Professional Documents

Culture Documents

03-04-2021 - JOB - 521 - GG - STR - DETRITOR MECHANISM - FINAL-Model

03-04-2021 - JOB - 521 - GG - STR - DETRITOR MECHANISM - FINAL-Model

Uploaded by

dineshOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

03-04-2021 - JOB - 521 - GG - STR - DETRITOR MECHANISM - FINAL-Model

03-04-2021 - JOB - 521 - GG - STR - DETRITOR MECHANISM - FINAL-Model

Uploaded by

dineshCopyright:

Available Formats

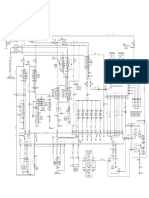

GEARED MOTOR

415V 10%/50HZ 5%/IE2/

CLASS-F/IP-55

GEARED MOTOR

CHAIN ORGANIC RETURN

GUARD MECHANISM

SCREW CLASSIFIER 415V 10%/50HZ 5%/IE2/ GEARED MOTOR 0.5HP/TEFC/

CLASS-F/IP-55 10%P/50HZ 5%/4POLE/ ORGANIC RETURN MECHANISM OUTLET NOZZLE-100NB 40x80x200DEEP

REF, IE2/CLASS-F/IP-55 OUTLET NOZZLE 100NB ANCHOR POCKET-3NOS.

DETAIL-K OUTLET

CHUTE ORGANIC RETURN

MECHANISM

T.O.T 107.00 T.O.T 107.00

107.00 INLET AND OUTLET

SCREW DISCHARGE 100NB NOZZLE(ORG.RETURN

T.W.L 106.70 T.W.L 106.70 INTERCONNECTION PIPE

POINT LINE MAIN TANK INLET)

(BY CONTRACTOR)

(BY CONTRACTOR)

106.25

PROPELLER

E

106.00

B.O.T 105.80

107.00

105.46 ORGANIC RETURN

PE

SL

MECHANISM TANK

C/L OF

O

ORM

SL

PE

107.00 105.05 INLET-100NB

800x700 OPENING 105.05

(BY CONTRACTOR)

ON FLOOR SLAB

C/L OF

PCC FILLING TO BE DONE AFTER CLASSIFIER

PCC FILLING TO BE DONE 100NB DRAIN NOZZLE WITH

SCREW INSTALLATION

AFTER SCREW INSTALLATION

SECTION D-D 100NB DRAIN NOZZLE WITH

BLIND FLANGE(BY CONTRACTOR)

SCOOP

BOX

T.O.T

107.00

BLIND FLANGE (BY CONTRACTOR)

SECTION F-F

BLADE

OVERLOAD

PROTECTION

DETAIL - K

ASSEMBLY

DEFLECTOR PIPE

TIE

107.00 ANGLE

REF, TANK-1 REF, TOT 107.00

DETAIL-M DRIVE

DETAIL-S HEAD (TO SUIT 32NB PIPE SLEEVE

CHAIN WITH STOPPER PLATE)

FEED GUARD DEFLECTOR PIPE TWL

B.O.T

DEFLECTOR SLEEVE (UPPER) 106.70

105.80

MS-FRP

RAKE DEFLECTOR

MACHINE

106.25 ARM

C/L OF

INLET 75 SQ x 65 DEEP POCKET

SL

PE ORGANIC RETURN MECHANISM (TO SUIT 60 SQ BOTTOM PLATE

O

LO INLET AND OUTLET INTERCONNECTION WITH 32 NB PIPE SLEEVE)

PE

S

PIPE(BY CONTRACTOR) 106.25

DEFLECTOR PIPE

OUTLET SLEEVE (LOWER)

ISOMETRIC VIEW OF SCREW AND ORM CHAMBER

PE SECTIONAL VIEW OF M-M

SL

[TYPICAL REPRESENTATION VIEW SHOWN, ACTUAL VIEW DIFFERS]

LO

O

PE

S

[TYPICAL REPRESENTATION VIEW SHOWN, ACTUAL VIEW DIFFERS] BOT

T.O.T 105.80

INLET 107.00

BRIDGE(BY CLIENT)

RCC WALKWAY

C/L OF

SCOOP GEARED MOTOR

BOX

106.25

OVERLOAD SECTION X-X

BLADE PROTECTION

ASSEMBLY

60SQ THROUGH C/L OF

ANCHOR POCKETS TANK

FEED TIE 4 NOS

DEFLECTOR ANGLE

TANK-2 DRIVE

HEAD

C/L OF CUT OUT

MACHINE

WORM SHAFT OPENING

C/L OF

B.O.T

107.00 105.80

SECTIONAL VIEW OF L-L D/H BASE FRAME FOUNDATION HOLES

SECTION Y-Y

HAND RAIL

RAKE [TYPICAL REPRESENTATION VIEW SHOWN,ACTUAL VIEW DIFFERS] (BY CONTRACTOR)

800x700 OPENING ARM RCC BRIDGE DETAIL - S

(BY CONTRACTOR)

ON FLOOR SLAB

T.O.T 107.00

SL

PE

CLIENT:

O

O

PE

SL T.W.L 106.70

VERTICAL GREATER WARANGAL SMART CITY CORPORATION LIMITED

SHAFT

106.25 PROJECT:

B.O.T 105.80

15 MLD STP AT PRAGATHI NAGAR, GWMC

SCREW DISCHARGE

CONTRACTOR:

50 THK SCREED (TO BE CARRIED OUT

POINT

107.00

AFTER INSTALLATION OF MECHANISM) GAJA ENGINEERING, CHENNAI

SECTION R-R

470 No. REVISIONS DATE BY

75 160 160 75 DRAWN DATE CHECKED DATE APPROVED DATE

PLAN TROUGH

MMT 11.02.21 RS 11.02.21 RSK 11.02.21

220

RCC CLASSIFIER

450

CHANNEL TITLE

GA DRAWING OF

230

PCC FILLING TO BE

DONE AFTER STATIC LOAD = ~850 KG

DETRITOR MECHANISM

INSTALLATION OF SCREW DYNAMIC LOAD = ~1020 KG

6.0 M SQ x 0.9 M SWD + 0.3 M FB

SECTION E-E C/L OF

MACHINE

NOTE: DRIVE ORDER NO DRAWING NO.

ORGANIC HEAD RCC BRIDGE

RETURN MECHANISM & HAND RAIL

- ALL DIMENSIONS ARE IN MM,LEVELS ARE IN M.(UNLESS OTHERWISE SPECIFIED). (BY CONTRACTOR)

107.00

T.O.T

SP-2076

- SUPPLY SCOPE : COLLECTION MECHANISM WITH DRIVE & OVERLOAD PROTECTION 106.70

C/L OF SCREW

ASSEMBLY, SCREW CLASSIFIER WITH DRIVE ASSEMBLY, ORGANIC RETURN MECHANISM

CLASSIFIER

TIE T.W.L

WITH DRIVE ASSEMBLY, FEED DEFLECTOR, WEIR PLATE, & ASSY HARDWARE. 106.25 ROD

- ALL MILD STEEL PARTS SHALL BE SAND BLASTED SA 2.5 WITH 2 COATS OF EPOXY PRIMER,

105.80

1 COAT OF MIO AND 2 COATS OF FINISH EPOXY PAINT WITH TOTAL DFT 150 MICRON. B.O.T

105.46

REF,

- QTY : 2 NOS. PCC FILLING TO BE DETAIL-T

105.05 DONE AFTER SCREW

This document is the property and the work of SHIVPAD ENGINEERS PVT LTD, Must be returned

INSTALLATION

SECTION C-C on demand Any use detrimental to the interest of SHIVPAD ENGINEERS PVT LTD, is prohibited.

You might also like

- 2002 Honda Civic EX Sedan L4-1668cc 1.7L SOHC (VTEC) MFI Vehicle Powertrain Management Diagrams Electrical - Interactive Color (Non OE) Engine Controls - Except HX & GX - Page 1 of 3Document3 pages2002 Honda Civic EX Sedan L4-1668cc 1.7L SOHC (VTEC) MFI Vehicle Powertrain Management Diagrams Electrical - Interactive Color (Non OE) Engine Controls - Except HX & GX - Page 1 of 3lucio100% (3)

- Matix PFD1 Rev3 CompleteDocument7 pagesMatix PFD1 Rev3 CompleteSanju ChauhanNo ratings yet

- Gambling Addiction PowerpointDocument11 pagesGambling Addiction PowerpointEK200620No ratings yet

- 2018 D4GA (Euro-2 4) D4GA (Euro-2 4) Exhaust Brake System Schematic DiagramsDocument1 page2018 D4GA (Euro-2 4) D4GA (Euro-2 4) Exhaust Brake System Schematic DiagramsLuis Alberto Gutierrez LeyvaNo ratings yet

- Sienna 16 EcmDocument6 pagesSienna 16 EcmEdgar GuzmanNo ratings yet

- VTV6NA Series1 Wiring ConnectorsDocument3 pagesVTV6NA Series1 Wiring Connectorsraraokt222No ratings yet

- Engine Controls (Powertrain Management)Document4 pagesEngine Controls (Powertrain Management)Alejandro Quiñones VelazquezNo ratings yet

- 2004 atDocument3 pages2004 atjohn luis MoralesNo ratings yet

- M1-1-9 - Equipment & Instrument List - 70078-0022 R01Document14 pagesM1-1-9 - Equipment & Instrument List - 70078-0022 R01Amirul AdliNo ratings yet

- 2006 D6CA Engine Control (ETC) System Schematic DiagramsDocument1 page2006 D6CA Engine Control (ETC) System Schematic DiagramsDavid GallegosNo ratings yet

- C346 Europe Mca My2016.5 High Audio With Sync Gen Iii (Rs Na Only)Document1 pageC346 Europe Mca My2016.5 High Audio With Sync Gen Iii (Rs Na Only)Alberto Matties100% (1)

- MotoventiladoresDocument1 pageMotoventiladoresMartin SantoyoNo ratings yet

- Beetle 2o TurboDocument6 pagesBeetle 2o TurboJosé Luis Martinez OsorioNo ratings yet

- VXV6NA Series1 5b WiringDocument2 pagesVXV6NA Series1 5b WiringDanniel PizattoNo ratings yet

- Audi2 0fsiDocument1 pageAudi2 0fsiAlejandro Quiñones VelazquezNo ratings yet

- Engine Controls g3 2009Document5 pagesEngine Controls g3 2009jorge masterNo ratings yet

- VTV6SC Series1 Wiring ConnectorsDocument3 pagesVTV6SC Series1 Wiring Connectorsraraokt222No ratings yet

- Plano Hidraulico PDFDocument2 pagesPlano Hidraulico PDFLuis ValenciaNo ratings yet

- Av Surround Receiver: Operating InstructionsDocument74 pagesAv Surround Receiver: Operating InstructionsAndrewNo ratings yet

- ls1 PCM 2Document3 pagesls1 PCM 2Mortada AlsonniNo ratings yet

- 2015 Grand Santafe D 2.2 Tci-R-DiagramDocument1 page2015 Grand Santafe D 2.2 Tci-R-Diagrammarcelo ravenaNo ratings yet

- Diagrama Hidraulico 336 DDocument2 pagesDiagrama Hidraulico 336 DGerardoNo ratings yet

- 0.3-LAM-plano Hidraulico 2016Document2 pages0.3-LAM-plano Hidraulico 2016Hector Zárate100% (1)

- 2019 Toyota Corolla 2.0L Eng VIN 4 SEDocument220 pages2019 Toyota Corolla 2.0L Eng VIN 4 SEalex acuña cordovaNo ratings yet

- PZV Pressurerelief ValveDocument3 pagesPZV Pressurerelief Valvepraveenice23No ratings yet

- Diagrama Hco D5C Iii PDFDocument2 pagesDiagrama Hco D5C Iii PDFanon_366480037100% (3)

- VXV6NA Series1 5c Wiring PDFDocument2 pagesVXV6NA Series1 5c Wiring PDFRhys BellmanNo ratings yet

- Diagram PID Nitrogen Membrane Package IFSDocument1 pageDiagram PID Nitrogen Membrane Package IFSHaris MunandarNo ratings yet

- Sir Ton - 2 Storey With Roof Deck - Mec - 1Document1 pageSir Ton - 2 Storey With Roof Deck - Mec - 1zaccNo ratings yet

- Eco 1nz Engine Controls (Powertrain Management) - ALLDATA RepairDocument3 pagesEco 1nz Engine Controls (Powertrain Management) - ALLDATA RepairRigoberto Buendía menaNo ratings yet

- Kia SoretoDocument136 pagesKia SoretoLUIS ALEJANDRO100% (1)

- 2Document1 page2lyanna120168No ratings yet

- Kia Forte EcmDocument7 pagesKia Forte EcmEdgar GuzmanNo ratings yet

- Plano 336d2lDocument2 pagesPlano 336d2lAdonaí MoralesNo ratings yet

- Cat 336D2 Hydr.&Elect - DiagramDocument10 pagesCat 336D2 Hydr.&Elect - DiagrammanuelNo ratings yet

- Engine JETTA 2012Document7 pagesEngine JETTA 2012Rogelio ArenasNo ratings yet

- .Trashed-1721226984-Engine Controls (Powertrain Management) - ALLDATA RepairDocument5 pages.Trashed-1721226984-Engine Controls (Powertrain Management) - ALLDATA RepaircarlosNo ratings yet

- Engine Controls (Powertrain Management) - ALLDATA RepairDocument3 pagesEngine Controls (Powertrain Management) - ALLDATA RepairAUTOEPC LAAM (LUFACANA)No ratings yet

- Opt Nissan 3Document4 pagesOpt Nissan 3YduR ZurCNo ratings yet

- VTV6NA Series2 5b Wiring ConnectorsDocument3 pagesVTV6NA Series2 5b Wiring Connectorsraraokt222No ratings yet

- Toggle Select Wire Mode Hide All Non Selected Wires Clear Selection Select Color Search Text PrintDocument2 pagesToggle Select Wire Mode Hide All Non Selected Wires Clear Selection Select Color Search Text PrintFelix Velasquez100% (2)

- JSM Camion 797BDocument4 pagesJSM Camion 797BMECANICA AIEPNo ratings yet

- Battery: Exhaust Gas Sensor (RH)Document3 pagesBattery: Exhaust Gas Sensor (RH)Joakin BcNo ratings yet

- Plano Hidraul 797BDocument2 pagesPlano Hidraul 797BBastian ParedesNo ratings yet

- 2014 Honda Accord Sedan V6-3.5L (J35Y1) Engine ControlsDocument7 pages2014 Honda Accord Sedan V6-3.5L (J35Y1) Engine ControlsdvdNo ratings yet

- General Notes:: Schedule of EquipmentDocument1 pageGeneral Notes:: Schedule of EquipmentBilly Joe BreakfastNo ratings yet

- VXV6 LPG Series2 WiringDocument2 pagesVXV6 LPG Series2 WiringDanniel PizattoNo ratings yet

- Multi-Coil / 2-Way Valve: Fan Detail Roof Mounted Exhaust Coil Piping Diagram Chilled Water PipingDocument2 pagesMulti-Coil / 2-Way Valve: Fan Detail Roof Mounted Exhaust Coil Piping Diagram Chilled Water PipingChristian TaboadaNo ratings yet

- Diagram A Tacoma 2013Document1 pageDiagram A Tacoma 2013Luis Trucking ReyesNo ratings yet

- Hyd ScheDocument2 pagesHyd SchechanlinNo ratings yet

- Navistar Manual de Taller DT466 Amp I530eDocument1 pageNavistar Manual de Taller DT466 Amp I530eAnonymous 7t2BOJb100% (2)

- Engine Control SystemDocument18 pagesEngine Control SystemkriskonediNo ratings yet

- TXSR 606Document215 pagesTXSR 606Eletrônica Maia Comércio e ServiçosNo ratings yet

- 980H PDFDocument2 pages980H PDFIgnacio Lazo JhsúsNo ratings yet

- Onkyo tx-sr876 SMDocument23 pagesOnkyo tx-sr876 SMMoto MottoNo ratings yet

- 2015 Hyundai Elantra GT Base 2.0LDocument116 pages2015 Hyundai Elantra GT Base 2.0LData TécnicaNo ratings yet

- Diagrama Hidraulico Del 980HDocument2 pagesDiagrama Hidraulico Del 980HMiguel GonzalezNo ratings yet

- Printer Friendly View 4Document5 pagesPrinter Friendly View 4Emanuel De Jesus LopezNo ratings yet

- Engine Controls (Powertrain Management) - ALLDATA RepairDocument5 pagesEngine Controls (Powertrain Management) - ALLDATA RepaircarlosNo ratings yet

- E&I Cost - Zone-1 & 2Document22 pagesE&I Cost - Zone-1 & 2dineshNo ratings yet

- Structural Design BasisDocument20 pagesStructural Design BasisdineshNo ratings yet

- Civil Inputs - PrelimDocument2 pagesCivil Inputs - PrelimdineshNo ratings yet

- DWC HDPE & HDPE Pipe SupplyDocument2 pagesDWC HDPE & HDPE Pipe SupplydineshNo ratings yet

- Concrete GradeDocument1 pageConcrete GradedineshNo ratings yet

- Index Map of Okkium Thoraipakkam in Chennai CityDocument1 pageIndex Map of Okkium Thoraipakkam in Chennai CitydineshNo ratings yet

- Technical Specifications - Painting of SteelDocument1 pageTechnical Specifications - Painting of SteeldineshNo ratings yet

- Micro TunnelingDocument2 pagesMicro TunnelingdineshNo ratings yet

- Winter Break H.H.W Class 1Document5 pagesWinter Break H.H.W Class 1dineshNo ratings yet

- Boq 339191Document440 pagesBoq 339191dineshNo ratings yet

- Class-I ContractorDocument7 pagesClass-I ContractordineshNo ratings yet

- Food Grade Epoxy Coating Centre Govt Lab Approved and Nabl Lab Tested As Per Fda GuidilinesDocument5 pagesFood Grade Epoxy Coating Centre Govt Lab Approved and Nabl Lab Tested As Per Fda GuidilinesdineshNo ratings yet

- Travel Expenses Reimbursement Form W.e.f-1.11.2020Document2 pagesTravel Expenses Reimbursement Form W.e.f-1.11.2020dineshNo ratings yet

- CRS R3 Drawing For Uf-Ro Building.Document1 pageCRS R3 Drawing For Uf-Ro Building.dineshNo ratings yet

- MANIPALANIYANDI - ResumeDocument6 pagesMANIPALANIYANDI - ResumedineshNo ratings yet

- BHELDocument2 pagesBHELdineshNo ratings yet

- BCD Sor 2022 CompressedDocument460 pagesBCD Sor 2022 CompresseddineshNo ratings yet

- SOR 2022-23 Final DraftDocument347 pagesSOR 2022-23 Final DraftdineshNo ratings yet

- SPRINTERSDocument6 pagesSPRINTERSdineshNo ratings yet

- WO-Aluminium Door, Windows & Rolling ShutterDocument3 pagesWO-Aluminium Door, Windows & Rolling ShutterdineshNo ratings yet

- 56, 57. R0 LP Building, Cooling PH, (66-2,57,53,56)Document97 pages56, 57. R0 LP Building, Cooling PH, (66-2,57,53,56)dineshNo ratings yet

- MDL - 20.07.2022Document2 pagesMDL - 20.07.2022dineshNo ratings yet

- Agenda For Weekly Review Meeting On 19.10.2022.Document22 pagesAgenda For Weekly Review Meeting On 19.10.2022.dineshNo ratings yet

- CRS Road - MergedDocument2 pagesCRS Road - MergeddineshNo ratings yet

- 1.AKAR IMPEX PVT LTD - Civil BOQ - THDC-WTP QTY-CS - (NEW QUANTITY)Document19 pages1.AKAR IMPEX PVT LTD - Civil BOQ - THDC-WTP QTY-CS - (NEW QUANTITY)dineshNo ratings yet

- Renamed BBU DrawingsDocument4 pagesRenamed BBU DrawingsdineshNo ratings yet

- Reshdule For Flight Ticket BookingDocument2 pagesReshdule For Flight Ticket BookingdineshNo ratings yet

- Final MDL List - 21.07Document8 pagesFinal MDL List - 21.07dineshNo ratings yet

- Script PyramidsDocument2 pagesScript PyramidsHaifa KattanNo ratings yet

- A Brief Check List of Labour Laws: H.R.DasguptaDocument54 pagesA Brief Check List of Labour Laws: H.R.DasguptaPravin KumarNo ratings yet

- Bwanya V The Master - 2021 - ZACC 51Document92 pagesBwanya V The Master - 2021 - ZACC 51toritNo ratings yet

- Happy Forgings Limited: Mock Drill ReportDocument3 pagesHappy Forgings Limited: Mock Drill Reportmool raj100% (1)

- CBCP Monitor Vol12-N21Document20 pagesCBCP Monitor Vol12-N21Areopagus Communications, Inc.No ratings yet

- 5 Metromedia Times Corp Vs PastorinDocument2 pages5 Metromedia Times Corp Vs Pastorinjed_sindaNo ratings yet

- From A Faded Past To Enduring Vividness: by Bhaswati ChakravortyDocument2 pagesFrom A Faded Past To Enduring Vividness: by Bhaswati ChakravortyTareq AzizNo ratings yet

- Labour - IIDocument7 pagesLabour - IIprathmesh agrawalNo ratings yet

- Greta GarboDocument2 pagesGreta GarboApple Ple21No ratings yet

- 09 Prophecies PDFDocument10 pages09 Prophecies PDFdalenielrivera100% (1)

- AMLA PP vs. Estrada 2009Document6 pagesAMLA PP vs. Estrada 2009Honey Mambuay-Barambangan0% (1)

- Dorian Gray Chapters' SummaryDocument3 pagesDorian Gray Chapters' SummaryRamonaGalarzaNo ratings yet

- CDADocument3 pagesCDADanish YaseenNo ratings yet

- Drones in Hybrid Warfare - 14-15Document2 pagesDrones in Hybrid Warfare - 14-15sakis lakisNo ratings yet

- The ColosseumDocument13 pagesThe ColosseumJake BryantNo ratings yet

- Freedom of Expression, Assembly and Petition Case DigestsDocument22 pagesFreedom of Expression, Assembly and Petition Case DigestsIvanne HisolerNo ratings yet

- IMMI Grant NotificationDocument3 pagesIMMI Grant NotificationYosia Clinton PurbaNo ratings yet

- Philex Mining Vs CIRDocument3 pagesPhilex Mining Vs CIRpreciousrain07100% (1)

- Intro To Law Reviewer MidtermDocument8 pagesIntro To Law Reviewer MidtermGuazon Jommel C.No ratings yet

- Democracy in Latin America? An AssesmentDocument12 pagesDemocracy in Latin America? An Assesmentstyvasio2055No ratings yet

- CenidoDocument26 pagesCenidoJennilyn TugelidaNo ratings yet

- CAS03 Xx-42 Shakespeare - Antony and CleopatraDocument3 pagesCAS03 Xx-42 Shakespeare - Antony and Cleopatraapi-3811132No ratings yet

- Letterhead: Securities and Exchange CommissionDocument2 pagesLetterhead: Securities and Exchange CommissionGlory Perez100% (1)

- Princess Cruise - Southeast Asia 2022 - BDocument2 pagesPrincess Cruise - Southeast Asia 2022 - BHerwanto KwanNo ratings yet

- Aroa, Bryle Khen - Act1 - CFLM211Document3 pagesAroa, Bryle Khen - Act1 - CFLM211John Mico CaballeroNo ratings yet

- Judicial Affidavit of Paul M. Cruz: "Public Safety Officers Basic Course" in January 2014Document3 pagesJudicial Affidavit of Paul M. Cruz: "Public Safety Officers Basic Course" in January 2014Samantha GNo ratings yet

- Complaint For Unlawful DetainerDocument3 pagesComplaint For Unlawful DetainerNicole SantoallaNo ratings yet

- CSC NCR Online Scheduling SystemDocument1 pageCSC NCR Online Scheduling SystemkaizzlemorganNo ratings yet

- US Vs AddisonDocument6 pagesUS Vs AddisonAaron Bailey Santos100% (1)