Professional Documents

Culture Documents

Fiberbond Fiberglass Piping Systems Series 20FR16-C: Description

Fiberbond Fiberglass Piping Systems Series 20FR16-C: Description

Uploaded by

ANDERSON NERESCopyright:

Available Formats

You might also like

- Chapter - 4-Simple Vapour Compression Refrigeration SystemDocument141 pagesChapter - 4-Simple Vapour Compression Refrigeration SystemMohamed Al-Odat0% (1)

- Bondstrand PDFDocument8 pagesBondstrand PDFkrisNo ratings yet

- MK 608 BPMDocument9 pagesMK 608 BPMrogelgerardo643No ratings yet

- PDC High Performance Butterfly Valve Available in Sizes 2" Thru 24"Document11 pagesPDC High Performance Butterfly Valve Available in Sizes 2" Thru 24"pablopasqualini18No ratings yet

- Firetuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionDocument2 pagesFiretuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionAngga SenjayaNo ratings yet

- 7.-F.tecnica Abrazadera B2000Document1 page7.-F.tecnica Abrazadera B2000Alejandro Ayrton Zambrano CinceNo ratings yet

- Medidores AMERICAN METERSDocument17 pagesMedidores AMERICAN METERSRaúl PalomoNo ratings yet

- Downhole Tubing/casingDocument6 pagesDownhole Tubing/casingDwiki RamadhaniNo ratings yet

- PROGEF Standard PolypropyleneDocument75 pagesPROGEF Standard Polypropyleneadriano.engmec.oliveiraNo ratings yet

- Fluoropolymer Tubing (MS 02 196)Document2 pagesFluoropolymer Tubing (MS 02 196)herysyam1980No ratings yet

- A 716 - 99 Qtcxni1sruqDocument7 pagesA 716 - 99 Qtcxni1sruqwahyudiNo ratings yet

- Product Note 3.107 N-12 SpecificationDocument2 pagesProduct Note 3.107 N-12 SpecificationFernando Guzman ContrerasNo ratings yet

- Type 550X: Miniature I/P, E/P TransducerDocument4 pagesType 550X: Miniature I/P, E/P TransducerDanang BagasNo ratings yet

- SFTPreal10 Cat7 6x4p Loom 900MHz AWG23Document2 pagesSFTPreal10 Cat7 6x4p Loom 900MHz AWG23Slobodan ĐenićNo ratings yet

- Firetuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionDocument25 pagesFiretuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionBhagoo HatheyNo ratings yet

- SFTPreal10 Cat6A 6x4p Loom 650MHz AWG26Document2 pagesSFTPreal10 Cat6A 6x4p Loom 650MHz AWG26Slobodan ĐenićNo ratings yet

- CTC Technical Manual.86918081Document45 pagesCTC Technical Manual.86918081Mohd AjmainNo ratings yet

- Manometro Badotherm BP-004-005Document2 pagesManometro Badotherm BP-004-005Luis Alberto Portugal MariacalNo ratings yet

- Aquarius+ UPVC Industrial Pipe & FittingsDocument16 pagesAquarius+ UPVC Industrial Pipe & Fittingspanchal harnishNo ratings yet

- RS 250 M Welding MachineDocument1 pageRS 250 M Welding MachineLucioNo ratings yet

- KIASMA Dredging Self Sinking 09 2018 ENGDocument26 pagesKIASMA Dredging Self Sinking 09 2018 ENGahceneaecNo ratings yet

- ABB Instrumentation: Specification SheetDocument6 pagesABB Instrumentation: Specification SheetRaja RamNo ratings yet

- Pir For Ice 3500Document5 pagesPir For Ice 3500Akshat ShawNo ratings yet

- STAR Aromatic Amine Line Pipe High Pressure API 15HR Design Data SheetDocument4 pagesSTAR Aromatic Amine Line Pipe High Pressure API 15HR Design Data SheetFirasNo ratings yet

- Serie 740Document4 pagesSerie 740Mabeli MartinezNo ratings yet

- UPVC Pipe DIN 8062 TdsDocument3 pagesUPVC Pipe DIN 8062 TdsAdany AdenNo ratings yet

- Stewarts GaugeDocument2 pagesStewarts GaugepetropartsqaNo ratings yet

- STAR Pipe LP API 15HR AliphaticDocument4 pagesSTAR Pipe LP API 15HR AliphaticTaras ByloNo ratings yet

- Esab, Dual Shield II 110 (265-En - US-FactSheet - Main-01) (26.10.16)Document2 pagesEsab, Dual Shield II 110 (265-En - US-FactSheet - Main-01) (26.10.16)RodrigoNo ratings yet

- Steel Braided Hose: Limusnunggal Rubber IndustryDocument5 pagesSteel Braided Hose: Limusnunggal Rubber IndustryIndra MaulanaNo ratings yet

- Ceramic Fiber Blanket CatalogDocument7 pagesCeramic Fiber Blanket Catalogevelyn reksaNo ratings yet

- MX - SS Pressure GaugesDocument2 pagesMX - SS Pressure Gaugessaurabhjerps231221No ratings yet

- Adarsh Product Catalog With ResolutionDocument2 pagesAdarsh Product Catalog With Resolutionjacob johnNo ratings yet

- NSB Ups BatteryDocument4 pagesNSB Ups BatteryLast Juan StandingNo ratings yet

- Vortex FMDocument10 pagesVortex FMram kNo ratings yet

- Pipe CatalogueDocument6 pagesPipe CatalogueirfanNo ratings yet

- 278 en US FactSheet Main 01Document1 page278 en US FactSheet Main 01Jorge Manuel GuillermoNo ratings yet

- 1200 Series DatasheetDocument12 pages1200 Series DatasheetbandaemetNo ratings yet

- Tech Data Sheet: Dual Shield T-115Document3 pagesTech Data Sheet: Dual Shield T-115carlosNo ratings yet

- AWA Unipolares Clase 2Document1 pageAWA Unipolares Clase 2Juan AdrianzenNo ratings yet

- SCP Part#: Cat5E-Aer: DescriptionDocument2 pagesSCP Part#: Cat5E-Aer: DescriptionAnonymous AOsAXgNo ratings yet

- Slip Ring Prod GuideDocument16 pagesSlip Ring Prod GuideJong Java100% (1)

- Glass PipeDocument7 pagesGlass Pipejesus_manrique2753No ratings yet

- Smith Fibercast Green Thread Performance Plus Fiberglass Pipe Piping BrochureDocument8 pagesSmith Fibercast Green Thread Performance Plus Fiberglass Pipe Piping BrochureWong Chung MengNo ratings yet

- Coriolis Mass Flowmeter For Medium Flow Also Suited For High Pressure ApplicationsDocument8 pagesCoriolis Mass Flowmeter For Medium Flow Also Suited For High Pressure ApplicationsamiraNo ratings yet

- Dual Shield T-75: Typical Tensile PropertiesDocument2 pagesDual Shield T-75: Typical Tensile PropertiescfloresNo ratings yet

- Mos3200 Bs 2000m FP Product DataDocument4 pagesMos3200 Bs 2000m FP Product DataJeromeNo ratings yet

- 30SCC160 2pdeDocument30 pages30SCC160 2pdeمحمد مرسيNo ratings yet

- MiscellaneousDocument49 pagesMiscellaneousjrsvalenzuelaNo ratings yet

- Air Compressor PDFDocument1 pageAir Compressor PDFaredeca042882No ratings yet

- Part VIDocument22 pagesPart VIRonak RanaNo ratings yet

- Quality Pressure G Auge: All Stainless Steel Construction Robust, Designed For Severe Operating ConditionsDocument2 pagesQuality Pressure G Auge: All Stainless Steel Construction Robust, Designed For Severe Operating ConditionsChhomNo ratings yet

- A New Era In: Filtration Performance and InnovationDocument6 pagesA New Era In: Filtration Performance and InnovationCARLOS SARMIENTONo ratings yet

- ID 250 T DC PulseDocument1 pageID 250 T DC PulseLucioNo ratings yet

- Fire Piping Astm A135Document2 pagesFire Piping Astm A135sinahimsNo ratings yet

- AMF601NTV1 1 9 A4 en PDFDocument4 pagesAMF601NTV1 1 9 A4 en PDFtruongNo ratings yet

- Dual Shield 7100 Ultra: Typical Tensile PropertiesDocument3 pagesDual Shield 7100 Ultra: Typical Tensile PropertiesDino Paul Castro HidalgoNo ratings yet

- ESAB Dual Shield 7100 UltraDocument3 pagesESAB Dual Shield 7100 UltrahaldunNo ratings yet

- Furring Channels and Custom Top Hat Sections Technical Data Sheet UnlockedDocument2 pagesFurring Channels and Custom Top Hat Sections Technical Data Sheet UnlockedCONSULTANTS KELNo ratings yet

- TeSys Deca - K and SK Control Relays - CA3KN22BDDocument4 pagesTeSys Deca - K and SK Control Relays - CA3KN22BDIvan OliveiraNo ratings yet

- Slip On Anel 400# AnsiDocument2 pagesSlip On Anel 400# AnsiANDERSON NERESNo ratings yet

- Hydratight LP-Series FlyerDocument4 pagesHydratight LP-Series FlyerANDERSON NERESNo ratings yet

- Slip On Anel 600# AnsiDocument2 pagesSlip On Anel 600# AnsiANDERSON NERESNo ratings yet

- Socket 300# AnsiDocument2 pagesSocket 300# AnsiANDERSON NERESNo ratings yet

- Couplings: Storz B and CDocument2 pagesCouplings: Storz B and CANDERSON NERESNo ratings yet

- Slip On Anel 300# AnsiDocument2 pagesSlip On Anel 300# AnsiANDERSON NERESNo ratings yet

- Socket 600# AnsiDocument2 pagesSocket 600# AnsiANDERSON NERESNo ratings yet

- Socket Weld 1500# AnsiDocument2 pagesSocket Weld 1500# AnsiANDERSON NERESNo ratings yet

- S Jb01 Fire Extinguisher CabinetDocument2 pagesS Jb01 Fire Extinguisher CabinetANDERSON NERESNo ratings yet

- The Fiberbond Fittings GuideDocument23 pagesThe Fiberbond Fittings GuideANDERSON NERESNo ratings yet

- 7 - LWNDocument8 pages7 - LWNANDERSON NERESNo ratings yet

- Socket 150# AnsiDocument2 pagesSocket 150# AnsiANDERSON NERESNo ratings yet

- Jis B 2220-2004Document58 pagesJis B 2220-2004ANDERSON NERES100% (1)

- 5 - MSSDocument5 pages5 - MSSANDERSON NERESNo ratings yet

- 9 - HubDocument4 pages9 - HubANDERSON NERESNo ratings yet

- 11 - OrificeDocument7 pages11 - OrificeANDERSON NERESNo ratings yet

- Drip Rings STD - Tb.Dri.5011 FF RFDocument1 pageDrip Rings STD - Tb.Dri.5011 FF RFANDERSON NERESNo ratings yet

- Class 150 - 2500 Reducing FlangesDocument2 pagesClass 150 - 2500 Reducing FlangesANDERSON NERESNo ratings yet

- Measuring DFT According SSPC PA2Document15 pagesMeasuring DFT According SSPC PA2ANDERSON NERESNo ratings yet

- Schedule 80 PVC/CPVC Unions: UNION (Old Style)Document6 pagesSchedule 80 PVC/CPVC Unions: UNION (Old Style)ANDERSON NERESNo ratings yet

- Cálculo de TubosDocument3 pagesCálculo de TubosANDERSON NERESNo ratings yet

- Thermoplastic Flanges: Technical Information Weights & DimensionsDocument11 pagesThermoplastic Flanges: Technical Information Weights & DimensionsANDERSON NERESNo ratings yet

- S Storz Couplings DatasheetDocument2 pagesS Storz Couplings DatasheetANDERSON NERESNo ratings yet

- 5" DN125 5" DN125: Nominal Size Nominal SizeDocument3 pages5" DN125 5" DN125: Nominal Size Nominal SizeANDERSON NERESNo ratings yet

- 5" DN125 5" DN125: Nominal Size Nominal SizeDocument3 pages5" DN125 5" DN125: Nominal Size Nominal SizeANDERSON NERESNo ratings yet

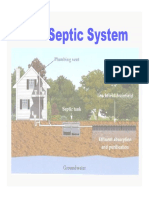

- Sistem SeptikDocument19 pagesSistem SeptikArvin SiniNo ratings yet

- Solutions For Problems Thermodynamics 2nd Edition by Turns & PauleyDocument38 pagesSolutions For Problems Thermodynamics 2nd Edition by Turns & Pauleylaryjenkinz100% (1)

- Pama CrystallizationDocument9 pagesPama CrystallizationCeddi PamiNo ratings yet

- Transport 252525252BPhenomena 252525252B 252525252B 252525252BIntroDocument54 pagesTransport 252525252BPhenomena 252525252B 252525252B 252525252BIntrocoolkanna100% (1)

- Controlling Fuel Gas To A Fired HeaterDocument4 pagesControlling Fuel Gas To A Fired HeaterMuhammad ImranNo ratings yet

- NFPA 20 Standard For The Installation of Stationary Pumps For Fire ProtectionDocument19 pagesNFPA 20 Standard For The Installation of Stationary Pumps For Fire ProtectionMOHAMED ABD ELGHANYNo ratings yet

- Webb 1981Document12 pagesWebb 1981sctcpdsNo ratings yet

- Completion Insertion and Removal Under Pressure Equipment: ApplicationsDocument2 pagesCompletion Insertion and Removal Under Pressure Equipment: ApplicationsmohamedNo ratings yet

- Flow Measurement TechnologyDocument59 pagesFlow Measurement TechnologyIamPedroNo ratings yet

- Pump SelectionDocument4 pagesPump SelectionmhmdjdgmailcomNo ratings yet

- Physics I Problems PDFDocument1 pagePhysics I Problems PDFBOSS BOSS0% (2)

- Roof Pond and SkythermDocument19 pagesRoof Pond and SkythermAbishaTeslinNo ratings yet

- CIVE 3305 LECTURE 3 - SedimentationDocument36 pagesCIVE 3305 LECTURE 3 - SedimentationIlyas Mohamed AliNo ratings yet

- Advances in Ozone Generation & Injection: Adam S. Kran, P.E. January 23, 2017Document36 pagesAdvances in Ozone Generation & Injection: Adam S. Kran, P.E. January 23, 2017Sergeo CruzNo ratings yet

- 1.3 Boiler OperationDocument23 pages1.3 Boiler OperationLydia RupidaraNo ratings yet

- AquaMatic Valve Overview Brochure 1018192Document8 pagesAquaMatic Valve Overview Brochure 1018192Fiddy FirmansyahNo ratings yet

- Calculation of Pipe Reinforcement ASME B31.3Document9 pagesCalculation of Pipe Reinforcement ASME B31.3yhnsharma80% (5)

- Experiment # 1: Prepared By: Engr. Vaiza ShirazDocument22 pagesExperiment # 1: Prepared By: Engr. Vaiza ShirazHamza NiazNo ratings yet

- MCQs Suface Tension & Interficial TensionDocument15 pagesMCQs Suface Tension & Interficial Tensionmukul sidhque100% (1)

- Design Calculation - STPDocument23 pagesDesign Calculation - STPForam ParekhNo ratings yet

- Tds Contro Heat RecoverylDocument31 pagesTds Contro Heat RecoverylHélder PascoalNo ratings yet

- Assignment 5Document3 pagesAssignment 5Moosa NaseerNo ratings yet

- Reciprocating Compressor IIDocument59 pagesReciprocating Compressor IIAhmad Aloudah100% (4)

- GEI 69688F Steam BlowingDocument20 pagesGEI 69688F Steam Blowingparvesh_awasthy100% (1)

- Wetscrubber VenturiDocument10 pagesWetscrubber Venturiakifah100% (1)

- Venturi Effect: Jump To Navigationjump To SearchDocument5 pagesVenturi Effect: Jump To Navigationjump To SearchMonika KshNo ratings yet

- Pump Performance Curve - XPS230-SS-VTSDocument1 pagePump Performance Curve - XPS230-SS-VTSjosephNo ratings yet

- Fixed and Fluidised Bed 01Document4 pagesFixed and Fluidised Bed 01JimNo ratings yet

- 13 Main Control ValveDocument13 pages13 Main Control ValveZawminhtunNo ratings yet

Fiberbond Fiberglass Piping Systems Series 20FR16-C: Description

Fiberbond Fiberglass Piping Systems Series 20FR16-C: Description

Uploaded by

ANDERSON NERESOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fiberbond Fiberglass Piping Systems Series 20FR16-C: Description

Fiberbond Fiberglass Piping Systems Series 20FR16-C: Description

Uploaded by

ANDERSON NERESCopyright:

Available Formats

FIBERBOND® Fiberglass Piping Systems

Series 20FR16-C

Description:

FIBERBOND 20FR16-C

The FIBERBOND® 20FR16-C Fiberglass Piping Series is an ABS and USCG approved fiberglass reinforced pipe

product manufactured by filament winding utilizing a premium grade fire retardant epoxy vinyl ester resin and a 20-

mil (0.50mm) liner, suitable for design pressures up to 232 psig (16.0 barg) and temperatures up to 185F (85c). The

20FR16 standard product is available in 1" to 24" (25mm - 610mm) nominal inside diameters, with custom products

up to 60" (1524mm) diameter. The 20FR16-C product is identical to 20FR16 except that it has an electrically

conductive exterior that may be grounded to earth. Series 20FR16, without the electrically conductive exterior, is

also available.

Applications:

Design Range: 232 psig (16.0 barg) up to 24in. and 185F (85c) (with standard fittings)

150psig (10.3 barg) up to 36in. and 185F (85c) (with standard fittings)

100psig (6.9 barg) up to 48in. and 185F (85c) (with standard fittings)

50psig (3.4 barg) up to 60in. and 185F (85c) (with standard fittings)

Applications: Seawater, freshwater, & sanitary/drain systems for marine and offshore installations per

IMO A.753(18) Level 0 and Level 3. Fire mains for offshore installations per USCG

PFM1-98; applications requiring an electrically conductive exterior

Piping Specifications:

®

Manufacture: Contact molded and filament wound 1" - 2" (25mm - 51mm)

Filament wound 3" - 60" (76mm - 1524mm)

Construction: Fire retardant epoxy vinyl ester resin, 55 degree wind pattern

20 mil (0.02in./0.50mm) C-Veil reinforced resin rich liner

Delivery: Random lengths or part of a shop-fabricated system

Fittings Specifications:

Manufacture: Contact molded 1" - 60" (25mm - 1524mm)

Dimensions: Per FIBERBOND® Fittings Guide

Delivery: Loose or part of a shop pre-fabricated system

Joining System Specifications:

Fabrication: Plain End Butt and Strap 1" - 60" (25mm - 1524mm)

Applicable Standards:

Testing: ASTM D635, D638/D2105, D1599, D2412, IMO A.753(18) L3 Fire Endurance

QA: ASTM D2563, D3567

EU Pressure Equipment Directive for Group 2 Liquids (Category 1, Module A - Internal

Production Control); SEP may also be used for sizes up to 12" at 16barg and all sizes up

to 10barg

Approvals: ABS Certificate No. 00-NO32171-X,

USCG Certificate of Approval 164.141/0023/0, Sizes 2" - 20"

Quick-Spec 20FR16-C-E4 www.fiberbond.com

Revised: May-25-2012 +1 (225) 752-2705 or (800) 752-7473

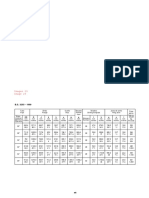

Typical Dimensions

Nominal Size I.D. O.D. Min. Wall Span Press. Rating Weight

(in. / mm) (in. / mm) (in. / mm) (in. / mm) (ft / m) (psig / bar) (lbs/ft - kg/m)

FIBERBOND 20FR16-C

2" (50) 2.00 (51) 2.56 (66) 0.28 (7) 12.8 (3.9) 232 (16.0) 1.5 (2.2)

3" (80) 3.00 (76) 3.50 (89) 0.25 (6) 14.5 (4.4) 232 (16.0) 2.2 (3.3)

4" (100) 4.00 (102) 4.50 (114) 0.25 (6) 15.7 (4.8) 232 (16.0) 2.9 (4.3)

6" (150) 6.00 (152) 6.50 (165) 0.25 (6) 16.6 (5.0) 232 (16.0) 4.3 (6.4)

8" (200) 8.00 (203) 8.64 (219) 0.32 (8) 19.1 (5.8) 232 (16.0) 7.8(11.6)

10" (250) 10.00 (254) 10.78 (274) 0.39 (10) 21.3 (6.5) 232 (16.0) 11.0 (16.4)

12" (300) 12.00 (305) 12.92 (329) 0.46 (12) 23.3 (7.1) 232 (16.0) 16.3 (24.3)

14" (350) 14.25 (362) 15.33 (389) 0.54 (14) 25.4 (7.7) 232 (16.0) 20.8 (31.0)

16" (400) 16.25 (413) 17.49 (444) 0.62 (16) 27.2 (8.2) 232 (16.0) 27.9 (41.6)

18" (450) 18.25 (463) 19.63 (499) 0.69 (18) 28.8 (8.7) 232 (16.0) 33.7 (50.2)

20" (500) 20.25 (514) 21.77 (553) 0.76 (19) 30.0 (9.0) 232 (16.0) 40.0 (59.6)

24" (600) 24.25 (616) 26.07 (662) 0.91 (23) 30.0 (9.0) 232 (16.0) 57.3 (85.4)

All spans rated for SG=1.0 (water) and is limited by 1) a bending stress of 1,000psi (6.9MPa) for dead weight

only, 2) a temperature of 150F (65c), and 3) a deflection of 0.50in. (12mm) over three spans. Maximum spacing

is 30ft (9.1m). Actual spacing in the field may be shorter due to other design conditions such as wind loads.

Information on larger pipe sizes is available from Specialty Plastics.

Typical Properties

®

Property Value (U.S.) Value (S.I.)

Pipe Axial Tensile Strength 8,400 psi 57.9 MPa

Pipe Axial Tensile Modulus 1,400,000 psi 9.7 GPa

Pipe Hoop Tensile Strength 26,400 psi 182.0 MPa

Pipe Hoop Tensile Modulus 2,200,000 psi 15.2 GPa

Pipe Bending Strength 16,800 psi 115.8 MPa

Pipe Bending Modulus 1,400,000 psi 9.7 GPa

Property Value (U.S.) Value (S.I.)

Density 0.06 lb/cu in. 1.7 g/cu cm

Thermal Expansion Coeff. 0.00001 in./in./deg F 0.000018 mm/mm/deg C

Minor Poisson's Ratio 0.55 0.55

Major Poisson's Ratio 0.35 0.35

Hazen Williams Coeff. 150 150

Specific Roughness 0.0002 in. 0.0005 cm

Future Pipe Industries, Inc.

P.O. Box 83277

Baton Rouge, Louisiana 70884-3277

Quick-Spec 20FR16-C-E4 www.fiberbond.com

Revised: May-25-2012 +1 (225) 752-2705 or (800) 752-7473

You might also like

- Chapter - 4-Simple Vapour Compression Refrigeration SystemDocument141 pagesChapter - 4-Simple Vapour Compression Refrigeration SystemMohamed Al-Odat0% (1)

- Bondstrand PDFDocument8 pagesBondstrand PDFkrisNo ratings yet

- MK 608 BPMDocument9 pagesMK 608 BPMrogelgerardo643No ratings yet

- PDC High Performance Butterfly Valve Available in Sizes 2" Thru 24"Document11 pagesPDC High Performance Butterfly Valve Available in Sizes 2" Thru 24"pablopasqualini18No ratings yet

- Firetuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionDocument2 pagesFiretuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionAngga SenjayaNo ratings yet

- 7.-F.tecnica Abrazadera B2000Document1 page7.-F.tecnica Abrazadera B2000Alejandro Ayrton Zambrano CinceNo ratings yet

- Medidores AMERICAN METERSDocument17 pagesMedidores AMERICAN METERSRaúl PalomoNo ratings yet

- Downhole Tubing/casingDocument6 pagesDownhole Tubing/casingDwiki RamadhaniNo ratings yet

- PROGEF Standard PolypropyleneDocument75 pagesPROGEF Standard Polypropyleneadriano.engmec.oliveiraNo ratings yet

- Fluoropolymer Tubing (MS 02 196)Document2 pagesFluoropolymer Tubing (MS 02 196)herysyam1980No ratings yet

- A 716 - 99 Qtcxni1sruqDocument7 pagesA 716 - 99 Qtcxni1sruqwahyudiNo ratings yet

- Product Note 3.107 N-12 SpecificationDocument2 pagesProduct Note 3.107 N-12 SpecificationFernando Guzman ContrerasNo ratings yet

- Type 550X: Miniature I/P, E/P TransducerDocument4 pagesType 550X: Miniature I/P, E/P TransducerDanang BagasNo ratings yet

- SFTPreal10 Cat7 6x4p Loom 900MHz AWG23Document2 pagesSFTPreal10 Cat7 6x4p Loom 900MHz AWG23Slobodan ĐenićNo ratings yet

- Firetuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionDocument25 pagesFiretuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionBhagoo HatheyNo ratings yet

- SFTPreal10 Cat6A 6x4p Loom 650MHz AWG26Document2 pagesSFTPreal10 Cat6A 6x4p Loom 650MHz AWG26Slobodan ĐenićNo ratings yet

- CTC Technical Manual.86918081Document45 pagesCTC Technical Manual.86918081Mohd AjmainNo ratings yet

- Manometro Badotherm BP-004-005Document2 pagesManometro Badotherm BP-004-005Luis Alberto Portugal MariacalNo ratings yet

- Aquarius+ UPVC Industrial Pipe & FittingsDocument16 pagesAquarius+ UPVC Industrial Pipe & Fittingspanchal harnishNo ratings yet

- RS 250 M Welding MachineDocument1 pageRS 250 M Welding MachineLucioNo ratings yet

- KIASMA Dredging Self Sinking 09 2018 ENGDocument26 pagesKIASMA Dredging Self Sinking 09 2018 ENGahceneaecNo ratings yet

- ABB Instrumentation: Specification SheetDocument6 pagesABB Instrumentation: Specification SheetRaja RamNo ratings yet

- Pir For Ice 3500Document5 pagesPir For Ice 3500Akshat ShawNo ratings yet

- STAR Aromatic Amine Line Pipe High Pressure API 15HR Design Data SheetDocument4 pagesSTAR Aromatic Amine Line Pipe High Pressure API 15HR Design Data SheetFirasNo ratings yet

- Serie 740Document4 pagesSerie 740Mabeli MartinezNo ratings yet

- UPVC Pipe DIN 8062 TdsDocument3 pagesUPVC Pipe DIN 8062 TdsAdany AdenNo ratings yet

- Stewarts GaugeDocument2 pagesStewarts GaugepetropartsqaNo ratings yet

- STAR Pipe LP API 15HR AliphaticDocument4 pagesSTAR Pipe LP API 15HR AliphaticTaras ByloNo ratings yet

- Esab, Dual Shield II 110 (265-En - US-FactSheet - Main-01) (26.10.16)Document2 pagesEsab, Dual Shield II 110 (265-En - US-FactSheet - Main-01) (26.10.16)RodrigoNo ratings yet

- Steel Braided Hose: Limusnunggal Rubber IndustryDocument5 pagesSteel Braided Hose: Limusnunggal Rubber IndustryIndra MaulanaNo ratings yet

- Ceramic Fiber Blanket CatalogDocument7 pagesCeramic Fiber Blanket Catalogevelyn reksaNo ratings yet

- MX - SS Pressure GaugesDocument2 pagesMX - SS Pressure Gaugessaurabhjerps231221No ratings yet

- Adarsh Product Catalog With ResolutionDocument2 pagesAdarsh Product Catalog With Resolutionjacob johnNo ratings yet

- NSB Ups BatteryDocument4 pagesNSB Ups BatteryLast Juan StandingNo ratings yet

- Vortex FMDocument10 pagesVortex FMram kNo ratings yet

- Pipe CatalogueDocument6 pagesPipe CatalogueirfanNo ratings yet

- 278 en US FactSheet Main 01Document1 page278 en US FactSheet Main 01Jorge Manuel GuillermoNo ratings yet

- 1200 Series DatasheetDocument12 pages1200 Series DatasheetbandaemetNo ratings yet

- Tech Data Sheet: Dual Shield T-115Document3 pagesTech Data Sheet: Dual Shield T-115carlosNo ratings yet

- AWA Unipolares Clase 2Document1 pageAWA Unipolares Clase 2Juan AdrianzenNo ratings yet

- SCP Part#: Cat5E-Aer: DescriptionDocument2 pagesSCP Part#: Cat5E-Aer: DescriptionAnonymous AOsAXgNo ratings yet

- Slip Ring Prod GuideDocument16 pagesSlip Ring Prod GuideJong Java100% (1)

- Glass PipeDocument7 pagesGlass Pipejesus_manrique2753No ratings yet

- Smith Fibercast Green Thread Performance Plus Fiberglass Pipe Piping BrochureDocument8 pagesSmith Fibercast Green Thread Performance Plus Fiberglass Pipe Piping BrochureWong Chung MengNo ratings yet

- Coriolis Mass Flowmeter For Medium Flow Also Suited For High Pressure ApplicationsDocument8 pagesCoriolis Mass Flowmeter For Medium Flow Also Suited For High Pressure ApplicationsamiraNo ratings yet

- Dual Shield T-75: Typical Tensile PropertiesDocument2 pagesDual Shield T-75: Typical Tensile PropertiescfloresNo ratings yet

- Mos3200 Bs 2000m FP Product DataDocument4 pagesMos3200 Bs 2000m FP Product DataJeromeNo ratings yet

- 30SCC160 2pdeDocument30 pages30SCC160 2pdeمحمد مرسيNo ratings yet

- MiscellaneousDocument49 pagesMiscellaneousjrsvalenzuelaNo ratings yet

- Air Compressor PDFDocument1 pageAir Compressor PDFaredeca042882No ratings yet

- Part VIDocument22 pagesPart VIRonak RanaNo ratings yet

- Quality Pressure G Auge: All Stainless Steel Construction Robust, Designed For Severe Operating ConditionsDocument2 pagesQuality Pressure G Auge: All Stainless Steel Construction Robust, Designed For Severe Operating ConditionsChhomNo ratings yet

- A New Era In: Filtration Performance and InnovationDocument6 pagesA New Era In: Filtration Performance and InnovationCARLOS SARMIENTONo ratings yet

- ID 250 T DC PulseDocument1 pageID 250 T DC PulseLucioNo ratings yet

- Fire Piping Astm A135Document2 pagesFire Piping Astm A135sinahimsNo ratings yet

- AMF601NTV1 1 9 A4 en PDFDocument4 pagesAMF601NTV1 1 9 A4 en PDFtruongNo ratings yet

- Dual Shield 7100 Ultra: Typical Tensile PropertiesDocument3 pagesDual Shield 7100 Ultra: Typical Tensile PropertiesDino Paul Castro HidalgoNo ratings yet

- ESAB Dual Shield 7100 UltraDocument3 pagesESAB Dual Shield 7100 UltrahaldunNo ratings yet

- Furring Channels and Custom Top Hat Sections Technical Data Sheet UnlockedDocument2 pagesFurring Channels and Custom Top Hat Sections Technical Data Sheet UnlockedCONSULTANTS KELNo ratings yet

- TeSys Deca - K and SK Control Relays - CA3KN22BDDocument4 pagesTeSys Deca - K and SK Control Relays - CA3KN22BDIvan OliveiraNo ratings yet

- Slip On Anel 400# AnsiDocument2 pagesSlip On Anel 400# AnsiANDERSON NERESNo ratings yet

- Hydratight LP-Series FlyerDocument4 pagesHydratight LP-Series FlyerANDERSON NERESNo ratings yet

- Slip On Anel 600# AnsiDocument2 pagesSlip On Anel 600# AnsiANDERSON NERESNo ratings yet

- Socket 300# AnsiDocument2 pagesSocket 300# AnsiANDERSON NERESNo ratings yet

- Couplings: Storz B and CDocument2 pagesCouplings: Storz B and CANDERSON NERESNo ratings yet

- Slip On Anel 300# AnsiDocument2 pagesSlip On Anel 300# AnsiANDERSON NERESNo ratings yet

- Socket 600# AnsiDocument2 pagesSocket 600# AnsiANDERSON NERESNo ratings yet

- Socket Weld 1500# AnsiDocument2 pagesSocket Weld 1500# AnsiANDERSON NERESNo ratings yet

- S Jb01 Fire Extinguisher CabinetDocument2 pagesS Jb01 Fire Extinguisher CabinetANDERSON NERESNo ratings yet

- The Fiberbond Fittings GuideDocument23 pagesThe Fiberbond Fittings GuideANDERSON NERESNo ratings yet

- 7 - LWNDocument8 pages7 - LWNANDERSON NERESNo ratings yet

- Socket 150# AnsiDocument2 pagesSocket 150# AnsiANDERSON NERESNo ratings yet

- Jis B 2220-2004Document58 pagesJis B 2220-2004ANDERSON NERES100% (1)

- 5 - MSSDocument5 pages5 - MSSANDERSON NERESNo ratings yet

- 9 - HubDocument4 pages9 - HubANDERSON NERESNo ratings yet

- 11 - OrificeDocument7 pages11 - OrificeANDERSON NERESNo ratings yet

- Drip Rings STD - Tb.Dri.5011 FF RFDocument1 pageDrip Rings STD - Tb.Dri.5011 FF RFANDERSON NERESNo ratings yet

- Class 150 - 2500 Reducing FlangesDocument2 pagesClass 150 - 2500 Reducing FlangesANDERSON NERESNo ratings yet

- Measuring DFT According SSPC PA2Document15 pagesMeasuring DFT According SSPC PA2ANDERSON NERESNo ratings yet

- Schedule 80 PVC/CPVC Unions: UNION (Old Style)Document6 pagesSchedule 80 PVC/CPVC Unions: UNION (Old Style)ANDERSON NERESNo ratings yet

- Cálculo de TubosDocument3 pagesCálculo de TubosANDERSON NERESNo ratings yet

- Thermoplastic Flanges: Technical Information Weights & DimensionsDocument11 pagesThermoplastic Flanges: Technical Information Weights & DimensionsANDERSON NERESNo ratings yet

- S Storz Couplings DatasheetDocument2 pagesS Storz Couplings DatasheetANDERSON NERESNo ratings yet

- 5" DN125 5" DN125: Nominal Size Nominal SizeDocument3 pages5" DN125 5" DN125: Nominal Size Nominal SizeANDERSON NERESNo ratings yet

- 5" DN125 5" DN125: Nominal Size Nominal SizeDocument3 pages5" DN125 5" DN125: Nominal Size Nominal SizeANDERSON NERESNo ratings yet

- Sistem SeptikDocument19 pagesSistem SeptikArvin SiniNo ratings yet

- Solutions For Problems Thermodynamics 2nd Edition by Turns & PauleyDocument38 pagesSolutions For Problems Thermodynamics 2nd Edition by Turns & Pauleylaryjenkinz100% (1)

- Pama CrystallizationDocument9 pagesPama CrystallizationCeddi PamiNo ratings yet

- Transport 252525252BPhenomena 252525252B 252525252B 252525252BIntroDocument54 pagesTransport 252525252BPhenomena 252525252B 252525252B 252525252BIntrocoolkanna100% (1)

- Controlling Fuel Gas To A Fired HeaterDocument4 pagesControlling Fuel Gas To A Fired HeaterMuhammad ImranNo ratings yet

- NFPA 20 Standard For The Installation of Stationary Pumps For Fire ProtectionDocument19 pagesNFPA 20 Standard For The Installation of Stationary Pumps For Fire ProtectionMOHAMED ABD ELGHANYNo ratings yet

- Webb 1981Document12 pagesWebb 1981sctcpdsNo ratings yet

- Completion Insertion and Removal Under Pressure Equipment: ApplicationsDocument2 pagesCompletion Insertion and Removal Under Pressure Equipment: ApplicationsmohamedNo ratings yet

- Flow Measurement TechnologyDocument59 pagesFlow Measurement TechnologyIamPedroNo ratings yet

- Pump SelectionDocument4 pagesPump SelectionmhmdjdgmailcomNo ratings yet

- Physics I Problems PDFDocument1 pagePhysics I Problems PDFBOSS BOSS0% (2)

- Roof Pond and SkythermDocument19 pagesRoof Pond and SkythermAbishaTeslinNo ratings yet

- CIVE 3305 LECTURE 3 - SedimentationDocument36 pagesCIVE 3305 LECTURE 3 - SedimentationIlyas Mohamed AliNo ratings yet

- Advances in Ozone Generation & Injection: Adam S. Kran, P.E. January 23, 2017Document36 pagesAdvances in Ozone Generation & Injection: Adam S. Kran, P.E. January 23, 2017Sergeo CruzNo ratings yet

- 1.3 Boiler OperationDocument23 pages1.3 Boiler OperationLydia RupidaraNo ratings yet

- AquaMatic Valve Overview Brochure 1018192Document8 pagesAquaMatic Valve Overview Brochure 1018192Fiddy FirmansyahNo ratings yet

- Calculation of Pipe Reinforcement ASME B31.3Document9 pagesCalculation of Pipe Reinforcement ASME B31.3yhnsharma80% (5)

- Experiment # 1: Prepared By: Engr. Vaiza ShirazDocument22 pagesExperiment # 1: Prepared By: Engr. Vaiza ShirazHamza NiazNo ratings yet

- MCQs Suface Tension & Interficial TensionDocument15 pagesMCQs Suface Tension & Interficial Tensionmukul sidhque100% (1)

- Design Calculation - STPDocument23 pagesDesign Calculation - STPForam ParekhNo ratings yet

- Tds Contro Heat RecoverylDocument31 pagesTds Contro Heat RecoverylHélder PascoalNo ratings yet

- Assignment 5Document3 pagesAssignment 5Moosa NaseerNo ratings yet

- Reciprocating Compressor IIDocument59 pagesReciprocating Compressor IIAhmad Aloudah100% (4)

- GEI 69688F Steam BlowingDocument20 pagesGEI 69688F Steam Blowingparvesh_awasthy100% (1)

- Wetscrubber VenturiDocument10 pagesWetscrubber Venturiakifah100% (1)

- Venturi Effect: Jump To Navigationjump To SearchDocument5 pagesVenturi Effect: Jump To Navigationjump To SearchMonika KshNo ratings yet

- Pump Performance Curve - XPS230-SS-VTSDocument1 pagePump Performance Curve - XPS230-SS-VTSjosephNo ratings yet

- Fixed and Fluidised Bed 01Document4 pagesFixed and Fluidised Bed 01JimNo ratings yet

- 13 Main Control ValveDocument13 pages13 Main Control ValveZawminhtunNo ratings yet