta, black, diamond green, french gray, battleship gray, light gray, brown and

tan. The final finish can be any texture normally achieved with concrete and should be specified by the owner. In

addition, the joints of the newly installed Surflex floor can be filled with a matching color available in the EUCO

QWIKJOINT UVR polyurea joint filler product.

RELATIVE ABRASION RESISTANCE ASTM C 779

Age Abrasion @ 30 min. Abrasion @ 60 min.

Rev-01/18

7 days 0.48 mm 1.07 mm

28 days 0.33 mm 0.91 mm

Flowcrete India Pvt Ltd

"Ganesh Towers" Door No.B-1, 1st floor, 1st Avenue, Ashok Nagar, Chennai - 600 083.

Tamilnadu, India. T: +91 44 40176600 | E-mail: india@flowcrete.com

PACKAGING

SURFLEX is packaged in 25 kg bags with polyethylene liners for moisture protection.

SHELF LIFE

1 year in original, unopened package

COVERAGE

SURFLEX may be applied at rates from 2.4 to 9.8 kg/m². Greater application rates yield better total abrasion

resistance, and may be used with special considerations. Contact your Euclid Chemical Company representative

for recommended procedures.

SPECIFICATIONS/COMPLIANCES

Canadian Food Inspection Agency

DIRECTIONS FOR USE

The contractor and engineer are encouraged to consult and review the Euclid Chemical bulletin "Dry Shake Floor

Hardeners - Application Instructions". The document offers instructions detailing the general installation of

Euclid Chemical manufactured dry shake floor hardeners. Note: If the contractor is not familiar with the standard

application techniques of a dry shake floor hardener, a pre-job meeting is suggested to review the project concrete

mix design as well as placement and curing details unique to the particular job. Contact your local Euclid Chemical

Company representative for additional information.

Application Tips: Colored (pigmented) dry shakes require special attention for a uniform color. If the job involves

placement of SURFLEX, care should be taken with regards to the following; delay application of the shake as long

as possible to get the maximum color saturation at the surface of the slab, apply the shake as evenly as possible and

in two applications for maximum uniformity, and do not burnish trowel the floor. Best appearance is achieved by

hand troweling the final finish.

Curing and Sealing: After finishing operations are complete and the surface will not be marred by foot traffic,

apply a Euclid Chemical curing compound or cure and seal according to product instructions. To produce an

exceptionally durable and dustproof surface, cure with a dissipating or removable curing compound such as

KUREZ DR VOX or KUREZ RC, then seal with EUCO DIAMOND HARD or ULTRASIL Li+.

CLEAN-UP

Clean tools and equipment with soap and water before material hardens.

PRECAUTIONS/LIMITATIONS

Ÿ The use of supplementary cementitious materials are not Ÿ For additional abrasion resistance beyond that

recommended for use with a dry shake hardener offered by SURFLEX, consider the use of EUCO-

Ÿ Proper curing and sealing is required. PLATE HD,an iron aggregate floor hardener.

Ÿ Sufficient manpower is required to produce consistent Ÿ Store product in a dry place.

results on large placements. Ÿ In all cases, refer the Safety Data Sheet before

Ÿ Important: Air-entraining admixtures may complicate use.

finishing operations and cause blistering. Contact The

manufacturer if application of this product will be over

air entrained concrete with more than 3% total air

content.

WARRANTY: Flowcrete India Private Limited solely and expressly warrants that its products shall be free from defects in materials and workmanship for one (1) year from

the date of purchase. Unless authorized in writing by an officer of Flowcrete India Private Limited no other representations or statements made by Flowcrete India or its

representatives, in writing or orally, shall alter this warranty. Flowcrete India MAKES NO WARRANTIES, IMPLIED OR OTHERWISE, AS TO THE MERCHANTABILITY OR

FITNESS FOR ORDINARY OR PARTICULAR PURPOSES OF ITS PRODUCTS AND EXCLUDES THE SAME. If any Flowcrete India product fails to conform with this warranty,

Flowcrete India will replace the product at no cost to Buyer. Replacement of any product shall be the sole and exclusive remedy available and buyer shall have no claim

for incidental or consequential damages. Any installation of Flowcrete India products which fails to conform with such installation information or instructions shall void this

warranty. Product demonstrations, if any, are done for illustrative purposes only and do not constitute a warranty or warranty alteration of any kind. Buyer shall be solely

responsible for determining the suitability of Flowcrete India’s products for the Buyer’s intended purposes.

You might also like

- General Work PermitDocument1 pageGeneral Work PermitJohn Shane100% (5)

- Chapter 5 - Vision and Mission AnalysisDocument40 pagesChapter 5 - Vision and Mission AnalysisNero Sha100% (5)

- Chat GPTDocument13 pagesChat GPTsuly maniyahNo ratings yet

- Emerchrome 1120 12Document5 pagesEmerchrome 1120 12Yusak UcakNo ratings yet

- The Challenges of Managerial Accounting 2Document5 pagesThe Challenges of Managerial Accounting 2therhine100% (2)

- Ucrete MF Flooring - BASF Data Sheet ADocument4 pagesUcrete MF Flooring - BASF Data Sheet A翟庆祥No ratings yet

- Ucrete Pfs TdsDocument2 pagesUcrete Pfs TdsAbdul YaskarNo ratings yet

- Supercast EPT PDFDocument2 pagesSupercast EPT PDFmilanbrasinaNo ratings yet

- Conbextra EP10 : High Strength, Epoxy Resin GroutDocument2 pagesConbextra EP10 : High Strength, Epoxy Resin GroutBudhi KurniawanNo ratings yet

- Ucrete MF TdsDocument4 pagesUcrete MF TdsMcr KumaraNo ratings yet

- TDS - Concresive ERLDocument2 pagesTDS - Concresive ERLVenkata RaoNo ratings yet

- Ucrete HPQ: Heavy Duty Polyurethane Coloured Quartz ScreedDocument4 pagesUcrete HPQ: Heavy Duty Polyurethane Coloured Quartz Screedsyifa latifa zahidaNo ratings yet

- Conbextra TsDocument51 pagesConbextra Tsm.basim.technitalNo ratings yet

- Duracrete FichaDocument2 pagesDuracrete FichavankarpNo ratings yet

- Conbextra EP150 UAEDocument4 pagesConbextra EP150 UAEjasonNo ratings yet

- Ucrete MF: Heavy Duty Polyurethane Hybrid Flooring SystemDocument3 pagesUcrete MF: Heavy Duty Polyurethane Hybrid Flooring SystemSean HarshaNo ratings yet

- 10 Conbextra EP10Document2 pages10 Conbextra EP10ahmad wildaanNo ratings yet

- Conbextra EP10TG PDFDocument2 pagesConbextra EP10TG PDFAcho SupraholicNo ratings yet

- Sikacrete-114 SADocument46 pagesSikacrete-114 SAinfoNo ratings yet

- Super Vulcaseal: General Purpose Polychloroprene-Based SealantDocument2 pagesSuper Vulcaseal: General Purpose Polychloroprene-Based SealantAdam Mark LegaspiNo ratings yet

- Mastertop 1324 v1Document3 pagesMastertop 1324 v1mahmoodawadhNo ratings yet

- Conbextra EP10Document2 pagesConbextra EP10m.elsanee.cubicNo ratings yet

- TDS - Masterkure 106Document2 pagesTDS - Masterkure 106Venkata RaoNo ratings yet

- (IS 101/1987, Part 1, Sec 6) : Exterior - Aesthetics Issued - 01 2017Document2 pages(IS 101/1987, Part 1, Sec 6) : Exterior - Aesthetics Issued - 01 2017Amit DhangarNo ratings yet

- 3 TekniFloor LDPDocument2 pages3 TekniFloor LDPAndy100% (1)

- Conbextra EP10Document2 pagesConbextra EP10MuhammedHafis100% (1)

- PRODUCTGUIDESatJan3010:40:45GMT 05:302021Document90 pagesPRODUCTGUIDESatJan3010:40:45GMT 05:302021Anonymous PkvM83sNo ratings yet

- MSDS-002 Sureflow 100Document45 pagesMSDS-002 Sureflow 100joker batmanNo ratings yet

- Flooring CompoundsDocument18 pagesFlooring CompoundsParashuram ChauhanNo ratings yet

- Florgard SLDocument3 pagesFlorgard SLcharibackupNo ratings yet

- Nitobond AR: Constructive SolutionsDocument2 pagesNitobond AR: Constructive SolutionsMohammad ArslanNo ratings yet

- Nitobond ArDocument46 pagesNitobond ArGavriel NgNo ratings yet

- Expangrout AGDocument2 pagesExpangrout AGPMG04 EKLNo ratings yet

- Conbextra EP75 PDFDocument3 pagesConbextra EP75 PDFKhaerul SidikNo ratings yet

- Conbextra EP75 PDFDocument4 pagesConbextra EP75 PDFsaroat moongwattanaNo ratings yet

- Euclid Chemical Dry Shake Floor Hardeners Application Instructions Installation Instructions B26664Document2 pagesEuclid Chemical Dry Shake Floor Hardeners Application Instructions Installation Instructions B26664John ShaneNo ratings yet

- Basf Mastertop 430 TdsDocument3 pagesBasf Mastertop 430 TdsPanruti S SathiyavendhanNo ratings yet

- Proofex SM PDFDocument4 pagesProofex SM PDFmilanbrasinaNo ratings yet

- ucrete_mf-tds_240506_093411Document3 pagesucrete_mf-tds_240506_093411Elsa NatayaNo ratings yet

- Sikagrout®-114 Ae: Product Data SheetDocument3 pagesSikagrout®-114 Ae: Product Data SheetAlexander Jonas Zach ValdrizNo ratings yet

- Renderoc RGDocument4 pagesRenderoc RGvenkatasuri999No ratings yet

- Conbextra EP120: High Strength, Epoxy Resin GroutDocument2 pagesConbextra EP120: High Strength, Epoxy Resin GroutzulfikarNo ratings yet

- Concrete Surface RetarderDocument2 pagesConcrete Surface RetarderHendra Squall LeonhartNo ratings yet

- 302 Epoxy Ester Floor Paint TDSDocument2 pages302 Epoxy Ester Floor Paint TDSraja qammar100% (1)

- Sikafloor-ColourSeal W 0307Document4 pagesSikafloor-ColourSeal W 0307Chris AdaminovicNo ratings yet

- Sikacem Gunit 133Document2 pagesSikacem Gunit 133the pilotNo ratings yet

- Sikagrout - 114Document3 pagesSikagrout - 114YASHICA VAITTIANATHANNo ratings yet

- Sikagrout - 105Document3 pagesSikagrout - 105YASHICA VAITTIANATHANNo ratings yet

- Ucrete UD200: Heavy Duty Polyurethane Hybrid Flooring SystemDocument2 pagesUcrete UD200: Heavy Duty Polyurethane Hybrid Flooring Systemsyifa latifa zahidaNo ratings yet

- Sika Grout - 114 SaDocument3 pagesSika Grout - 114 SaGavriel NgNo ratings yet

- Super Diamond ClearDocument2 pagesSuper Diamond ClearElisa Pavez A.No ratings yet

- 15 - TDS - Concresive ERLDocument3 pages15 - TDS - Concresive ERLAlexi ALfred H. TagoNo ratings yet

- Fosroc Conbextra EP10: Constructive SolutionsDocument2 pagesFosroc Conbextra EP10: Constructive SolutionsVincent JavateNo ratings yet

- Sikarep® Microcrete-4: Product Data SheetDocument2 pagesSikarep® Microcrete-4: Product Data Sheetsidharthsud28No ratings yet

- Ucrete Mf40as Tds Mbs Version 2Document5 pagesUcrete Mf40as Tds Mbs Version 2Emre TonguçNo ratings yet

- Masterflow 400 TdsDocument3 pagesMasterflow 400 TdsverNo ratings yet

- Florgard EsdDocument3 pagesFlorgard Esddox4printNo ratings yet

- Flexiroof Tds 26-9-10 - NewDocument3 pagesFlexiroof Tds 26-9-10 - Newmiratif19_860027847No ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Your Home Inspected: An Addendum for Residential Home Inspection ReportsFrom EverandYour Home Inspected: An Addendum for Residential Home Inspection ReportsNo ratings yet

- CS E10:2014: Guidelines on Design Loads for Skyrise GreeneryFrom EverandCS E10:2014: Guidelines on Design Loads for Skyrise GreeneryNo ratings yet

- Drilled Shaft Inspector's ChecklistDocument5 pagesDrilled Shaft Inspector's ChecklistJohn ShaneNo ratings yet

- Twintec Global BrochuresDocument16 pagesTwintec Global BrochuresJohn ShaneNo ratings yet

- Euclid Chemical Dry Shake Floor Hardeners Application Instructions Installation Instructions B26664Document2 pagesEuclid Chemical Dry Shake Floor Hardeners Application Instructions Installation Instructions B26664John ShaneNo ratings yet

- SOP For Managing Risk From Covid-19Document17 pagesSOP For Managing Risk From Covid-19John ShaneNo ratings yet

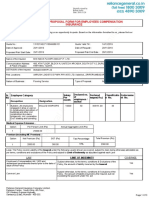

- Reliance General Insurance Company Limited: Quotation Cum Proposal Form For Employees Compensation InsuranceDocument3 pagesReliance General Insurance Company Limited: Quotation Cum Proposal Form For Employees Compensation InsuranceJohn ShaneNo ratings yet

- PS-149 Lidl NewbridgeDocument2 pagesPS-149 Lidl NewbridgeJohn ShaneNo ratings yet

- Reliance General Insurance Company LimitedDocument7 pagesReliance General Insurance Company LimitedJohn ShaneNo ratings yet

- Udaipur Tour Guide PDFDocument19 pagesUdaipur Tour Guide PDFJohn Shane50% (2)

- Antisol White (IN) PDFDocument2 pagesAntisol White (IN) PDFJohn ShaneNo ratings yet

- 1350 e PDFDocument398 pages1350 e PDFJohn ShaneNo ratings yet

- Specifying For Performance: EngineeringDocument5 pagesSpecifying For Performance: EngineeringJohn ShaneNo ratings yet

- CBR and Plate Bearing InfographicDocument1 pageCBR and Plate Bearing InfographicJohn ShaneNo ratings yet

- (Monographs in Geoscience) Benjamin S. Persons (Auth.) - Laterite - Genesis, Location, Use-Springer US (1995) PDFDocument112 pages(Monographs in Geoscience) Benjamin S. Persons (Auth.) - Laterite - Genesis, Location, Use-Springer US (1995) PDFJohn ShaneNo ratings yet

- Literature Review: Chapter - 2Document53 pagesLiterature Review: Chapter - 2John ShaneNo ratings yet

- (Monographs in Geoscience) Benjamin S. Persons (Auth.) - Laterite - Genesis, Location, Use-Springer US (1995)Document112 pages(Monographs in Geoscience) Benjamin S. Persons (Auth.) - Laterite - Genesis, Location, Use-Springer US (1995)John ShaneNo ratings yet

- Intro To Career in Data Science: Md. Rabiul IslamDocument62 pagesIntro To Career in Data Science: Md. Rabiul Islamgouri67100% (1)

- M Cecconi 2023 Intensive Care FundamentalsDocument278 pagesM Cecconi 2023 Intensive Care FundamentalsGustavo ParedesNo ratings yet

- Unit of Competence:: Plan and Monitor System PilotDocument14 pagesUnit of Competence:: Plan and Monitor System PilotDo Dothings100% (2)

- 9 Polyethylene Piping SystemDocument4 pages9 Polyethylene Piping SystemPrashant PatilNo ratings yet

- Portfolio AnswersDocument4 pagesPortfolio Answersa73609No ratings yet

- Presentation of A Golden FIBC Made From PET Bottle Flakes enDocument2 pagesPresentation of A Golden FIBC Made From PET Bottle Flakes enMILADNo ratings yet

- MDSW TamilNadu06Document14 pagesMDSW TamilNadu06miningnova1No ratings yet

- Parallel SerialDocument12 pagesParallel SerialjuampicNo ratings yet

- 1631 - Eu - 0911 - 064739 - Dpa M Cle RJ45B 48 PDFDocument2 pages1631 - Eu - 0911 - 064739 - Dpa M Cle RJ45B 48 PDFIrving GuatemalaNo ratings yet

- Succession DigestDocument407 pagesSuccession DigestToni Gabrielle Ang EspinaNo ratings yet

- Kirch GroupDocument13 pagesKirch GroupStacy ChackoNo ratings yet

- List of Holidays in Chandigarh University (CU) 2020Document2 pagesList of Holidays in Chandigarh University (CU) 2020Ālok KrNo ratings yet

- AralPan9 q2 Mod10 Ang-Pamilihan-V5Document29 pagesAralPan9 q2 Mod10 Ang-Pamilihan-V5Wizly Von Ledesma TanduyanNo ratings yet

- Guidelines - In-Hospital ResuscitationDocument18 pagesGuidelines - In-Hospital ResuscitationparuNo ratings yet

- Inquiries and Immersion, Krg846Document33 pagesInquiries and Immersion, Krg846Hannah Louise Gutang PortilloNo ratings yet

- Whats New With Smarts and Watch4net - PostDocument21 pagesWhats New With Smarts and Watch4net - PostJesse Dias100% (1)

- Procedure For Vaginal Examination 2.1 PDFDocument8 pagesProcedure For Vaginal Examination 2.1 PDFAlfonso AnggriawanNo ratings yet

- Full Chapter Blockchain and Smart Contract Technologies For Innovative Applications 1St Edition Nour El Madhoun PDFDocument54 pagesFull Chapter Blockchain and Smart Contract Technologies For Innovative Applications 1St Edition Nour El Madhoun PDFjames.harrington239100% (4)

- Norma ASTM B733Document14 pagesNorma ASTM B733diegohrey239100% (3)

- CS Lecture Notes PDFDocument138 pagesCS Lecture Notes PDFNikhil GaidhaneNo ratings yet

- SDL 11Document14 pagesSDL 11Sharmila BalaNo ratings yet

- The Leverage Effect Uncovering The True Nature of VolatilityDocument68 pagesThe Leverage Effect Uncovering The True Nature of VolatilityVlad StNo ratings yet

- Dr. N.P SheteDocument28 pagesDr. N.P SheteMD Noyon IslamNo ratings yet

- SLIM Sparse Linear Methods For Top-N Recommender SystemsDocument10 pagesSLIM Sparse Linear Methods For Top-N Recommender SystemsfcrkudxujdemptrdapNo ratings yet

- Financial Assets Vs Real AssetsDocument2 pagesFinancial Assets Vs Real AssetsRaja Faheem ShoukatNo ratings yet

- ETM-OT - Electronic Temperature Monitor: DescriptionDocument3 pagesETM-OT - Electronic Temperature Monitor: DescriptionMKNo ratings yet

- Tri 21 DMP 002Document3 pagesTri 21 DMP 002adi sihombingNo ratings yet