Professional Documents

Culture Documents

Resumen de Especificaciones Motores

Resumen de Especificaciones Motores

Uploaded by

Javier ArdilesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Resumen de Especificaciones Motores

Resumen de Especificaciones Motores

Uploaded by

Javier ArdilesCopyright:

Available Formats

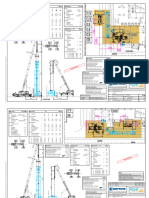

RE|FLEX

DRILL

PREMIUM DRILLING MOTORS

RE/FLEX Technologies

FEATURES & BENEFITS

RE|FLEX Premium Drilling Motors

Maximum Differential Pressure

by InFocus are a major advancement in

Maximum Weight On Bit

PDM technology. Metal-to-Metal power sec-

Bottom Connection

Bit-to-Bend Length

tions are rated to temperatures greater than

No Load Bit Speed

RE|FLEX Motor

Nominal Diameter

Full Load Torque

Top Connection

Overall Length

200°C (400°F), so they are not susceptible

to extreme temperature and most mud-re-

Flow Rate

Well Size

Power

(RPM)

lated issues seen with traditional PDM’s.

2 7/8 in 164 in 2.90 in NC 16 3 5/8 - 3 7/8 in 22500 lbf 50 - 150 GPM 1950 psi 890 ft-lb 93 HP

* 183 - 550

73 mm 4166 mm 74 mm (2 3/8 PAC) 92 - 98 mm 10000 daN 189 - 567 LPM 13445 kPa 1206 Nm 70 kW

5 in 180 in 56 in 5.15 in NC 38 3 1/2 API 6 - 7 7/8 in 75000 lbf 150 - 350 GPM 1850 psi 7035 ft-lb 268 HP

84 - 200

127 mm 4572 mm 1422 mm 131 mm (3 1/2 IF) BOX REG. BOX 152 - 200 mm 33360 daN 567 - 1324 LPM 12755 kPa 9535 Nm 200 kW

7 in 204 in 53.5 in 7.15 in NC 50 4 1/2 REG. 8 1/2 - 12-1/4 in 320000 lbf 300 - 600 GPM 660 psi 8044 ft-lb 154 HP

The RE|FLEX Premium bearing section is a 53 - 107

178 mm 5182 mm 1359 mm 182 mm (4 1/2 IF BOX) BOX 216 - 311 mm 142336 daN 1140 - 2271 LPM 10906 kPa 10906 Nm 115 kW

proprietary design, developed to convert

8 in 375 in 80 in 9.25 in 9 5/8 - 12-1/4 in 185000 lbf 400 - 900 GPM 650 psi 14920 ft-lb 282 HP

extreme loading parameters into efficient 6 5/8 REG. BOX 46 - 100

203 mm 9525 mm 2032 mm 235 mm 244 - 311 mm 82288 daN 1514 - 3406 LPM 4482 kPa 20228 Nm 210 kW

drilling action.

6 5/8 REG. BOX

9 5/8 250 in 70 in 9.63 in 12 - 26 in 310000 lbf 700 - 1200 GPM 880 psi 28352 ft-lb 445 HP

or 44 - 76

The RE|FLEX Premium motor features pro- 244 mm 6350 mm 1778 mm 244 mm 305 - 660 mm 137888 daN 2650 - 4540 LPM 6050 kPa 38440 Nm 332 kW

7 5/8 REG. BOX

prietary fatigue-resistant connections not

only for best-in-class torque capacity, but * Available Upon Request

Operational specifications are for reference only. Actual tool performance may vary depending on a variety of downhole conditions.

intended to maximize resistance to bending Performance data is subject to change without notice.

stress.

Internal components are optimized for cy-

clic fatigue-loading (bending stress) which is Fixed or Adjustable Bend Assembly options available.

another common failure mechanism seen in Optional Slick or Bladed Housing.

the form of twist-offs.

The unique, simplified design of the RE|FLEX

Premium bearing section is built with the 2-7/8” Thru-Tubing RE|FLEX

highest quality materials and patent-pending

© InFocus Energy Services Inc. All Rights Reserved.

motor with AMP shown.

processes to ensure reliable operating life

for years to come.

Document no. IFES-QF-BRO-0006 rB.5

Check back to our website periodically, and follow us on social media.

9759 51 Avenue NW, Edmonton, AB, Canada T6E 4W8 www.infocusenergy.com info@infocusenergy.com

You might also like

- Sundrop Swot AnalysisDocument18 pagesSundrop Swot AnalysisGopal Chandra Saha100% (3)

- Qatari Eid Charity's Suspicious Donations To Obscure Nigerian GroupsDocument29 pagesQatari Eid Charity's Suspicious Donations To Obscure Nigerian GroupsDavid HundeyinNo ratings yet

- 04 Concrete-Testing Range-LowDocument22 pages04 Concrete-Testing Range-LowRavinder GulairNo ratings yet

- E 107Document15 pagesE 107Thomas MelgarNo ratings yet

- Unit 2 - Market SegmentationDocument11 pagesUnit 2 - Market Segmentationlovellmenezes100% (3)

- Regulatory Expert Document-Barry Swanson RevisedDocument3 pagesRegulatory Expert Document-Barry Swanson RevisedVinish SrivastavaNo ratings yet

- Ard D 01 en Ma Drw171437aa 20171220 He 20171227 PDFDocument1 pageArd D 01 en Ma Drw171437aa 20171220 He 20171227 PDFUus SuhadaNo ratings yet

- American March Pump 460 ODSDocument24 pagesAmerican March Pump 460 ODSjuan davidNo ratings yet

- Acme Thread General Purpose - Class 2G: Reference PWM Drawing PC50563, Rev. 5Document1 pageAcme Thread General Purpose - Class 2G: Reference PWM Drawing PC50563, Rev. 5metroroadNo ratings yet

- Registro 8Document31 pagesRegistro 8Juan Camilo Arias QuintanaNo ratings yet

- Geh 6225Document1 pageGeh 6225AztvNo ratings yet

- 14s Con ComentariosDocument35 pages14s Con ComentariosErika Daniela ReyesNo ratings yet

- Abid CJV ConstructionDocument4 pagesAbid CJV ConstructionAliNo ratings yet

- Diamer Basha Dam Project: Borehole No. BDL-4 Upper Left Bank, Down Stream C-Axis, Central LineDocument4 pagesDiamer Basha Dam Project: Borehole No. BDL-4 Upper Left Bank, Down Stream C-Axis, Central LineAliNo ratings yet

- Bridge No Bearing Capacity Calculation As Per IS: 6403 and 8009 Bore Hole No P3BH-4 Chaninage: Section-Budhwal-Sitapur 104Document3 pagesBridge No Bearing Capacity Calculation As Per IS: 6403 and 8009 Bore Hole No P3BH-4 Chaninage: Section-Budhwal-Sitapur 104Dileep singhNo ratings yet

- Hoppecke Sun Power VR M BrochureDocument2 pagesHoppecke Sun Power VR M Brochurediego santiago paucarNo ratings yet

- Cabillas AOTDocument20 pagesCabillas AOTLuis HerediaNo ratings yet

- Souq Waqif CHW Pump Head - Rev-01a As Per Approved DWGDocument1 pageSouq Waqif CHW Pump Head - Rev-01a As Per Approved DWGKarthy GanesanNo ratings yet

- Electrical Load ListDocument2 pagesElectrical Load ListAhmed EssaNo ratings yet

- Pumps Head Loss Calculation (Colbrook Formula) : Local Factors of FittingsDocument22 pagesPumps Head Loss Calculation (Colbrook Formula) : Local Factors of FittingsAhmed EbrahimNo ratings yet

- SQBSQ CatalogDocument12 pagesSQBSQ CataloginterventoriainstalacionesNo ratings yet

- Company Welder & Welding Operator Register Based On Aws D1.5 2015Document1 pageCompany Welder & Welding Operator Register Based On Aws D1.5 2015REZKINo ratings yet

- Head LossDocument1 pageHead LossNghiaNo ratings yet

- Cable Sizing CalculationDocument125 pagesCable Sizing Calculationcrazy devilNo ratings yet

- Heavy Duty Post Shore:: Increase The Load, Decrease The CostDocument2 pagesHeavy Duty Post Shore:: Increase The Load, Decrease The CostJonathan ThomasNo ratings yet

- 1701-Discrepancy Bored Pile Example From STR-003Document1 page1701-Discrepancy Bored Pile Example From STR-003kingngai2013No ratings yet

- GA BRAUN Specifications Neutron 100-2 200-2 300-3 400-3Document2 pagesGA BRAUN Specifications Neutron 100-2 200-2 300-3 400-3mairimsp2003No ratings yet

- Line Sizing - Pouria SabbaghDocument1 pageLine Sizing - Pouria Sabbaghadil alameenNo ratings yet

- Bore Pump Lookup Data (MC Rev B)Document12 pagesBore Pump Lookup Data (MC Rev B)chrisNo ratings yet

- Lp-000090-A - GTL - Ac - BC - Valves - 60 Ton - R4-22-02-2024Document1 pageLp-000090-A - GTL - Ac - BC - Valves - 60 Ton - R4-22-02-2024Nadeem AkramNo ratings yet

- Aerotropolis Storm Pocket C 15-04-2024Document1 pageAerotropolis Storm Pocket C 15-04-2024Manish BhutaniNo ratings yet

- Selection Guide For Energy Recovery, Packaged Ventilation Systems and Make-Up AirDocument2 pagesSelection Guide For Energy Recovery, Packaged Ventilation Systems and Make-Up AirCarlos GonzalezNo ratings yet

- P843 GEM Poster - JK CiDocument1 pageP843 GEM Poster - JK CiTsubasa OozoraNo ratings yet

- Fill in The Data For The Grey Shaded Areas Only: 2019 Inlet Spacing - Curb and Gutter Spreadsheet (English Units)Document3 pagesFill in The Data For The Grey Shaded Areas Only: 2019 Inlet Spacing - Curb and Gutter Spreadsheet (English Units)Mauricio DelgadoNo ratings yet

- QFD Assignment 2Document1 pageQFD Assignment 2salsid916No ratings yet

- S-18-13306 - DR7050 - A - V-169AB-01 Stack (Max.31t)Document3 pagesS-18-13306 - DR7050 - A - V-169AB-01 Stack (Max.31t)Hanif Nur Fauzi MargonoNo ratings yet

- AE 20017 GN 01 30mHMDocument1 pageAE 20017 GN 01 30mHMVinz ChiaNo ratings yet

- Hydaulic Design of Mo-P-Dr2Document7 pagesHydaulic Design of Mo-P-Dr2sudhirkumarsharma1966No ratings yet

- Ground Floor Lighting Layout Second Floor Lighting Layout: Kitchen Lanai Master BedroomDocument1 pageGround Floor Lighting Layout Second Floor Lighting Layout: Kitchen Lanai Master BedroomJefferson SubilNo ratings yet

- 1 Chilled Water Pump Head CalculationDocument6 pages1 Chilled Water Pump Head CalculationMohammed TanveerNo ratings yet

- Transformation To An Agile and Virtualized World: Operations Center of The FutureDocument1 pageTransformation To An Agile and Virtualized World: Operations Center of The FuturepinardoNo ratings yet

- Powergate Silver LoDocument2 pagesPowergate Silver LoYanai ValdésNo ratings yet

- LLG Low Locknut Load Return: Innovative Hydraulic SolutionsDocument1 pageLLG Low Locknut Load Return: Innovative Hydraulic SolutionsSanti CheewabantherngNo ratings yet

- Job No 7190 e Brochure - Grey - FinalDocument6 pagesJob No 7190 e Brochure - Grey - FinalHarish KumarNo ratings yet

- Comau Medium Payload Eng NJDocument2 pagesComau Medium Payload Eng NJHakan BayrakNo ratings yet

- Step Angle 1.8°Document26 pagesStep Angle 1.8°Miguel MaahNo ratings yet

- Physics Reviewer Jusq TabangDocument1 pagePhysics Reviewer Jusq TabangIan DibNo ratings yet

- Shiplift Docking Plan For ICGS VIKRAM - 23032018 (Keel Beam) 1Document2 pagesShiplift Docking Plan For ICGS VIKRAM - 23032018 (Keel Beam) 1Kyaw Win TunNo ratings yet

- FTTX PosterDocument1 pageFTTX Posterapi-3806249100% (1)

- PRIMARY Chilled Water PUMP HEAD CALCULATIONDocument1 pagePRIMARY Chilled Water PUMP HEAD CALCULATIONNIDHILNo ratings yet

- LIGHTINGDocument5 pagesLIGHTINGmostafaNo ratings yet

- RUBY GRAND 4200 - PRICE LIST - REV - 16 16-10-14 - LatestDocument24 pagesRUBY GRAND 4200 - PRICE LIST - REV - 16 16-10-14 - LatestAnshul KumarNo ratings yet

- Master Table: General Energy Conservation Special NotesDocument1 pageMaster Table: General Energy Conservation Special NotesSiyad p salamNo ratings yet

- Suction Head CalcDocument5 pagesSuction Head CalcNghiaNo ratings yet

- CB3 Me-13Document1 pageCB3 Me-13J-R MERLIN CabatoNo ratings yet

- Catalogos PDFDocument2 pagesCatalogos PDFJimmy AbreuNo ratings yet

- Jayson Ruales Final Output p1Document1 pageJayson Ruales Final Output p1Arnel Pamaos Lopiba MontañezNo ratings yet

- Fire FightingDocument8 pagesFire FightingmostafaNo ratings yet

- Gebruiksaanwijziging: Pro EquipmentDocument6 pagesGebruiksaanwijziging: Pro Equipment9kjk8bhfbrNo ratings yet

- Head LossDocument1 pageHead LossamrNo ratings yet

- 90° Elbow Light-Duty Rigid Coupling: Vds VdsDocument1 page90° Elbow Light-Duty Rigid Coupling: Vds VdsMirko Gutierrez QuirozNo ratings yet

- Ee PlanDocument1 pageEe PlanPaul MendozaNo ratings yet

- 06 - Chapter 3Document28 pages06 - Chapter 3Tech NestNo ratings yet

- Click Here For A Video Demonstration: UnresponsivenessDocument3 pagesClick Here For A Video Demonstration: UnresponsivenessJnana YumnaNo ratings yet

- Bearings For BridgesDocument22 pagesBearings For Bridgesshahbaz_uetian100% (1)

- Para Jumble PDF Set 1Document25 pagesPara Jumble PDF Set 1RajuNo ratings yet

- Decon Technologies Information PackDocument22 pagesDecon Technologies Information PacksoldatosnNo ratings yet

- Geophysical Investigation and Geochemical Study of Sediment Along The Coastal Area in Kota Belud Sabah, MalaysiaDocument10 pagesGeophysical Investigation and Geochemical Study of Sediment Along The Coastal Area in Kota Belud Sabah, MalaysiaLing Sin YiNo ratings yet

- CH17 Past Entry QuestionsDocument2 pagesCH17 Past Entry QuestionsKhanNo ratings yet

- Jinny Choe Temp Mem CardDocument1 pageJinny Choe Temp Mem CardginauineNo ratings yet

- Biederman I Perceptual Pleasure and The Brain A Novel Theory Explains Why The Brain Craves Information and Seeks It Through The SensesDocument10 pagesBiederman I Perceptual Pleasure and The Brain A Novel Theory Explains Why The Brain Craves Information and Seeks It Through The SensesKwong Gueng ToNo ratings yet

- Full Solution Manual For Introduction To Environmental Engineering Si Version 3Rd Edition PDF Docx Full Chapter ChapterDocument36 pagesFull Solution Manual For Introduction To Environmental Engineering Si Version 3Rd Edition PDF Docx Full Chapter Chapterhanukka.fleabite620r0o100% (15)

- Soal Procedure Text 1Document8 pagesSoal Procedure Text 1Nina Sri AstutiNo ratings yet

- Impco 425 CarburetorDocument6 pagesImpco 425 Carburetors_boots100% (2)

- Control Valve Sourcebook (Refining) PDFDocument198 pagesControl Valve Sourcebook (Refining) PDFnaraNJORNo ratings yet

- Up in The AirDocument1 pageUp in The AirMyzheleen RomanNo ratings yet

- Pancha Paskshi Shirt LessonsDocument46 pagesPancha Paskshi Shirt Lessonsvenkatinc_vj100% (3)

- Baby's Best ChanceDocument140 pagesBaby's Best ChanceLiam BuiNo ratings yet

- IB Merger ModelDocument12 pagesIB Merger Modelkirihara95100% (1)

- Course Syllabus in SuccessionDocument16 pagesCourse Syllabus in SuccessionCharina BalunsoNo ratings yet

- Practice Test 4: Lớp Tiếng Anh Phúc Đức - chuyên luyện thi Đại họcDocument25 pagesPractice Test 4: Lớp Tiếng Anh Phúc Đức - chuyên luyện thi Đại họclevukhanhlinh2262004No ratings yet

- Turkish Airlines Inc. A320 / B737 First Officer Minimum RequirementsDocument5 pagesTurkish Airlines Inc. A320 / B737 First Officer Minimum RequirementsLin CYNo ratings yet

- Cable Entry Seals: We Seal Your WorldDocument56 pagesCable Entry Seals: We Seal Your WorldErick Josue Mart100% (1)

- High Performance Plastic Materials Guide Aug 2009Document8 pagesHigh Performance Plastic Materials Guide Aug 2009JeanMichelMNo ratings yet

- Ammonia MeasurementDocument10 pagesAmmonia Measurement9326773777No ratings yet

- TLEDocument2 pagesTLEayesha teroNo ratings yet

- Comparative Study of Different Waste Biomass For Energy ApplicationDocument6 pagesComparative Study of Different Waste Biomass For Energy Applicationvitor_alberto_7No ratings yet

- 01-75paa-3-2 CH 17 Edited For BR - 306476Document500 pages01-75paa-3-2 CH 17 Edited For BR - 306476Hugo NascimentoNo ratings yet