Professional Documents

Culture Documents

Series 19 CDI Capacitors

Series 19 CDI Capacitors

Uploaded by

Emir DelicOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Series 19 CDI Capacitors

Series 19 CDI Capacitors

Uploaded by

Emir DelicCopyright:

Available Formats

CAPACITOR DISCHARGE IGNITION CDI CAPACITORS

MAIN APPLICATION: Capacitor discharge ignition used in twowheeler ignition systems. CONSTRUCTION: Low inductive cell of metallised polyester or metallised polypropylene film coated with flame retardant grade epoxy resin. CLIMATIC CATEGORY: 40/85/56 APPLICABLE SPECIFICATION: IEC 384-2 (MPET), IEC 384-16 (MPP) CAPACITANCE VALUE: Refer dimension chart. RATED VOLTAGE (DC): 400V CAPACITANCE TOLERANCE: 10% VOLTAGE PROOF Between terminals: 1.6 times of rated voltage for 2 seconds. INSULATION RESISTANCE Minimum Insulation Resistance RIS >10000s at 100 VDC (or) time constant T=CR x RIS at 25 C, relative humidity 70% TAN 3.0 %(maximum) at 100 kHz (MPET). 0.5 %(maximum) at 100kHz (MPP). LIFE TEST CONDITIONS - MPET (Loading at elevated temperature) Loaded at 1.25 times of rated voltage at 85 C or 1.25 times Of the category voltage at 100 C for 2000 hours. Category voltage is 80% of rated voltage. AFTER THE TEST c/c: 5% of initial value. Change in Tan : 0.002, CR > 1 f. Insulation resistance: 50% of the value mentioned in IR chart. LIFE TEST CONDITIONS - MPP (Loading at elevated temperature) Loaded at 1.25 times of rated voltage at 85 C or 1.25 times of category voltage at 100 C for 2000 hours. Category voltage is 80% of rated voltage. AFTER THE TEST c/c: 3% of initial value. Change in Tan : 0.004. Insulation resistance: 50% of the value mentioned in IR chart. APPROVALS: Tested as per IEC 384-16 for MPP and IEC 384-2 for MPET.

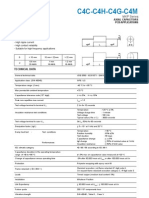

Ordering Code and Packing Units: CDI Capacitors

Rated Voltage Rated Cap. (f) W

400V DC 1.0 MPET Series 1.4 1.5 2.2 3.3 400V DC MPP Series 0.68 1.0 1.4 1.5 2.2 8 9 10 11 13 12 13 14 14 16

Maximum Dimensions (mm) H L d F

0.5 18 18 18 22 24 20 24 25 25 28 32 32 32 32 32 32 32 32 32 32 0.8 0.8 0.8 0.8 0.8 0.8 0.8 0.8 0.8 0.8 1.0 27.5 27.5 27.5 27.5 27.5 27.5 27.5 27.5 27.5 27.5

Wt g

Ordering code

Packing units Bulk

4.0 5.5 6.1 10.2 12.5 4.5 6.0 10.0 12.5 14.0

08 105 +2G*^ 08 145 +2G*^ 08 155 +2G*^ 08 225 +2G*^ 08 335 +2G*^ 09 684 +2G*^ 09 105 +2G*^ 09 145 +2G*^ 09 155 +2G*^ 09 225 +2G*^

500 250 250 250 250 250 250 250 250 250

NOTE 1. Replace the + by the code letter for the required tolerance. F:1%, G:2%, H:2.5%, J:5%, K:10%, M:20% 2. Replace * by the code letter for packing type. 1 : Bulk Packing 2 : Bulk Packing (After forming & cutting) 3 : Ammo Packing (F&T) 4 : Bulk Packing (forming in original pitch) 5 : Bulk Packing (formed & without cut) 6 : Ammo Packing (Straight Lead) 7 : Bulk Packing (Straight Lead cut) 3. Replace ^ by the code letter indicated drawing reference. A : As per the catalogue B-Z : customer drawing reference 4. These are the most popular values. Other values in the range are available on request. For dimensions, please refer to the closest higher value.

- 54 -

You might also like

- Eccentric Lives and Peculiar Notions (John Michell)Document3 pagesEccentric Lives and Peculiar Notions (John Michell)Emir DelicNo ratings yet

- Pilkor PCX2 335MDocument7 pagesPilkor PCX2 335MadminagentNo ratings yet

- Pilkor PCX2 335Document7 pagesPilkor PCX2 335Claudia Alejandra López100% (1)

- STW21NM50N MosfetDocument16 pagesSTW21NM50N MosfetrigowNo ratings yet

- STTA1206D/DI/G: Turboswitch Ultra-Fast High Voltage DiodeDocument9 pagesSTTA1206D/DI/G: Turboswitch Ultra-Fast High Voltage DiodeMarcos AndréNo ratings yet

- TDA7262Document9 pagesTDA7262Nelson PereiraNo ratings yet

- SCRDocument10 pagesSCRHugo LopezNo ratings yet

- Wide Bandwidth Dual Bipolar Operational Amplifier: DescriptionDocument10 pagesWide Bandwidth Dual Bipolar Operational Amplifier: DescriptionAlexander MasiasNo ratings yet

- TDA2008Document10 pagesTDA2008miusayNo ratings yet

- MH 182Document11 pagesMH 182harshalvikasNo ratings yet

- 110 DS3 - DSheet Minipack Rectifier - 48 800 - 3v0 PDFDocument2 pages110 DS3 - DSheet Minipack Rectifier - 48 800 - 3v0 PDFleonardomarinNo ratings yet

- Data SheetDocument6 pagesData SheetcornolioNo ratings yet

- DatasheetDocument9 pagesDatasheetloisaomNo ratings yet

- TLP291 4 PDFDocument14 pagesTLP291 4 PDFBruno SilvaNo ratings yet

- SD840S PDF, SD840S Description, SD840S Datasheets, SD840S View - ALLDATASHEET - PDFDocument2 pagesSD840S PDF, SD840S Description, SD840S Datasheets, SD840S View - ALLDATASHEET - PDFOralia MendezNo ratings yet

- Tiny, Low-Cost, Single/Dual-Input, Fixed-Gain Microphone Amplifiers With Integrated BiasDocument11 pagesTiny, Low-Cost, Single/Dual-Input, Fixed-Gain Microphone Amplifiers With Integrated BiasWei CheanNo ratings yet

- TY616Document8 pagesTY616Anupam AshokNo ratings yet

- DSDocument13 pagesDSazmanjamaatNo ratings yet

- PS HGZM PDFDocument3 pagesPS HGZM PDFVenkatesh KarriNo ratings yet

- Aluminum Electrolytic Capacitors: SpecificationsDocument1 pageAluminum Electrolytic Capacitors: SpecificationsbehzadNo ratings yet

- Ca3kn22bd Telemecanique - Unit5.relayDocument8 pagesCa3kn22bd Telemecanique - Unit5.relaykapenziNo ratings yet

- Codificare Rezistente SMD 60A Are 412 Ohmi CF TabelDocument6 pagesCodificare Rezistente SMD 60A Are 412 Ohmi CF Tabelromeo1966No ratings yet

- Datasheet ET1100Document10 pagesDatasheet ET1100Manal FeghaliNo ratings yet

- K2Series DS 1015370 5 20141104Document4 pagesK2Series DS 1015370 5 20141104曾乙申No ratings yet

- Specifications: 4.5Mml Chip Type, Wide Temperature RangeDocument1 pageSpecifications: 4.5Mml Chip Type, Wide Temperature RangeselocaNo ratings yet

- IC-ON-LINE - CN p75nf75 71035Document16 pagesIC-ON-LINE - CN p75nf75 71035Daniel David PeñaNo ratings yet

- Data Shett 8eth06pbDocument9 pagesData Shett 8eth06pbDolly Arthur SiregarNo ratings yet

- TSOP382.., TSOP384.., TSOP392.., TSOP394..: Vishay SemiconductorsDocument7 pagesTSOP382.., TSOP384.., TSOP392.., TSOP394..: Vishay SemiconductorssickdogNo ratings yet

- 10NK80Document15 pages10NK80Abubakar SidikNo ratings yet

- MLX91205 DatasheetDocument14 pagesMLX91205 DatasheetRicardo ReisNo ratings yet

- Rohm Catalog2010Document24 pagesRohm Catalog2010Timofte Lazar100% (2)

- K814P/K824P/K844P: Vishay SemiconductorsDocument8 pagesK814P/K824P/K844P: Vishay SemiconductorsJessica JenkinsNo ratings yet

- Siemens - Tyco V23084 C2001 A303Document5 pagesSiemens - Tyco V23084 C2001 A303meda меда100% (1)

- 5 Thick Film Array Chip ResistorsDocument11 pages5 Thick Film Array Chip ResistorsRajesh PatelNo ratings yet

- Ferrite Chip Inductors - 0805AF (2012)Document2 pagesFerrite Chip Inductors - 0805AF (2012)TestronicpartsNo ratings yet

- 890 Resistor CI (Obsolete)Document4 pages890 Resistor CI (Obsolete)Juan Pablo AmadorNo ratings yet

- 4N252Document8 pages4N252Taumar MoraisNo ratings yet

- DC/DC Converters: FeaturesDocument6 pagesDC/DC Converters: FeaturesDalibor CetojevicNo ratings yet

- Stp8Nc50 - Stp8Nc50Fp Stb8Nc50-1: N-Channel 500V - 0.7 - 8A To-220/To-220Fp/I2Pak Powermesh Ii MosfetDocument11 pagesStp8Nc50 - Stp8Nc50Fp Stb8Nc50-1: N-Channel 500V - 0.7 - 8A To-220/To-220Fp/I2Pak Powermesh Ii Mosfetmiguel angel jaramilloNo ratings yet

- Weidmuller DRM Relays PDFDocument6 pagesWeidmuller DRM Relays PDFryreddyNo ratings yet

- Datasheet DM12Document9 pagesDatasheet DM12dff1967dffNo ratings yet

- PT928 6C F DatasheetDocument7 pagesPT928 6C F DatasheetLuis PintoNo ratings yet

- Transistor Mtp8n50eDocument6 pagesTransistor Mtp8n50eGamal YonesNo ratings yet

- Pilkor PCX2 335MDocument7 pagesPilkor PCX2 335MJamerson DuarteNo ratings yet

- ET1103Document11 pagesET1103fredy arias duranNo ratings yet

- TY Rev (4) 01 2013Document1 pageTY Rev (4) 01 2013isotempNo ratings yet

- General InformationDocument3 pagesGeneral InformationsrobayocNo ratings yet

- Tsop 4038Document8 pagesTsop 4038Rafael AlegreNo ratings yet

- HIT Power 220A DatasheetDocument2 pagesHIT Power 220A DatasheetHadeedAhmedSherNo ratings yet

- 2N5551 - NPN General Purpose AmplifierDocument13 pages2N5551 - NPN General Purpose AmplifierflaviorochaavilaNo ratings yet

- CNY21Document10 pagesCNY21Leo KralNo ratings yet

- ArcotronicDocument6 pagesArcotronicangel1885No ratings yet

- Titan Energy Systems LTD: Solar Module TITAN M5-72Document2 pagesTitan Energy Systems LTD: Solar Module TITAN M5-72BADRI VENKATESHNo ratings yet

- Digital DSP Control, Isolating by Transformer. LCD Display Protection:input Power, Output Power InputDocument5 pagesDigital DSP Control, Isolating by Transformer. LCD Display Protection:input Power, Output Power InputsubsoniqueNo ratings yet

- Tn12, Ts12 and Tynx12 Series: 12A SCRDocument11 pagesTn12, Ts12 and Tynx12 Series: 12A SCREdwardFernandoBocanegraQuinteroNo ratings yet

- The Fourth Terminal: Benefits of Body-Biasing Techniques for FDSOI Circuits and SystemsFrom EverandThe Fourth Terminal: Benefits of Body-Biasing Techniques for FDSOI Circuits and SystemsSylvain ClercNo ratings yet

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsFrom EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNo ratings yet

- Boem Torta - ReceptDocument1 pageBoem Torta - ReceptEmir DelicNo ratings yet

- Simatic Ipc547e en Web PDFDocument7 pagesSimatic Ipc547e en Web PDFEmir DelicNo ratings yet

- Using Using Using Using Using Using Using Using Using Namespace Public Partial Class Public String Public StringDocument4 pagesUsing Using Using Using Using Using Using Using Using Namespace Public Partial Class Public String Public StringEmir DelicNo ratings yet

- Recept KolačiDocument1 pageRecept KolačiEmir DelicNo ratings yet

- Simatic Ipc847d-En WebDocument5 pagesSimatic Ipc847d-En WebEmir DelicNo ratings yet

- PCS 7 - Know-How in All Aspects of The Process Control SystemDocument8 pagesPCS 7 - Know-How in All Aspects of The Process Control SystemEmir DelicNo ratings yet

- MK3263GSX: 2.5-Inch SATA HDDDocument1 pageMK3263GSX: 2.5-Inch SATA HDDEmir DelicNo ratings yet

- Tip 3241-7 PozicionatorDocument8 pagesTip 3241-7 PozicionatorEmir DelicNo ratings yet

- Ideal GasDocument1 pageIdeal GasEmir DelicNo ratings yet

- College Park Auto Repair: Customer InformationDocument5 pagesCollege Park Auto Repair: Customer InformationEmir DelicNo ratings yet