Professional Documents

Culture Documents

1ce Series Overcentre Valve: Pilot Assisted Relief With Check 1CE90

1ce Series Overcentre Valve: Pilot Assisted Relief With Check 1CE90

Uploaded by

hoiCopyright:

Available Formats

You might also like

- Plumbing Plans 2-StoreyDocument4 pagesPlumbing Plans 2-StoreySteel Caballero100% (1)

- Operation Instructions For Duplex-Body Flow Meter SkidDocument21 pagesOperation Instructions For Duplex-Body Flow Meter SkidGeorge GuoNo ratings yet

- Instruction Manual: Sewage Treatment Plant (New Type) MODEL: ISS-N SeriesDocument31 pagesInstruction Manual: Sewage Treatment Plant (New Type) MODEL: ISS-N SeriesMuhammed Riaz100% (1)

- Gear Pump PGP511Document11 pagesGear Pump PGP511Ayman AlhalfawyNo ratings yet

- 3.06 10K EK Quad BOP PDFDocument25 pages3.06 10K EK Quad BOP PDFJose Leonardo Materano Perozo100% (1)

- Tucson CBVDocument2 pagesTucson CBVSridhar PillaNo ratings yet

- Datasheet 4110 Overspeed Sensing Valve 1015 Rev1 PDFDocument6 pagesDatasheet 4110 Overspeed Sensing Valve 1015 Rev1 PDFshahrol effendy rodziNo ratings yet

- maxtonruptureOSV HydraulicDocument8 pagesmaxtonruptureOSV HydraulicjyoungNo ratings yet

- Paladon Systems Limited: Operating and Maintenance InstructionsDocument23 pagesPaladon Systems Limited: Operating and Maintenance Instructionssigit100% (1)

- RNP Actuator Metso NewDocument11 pagesRNP Actuator Metso NewOGPE-AMC1No ratings yet

- Atvus PRVDocument6 pagesAtvus PRVvipulpanchotiyaNo ratings yet

- Portable Dynamometers For Testing Aerospace Turbines: Kahn SeriesDocument4 pagesPortable Dynamometers For Testing Aerospace Turbines: Kahn SeriesEsteban Alejandro Méndez WebarNo ratings yet

- OI - OSE - 5 - 10 - 20 - 40 - 80 - 120 EN - tcm11-37378Document2 pagesOI - OSE - 5 - 10 - 20 - 40 - 80 - 120 EN - tcm11-37378Olga RepetskaNo ratings yet

- CT365 CT400S (QSG12 50Hz)Document3 pagesCT365 CT400S (QSG12 50Hz)Md ShNo ratings yet

- Valv-Powr® Series VPVL Model D Double-Acting and Spring-Return Rack-And-Pinion Compact Pneumatic ActuatorsDocument10 pagesValv-Powr® Series VPVL Model D Double-Acting and Spring-Return Rack-And-Pinion Compact Pneumatic ActuatorsibharNo ratings yet

- LUB Surematic-PDI DS-R7Document4 pagesLUB Surematic-PDI DS-R7li geneNo ratings yet

- Series 100 Flange Mounted Hydraulic Dynamometers For Load Testing Aerospace EnginesDocument2 pagesSeries 100 Flange Mounted Hydraulic Dynamometers For Load Testing Aerospace Engines唐波No ratings yet

- 3.06 Quad BOP 10K EH PDFDocument28 pages3.06 Quad BOP 10K EH PDFOvRrj Ahmed50% (2)

- 2:1 Pilot Ratio, Vented Counterbalance ValveDocument3 pages2:1 Pilot Ratio, Vented Counterbalance Valvefrancis_15inNo ratings yet

- Valves Grese NDocument92 pagesValves Grese NYair Alexis Muñoz Rojas100% (1)

- Valves Grese NDocument92 pagesValves Grese NRandall KirchbergNo ratings yet

- Model Da8: (Formerly DA8/9) Direct-Acting, Positive Bias Differential Back Pressure RegulatorDocument18 pagesModel Da8: (Formerly DA8/9) Direct-Acting, Positive Bias Differential Back Pressure RegulatorBoubekeur HamegNo ratings yet

- CV300 2Document13 pagesCV300 2Achariya ParpromNo ratings yet

- d200318x012 PDFDocument12 pagesd200318x012 PDFLimuel EspirituNo ratings yet

- CT150 CT165S (50Hz)Document3 pagesCT150 CT165S (50Hz)M. ShaatNo ratings yet

- Parker (MR, MRE, MR350, MR450, MRE500) Hydraulic Motors, Denison Calzoni, Radial Piston MotorDocument24 pagesParker (MR, MRE, MR350, MR450, MRE500) Hydraulic Motors, Denison Calzoni, Radial Piston MotorAngel Santiago Brusini OrozcoNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValvemateusT850No ratings yet

- Válvulas Modelo CTDocument5 pagesVálvulas Modelo CTOdlanier José MendozaNo ratings yet

- G77x - 77xK Valve - CatalogueDocument8 pagesG77x - 77xK Valve - CatalogueEzgi PelitNo ratings yet

- Catálogo Compresores Baja Presion-AersenDocument32 pagesCatálogo Compresores Baja Presion-AersenJuan Camilo RestrepoNo ratings yet

- Sure Cure Kit: Chrysler 41TE (A604), 42LE (A606)Document10 pagesSure Cure Kit: Chrysler 41TE (A604), 42LE (A606)carloaex23No ratings yet

- ER-56-07 Instrumentation PDFDocument8 pagesER-56-07 Instrumentation PDFFaisal NaeemNo ratings yet

- CVS 128PQ Series Oct 2013Document12 pagesCVS 128PQ Series Oct 2013SamulaNo ratings yet

- Ballast PumpDocument18 pagesBallast Pumptim kaminskyNo ratings yet

- Product Bulletin Fisher 377 Trip Valve en 125044Document10 pagesProduct Bulletin Fisher 377 Trip Valve en 125044Tomás MercadoNo ratings yet

- Technical Data For Compact Directional ValvesDocument8 pagesTechnical Data For Compact Directional ValvesAgustín TorresNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity, Loadadaptive™ Counterbalance ValveDocument1 pageModel 3:1 Pilot Ratio, Standard Capacity, Loadadaptive™ Counterbalance ValveAlexis PeñaNo ratings yet

- KAT-A 5512 EKN-HYsec Edition1 en 07-11Document4 pagesKAT-A 5512 EKN-HYsec Edition1 en 07-11Sonny LuuNo ratings yet

- Model 3:1 Pilot Ratio, Vented Counterbalance Valve: SERIES 4 / CAPACITY: 480 L/min. / CAVITY: T-24ADocument2 pagesModel 3:1 Pilot Ratio, Vented Counterbalance Valve: SERIES 4 / CAPACITY: 480 L/min. / CAVITY: T-24AАндрей9No ratings yet

- ML 7984Document12 pagesML 7984DAVOOD FAZILATNo ratings yet

- Fisher 377 Trip Valve: FeaturesDocument12 pagesFisher 377 Trip Valve: FeaturesGOPIKRISHNAHPTNo ratings yet

- Grundfos - SEG 40 31 2 50BDocument17 pagesGrundfos - SEG 40 31 2 50BMarina CoskovicNo ratings yet

- Beacon Medaes ManifoldDocument4 pagesBeacon Medaes ManifoldMelanie Riquelme CastilloNo ratings yet

- Catalog Ultra High Purity Regulator Compact Panel Tescom en 5386990Document2 pagesCatalog Ultra High Purity Regulator Compact Panel Tescom en 5386990Joshua Garcia CarrilloNo ratings yet

- CT2850-CT3150S (60 HZ)Document3 pagesCT2850-CT3150S (60 HZ)Rani OsmanNo ratings yet

- Testing Sdjusting Implement PumpDocument9 pagesTesting Sdjusting Implement Pumpardan fadilahNo ratings yet

- Regulator Iom EnglishDocument32 pagesRegulator Iom EnglishShaoranNo ratings yet

- IH RedukDocument14 pagesIH RedukPioneer PaperboyNo ratings yet

- SC 41te inDocument10 pagesSC 41te inBrad FrancNo ratings yet

- 5 - Counter Balance Valve TSCA 70-10 - CBCHDocument4 pages5 - Counter Balance Valve TSCA 70-10 - CBCHIvan MaltsevNo ratings yet

- Mooney Flexflo 887 Surge RelieversDocument6 pagesMooney Flexflo 887 Surge RelieversSajjad MehdiNo ratings yet

- Technical Leaflet Cim 776 & Cim 777Document16 pagesTechnical Leaflet Cim 776 & Cim 777blindjaxxNo ratings yet

- Venting Series 6000 PVRVDocument8 pagesVenting Series 6000 PVRVAlex SandroNo ratings yet

- Alfa Laval Unique Mixproof Tank Outlet Valve Unique To Product LeafletDocument7 pagesAlfa Laval Unique Mixproof Tank Outlet Valve Unique To Product LeafletAnonymous KdnOsd9No ratings yet

- TF100-53B 3900 Series QD CouplingsDocument6 pagesTF100-53B 3900 Series QD CouplingsrrrrNo ratings yet

- Rig Specification Rev1Document15 pagesRig Specification Rev1ImanNo ratings yet

- Model 4.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 4.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveAnurag JainNo ratings yet

- Gear PumpsDocument48 pagesGear PumpsAhmet gözükeleşNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Testing ReportDocument17 pagesTesting ReporthoiNo ratings yet

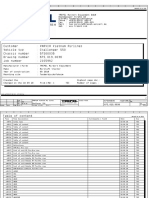

- 04 73037-38 PartslistDocument30 pages04 73037-38 PartslisthoiNo ratings yet

- Gear Code BookDocument81 pagesGear Code BookhoiNo ratings yet

- DanfossomrDocument30 pagesDanfossomrhoiNo ratings yet

- Closed Swage Sockets National Swage ButtonsDocument1 pageClosed Swage Sockets National Swage ButtonshoiNo ratings yet

- ActuatorsDocument37 pagesActuatorshoiNo ratings yet

- BasicsDocument170 pagesBasicshoiNo ratings yet

- Ols 120Document1 pageOls 120hoiNo ratings yet

- Parts ListDocument19 pagesParts ListhoiNo ratings yet

- S-423T Super TerminatorDocument1 pageS-423T Super TerminatorhoiNo ratings yet

- Sunstar SPS D-B1201Document86 pagesSunstar SPS D-B1201hoiNo ratings yet

- 01b - 6720168-169 - CHAPTER1 - BA - 191130 - en (Us)Document190 pages01b - 6720168-169 - CHAPTER1 - BA - 191130 - en (Us)hoiNo ratings yet

- A Full Range of Hydraulic Parts Such As: Pumps, Hydraulic Valves, Hoses, Steering Pumps, Lift Cylinders, Cylinder Repair Kits, Fittings, ..Document74 pagesA Full Range of Hydraulic Parts Such As: Pumps, Hydraulic Valves, Hoses, Steering Pumps, Lift Cylinders, Cylinder Repair Kits, Fittings, ..hoiNo ratings yet

- 04 6750036 EL 180910 enDocument227 pages04 6750036 EL 180910 enhoiNo ratings yet

- 00a 6720169 CONTENTS CHALLENGER280 PDFDocument1 page00a 6720169 CONTENTS CHALLENGER280 PDFhoiNo ratings yet

- ServiceInfo15-WT-05 Rev ADocument38 pagesServiceInfo15-WT-05 Rev AhoiNo ratings yet

- 08 000 630 0263 Gearbox Dana Wa 041101 D3Document106 pages08 000 630 0263 Gearbox Dana Wa 041101 D3hoi100% (1)

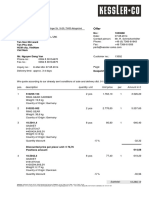

- Angebot 1033668 PDFDocument2 pagesAngebot 1033668 PDFhoiNo ratings yet

- 00a 6720168 CONTENTS CHALLENGER280 PDFDocument1 page00a 6720168 CONTENTS CHALLENGER280 PDFhoiNo ratings yet

- 9 Hydraulic2006Document91 pages9 Hydraulic2006hoiNo ratings yet

- Angebot 1042622 (81 - 8492 - 3h)Document2 pagesAngebot 1042622 (81 - 8492 - 3h)hoiNo ratings yet

- Angebot 1047857Document2 pagesAngebot 1047857hoiNo ratings yet

- 01a - 6720168-169 - BRIEFINSTRUCTIONS - 171108 - en (GB)Document8 pages01a - 6720168-169 - BRIEFINSTRUCTIONS - 171108 - en (GB)hoiNo ratings yet

- Angebot 1027718Document2 pagesAngebot 1027718hoi100% (1)

- Gasbage Baling MS - GCDocument5 pagesGasbage Baling MS - GChoiNo ratings yet

- HMF/A/V/R-02. Hydraulic Motors For Closed and Open Loop OperationDocument44 pagesHMF/A/V/R-02. Hydraulic Motors For Closed and Open Loop OperationhoiNo ratings yet

- 00b - 6720168-169 - VORSPANN - BA - 191130 - en (Us)Document2 pages00b - 6720168-169 - VORSPANN - BA - 191130 - en (Us)hoiNo ratings yet

- PGP020™ Series: Pumps and MotorsDocument16 pagesPGP020™ Series: Pumps and MotorshoiNo ratings yet

- 09 6720168-9 EK 200214 enDocument449 pages09 6720168-9 EK 200214 enhoiNo ratings yet

- Xi Lanh Nang HaDocument1 pageXi Lanh Nang HahoiNo ratings yet

- HVAC Controls Operation and MaintenanceDocument355 pagesHVAC Controls Operation and Maintenancebabis198092% (12)

- LNGC Singapore Energy - IMO 9238040 - Machinery Operating ManualDocument420 pagesLNGC Singapore Energy - IMO 9238040 - Machinery Operating Manualseawolf50No ratings yet

- Piping Design Info (Version 2)Document279 pagesPiping Design Info (Version 2)MANIKANDANo ratings yet

- Price Fitting Besi 2Document8 pagesPrice Fitting Besi 2opik97No ratings yet

- DIN 2353 Adaptors: Nut Cutting RingsDocument70 pagesDIN 2353 Adaptors: Nut Cutting RingsSiddhant JoglekarNo ratings yet

- ESP Design - Step 4 Total Dynamic HeadDocument6 pagesESP Design - Step 4 Total Dynamic HeadazareiforoushNo ratings yet

- An Overview of Pipe Stress Engineering (Sample)Document34 pagesAn Overview of Pipe Stress Engineering (Sample)Vu Truong Giang100% (2)

- American Electrical HeycoAgro Cross ReferenceDocument2 pagesAmerican Electrical HeycoAgro Cross ReferenceSreegith ChelattNo ratings yet

- Design of Water Storage Tanks, and Down Take Pipes: Building Services - Semester 3Document33 pagesDesign of Water Storage Tanks, and Down Take Pipes: Building Services - Semester 3sakshi meherNo ratings yet

- Code Coupling For Simulation of Flow-Induced Vibrations: Elisabeth LONGATTE Fabien HUVELIN Mhamed SOULIDocument28 pagesCode Coupling For Simulation of Flow-Induced Vibrations: Elisabeth LONGATTE Fabien HUVELIN Mhamed SOULIAshraf S. HusseinNo ratings yet

- Comparasion of CSTR With Covered LagoonsDocument3 pagesComparasion of CSTR With Covered LagoonsIbrahim SyaharuddinNo ratings yet

- Design of Dual Media Water Filtration System in Debesmscat Mabigo Water ReserveDocument26 pagesDesign of Dual Media Water Filtration System in Debesmscat Mabigo Water ReserveInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Rawson Gulf Coast Product Line SheetDocument6 pagesRawson Gulf Coast Product Line SheetJose EvansNo ratings yet

- Water Shut Off Review - Slumberger - Technology With Cover Page v2Document23 pagesWater Shut Off Review - Slumberger - Technology With Cover Page v2Aminollah PayvandNo ratings yet

- CH 5Document56 pagesCH 5Mintesinot KasaNo ratings yet

- 518 Model DDX Deluge Valve, 2 To 8 InchesDocument12 pages518 Model DDX Deluge Valve, 2 To 8 InchesmuhamedzNo ratings yet

- Notes Answers PDFDocument39 pagesNotes Answers PDFkbkwebs0% (1)

- Buoyancy-Induced Flow in Open Rotating CavitiesDocument8 pagesBuoyancy-Induced Flow in Open Rotating CavitiesAjith KrishnanNo ratings yet

- D Flow Control Valves Flow Control and Check ValvesDocument12 pagesD Flow Control Valves Flow Control and Check ValvesSaurabhNo ratings yet

- TDS - Total - WT Supra - J6T - 201610 - enDocument2 pagesTDS - Total - WT Supra - J6T - 201610 - enwindiNo ratings yet

- Kinetics: The Rate of Chemical ReactionDocument4 pagesKinetics: The Rate of Chemical Reactioncrybaby0% (1)

- CO2 Bottle System and MaintenanceDocument13 pagesCO2 Bottle System and Maintenancesamar jeetNo ratings yet

- Secondary Reformer Refractory - Dry - Out - OpDocument10 pagesSecondary Reformer Refractory - Dry - Out - OpAlfonso BlancoNo ratings yet

- Lecture 4-Combustion and Boilers PDFDocument39 pagesLecture 4-Combustion and Boilers PDFjuan maganNo ratings yet

- Experiment 7 Cooling TowerDocument9 pagesExperiment 7 Cooling TowerRicky Jay0% (1)

- DEC Short-Term Training - 2014Document173 pagesDEC Short-Term Training - 2014Getachew TikueNo ratings yet

- g4gmv564 Aspen Plus CycloneDocument6 pagesg4gmv564 Aspen Plus CyclonedonyaNo ratings yet

- Pipeline HydrotestingDocument32 pagesPipeline Hydrotestingwindsurferke007No ratings yet

1ce Series Overcentre Valve: Pilot Assisted Relief With Check 1CE90

1ce Series Overcentre Valve: Pilot Assisted Relief With Check 1CE90

Uploaded by

hoiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1ce Series Overcentre Valve: Pilot Assisted Relief With Check 1CE90

1ce Series Overcentre Valve: Pilot Assisted Relief With Check 1CE90

Uploaded by

hoiCopyright:

Available Formats

1CE SERIES OVERCENTRE VALVE

PILOT ASSISTED RELIEF WITH CHECK

1CE90

VALVE (2) PILOT (3)

1

CYL (1)

3

APPLICATION PILOT RATIOS

Overcentre valves give static and dynamic control of 4:1 Best suited for applications where the load

loads by regulating the flow into and out of hydraulic varies and machine structure can induce

actuators. When installed close to or within an instability.

actuator, the overcentre valve will stop runaway in the

event of hose burst and if open centre directional 8:1 Best suited for applications where the load

6 control valves are used, will allow thermal expansion

relief of the hydraulic fluid.

remains relatively constant.

Other ratios available upon request.

The overcentre cartridge is ideal for mounting directly

into a cavity machined in the body of the cylinder, motor

or rotary actuator. The cartridge can also be mounted SPECIFICATIONS

directly to the ports via a specifically machined body as Figures based on: Oil Temp = 40°C Viscosity = 40 cSt

part of a Hydraulic Integrated Circuit or single unit, or

contained within one of our standard line bodies.

Rated Flow 90 litres/min (23 US GPM)

Single overcentre valves are normally used when the

load is unidirectional, for example an aerial platform or Max Load Induced

crane and dual overcentre valves are used for Max Setting Pressure: 270 bar (4000 psi)

Relief Setting: 350 bar (5000 psi)

controlling loads in both directions for motor

applications or for cylinders going over centre.

Cartridge Material Working parts hardened and ground

steel. External surfaces zinc plated

OPERATION

Standard aluminium (up to 210 bar*)

The check section allows free flow into the actuator Body Material

Add suffix ‘377’ for steel option

then holds and locks the load against movement. The

pilot assisted relief valve section will give controlled Mounting Position Unrestricted

movement when pliot pressure is applied. The relief Cavity Number A12336 (See Section 17)

section is normally set to open at a pressure at least

1.3 times the maximum load induced pressure but the Torque Cartridge

60 Nm (44 lbs ft)

pressure required to open the valve and allow into Cavity

movement depends on the pilot ratio of the valve. For

optimisation of load control and energy usage, a 1CE90 0.29 kg (0.63 lbs)

choice of pilot ratios is available. Weight 1CE95 1.35 kg (2.97 lbs)

1CEE95 2.10 kg (4.62 lbs)

The pressure required to open the valve and start

actuator movement can be calculated as follows: Seal Kit Number SK633 (Nitrile) SK633V (Viton)

Pilot Pressure = (Relief Setting) - (Load Pressure) Recommended BS5540/4 Class 18/13

Pilot Ratio Filtration Level (25 micron nominal)

Operating Temp -20°C to +90°C

FEATURES Leakage 0.3 millilitres/min nominal (5 dpm)

Cartridge is economical and fits simple cavity. Allows

Nominal Viscosity

quick, easy field service - reduces down time. Range

5 to 500 cSt

*For applications above 210 bar please consult our technical department or use the steel body option.

Integrated Hydraulics Ltd Integrated Hydraulics Inc

Collins Road, Heathcote Ind. Est., Warwick, CV34 6TF, UK. 7047 Spinach Drive, Mentor, Ohio 44060, USA

Tel: +44 (0) 1926 881171 Fax: +44 (0) 1926 315729 Tel: (440) 974 3171 Fax: (440) 974 3170

Website: www.integratedhydraulics.com Website: www.integratedhydraulics.com

6-151.D

PRESSURE DROP CARTRIDGE ONLY

4:1 VERSION 8:1 VERSION BASIC CODE: 1CE90

HEX SOCKET ADJUST

5.0 A/F

FLOW-US GPM FLOW-US GPM

0 6.5 13 19.5 26 0 6.5 13 19.5 26

17.0 A/F

40 600

16 240

62.0 MAX

14 210 35 500

30 32.0 A/F

12

PRESSURE-BAR

180

PRESSURE-PSI

FREE FLOW 400

PRESSURE-BAR

FREE FLOW

PRESSURE-PSI

10 150 25

8 120 20 300 M27 X 1.5-6g

6 90 15

200 PILOT (3)

54.0

4 60 10

100 VALVE (2)

2 30 5

PILOTED OPEN PILOTED OPEN

0 0 Tightening torque of “F” adjuster

0 25 50 75 100 0 25 50 75 100

FLOW LITRES/MIN FLOW LITRES/MIN CYL (1) locknut - 20 to 25 Nm

SINGLE VALVE 1/2” PORTS DUAL VALVE 1/2” PORTS

BASIC CODE:

Body ONLY part numbers

1CE95 BASIC CODE:

Body ONLY part numbers

1CEE95 (INTERNALLY CROSS PILOTED)

6

BSP, aluminium SAE, aluminium BSP, steel SAE, steel BSP, aluminium SAE, aluminium BSP, steel SAE, steel

1/2” B13625 1/2” B10806 1/2” B13626 1/2” B10922 1/2” C13627 1/2” C10807 1/2” C13628 1/2” C11561

C1 C2

86.5

40.5

V1 V2

38.1

18.0

132.0 MAX

139.0 MAX

3

36.0

36.0

2

V1 V2

58.0

58.0

70.0

76.2

1 C1 C2

19.0 10.0 56.0

38.1 76.2 19.0 10.0 107.0

2 HOLES Ø11.0 THRO' 38.1 127.0

2 HOLES ø11.0 THRO'

Where measurements are critical request certified drawings

ORDERING CODE EXAMPLE

1CE**** F 4W 35 S 4

Basic Code Pilot Ratio

1CE90 = Cartridge Only 4 = 4:1

1CE95 = Cartridge and Body 8 = 8:1

1CEE95 = Cartridges and Dual Body Other ratios available upon request

Adjustment Means Seals

F = Screw Adjustment S = Nitrile (For use with most

N = Fixed - State pressure setting required industrial hydraulic oils)

For fixed versions add setting in 10 bar increments to end of SV = Viton (For high temperature

part number. Subject to a +-10% tolerance. and most special fluid

applications

Port Sizes - Bodied Valves Only Pressure Range @ 4.8 l/min

4W = 1/2” BSP Valve & Cyl Port. 1/4” BSP Pilot Port 20 = 70-225 bar. Std setting 100 bar

8T = 1/2” SAE Valve & Cyl Port. 1/4” SAE Pilot Port 35 = 200-350 bar. Std setting 210 bar

Std setting made at 4.8 litres/min

We reserve the right to change specifications without notice

6-152.E

You might also like

- Plumbing Plans 2-StoreyDocument4 pagesPlumbing Plans 2-StoreySteel Caballero100% (1)

- Operation Instructions For Duplex-Body Flow Meter SkidDocument21 pagesOperation Instructions For Duplex-Body Flow Meter SkidGeorge GuoNo ratings yet

- Instruction Manual: Sewage Treatment Plant (New Type) MODEL: ISS-N SeriesDocument31 pagesInstruction Manual: Sewage Treatment Plant (New Type) MODEL: ISS-N SeriesMuhammed Riaz100% (1)

- Gear Pump PGP511Document11 pagesGear Pump PGP511Ayman AlhalfawyNo ratings yet

- 3.06 10K EK Quad BOP PDFDocument25 pages3.06 10K EK Quad BOP PDFJose Leonardo Materano Perozo100% (1)

- Tucson CBVDocument2 pagesTucson CBVSridhar PillaNo ratings yet

- Datasheet 4110 Overspeed Sensing Valve 1015 Rev1 PDFDocument6 pagesDatasheet 4110 Overspeed Sensing Valve 1015 Rev1 PDFshahrol effendy rodziNo ratings yet

- maxtonruptureOSV HydraulicDocument8 pagesmaxtonruptureOSV HydraulicjyoungNo ratings yet

- Paladon Systems Limited: Operating and Maintenance InstructionsDocument23 pagesPaladon Systems Limited: Operating and Maintenance Instructionssigit100% (1)

- RNP Actuator Metso NewDocument11 pagesRNP Actuator Metso NewOGPE-AMC1No ratings yet

- Atvus PRVDocument6 pagesAtvus PRVvipulpanchotiyaNo ratings yet

- Portable Dynamometers For Testing Aerospace Turbines: Kahn SeriesDocument4 pagesPortable Dynamometers For Testing Aerospace Turbines: Kahn SeriesEsteban Alejandro Méndez WebarNo ratings yet

- OI - OSE - 5 - 10 - 20 - 40 - 80 - 120 EN - tcm11-37378Document2 pagesOI - OSE - 5 - 10 - 20 - 40 - 80 - 120 EN - tcm11-37378Olga RepetskaNo ratings yet

- CT365 CT400S (QSG12 50Hz)Document3 pagesCT365 CT400S (QSG12 50Hz)Md ShNo ratings yet

- Valv-Powr® Series VPVL Model D Double-Acting and Spring-Return Rack-And-Pinion Compact Pneumatic ActuatorsDocument10 pagesValv-Powr® Series VPVL Model D Double-Acting and Spring-Return Rack-And-Pinion Compact Pneumatic ActuatorsibharNo ratings yet

- LUB Surematic-PDI DS-R7Document4 pagesLUB Surematic-PDI DS-R7li geneNo ratings yet

- Series 100 Flange Mounted Hydraulic Dynamometers For Load Testing Aerospace EnginesDocument2 pagesSeries 100 Flange Mounted Hydraulic Dynamometers For Load Testing Aerospace Engines唐波No ratings yet

- 3.06 Quad BOP 10K EH PDFDocument28 pages3.06 Quad BOP 10K EH PDFOvRrj Ahmed50% (2)

- 2:1 Pilot Ratio, Vented Counterbalance ValveDocument3 pages2:1 Pilot Ratio, Vented Counterbalance Valvefrancis_15inNo ratings yet

- Valves Grese NDocument92 pagesValves Grese NYair Alexis Muñoz Rojas100% (1)

- Valves Grese NDocument92 pagesValves Grese NRandall KirchbergNo ratings yet

- Model Da8: (Formerly DA8/9) Direct-Acting, Positive Bias Differential Back Pressure RegulatorDocument18 pagesModel Da8: (Formerly DA8/9) Direct-Acting, Positive Bias Differential Back Pressure RegulatorBoubekeur HamegNo ratings yet

- CV300 2Document13 pagesCV300 2Achariya ParpromNo ratings yet

- d200318x012 PDFDocument12 pagesd200318x012 PDFLimuel EspirituNo ratings yet

- CT150 CT165S (50Hz)Document3 pagesCT150 CT165S (50Hz)M. ShaatNo ratings yet

- Parker (MR, MRE, MR350, MR450, MRE500) Hydraulic Motors, Denison Calzoni, Radial Piston MotorDocument24 pagesParker (MR, MRE, MR350, MR450, MRE500) Hydraulic Motors, Denison Calzoni, Radial Piston MotorAngel Santiago Brusini OrozcoNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValvemateusT850No ratings yet

- Válvulas Modelo CTDocument5 pagesVálvulas Modelo CTOdlanier José MendozaNo ratings yet

- G77x - 77xK Valve - CatalogueDocument8 pagesG77x - 77xK Valve - CatalogueEzgi PelitNo ratings yet

- Catálogo Compresores Baja Presion-AersenDocument32 pagesCatálogo Compresores Baja Presion-AersenJuan Camilo RestrepoNo ratings yet

- Sure Cure Kit: Chrysler 41TE (A604), 42LE (A606)Document10 pagesSure Cure Kit: Chrysler 41TE (A604), 42LE (A606)carloaex23No ratings yet

- ER-56-07 Instrumentation PDFDocument8 pagesER-56-07 Instrumentation PDFFaisal NaeemNo ratings yet

- CVS 128PQ Series Oct 2013Document12 pagesCVS 128PQ Series Oct 2013SamulaNo ratings yet

- Ballast PumpDocument18 pagesBallast Pumptim kaminskyNo ratings yet

- Product Bulletin Fisher 377 Trip Valve en 125044Document10 pagesProduct Bulletin Fisher 377 Trip Valve en 125044Tomás MercadoNo ratings yet

- Technical Data For Compact Directional ValvesDocument8 pagesTechnical Data For Compact Directional ValvesAgustín TorresNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity, Loadadaptive™ Counterbalance ValveDocument1 pageModel 3:1 Pilot Ratio, Standard Capacity, Loadadaptive™ Counterbalance ValveAlexis PeñaNo ratings yet

- KAT-A 5512 EKN-HYsec Edition1 en 07-11Document4 pagesKAT-A 5512 EKN-HYsec Edition1 en 07-11Sonny LuuNo ratings yet

- Model 3:1 Pilot Ratio, Vented Counterbalance Valve: SERIES 4 / CAPACITY: 480 L/min. / CAVITY: T-24ADocument2 pagesModel 3:1 Pilot Ratio, Vented Counterbalance Valve: SERIES 4 / CAPACITY: 480 L/min. / CAVITY: T-24AАндрей9No ratings yet

- ML 7984Document12 pagesML 7984DAVOOD FAZILATNo ratings yet

- Fisher 377 Trip Valve: FeaturesDocument12 pagesFisher 377 Trip Valve: FeaturesGOPIKRISHNAHPTNo ratings yet

- Grundfos - SEG 40 31 2 50BDocument17 pagesGrundfos - SEG 40 31 2 50BMarina CoskovicNo ratings yet

- Beacon Medaes ManifoldDocument4 pagesBeacon Medaes ManifoldMelanie Riquelme CastilloNo ratings yet

- Catalog Ultra High Purity Regulator Compact Panel Tescom en 5386990Document2 pagesCatalog Ultra High Purity Regulator Compact Panel Tescom en 5386990Joshua Garcia CarrilloNo ratings yet

- CT2850-CT3150S (60 HZ)Document3 pagesCT2850-CT3150S (60 HZ)Rani OsmanNo ratings yet

- Testing Sdjusting Implement PumpDocument9 pagesTesting Sdjusting Implement Pumpardan fadilahNo ratings yet

- Regulator Iom EnglishDocument32 pagesRegulator Iom EnglishShaoranNo ratings yet

- IH RedukDocument14 pagesIH RedukPioneer PaperboyNo ratings yet

- SC 41te inDocument10 pagesSC 41te inBrad FrancNo ratings yet

- 5 - Counter Balance Valve TSCA 70-10 - CBCHDocument4 pages5 - Counter Balance Valve TSCA 70-10 - CBCHIvan MaltsevNo ratings yet

- Mooney Flexflo 887 Surge RelieversDocument6 pagesMooney Flexflo 887 Surge RelieversSajjad MehdiNo ratings yet

- Technical Leaflet Cim 776 & Cim 777Document16 pagesTechnical Leaflet Cim 776 & Cim 777blindjaxxNo ratings yet

- Venting Series 6000 PVRVDocument8 pagesVenting Series 6000 PVRVAlex SandroNo ratings yet

- Alfa Laval Unique Mixproof Tank Outlet Valve Unique To Product LeafletDocument7 pagesAlfa Laval Unique Mixproof Tank Outlet Valve Unique To Product LeafletAnonymous KdnOsd9No ratings yet

- TF100-53B 3900 Series QD CouplingsDocument6 pagesTF100-53B 3900 Series QD CouplingsrrrrNo ratings yet

- Rig Specification Rev1Document15 pagesRig Specification Rev1ImanNo ratings yet

- Model 4.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 4.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveAnurag JainNo ratings yet

- Gear PumpsDocument48 pagesGear PumpsAhmet gözükeleşNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Testing ReportDocument17 pagesTesting ReporthoiNo ratings yet

- 04 73037-38 PartslistDocument30 pages04 73037-38 PartslisthoiNo ratings yet

- Gear Code BookDocument81 pagesGear Code BookhoiNo ratings yet

- DanfossomrDocument30 pagesDanfossomrhoiNo ratings yet

- Closed Swage Sockets National Swage ButtonsDocument1 pageClosed Swage Sockets National Swage ButtonshoiNo ratings yet

- ActuatorsDocument37 pagesActuatorshoiNo ratings yet

- BasicsDocument170 pagesBasicshoiNo ratings yet

- Ols 120Document1 pageOls 120hoiNo ratings yet

- Parts ListDocument19 pagesParts ListhoiNo ratings yet

- S-423T Super TerminatorDocument1 pageS-423T Super TerminatorhoiNo ratings yet

- Sunstar SPS D-B1201Document86 pagesSunstar SPS D-B1201hoiNo ratings yet

- 01b - 6720168-169 - CHAPTER1 - BA - 191130 - en (Us)Document190 pages01b - 6720168-169 - CHAPTER1 - BA - 191130 - en (Us)hoiNo ratings yet

- A Full Range of Hydraulic Parts Such As: Pumps, Hydraulic Valves, Hoses, Steering Pumps, Lift Cylinders, Cylinder Repair Kits, Fittings, ..Document74 pagesA Full Range of Hydraulic Parts Such As: Pumps, Hydraulic Valves, Hoses, Steering Pumps, Lift Cylinders, Cylinder Repair Kits, Fittings, ..hoiNo ratings yet

- 04 6750036 EL 180910 enDocument227 pages04 6750036 EL 180910 enhoiNo ratings yet

- 00a 6720169 CONTENTS CHALLENGER280 PDFDocument1 page00a 6720169 CONTENTS CHALLENGER280 PDFhoiNo ratings yet

- ServiceInfo15-WT-05 Rev ADocument38 pagesServiceInfo15-WT-05 Rev AhoiNo ratings yet

- 08 000 630 0263 Gearbox Dana Wa 041101 D3Document106 pages08 000 630 0263 Gearbox Dana Wa 041101 D3hoi100% (1)

- Angebot 1033668 PDFDocument2 pagesAngebot 1033668 PDFhoiNo ratings yet

- 00a 6720168 CONTENTS CHALLENGER280 PDFDocument1 page00a 6720168 CONTENTS CHALLENGER280 PDFhoiNo ratings yet

- 9 Hydraulic2006Document91 pages9 Hydraulic2006hoiNo ratings yet

- Angebot 1042622 (81 - 8492 - 3h)Document2 pagesAngebot 1042622 (81 - 8492 - 3h)hoiNo ratings yet

- Angebot 1047857Document2 pagesAngebot 1047857hoiNo ratings yet

- 01a - 6720168-169 - BRIEFINSTRUCTIONS - 171108 - en (GB)Document8 pages01a - 6720168-169 - BRIEFINSTRUCTIONS - 171108 - en (GB)hoiNo ratings yet

- Angebot 1027718Document2 pagesAngebot 1027718hoi100% (1)

- Gasbage Baling MS - GCDocument5 pagesGasbage Baling MS - GChoiNo ratings yet

- HMF/A/V/R-02. Hydraulic Motors For Closed and Open Loop OperationDocument44 pagesHMF/A/V/R-02. Hydraulic Motors For Closed and Open Loop OperationhoiNo ratings yet

- 00b - 6720168-169 - VORSPANN - BA - 191130 - en (Us)Document2 pages00b - 6720168-169 - VORSPANN - BA - 191130 - en (Us)hoiNo ratings yet

- PGP020™ Series: Pumps and MotorsDocument16 pagesPGP020™ Series: Pumps and MotorshoiNo ratings yet

- 09 6720168-9 EK 200214 enDocument449 pages09 6720168-9 EK 200214 enhoiNo ratings yet

- Xi Lanh Nang HaDocument1 pageXi Lanh Nang HahoiNo ratings yet

- HVAC Controls Operation and MaintenanceDocument355 pagesHVAC Controls Operation and Maintenancebabis198092% (12)

- LNGC Singapore Energy - IMO 9238040 - Machinery Operating ManualDocument420 pagesLNGC Singapore Energy - IMO 9238040 - Machinery Operating Manualseawolf50No ratings yet

- Piping Design Info (Version 2)Document279 pagesPiping Design Info (Version 2)MANIKANDANo ratings yet

- Price Fitting Besi 2Document8 pagesPrice Fitting Besi 2opik97No ratings yet

- DIN 2353 Adaptors: Nut Cutting RingsDocument70 pagesDIN 2353 Adaptors: Nut Cutting RingsSiddhant JoglekarNo ratings yet

- ESP Design - Step 4 Total Dynamic HeadDocument6 pagesESP Design - Step 4 Total Dynamic HeadazareiforoushNo ratings yet

- An Overview of Pipe Stress Engineering (Sample)Document34 pagesAn Overview of Pipe Stress Engineering (Sample)Vu Truong Giang100% (2)

- American Electrical HeycoAgro Cross ReferenceDocument2 pagesAmerican Electrical HeycoAgro Cross ReferenceSreegith ChelattNo ratings yet

- Design of Water Storage Tanks, and Down Take Pipes: Building Services - Semester 3Document33 pagesDesign of Water Storage Tanks, and Down Take Pipes: Building Services - Semester 3sakshi meherNo ratings yet

- Code Coupling For Simulation of Flow-Induced Vibrations: Elisabeth LONGATTE Fabien HUVELIN Mhamed SOULIDocument28 pagesCode Coupling For Simulation of Flow-Induced Vibrations: Elisabeth LONGATTE Fabien HUVELIN Mhamed SOULIAshraf S. HusseinNo ratings yet

- Comparasion of CSTR With Covered LagoonsDocument3 pagesComparasion of CSTR With Covered LagoonsIbrahim SyaharuddinNo ratings yet

- Design of Dual Media Water Filtration System in Debesmscat Mabigo Water ReserveDocument26 pagesDesign of Dual Media Water Filtration System in Debesmscat Mabigo Water ReserveInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Rawson Gulf Coast Product Line SheetDocument6 pagesRawson Gulf Coast Product Line SheetJose EvansNo ratings yet

- Water Shut Off Review - Slumberger - Technology With Cover Page v2Document23 pagesWater Shut Off Review - Slumberger - Technology With Cover Page v2Aminollah PayvandNo ratings yet

- CH 5Document56 pagesCH 5Mintesinot KasaNo ratings yet

- 518 Model DDX Deluge Valve, 2 To 8 InchesDocument12 pages518 Model DDX Deluge Valve, 2 To 8 InchesmuhamedzNo ratings yet

- Notes Answers PDFDocument39 pagesNotes Answers PDFkbkwebs0% (1)

- Buoyancy-Induced Flow in Open Rotating CavitiesDocument8 pagesBuoyancy-Induced Flow in Open Rotating CavitiesAjith KrishnanNo ratings yet

- D Flow Control Valves Flow Control and Check ValvesDocument12 pagesD Flow Control Valves Flow Control and Check ValvesSaurabhNo ratings yet

- TDS - Total - WT Supra - J6T - 201610 - enDocument2 pagesTDS - Total - WT Supra - J6T - 201610 - enwindiNo ratings yet

- Kinetics: The Rate of Chemical ReactionDocument4 pagesKinetics: The Rate of Chemical Reactioncrybaby0% (1)

- CO2 Bottle System and MaintenanceDocument13 pagesCO2 Bottle System and Maintenancesamar jeetNo ratings yet

- Secondary Reformer Refractory - Dry - Out - OpDocument10 pagesSecondary Reformer Refractory - Dry - Out - OpAlfonso BlancoNo ratings yet

- Lecture 4-Combustion and Boilers PDFDocument39 pagesLecture 4-Combustion and Boilers PDFjuan maganNo ratings yet

- Experiment 7 Cooling TowerDocument9 pagesExperiment 7 Cooling TowerRicky Jay0% (1)

- DEC Short-Term Training - 2014Document173 pagesDEC Short-Term Training - 2014Getachew TikueNo ratings yet

- g4gmv564 Aspen Plus CycloneDocument6 pagesg4gmv564 Aspen Plus CyclonedonyaNo ratings yet

- Pipeline HydrotestingDocument32 pagesPipeline Hydrotestingwindsurferke007No ratings yet