Professional Documents

Culture Documents

LUBCON Poster Lubricantstextile Industry en

LUBCON Poster Lubricantstextile Industry en

Uploaded by

Omin PostingOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LUBCON Poster Lubricantstextile Industry en

LUBCON Poster Lubricantstextile Industry en

Uploaded by

Omin PostingCopyright:

Available Formats

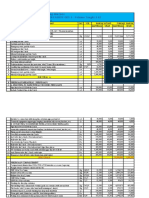

Superior High Quality Lubricants

for the Textile Industry

* ■= Spinning ►= Dyeing & Finishing ♦=Weaving ●= Knitting

Industrial Base Oil Temperature

Application Products Base Oil/Thickener Viscosity Benefits

Area* (at 40°C)

range in °C

Bearings

Turmoplex 2 EP ■ ► ♦ ● Mineral oil/Li-soap 120 mm²/s -30 up to +120 Universal grease with good water resistance & high load carrying capacity.

Multipurpose Grease

Turmogrease Li 802 EP ■ ► ♦ ● SHC-Mineral oil/Li-soap 82 mm²/s -40 up to +140 Multipurpose grease for high loads and a broad temperature range.

Turmosynthgrease 4602 R ■ White oil/inorganic 460 mm²/s -20 up to +140 Synthetic multipurpose grease. Resistant to cold and hot water.

Turmogrease CAK 2502 ► Mineral oil/Ca-sulfonate complex soap 250 mm²/s -30 up to +150 Excellent water and media resistance,very good protection against corrosion.

Turmogrease 2 PA ► Al-complex soap/Mineral oil 220 mm²/s -30 up to +160 Water-resistant grease with high load carrying capacity.

Turmogrease N2 ■ ► ♦ SHC – Ester/Polyurea 150 mm²/s -40 up to +160 Synthetic grease stable to water and steam, high temperature stability.

High Performance Synthetic Turmogrease N2 MF ► ♦ SHC - Ester/Polyurea 150 mm²/s -40 up to +200 Synthetic special grease including a solid lubricant for high load applications.

Grease Turmogrease HDC 2 ■ ► ♦ Mineral oil/Ca-sulfonate complex soap 410 mm²/s -30 up to +150 Grease with high load carrying capacity and excellent corrosion protection.

Turmogrease PHS 1002 ■ ► ♦ SHC - Mineral oil/ Polyurea 105 mm²/s -40 up to +160 Temperature stable grease, resistant to water, steam, acid and alkaline media.

Turmogrease Highspeed L 252 ■ SHC-Ester/Li-special soap 25 mm²/s -50 up to +120 Grease with long service life, also for low temperature applications .

High speed Grease

Turmogrease LC 252 ■ SHC-Ester/Li-Ca special soap 25 mm²/s -45 up to +120 For high speed bearings with good water resistance.

Thermoplex 2 TML special ■ Ester/Lithium soap 18.5 mm²/s -70 up to +130 Synthetic high speed grease. Lifetime lubrication, also for low temperatures.

Extreme Temperature Grease Turmotemp II/400 KL ► ♦ PFPE/PTFE 400 mm²/s -30 up to +260 Special grease for high temperatures, excellent chemical stability.

Sintono Mega 2 KL ► ♦ PFPE/PTFE 403 mm²/s -30 up to + 260 Special grease for high temperatures & long term lubrication of roller bearings.

Special grease with solid lubricants for applications with oscillating movements

Oscilating movement Turmoplex 1585 WS ► Mineral oil/lithium soap 103 mm²/s -25 up to +120

and vibrations.

Rapier Front roller Turmogrease Highspeed L 251 ► PAO-Ester/Li-special soap 25 mm²/s -40 up to +120 Soft high speed grease for bearings and gears with high metal affinity.

Chain

High temperature chain oil Turmofluid 40 B ■ ► ♦ Ester - SHC 270 mm²/s -20 up to +300 High temperature chain oil. High ageing stability and wear protection.

Paste

Assembly paste, threads, Bolts, Water-resistant paste with white solid lubricants, prevents fretting and

Turmopast NBI 2 white ■ ► ♦ Mineral oil/Ca-complex soap 100 mm²/s -30 up to +150

tribocorossion.

Hinges, guides, cams

Turmopast GM 5 ■ ► ♦ Polyglycol/inorganic thickener 220 mm²/s -40 up to +450 Special paste with high load carrying capacity and high temperature stability.

Gears

Open Gear Grease Grizzlygrease No.1 ■ ► ♦ ● Mineral oil/Li-Ca special soap 800 mm²/s -30 up to +150 Grease for heavy loaded gears, excellent corrosion and wear protection.

Semifluid Gear Grease Turmoplex EL 000 EP ■ ► ♦ ● Mineral oil/lithium soap 150 mm²/s -35 up to +120 Soft flow grease offering excellent wear protection.

Multipurpose Gear Oil Turmogearoil OM Series ■ ► ♦ ● Mineral oil 22 – 664 mm²/s up to +120 Gear oils for high loads and good corrosion protection.

High Performance Synth. Gear Oil Turmofluid GV Series ■ ► ♦ ● Synthetic hydrocarbons (SHC) 19 – 686 mm²/s see datasheet Synthetic oils for broad temperature ranges with high load capacity.

Worm, Bevel Gear and

Geared Motor Oil

Turmopoloil HT Series ■ ♦ Polyglycol 68-1060 mm²/s -40 up to +200 Polyglycol based oils for extreme mechanical and thermal requirements.

Hydraulic Systems

Multipurpose Hydraulic Oil Turmofluid HLP Series ■ ♦ Mineral oils 11 – 98 mm²/s up to +120 Hydraulic oil with good corrosion protection and selected EP additives.

Compressors

Rotary Screw/ Fully synthetic oil with good thermal stability. Excellent wear and corrosion

Reciprocating Compressors

Compguard MT series ■ ► ♦ ● PAO-Ester 32 – 99 mm²/s up to +200

protection.

Knitting Oil

Circular/Flat bed Knitting Oil for Turmotex Oil LP “ “ S series ● Semi-synthetic 20 – 40 mm²/s - Synthetic knitting oils, reduce operating temperature, easy scouring.

Needles and Sinkers Turmotex Oil LP “ “ W series ● White oil 22 – 65 mm²/s - Mineral knitting oils, reduce operating temperatures, easy scouring.

Turmotex Oil LP R 14 ● Paraffinic hydrocarbons 14 mm²/s - Lubricating & cleaning oil, ensures good lubrication during cleaning operation.

Vacuum Pumps

Turmofluid VAC series ■ ♦ Hydrocarbons 33 – 130 mm²/s see datasheet Oils with low volatility, preventing oil loss by evaporation.

Maintenance/ Spray

Dissolves dirt, oils, greases, waxes, asphalt, resins and adhesives, evaporates

Degreaser/Cleaner LUBCON LC 500 ■ ► ♦ ● Mixture of hydrocarbons < 0.5 mm2/s up to 40

quickly without residues.

Penetrating Oil Korroquick ■ ► ♦ ● Mineral oil -30 up to +150 Rust loosener with excellent creeping and dewatering properties.

Chain spray Turmofluid 40 B spray ■ ► ♦ Ester – SHC 270 mm²/s -20 up to +300 Good wear protection, resistant to oxidation, for high temperatures.

Hi-viscosity chain spray Turmofluid 300 OM spray ■ ► ♦ Synthetic hydrocarbons 3750 mm²/s -5 up to +240 High temperature chain oil, high ageing stability and wear protection.

Cams spray Turmolyb PA spray ■ Synthetic hydrocarbons 130 mm²/s -20 up to +450 Water-resistant grease, high load carrying capacity.

Splicer scissors Turmofluid LS 400 plus ■ Synthetic hydrocarbons approx. 3.5 -65 up to +150 Synthetic lubricating oil, water displacing behaviour, good spreading effect.

Screw spindle (stenter) Turmolyb MDC spray ■ ► ♦ Molybdenum disulfide -180 up to +450 Adhesive soft sliding film of molybdenum disulfid.

Chain & Chain Drives Turmofluid 4 S spray ► Synthetic hydrocarbons 80 mm²/s -50 up to +150 Synthetic oil with PTFE for cleaning, lubrication and preserving.

Technical Assistance: LUBCON COMPRESSOR CLEANER - COMPCLEAN STS

LUBRICANT CONSULT GmbH How to change from Mineral, PAO, Esters to PG or vice-versa for compressor ?

Gutenbergstr. 13 Ÿ Flush the compressor with PG oil if changes from different base oil (esters, PAO, mineral are not miscible with PG). No flushing needed if changes from base oil family of mineral, PAO and esters.

63477 Maintal-Bischofsheim Ÿ Drain maximum 5% used oil from compressor. Add maximum 5% Compclean STS into the compressor and run for next 40 to 60 hrs.

GERMANY Ÿ Drain all the oil-Compclean STS mixture (Best when it is still hot). Clean hoses, pipes, reservoir.

Tel: +49 6109 7650-0 Ÿ Change oil separator and oil filter. Check bearing conditions.

Fax: +49 6109 7650-51 Ÿ Fill in the new oil.

webmaster@lubcon.com

www.lubcon.com

2015-08-31

This poster contains only general product information. For specific information please refer to our technical data and safety data sheets. The content represents the actual state of development and knowledge of LUBRICANT CONSULT GmbH that can be subject to change without

notification. The products mentioned fully comply with the specifications defined by our company, but due to the multitude of different applications and influencing factors, we cannot guarantee suitability for the individual application. To determine the suitability of a lubricant we,

therefore, recommend contacting an application engineer and, if necessary, performing individual field tests. Any furhter liability by LUBRICANT CONSULT GmbH is expressively excluded.

You might also like

- Gianneschi AccumulatorTank TMDocument12 pagesGianneschi AccumulatorTank TMAldrine Dela Cruz100% (1)

- LUBCON High Performance H1 Food Grade Lubricants: ProductsDocument1 pageLUBCON High Performance H1 Food Grade Lubricants: ProductsNuno AlvesNo ratings yet

- LUBCON Lubricants-Wood IndustryDocument1 pageLUBCON Lubricants-Wood IndustryOmin PostingNo ratings yet

- Bearing Lubrication: Grease Quantity 0.05 X D X B GmsDocument2 pagesBearing Lubrication: Grease Quantity 0.05 X D X B GmsMH M100% (1)

- LUBCON Service For The Wood Working IndustryDocument7 pagesLUBCON Service For The Wood Working IndustryChanJunKaiNo ratings yet

- Perma LUBRICANTS - Lubricant OverviewDocument2 pagesPerma LUBRICANTS - Lubricant Overviewfilipe80tavaresNo ratings yet

- Renolit H 443-HD 88Document2 pagesRenolit H 443-HD 88miguelfpintoNo ratings yet

- General Engineering PDFDocument12 pagesGeneral Engineering PDFRUTA TLAXCALA (SHELL)No ratings yet

- TP 2502HTDocument2 pagesTP 2502HTEmanuel Ciprian CiucurNo ratings yet

- Tarmela Non Drop Data SheetDocument1 pageTarmela Non Drop Data SheetIkhlaq AhmedNo ratings yet

- G. Beslux Liplex M 1-2/S: Technical InformationDocument1 pageG. Beslux Liplex M 1-2/S: Technical InformationHassanSheikhNo ratings yet

- Torq - Ep 3 Ultra LoadDocument2 pagesTorq - Ep 3 Ultra LoadVISHAL SINHANo ratings yet

- Alpha Grease - 18 10 21Document12 pagesAlpha Grease - 18 10 21Shahid AsifNo ratings yet

- Spec SF05Document2 pagesSpec SF05Priskilia WendaNo ratings yet

- Grease As A LubricantDocument3 pagesGrease As A Lubricantkarubanga wycklifNo ratings yet

- Velloils High Temperature & Speciality Grease Velloplex GreaseDocument6 pagesVelloils High Temperature & Speciality Grease Velloplex GreaseBhusarapu SrinivasNo ratings yet

- LUBCON Turmotemp LP 2502 ENDocument2 pagesLUBCON Turmotemp LP 2502 ENNuno AlvesNo ratings yet

- LUBCON Lubricants Rail Industry enDocument7 pagesLUBCON Lubricants Rail Industry enOmin PostingNo ratings yet

- PSC TS Moly RangeDocument3 pagesPSC TS Moly RangeProject Sales CorpNo ratings yet

- Asonic HQ 72-102: High-Temperature Lubricating Grease For Low-Noise Rolling BearingsDocument2 pagesAsonic HQ 72-102: High-Temperature Lubricating Grease For Low-Noise Rolling BearingsShaleh AhmadNo ratings yet

- Eni Grease LCX 2-220 PDFDocument2 pagesEni Grease LCX 2-220 PDFranjanguptNo ratings yet

- Shell - Lubricants - Product Data GuideDocument20 pagesShell - Lubricants - Product Data GuideRolando DaclanNo ratings yet

- Fiche Technique Lub Vib enDocument1 pageFiche Technique Lub Vib enSanjanNo ratings yet

- Total Nevastane Xs 80 Food Grade GreaseDocument2 pagesTotal Nevastane Xs 80 Food Grade GreaseAnya PamungkasNo ratings yet

- Autol Top 2000 Getriebefliessfett 000 PDFDocument1 pageAutol Top 2000 Getriebefliessfett 000 PDFranjanguptNo ratings yet

- Tds Total Nevastane Xs 80 b4m 201806 enDocument2 pagesTds Total Nevastane Xs 80 b4m 201806 enPetrus MalailakNo ratings yet

- Ultramill Grease PU Premium grade 1Document1 pageUltramill Grease PU Premium grade 1VISHAL SINHANo ratings yet

- Product Information: Cassida Grease Eps SeriesDocument2 pagesProduct Information: Cassida Grease Eps SeriesChiranjeevi VijayaraghavanNo ratings yet

- Bentone HD Grease: Package Sizes: 450g Cartridge Product Codes: BENHDGR00045 Issue: December 2012Document1 pageBentone HD Grease: Package Sizes: 450g Cartridge Product Codes: BENHDGR00045 Issue: December 2012Fikreslasie LemaNo ratings yet

- 6789 EnuDocument3 pages6789 EnuИван ЖивановићNo ratings yet

- Grease and ApplicationsDocument21 pagesGrease and ApplicationsDinesh babuNo ratings yet

- TDS Total Ceran-Xm-220 4KF 201607 en UsaDocument2 pagesTDS Total Ceran-Xm-220 4KF 201607 en Usathe anhNo ratings yet

- Multis Ep 2 TDS v171023Document1 pageMultis Ep 2 TDS v171023Stefan UngurNo ratings yet

- Aceites-Para-Cadenas CastrolDocument1 pageAceites-Para-Cadenas Castrolmiguel angelNo ratings yet

- Asonic Ghy 72 IngDocument2 pagesAsonic Ghy 72 IngseegnaNo ratings yet

- Calipsol H 443-HD 88Document2 pagesCalipsol H 443-HD 88Oscar CabreraNo ratings yet

- Ultra Grease Lithium EP2Document12 pagesUltra Grease Lithium EP2Balaji BalaNo ratings yet

- Shell Alvania Grease HDX 2: High Perfomrance Heavy Duty Grease Containing Solid LubricantsDocument2 pagesShell Alvania Grease HDX 2: High Perfomrance Heavy Duty Grease Containing Solid LubricantsJoko SusiloNo ratings yet

- Xingang Catalogue 2020Document9 pagesXingang Catalogue 2020sunhell1611No ratings yet

- Grease NemcoDocument2 pagesGrease Nemcodk_moehammedNo ratings yet

- Perma Multipurpose Grease SF01 TDS enDocument2 pagesPerma Multipurpose Grease SF01 TDS enDwi April YantoNo ratings yet

- PERTAMINA - GREASE - EPX-NL SERIES (English Version)Document1 pagePERTAMINA - GREASE - EPX-NL SERIES (English Version)apriambadhaNo ratings yet

- MAK Lanthax EP GreaseDocument2 pagesMAK Lanthax EP GreaseshobhaNo ratings yet

- SP Eng 7036 High Low Temperature GreaseDocument1 pageSP Eng 7036 High Low Temperature GreaseundraazolbayarNo ratings yet

- Aerzen Lubricants BrochureDocument1 pageAerzen Lubricants BrochureRanier Garcia0% (1)

- Alvania r3Document2 pagesAlvania r3Senthil Kumar Ganesan75% (4)

- Shell Albida EP 2 GreaseDocument2 pagesShell Albida EP 2 GreasearyawigiNo ratings yet

- TDS Altis SH 2Document1 pageTDS Altis SH 2Daniel CaviedesNo ratings yet

- Eni Top 2000Document2 pagesEni Top 2000Iftikhar AmjadNo ratings yet

- FUCHS LUBRITECH Product RangeDocument76 pagesFUCHS LUBRITECH Product RangeBurak GüleşNo ratings yet

- Grease FlyerDocument2 pagesGrease FlyerBình LươngNo ratings yet

- Lubricants ChainoilsDocument6 pagesLubricants ChainoilsWan SaktiawanNo ratings yet

- Greases Catalog tcm14-46449Document24 pagesGreases Catalog tcm14-46449Sophia RoseNo ratings yet

- Renolin Hi Temp Chain LubeDocument2 pagesRenolin Hi Temp Chain Lubempe.mohamed2010No ratings yet

- Opet FuchsDocument39 pagesOpet Fuchsoner erdeveNo ratings yet

- BROCHURE Premium Greases Guide TNRDocument7 pagesBROCHURE Premium Greases Guide TNRRezhaNo ratings yet

- Turmosynthgrease Aln 2502 Pm-EngDocument1 pageTurmosynthgrease Aln 2502 Pm-EngOmin PostingNo ratings yet

- Turmosynthgrease A 1002-EngDocument1 pageTurmosynthgrease A 1002-EngOmin PostingNo ratings yet

- Turmosynth VG 46 TF Ti enDocument1 pageTurmosynth VG 46 TF Ti enOmin PostingNo ratings yet

- Turmosynthgrease Al 4602 Ti enDocument1 pageTurmosynthgrease Al 4602 Ti enOmin PostingNo ratings yet

- Turmosynth VG 32 Ti enDocument1 pageTurmosynth VG 32 Ti enOmin PostingNo ratings yet

- LUBCON Printing ServicesDocument2 pagesLUBCON Printing ServicesOmin PostingNo ratings yet

- LUBCON MicroMax 120 EngDocument2 pagesLUBCON MicroMax 120 EngOmin PostingNo ratings yet

- Turmopast Tas WT Ti enDocument1 pageTurmopast Tas WT Ti enOmin PostingNo ratings yet

- LUBCON Lubricants Rail Industry enDocument7 pagesLUBCON Lubricants Rail Industry enOmin PostingNo ratings yet

- LUBCON Cutting Oils Corrugator enDocument2 pagesLUBCON Cutting Oils Corrugator enOmin PostingNo ratings yet

- LUBCON Lubricants-Wood IndustryDocument1 pageLUBCON Lubricants-Wood IndustryOmin PostingNo ratings yet

- Compguard FGX 46-EngDocument1 pageCompguard FGX 46-EngOmin PostingNo ratings yet

- LUBCON Automotive Industry enDocument7 pagesLUBCON Automotive Industry enOmin PostingNo ratings yet

- What Is Buoyancy?: Archimedes' PrincipleDocument1 pageWhat Is Buoyancy?: Archimedes' PrincipleYelchuri Kumar PhanindraNo ratings yet

- Log Sheet Ylaa 150.72-Mr1Document4 pagesLog Sheet Ylaa 150.72-Mr1dhcastanoNo ratings yet

- Catastrophic Failure of Large Storage TanksDocument12 pagesCatastrophic Failure of Large Storage Tankszepol051No ratings yet

- Liquid Ring Compressor System PrincipleDocument3 pagesLiquid Ring Compressor System Principleboom1067% (3)

- Sijal Ahmed Sir DoubtsDocument6 pagesSijal Ahmed Sir Doubtssijal2005No ratings yet

- The Rheology Handbook: Thomas G. MezgerDocument6 pagesThe Rheology Handbook: Thomas G. MezgerCereliaNo ratings yet

- Servo Prime & LP: Description ApplicationDocument1 pageServo Prime & LP: Description ApplicationRAHULGUNDHER25No ratings yet

- 1D Model To Predict Ejector Performance at Critical and Sub-Critical Operation in The Refrigeration SystemDocument7 pages1D Model To Predict Ejector Performance at Critical and Sub-Critical Operation in The Refrigeration Systemaff123051No ratings yet

- 1a. PS1000 PC200-8MO Adi WDocument28 pages1a. PS1000 PC200-8MO Adi WDeni SetiawanNo ratings yet

- Rifaie Group Presentation PDFDocument29 pagesRifaie Group Presentation PDFAlaa saidNo ratings yet

- Density, Viscosity & Drag 2 QPDocument13 pagesDensity, Viscosity & Drag 2 QPSam JoeNo ratings yet

- 02, Outflow and System 20202019Document28 pages02, Outflow and System 20202019El Moustapha Ould CheikhNo ratings yet

- Oil For Toyota Land Cruiser Prado J90Document2 pagesOil For Toyota Land Cruiser Prado J90Resa Melby SanjayaNo ratings yet

- FestoDocument8 pagesFestoHernandez Rodriges Alexis BryamNo ratings yet

- 541, 551, and 552 Hydraulic System Track Feller Buncher: DD EEDocument8 pages541, 551, and 552 Hydraulic System Track Feller Buncher: DD EEPinheiro WelintonNo ratings yet

- Boiler Installation and SetupDocument30 pagesBoiler Installation and Setupcakhokhe100% (1)

- Hydraulic Circuit, EDM 2000Document2 pagesHydraulic Circuit, EDM 2000frfgfNo ratings yet

- Assemblies: Numbering and Identification For Turbocompressors and Turbines 800 450 98Document7 pagesAssemblies: Numbering and Identification For Turbocompressors and Turbines 800 450 98SreekanthMylavarapuNo ratings yet

- Design Calcu - MarsaDocument19 pagesDesign Calcu - MarsaAlaa RamadanNo ratings yet

- Civil Rainwater HarvestingDocument19 pagesCivil Rainwater HarvestingBabaji SharmaNo ratings yet

- Statoil Hydraulic Oil 131Document2 pagesStatoil Hydraulic Oil 131RZW RNo ratings yet

- Start W 21 MMDocument2 pagesStart W 21 MMGHAZY TUBeNo ratings yet

- Coriolis PDFDocument11 pagesCoriolis PDFdanielaNo ratings yet

- Fluid Mechanics Past Exam AnswersDocument4 pagesFluid Mechanics Past Exam AnswersOsarieme OsakueNo ratings yet

- Experiment No. 2 Performance Test of Rotary Pump: GradeDocument26 pagesExperiment No. 2 Performance Test of Rotary Pump: GradeAli Requiso MahmudNo ratings yet

- Sal Con Corp BrochureDocument12 pagesSal Con Corp BrochureTong ChaipanyakulNo ratings yet

- Perencanaan Pengadaan Barang Dan Jasa Pekerjaan Pengadaan Unit Pertashop Gen 4 - Volume Tangki 3 KL Pt. Radia Denta NusantaraDocument4 pagesPerencanaan Pengadaan Barang Dan Jasa Pekerjaan Pengadaan Unit Pertashop Gen 4 - Volume Tangki 3 KL Pt. Radia Denta NusantarayuwonoNo ratings yet

- CFD - Solver PDFDocument55 pagesCFD - Solver PDFYogitha Sarah BabyNo ratings yet

- P3 3B Bernardo KathryneDocument5 pagesP3 3B Bernardo KathryneKATHRYNE BERNARDONo ratings yet